Method for arsenic removal of high-arsenic multi-metal complex materials and device thereof

A multi-metal and material technology, applied in the fields of non-ferrous metallurgy and environmental protection, can solve the problems of increasing the amount of flue gas and dust to be processed, increasing the amount of flue gas and dust, and long heating time, so as to reduce the amount of flue gas and dust amount, enrichment reduction, and obvious environmental protection effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

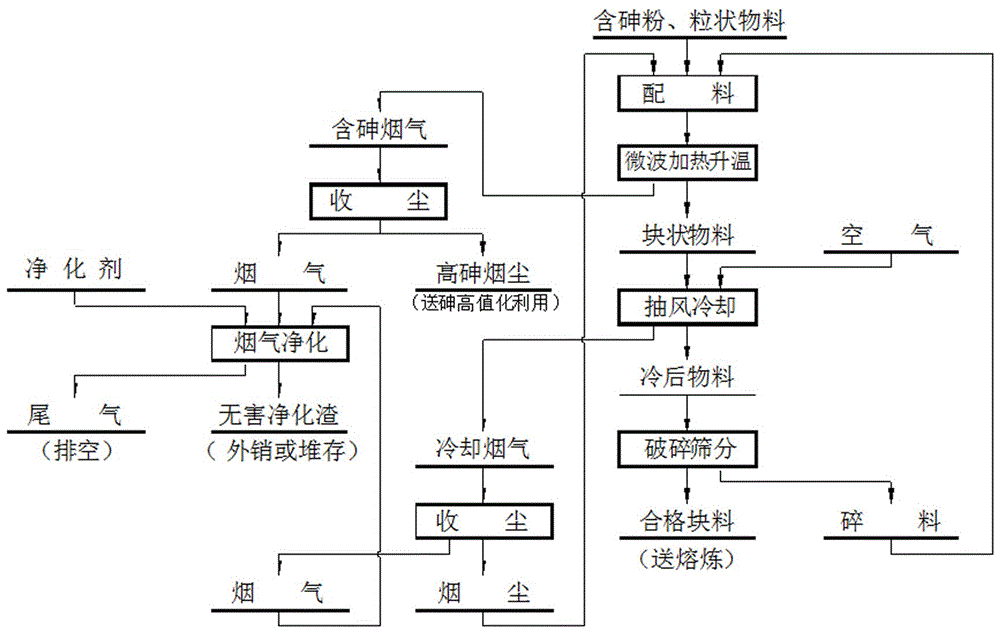

Method used

Image

Examples

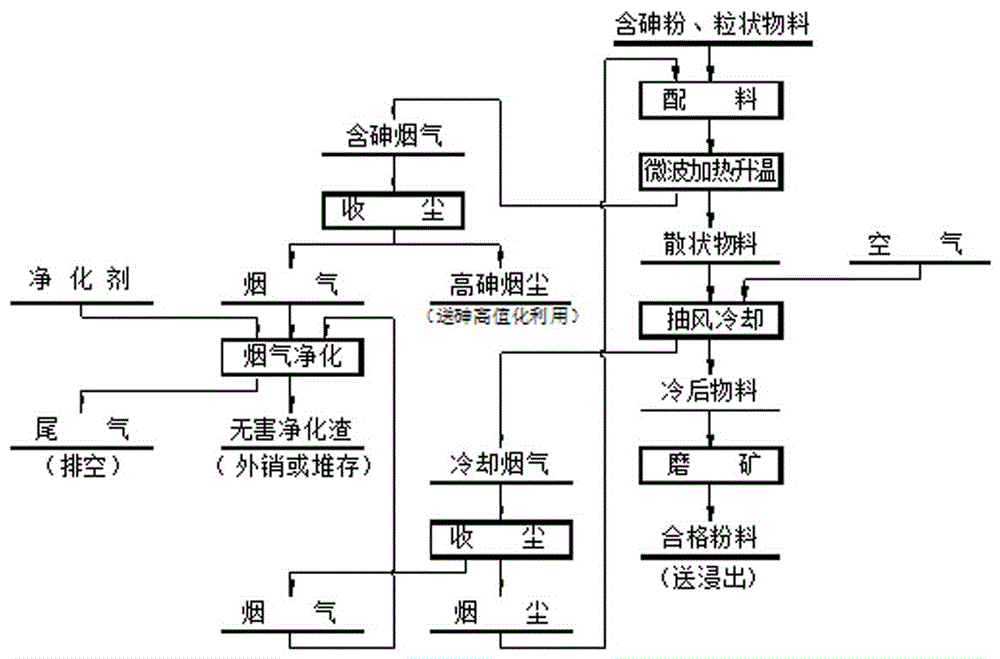

Embodiment approach 2

[0046]Implementation Mode 2: This is an implementation mode for de-arsenic treatment of materials that do not require agglomeration before leaching. For high-arsenic multi-metal complex materials that are not dominated by arsenic oxide, mainly black copper powder, anode slime, arsenic slag, etc. After that, it still maintains its loose, granular and powdery form to meet the requirements of leaching. The specific implementation steps are as follows:

