Patents

Literature

163results about How to "Meet the requirements of circular economy" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

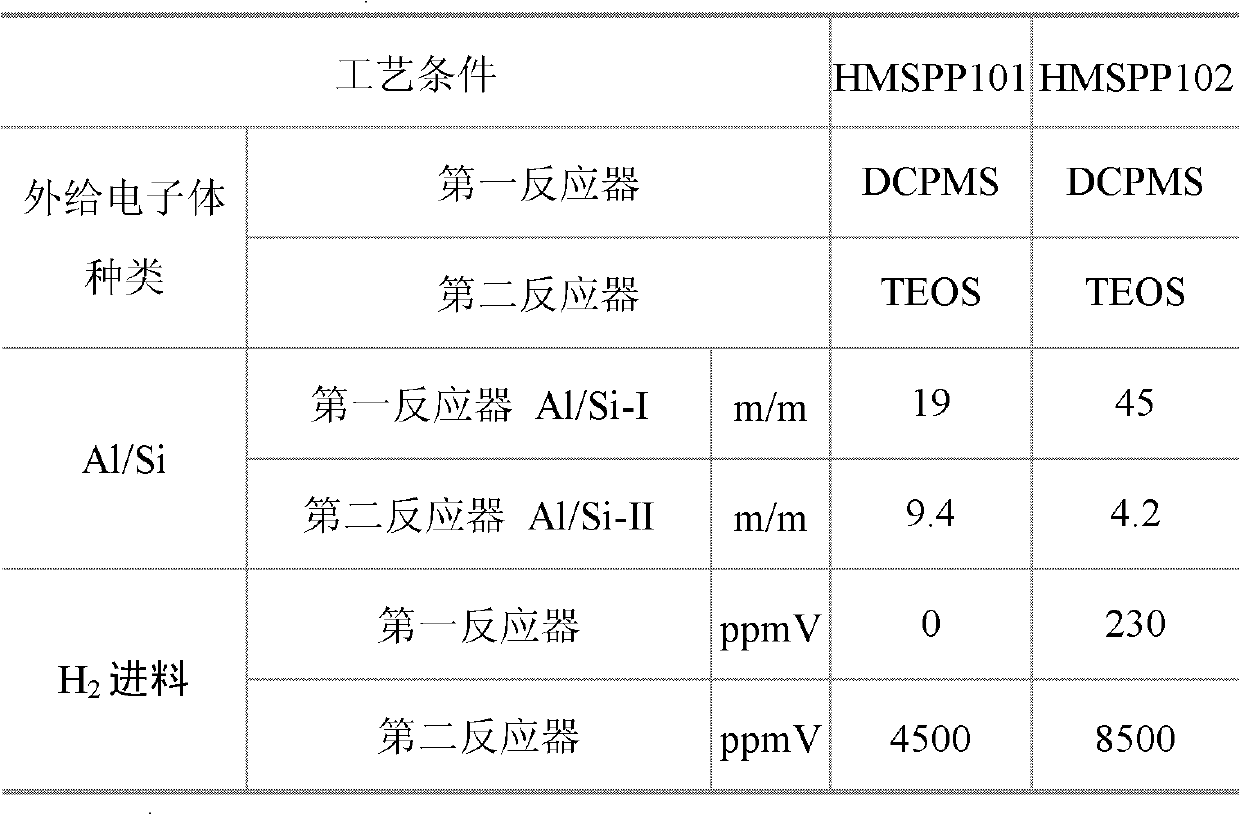

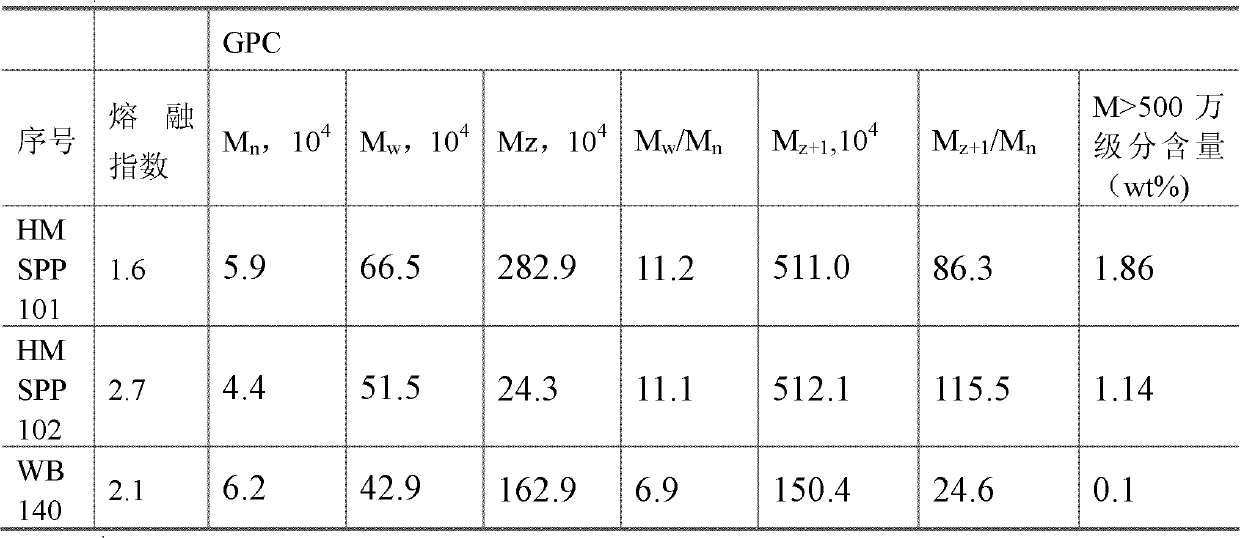

High-melt strength polypropylene foam material and preparation method thereof

