Preparation method of gel entrapped type efficient arsenic removing material

A high-efficiency, gel technology, applied in chemical instruments and methods, alkali metal oxides/hydroxides, inorganic chemistry, etc., can solve problems such as the inability of arsenic adsorbents to be used, and achieve short treatment cycles, high arsenic removal rates, Wide range of effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

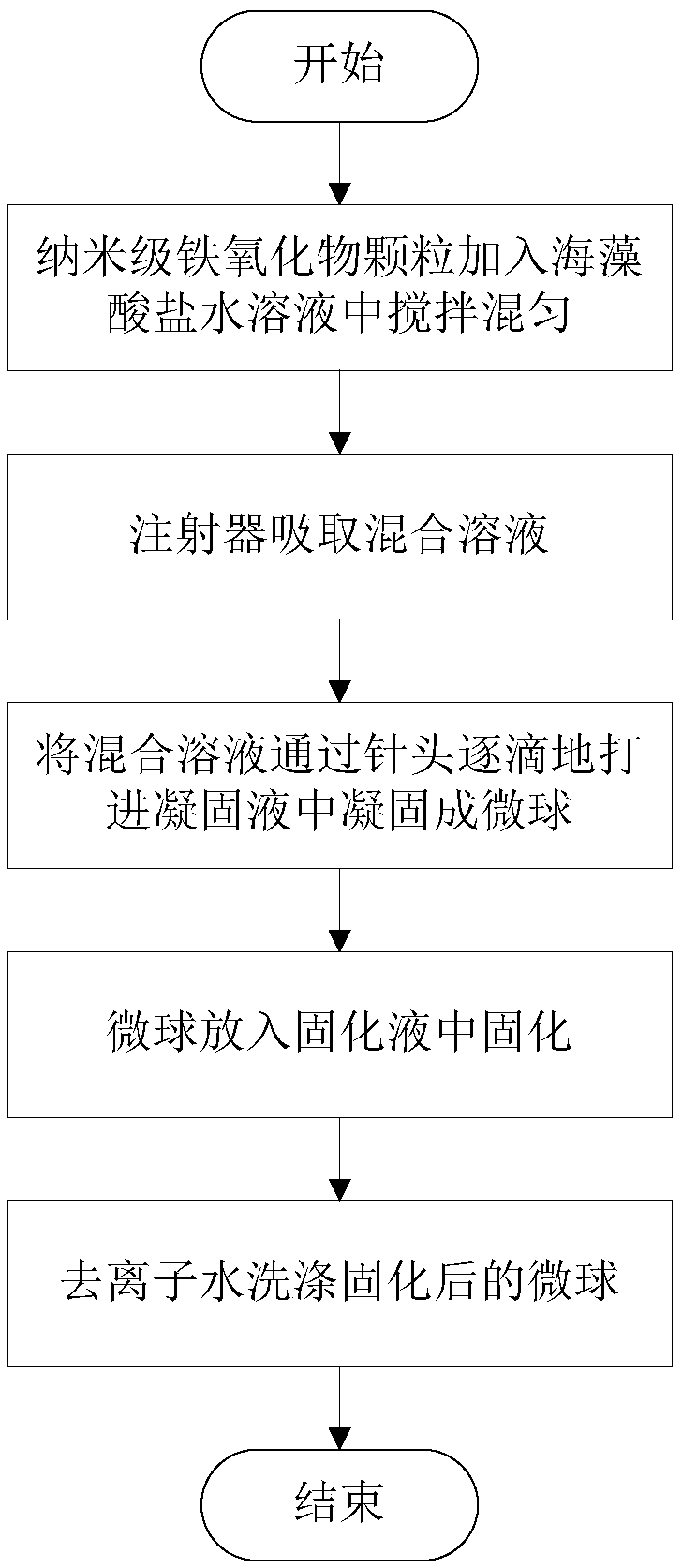

[0022] like figure 1 As shown, the preparation method of the gel-embedded high-efficiency arsenic removal material disclosed in the present invention comprises the following steps:

[0023] Step 1, adding the nanoscale iron oxide particles into the alginate aqueous solution, stirring and mixing, the stirring rate is 500-1000rmp, the stirring time is 10-30min, preferably 15 minutes, the nanoscale iron oxide particles and the alginate aqueous solution The dosage ratio is 10-200g: 1L; the alginate is more than one of sodium alginate and potassium alginate, and the concentration of the alginate aqueous solution is 2.5-20g / L;

[0024] Step 2, use a syringe to absorb the mixed solution of nanoscale iron oxide and alginate, and the single absorption volume is 2-60mL;

[0025] Step 3, use a syringe pump to inject the mixed solution of nano-scale iron oxide and alginate in the syringe into the coagulation solution drop by drop through the needle, and coagulate into microspheres, and t...

Embodiment 1

[0030] Add 20g of nanoscale iron oxide particles into 100mL, 10g / L sodium alginate aqueous solution and stir for 15min, then draw the mixed solution with a syringe, the single absorption volume is 60mL, and use a syringe pump to pass the mixed solution through at a rate of 3mL / min. Inject 50mmol / L of CaCl drop by drop with a needle with an inner diameter of 0.21mm 2 solution, coagulate into microspheres, and then put the microspheres into 1L, 500mmol / L CaCl 2 The solution was solidified for 1 hour, and finally the cured microspheres were washed three times with 2 L of deionized water, and the particle size of the obtained microspheres was 0.56 mm.

Embodiment 2

[0032] Add 20g of nanoscale iron oxide particles into 100mL, 10g / L sodium alginate aqueous solution and stir for 15min, then draw the mixed solution with a syringe, the single absorption volume is 60mL, and use a syringe pump to pass the mixed solution through at a rate of 2mL / min. Inject 50mmol / L of CaCl drop by drop with a needle with an inner diameter of 0.06mm 2 solution, coagulate into microspheres, and then put the microspheres into 1L, 500mmol / L CaCl 2 The solution was solidified for 1 hour, and finally the cured microspheres were washed 3 times with 2 L of deionized water, and the obtained microspheres had a particle size of 0.11 mm.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com