[0047] (1) Ingredients:

[0048] The loose, granular, powdery high-arsenic and multi-metal complex materials and the return materials after arsenic removal are mixed according to the predetermined ingredients; the prepared materials are sent into the microwave cavity;

[0049] (2) Microwave heating to separate arsenic:

[0050] After the pellets enter the microwave chamber, the microwave generator emits microwaves to the material to heat up the material rapidly; within 3 to 9 minutes, the temperature of the material rises from ...

Embodiment approach 3

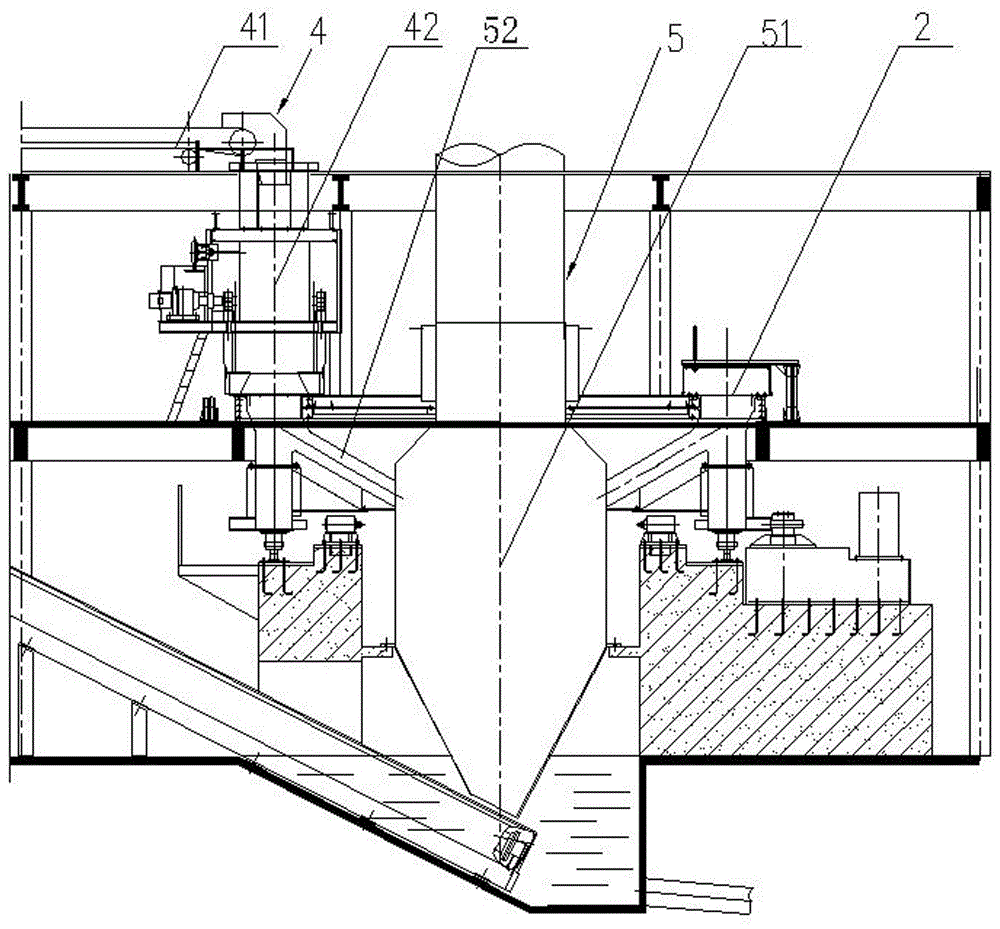

[0064] Embodiment 3: This is a device that is suitable for the method of the present invention and can be used for industrial production. Figure 3 to Figure 5 Reflects the structure of the device.

[0065] It can be seen from the figure that the device of the present invention is mainly composed of a microwave generator 1 , a rotatable storage tray 2 , a sealing cover 3 , a feeding device 4 , an exhaust system 5 and a special pipe 10 for collecting arsenic.

[0066] The following of the charging tray platform 2 is an annular turntable 6 fixedly connected with the charging tray platform 2, and the charging tray platform 2 slowly rotates with the annular turntable 6 to become a rotatable charging tray platform 2. There is a concrete foundation 7 below the annular turntable 6, and supporting rollers 8 are arranged on this foundation to support the annular turntable 6. The charging tray 2 is mainly composed of several fan-shaped bellows 21, and the grate bar 22 is directly insta...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com