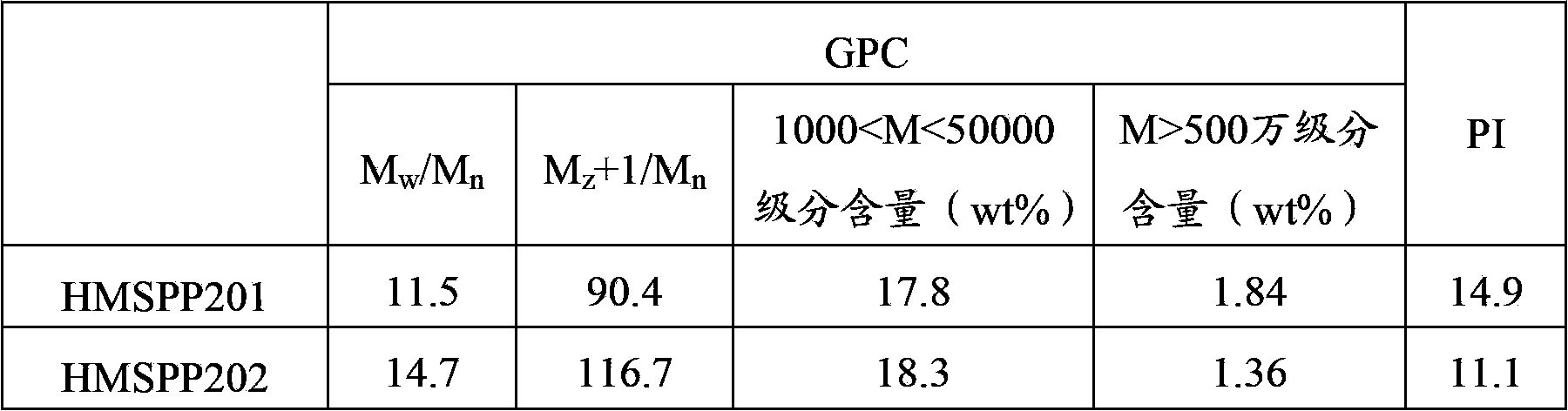

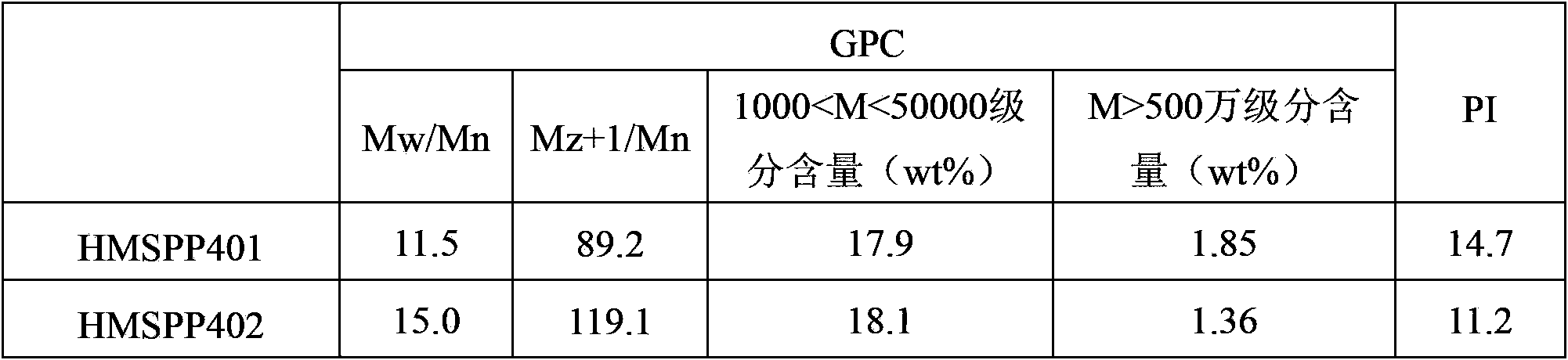

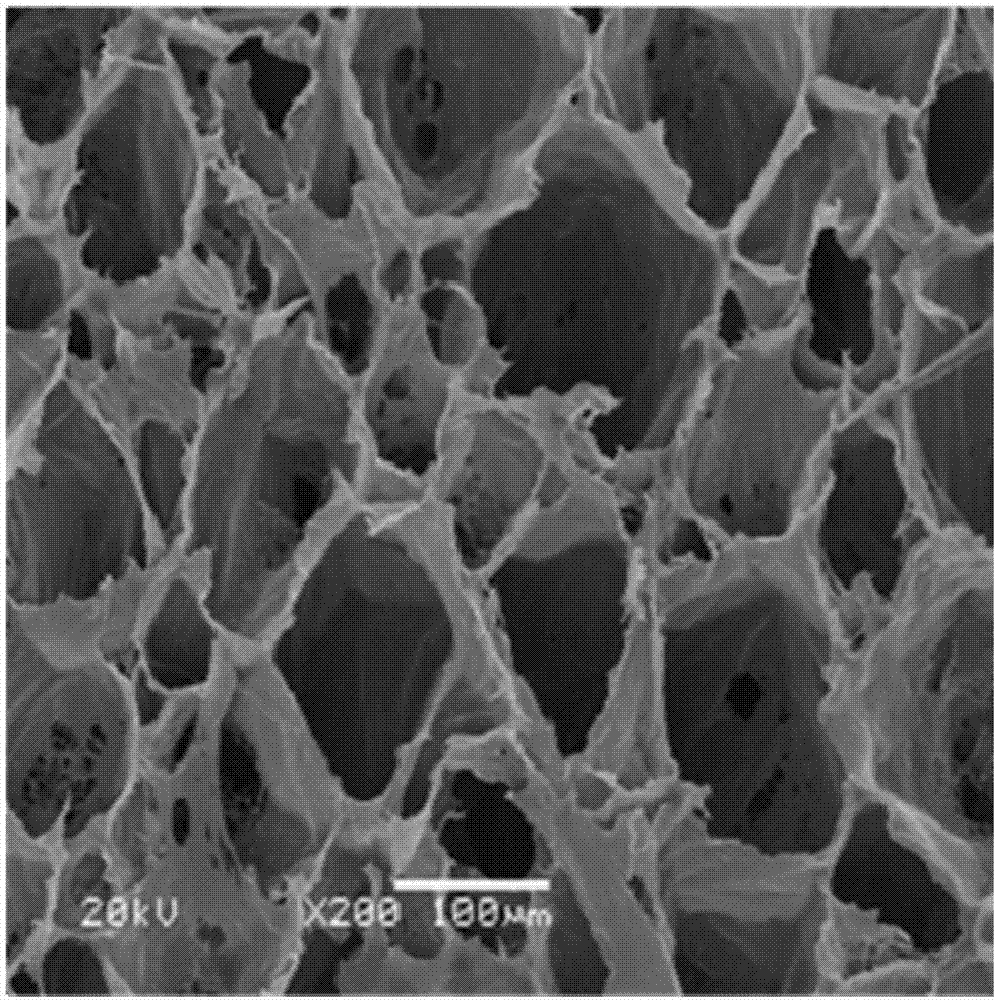

