Metal compound-type arsenic removal agent, preparation method and application thereof

A metal complex and arsenic removal technology, which can be used in the refining of metal oxides, chemical instruments and methods, and refined hydrocarbon oil, etc. Simple, extended regeneration cycle, and the effect of large specific surface area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0045] Activated carbon treatment (for all activated carbons)

[0046] Weigh 10g of coconut shell activated carbon (the average pore diameter is about 1.5nm, the particle size is about 3×6mm, and the specific surface area is ≥500m2 / g) and add it to 50ml of mixed acid of 0.1N nitric acid and 0.3N hydrochloric acid (the volume ratio of the two acids is 1 : 1), boiled for 7 hours, filtered and washed until the pH value of the filtrate was 6-7, and the obtained activated carbon was dried at 120° C. for 6 hours to obtain acid-treated activated carbon.

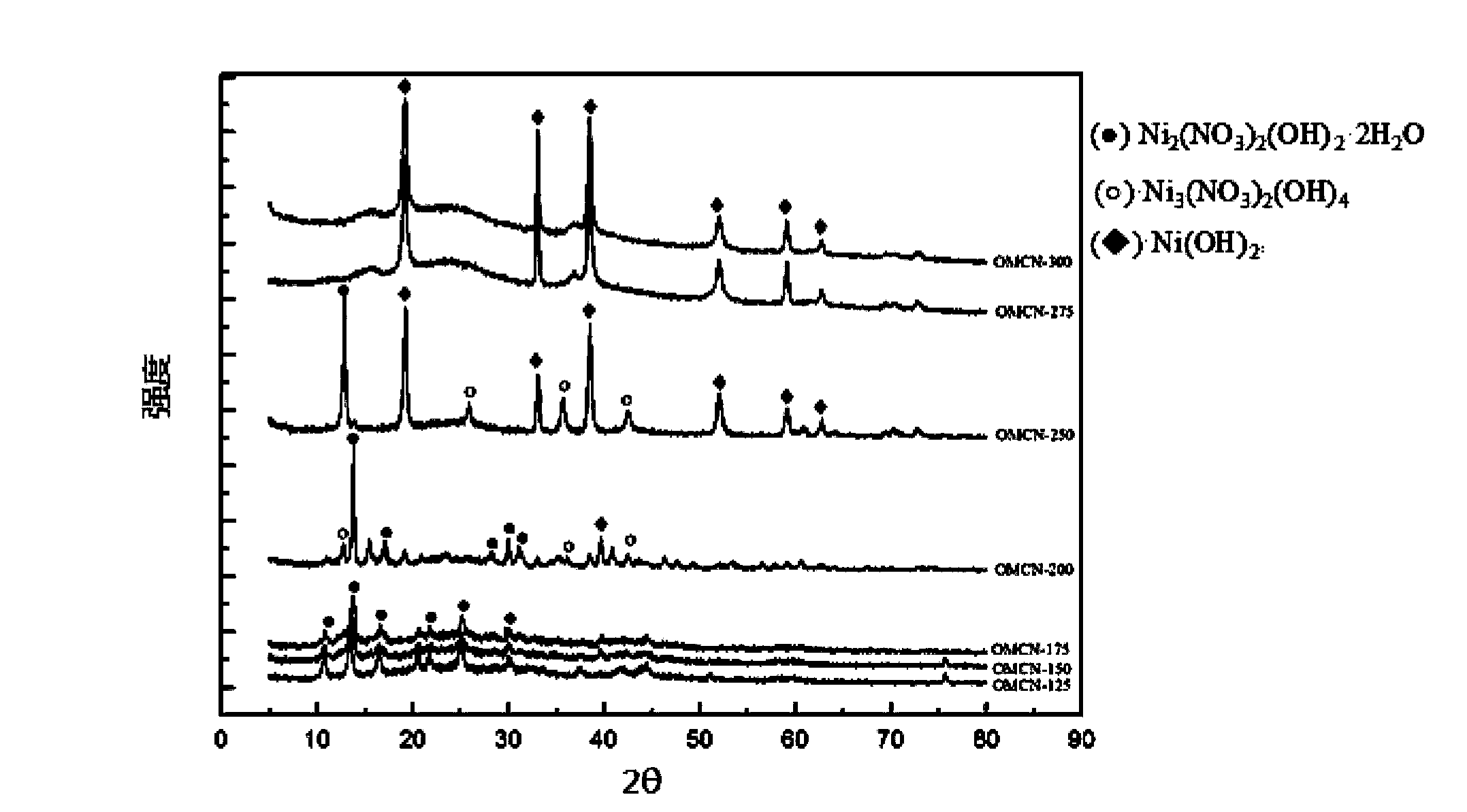

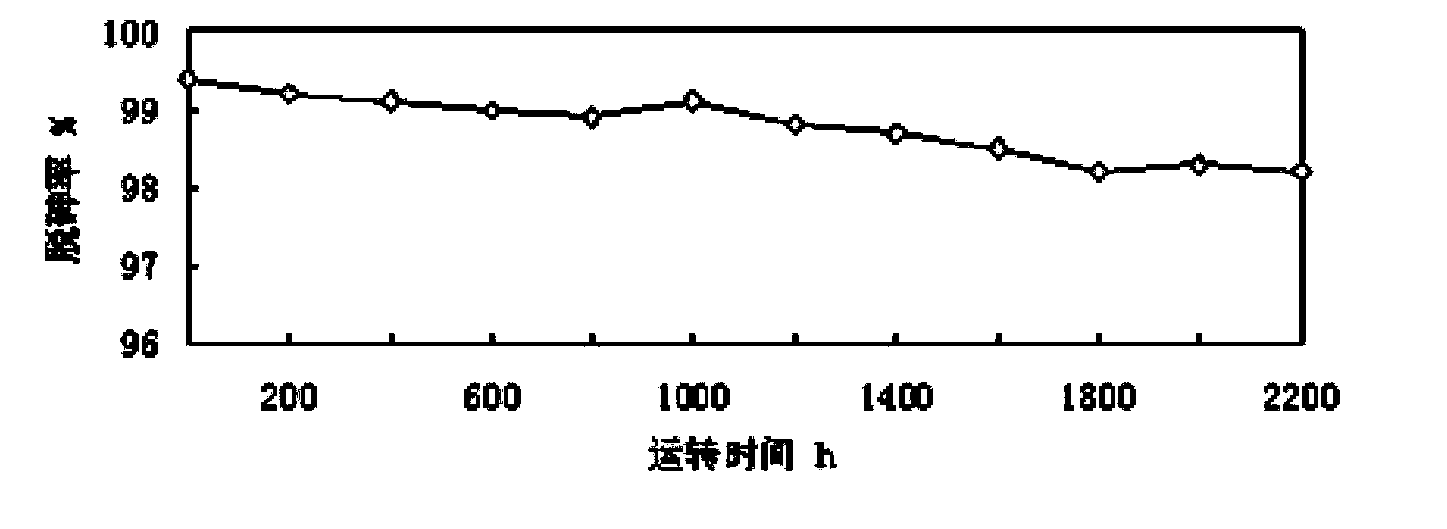

