Dearsenization method for iron ore

An iron ore and arsenic removal technology, applied in the field of iron and steel smelting, can solve the problems of deep arsenic removal and environmental pollution, and achieve the effect of reducing impact and avoiding pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

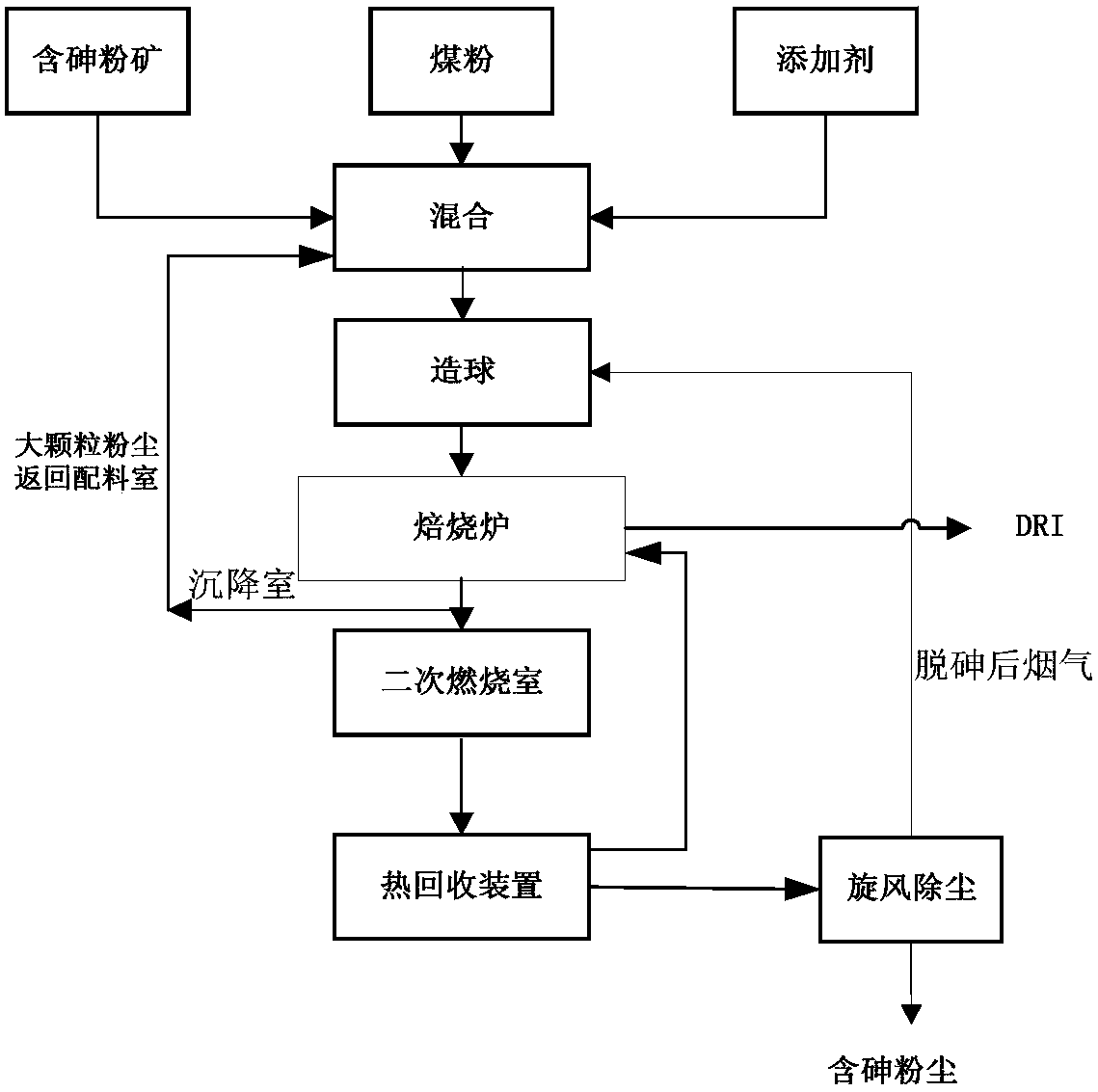

Method used

Image

Examples

Embodiment 1

[0040] 100 parts by weight of arsenic-containing ore powder, 5 parts by weight of coal powder, and 3 parts by weight of dolomite are mixed and pelletized, and the particle size of the pellets is 8mm. Put the dried green balls into the roasting furnace and heat to 800°C. By adjusting the air-fuel ratio, the atmosphere in the furnace is controlled to be a weak oxidizing atmosphere, in which CO 2 The / CO volume ratio is 1.67:1, and the temperature is maintained for 5 minutes. At this stage, arsenic in the form of iron sulfur arsenide can be effectively removed. Then heat the roasting furnace to 1200°C, then adjust the air-fuel ratio, and control the atmosphere in the furnace to be a reducing atmosphere, where CO / CO 2 The volume ratio is 1.9:1, and the temperature is maintained for 30 minutes. At this stage, the arsenic in the form of arsenate can be effectively removed, and the metallized pellets after arsenic removal can be obtained. The flue gas obtained from the reaction in t...

Embodiment 2

[0043] 100 parts by weight of arsenic-containing ore powder, 10 parts by weight of coal powder, and 3 parts by weight of dolomite are mixed and pelletized, and the particle size of the pellet is 12 mm. Put the dried green balls into the roasting furnace and heat it to 900°C. By adjusting the air-fuel ratio, the atmosphere in the furnace is controlled to be a weak oxidizing atmosphere, in which CO 2 The / CO volume ratio is 1.2:1, and the temperature is maintained for 10 minutes. At this stage, arsenic in the form of iron sulfur arsenide can be effectively removed. Then heat the roasting furnace to 1200°C, then adjust the air-fuel ratio, and control the atmosphere in the furnace to be a reducing atmosphere, where CO / CO 2 The volume ratio is 1.9:1, and the temperature is maintained for 25 minutes. At this stage, the arsenic in the form of arsenate can be effectively removed, and the metallized pellets after arsenic removal can be obtained. The flue gas obtained from the reaction...

Embodiment 3

[0046] 100 parts by weight of arsenic-containing ore powder, 15 parts by weight of coal powder, and 3 parts by weight of dolomite are mixed and pelletized, and the particle size of the pellets is 16 mm. Put the dried green balls into the roasting furnace and heat to 1000°C. By adjusting the air-fuel ratio, the atmosphere in the furnace is controlled to be a weak oxidizing atmosphere, in which CO 2 The / CO volume ratio is 0.85:1, and the temperature is maintained for 10 minutes. At this stage, arsenic in the form of iron sulfur arsenide can be effectively removed. Then heat the roasting furnace to 1300°C, then adjust the air-fuel ratio, and control the atmosphere in the furnace to be a reducing atmosphere, in which CO / CO 2 The volume ratio is 2.25:1, and the temperature is maintained for 20 minutes. At this stage, the arsenic in the form of arsenate can be effectively removed, and the metallized pellets after arsenic removal can be obtained. The flue gas obtained from the reac...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com