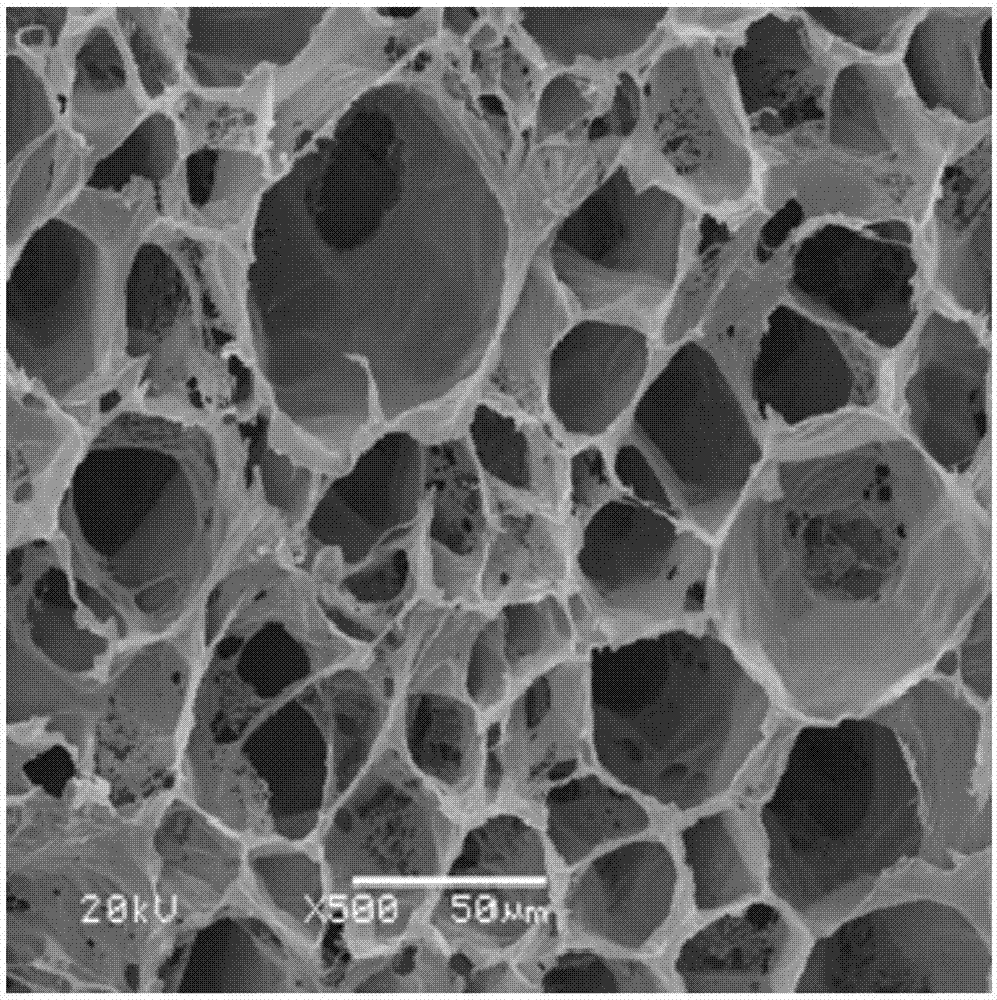

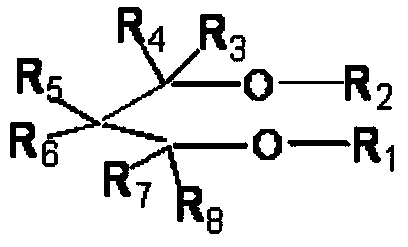

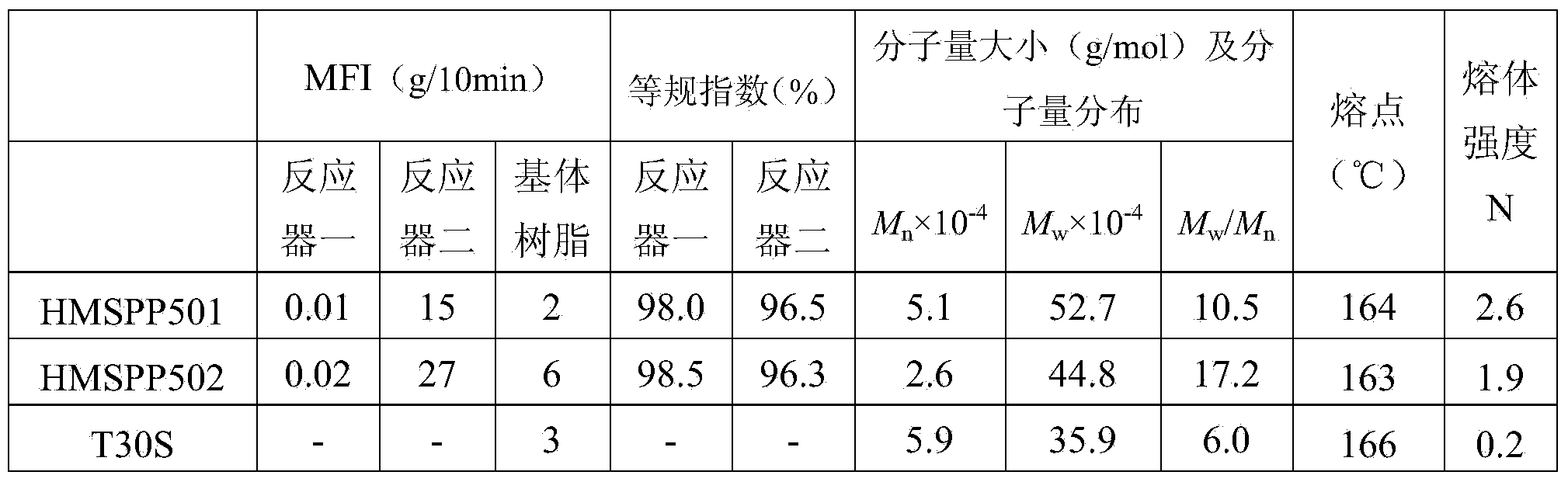

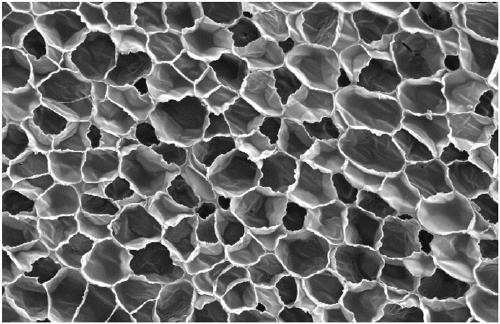