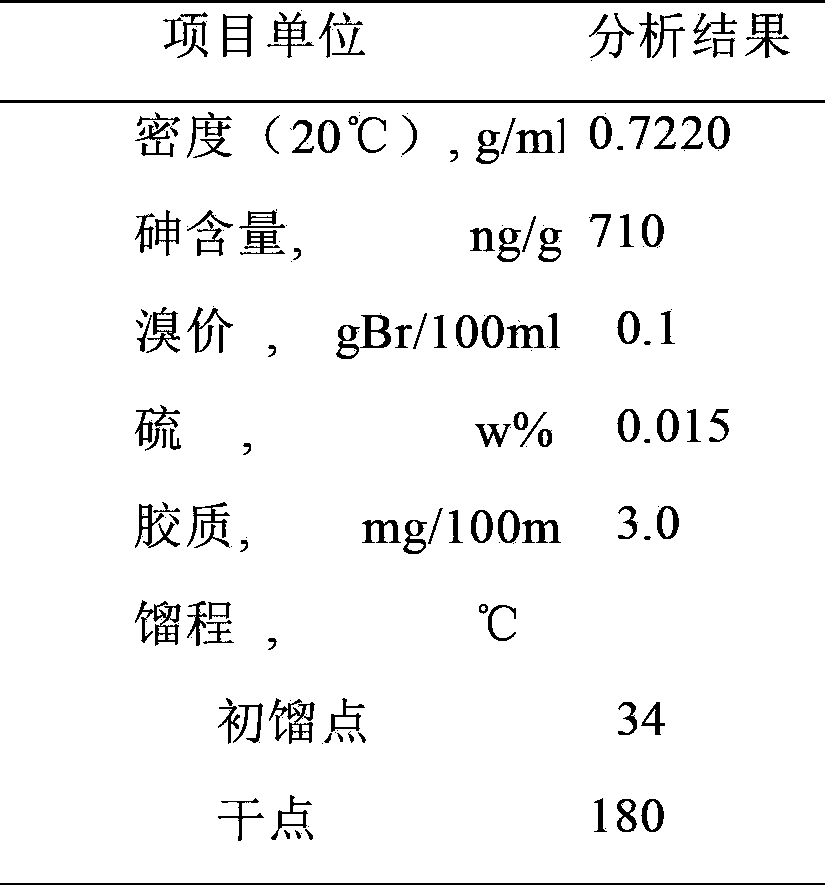

[0047] Preparation of arsenic removal agent (Ni(OH) 2 20% / coconut shell charcoal)

[0048] 10.5g of Ni(NO 3 ) 2 ·6H 2 O is dissolved in water to the mark of 40ml (as Ni(OH) 220% by weight), under stirring, add the above-mentioned activated carbon (absorption rate is about 400%) to make the solution completely absorbed in the carbon carrier and let it stand for 2 hours, then put it into an 80ml hydrothermal reaction kettle and...

Embodiment 2

[0050] Preparation of arsenic removal agent (Cu(OH) 2 20% / coconut shell charcoal)

[0051] Process coconut shell charcoal by embodiment 1 method. 8.3 g of Cu(NO 3 ) 2 ·3H 2 O is dissolved in water to the mark of 40ml (as Cu(OH) 2 20% by weight), under stirring, add the above-mentioned activated carbon (absorption rate is about 400%) to make the solution completely absorbed in the carbon carrier and let it stand for 2 hours, then put it into an 80ml hydrothermal reaction kettle and add 20ml Water, under the condition of 200°C, carry out hydrothermal reaction for 5 hours. After the sample was taken out, it was dried in a vacuum oven at 100° C. to obtain the catalyst of Example 2. The evaluation results of arsenic removal showed that the arsenic removal rate was 84.8%.

Embodiment 3

[0053] Preparation of arsenic removal agent (Fe(OH) 3 20% / coconut shell charcoal)

[0054] Process coconut shell charcoal by embodiment 1 method. 12.6 g of Fe(NO 3 ) 2 9H 2 O is dissolved in water to the mark of 40ml (as Fe(OH) 3 20% by weight), under stirring, add the above-mentioned activated carbon (absorption rate is about 400%) to make the solution completely absorbed in the carbon carrier and let it stand for 2 hours, then put it into an 80ml hydrothermal reaction kettle and add 20ml Water, under the condition of 200°C, carry out hydrothermal reaction for 5 hours. After the sample was taken out, it was dried in a vacuum oven at 100° C. to obtain the catalyst of Example 3. The evaluation results of arsenic removal showed that the arsenic removal rate was 71.1%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com