High-arsenic-content metallurgical sludge harmless treatment method and arsenic recovery method

A harmless treatment and recovery method technology, applied in the direction of sludge treatment, water/sludge/sewage treatment, chemical instruments and methods, etc., can solve the problem that product stability cannot be well guaranteed, and achieve low cost, Wide application range and high arsenic removal rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

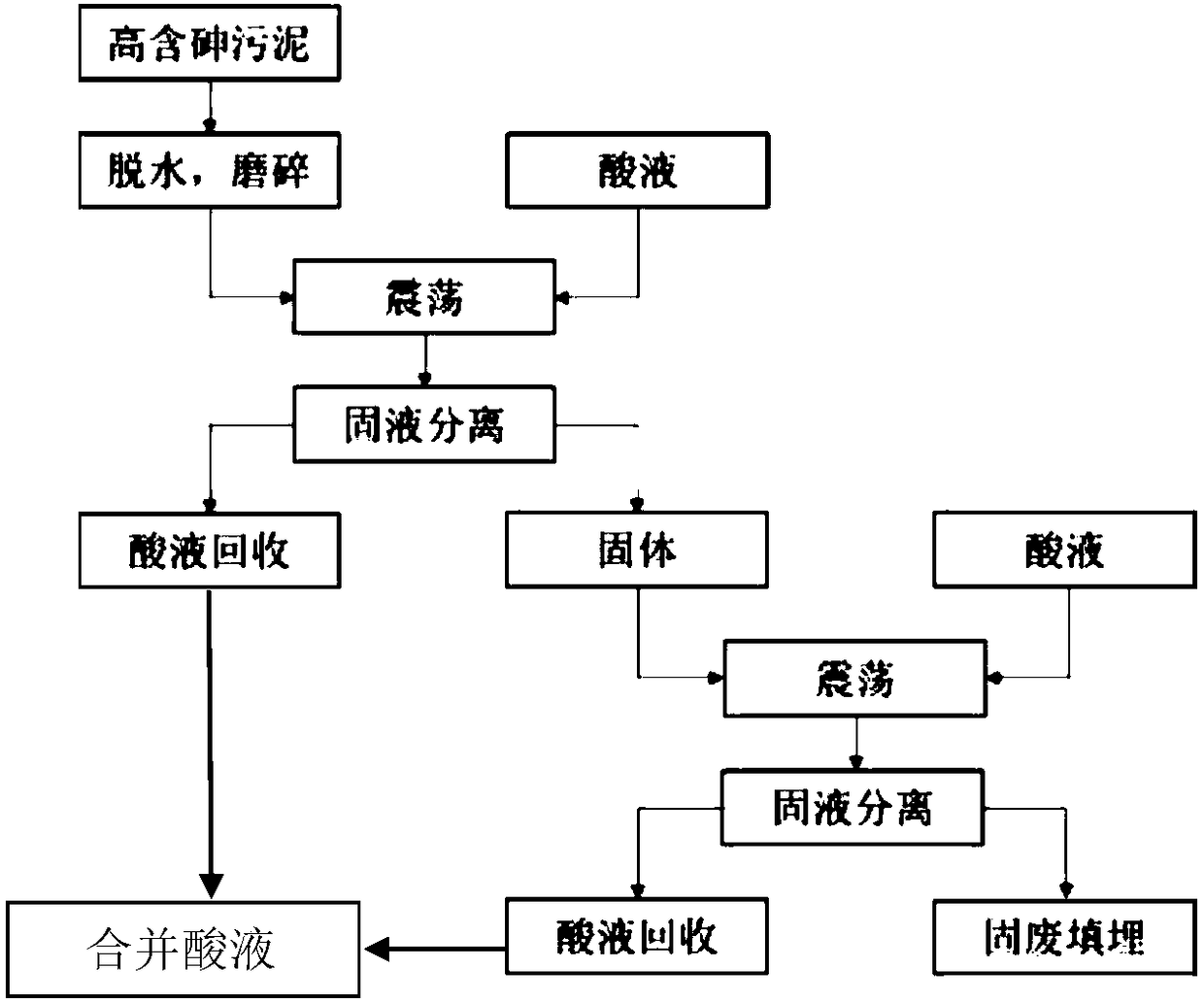

[0041] 1 The harmless treatment method of high arsenic-containing metallurgical sludge in this embodiment, such as figure 1 shown, including the following steps:

[0042] 1.1 Pretreatment: Air-dry the arsenic-containing sludge until the moisture content is lower than 15%, and grind it to 100 mesh with a soil ball mill to obtain dried arsenic-containing sludge with a mass fraction of arsenic of 15%;

[0043] 1.2 Separation by adding acid and shaking for the first time: Weigh 4.0g of dried arsenic-containing sludge into a 250mL polytetrafluoroethylene plastic bottle, add 20mL of 10% nitric acid solution, mix well and place in a 20°C In a constant temperature shaker, shake at 120rpm for 24 hours; use a Buchner funnel to filter, and wash the leaching residue 3 times with pure water;

[0044] 1.3 The second acid-adding shock separation: put the cleaned leaching residue in a 250mL polytetrafluoroethylene plastic bottle, add 20mL of 10% nitric acid solution, mix well and place in a ...

Embodiment 2

[0052] 1 The harmless treatment method for high arsenic-containing metallurgical sludge in this embodiment comprises the following steps:

[0053] 1.1 Pretreatment: Air-dry the arsenic-containing sludge until the moisture content is lower than 15%, and grind it to 100 mesh with a soil ball mill to obtain dried arsenic-containing sludge with a mass fraction of arsenic of 15%;

[0054] 1.2 Separation by adding acid and shaking for the first time: Weigh 4.0g of dried arsenic-containing sludge into a 250mL polytetrafluoroethylene plastic bottle, add 30mL of 10% nitric acid solution, mix well and place in a 20°C In a constant temperature shaker, shake at 120rpm for 24 hours; use a Buchner funnel to filter, and wash the leaching residue 3 times with pure water;

[0055] 1.3 The second acid addition and shock separation: put the cleaned leaching residue in a 250mL polytetrafluoroethylene plastic bottle, add 30mL of 10% nitric acid solution, mix well and place in a constant temperatur...

Embodiment 3

[0063] 1 The harmless treatment method for high arsenic-containing metallurgical sludge in this embodiment comprises the following steps:

[0064] 1.1 Pretreatment: Air-dry the arsenic-containing sludge until the moisture content is lower than 15%, and grind it to 100 mesh with a soil ball mill to obtain dried arsenic-containing sludge with a mass fraction of arsenic of 15%;

[0065] 1.2 Separation by adding acid and shaking for the first time: Weigh 4.0g of dried arsenic-containing sludge into a 250mL polytetrafluoroethylene plastic bottle, add 40mL of nitric acid solution with a mass fraction of 20%, mix well and place in a 20°C In a constant temperature shaker, shake at 120rpm for 18h; use a Buchner funnel to filter, and wash the leaching residue with pure water for 3 times;

[0066] 1.3 The second acid-adding shock separation: put the cleaned leaching residue in a 250mL polytetrafluoroethylene plastic bottle, add 40mL of 20% nitric acid solution, mix well and place in a co...

PUM

| Property | Measurement | Unit |

|---|---|---|

| quality score | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com