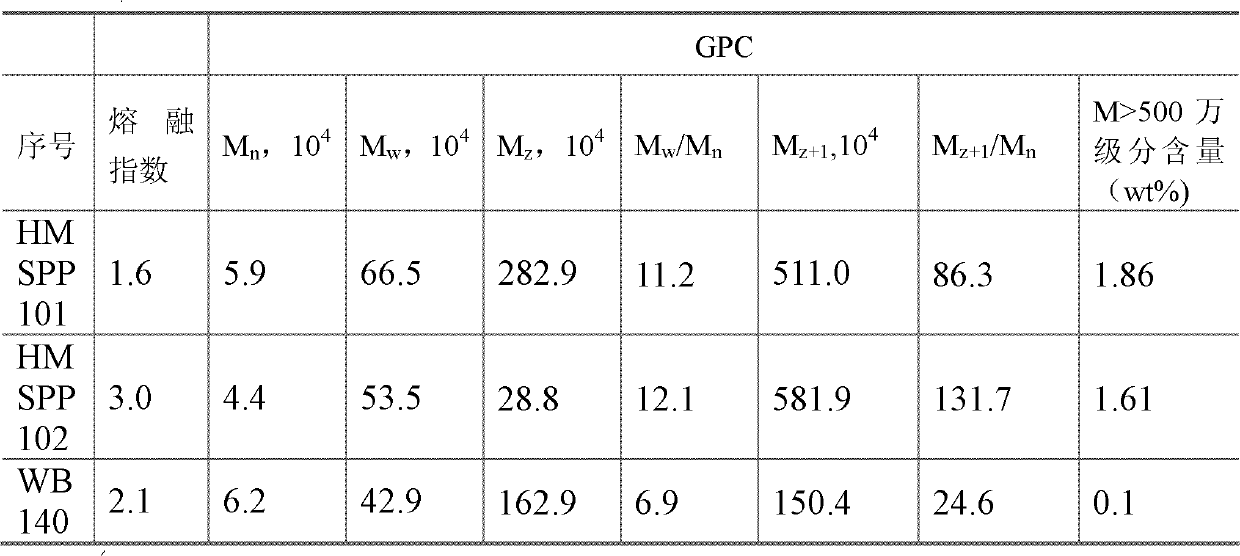

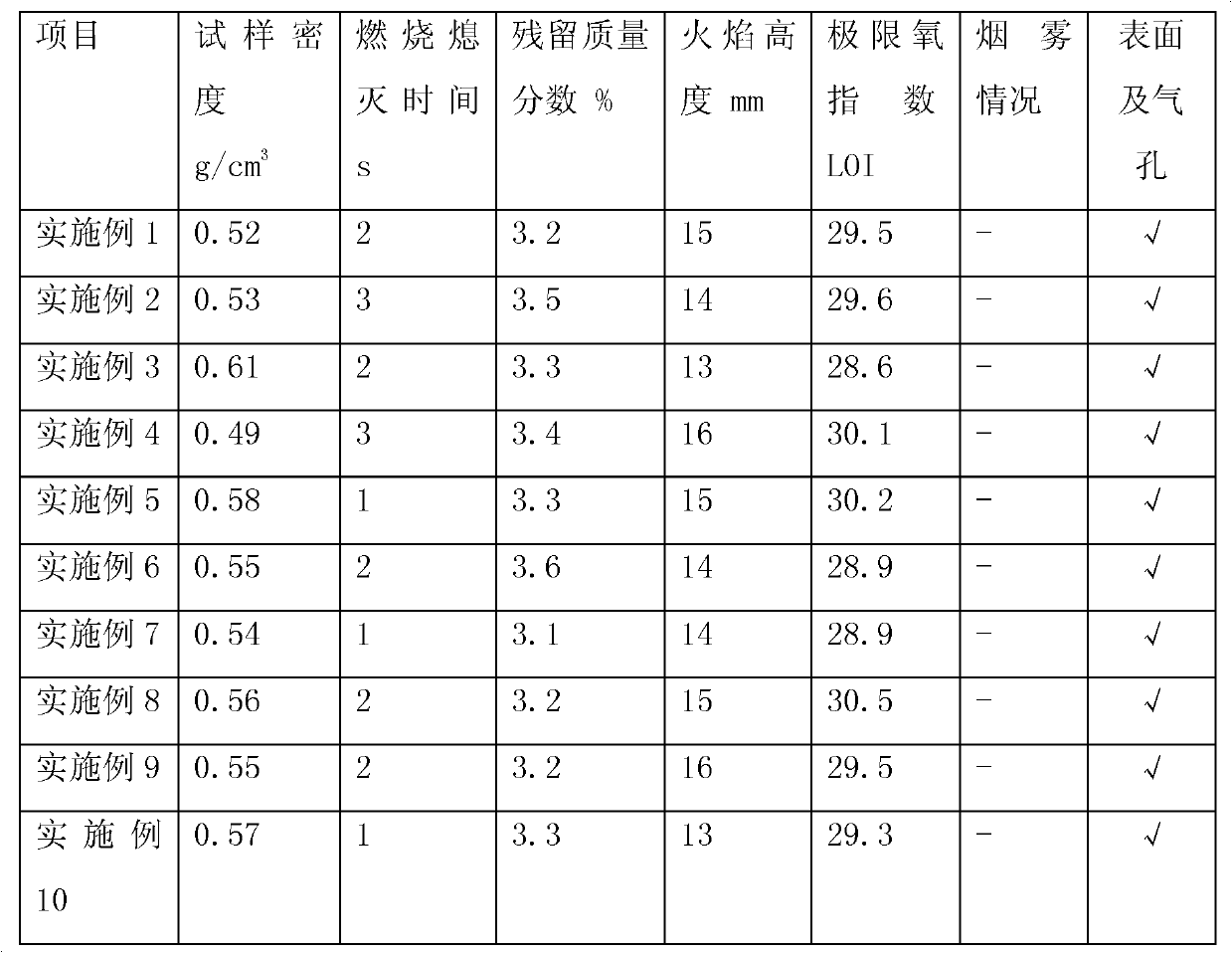

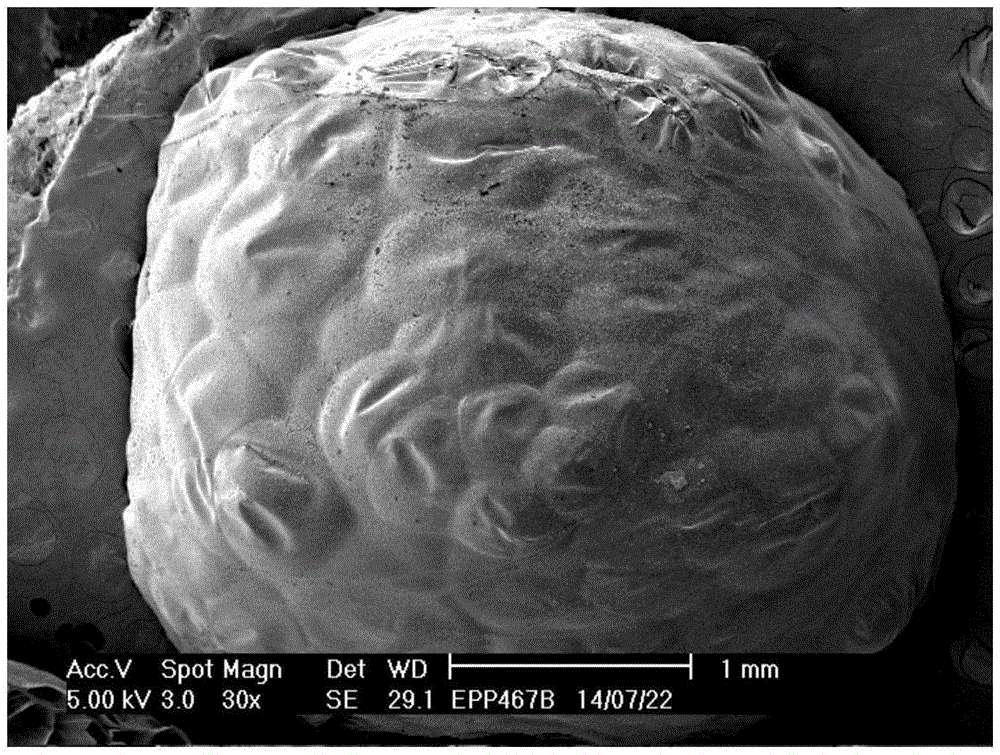

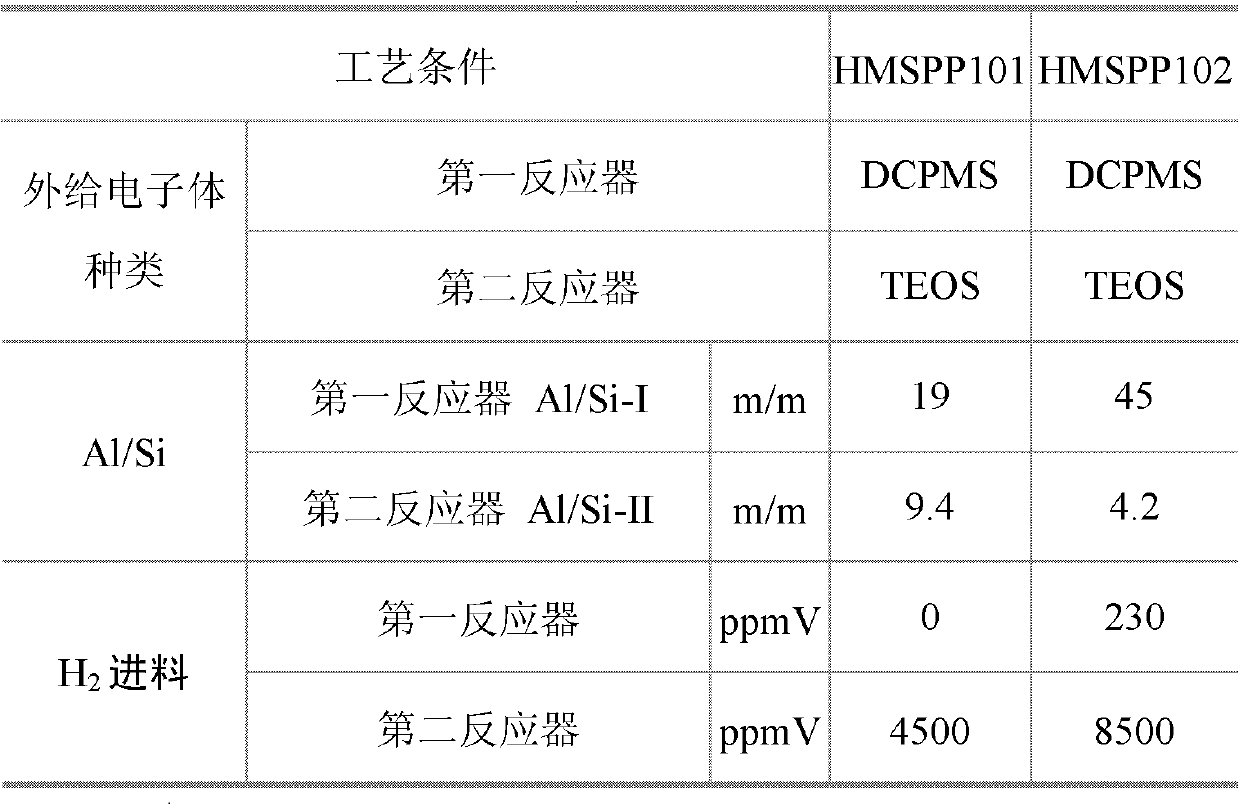

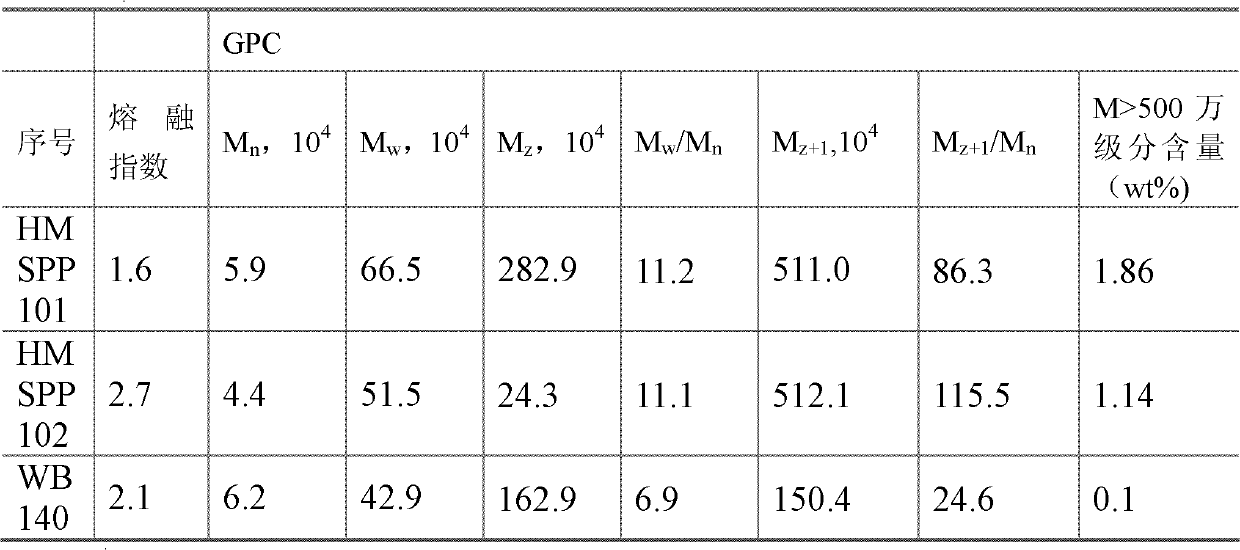

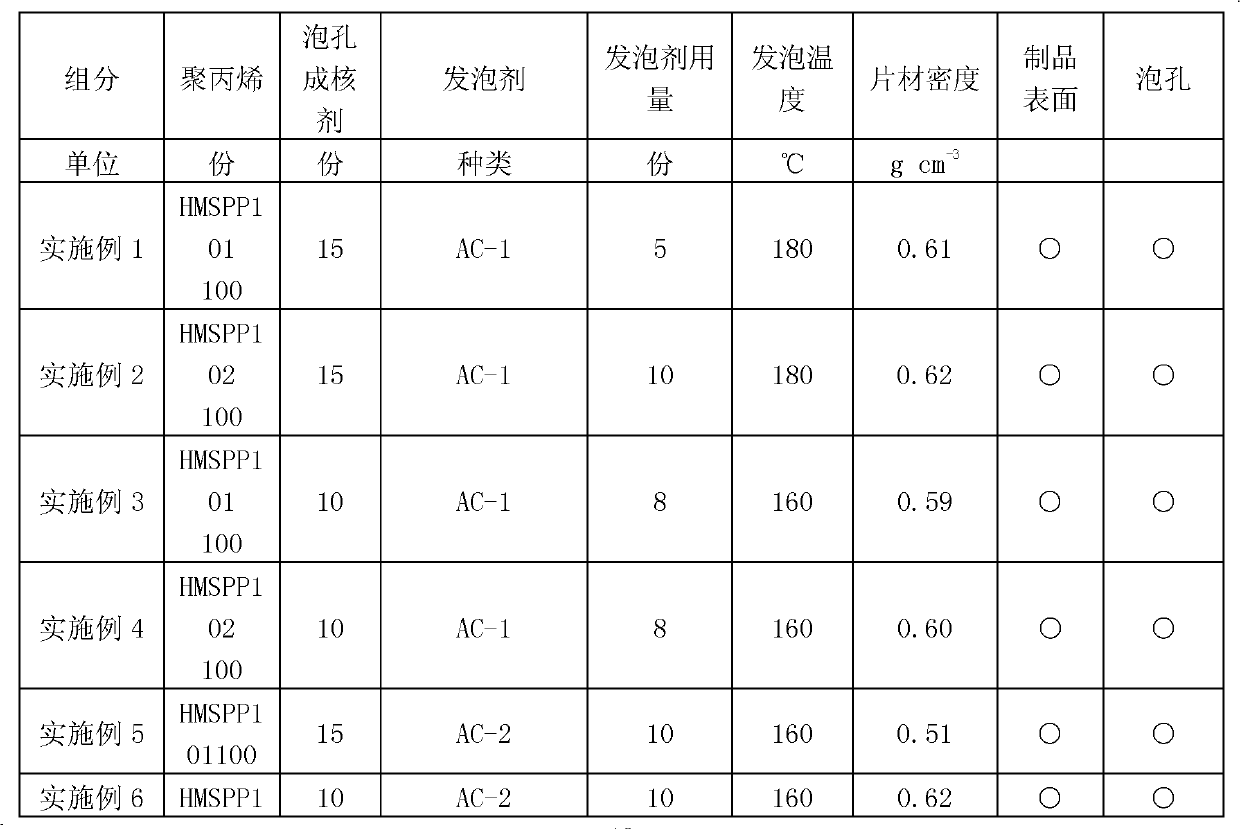

The invention discloses a high-melt strength polypropylene foam material and a preparation method thereof. The matrix resin of the foam material is high-melt strength polypropylene. The high-melt strength polypropylene foam material has the following characteristics: (1) the melt index (190 DEGC / 2.16kg) is 1.0-10g / min; (2) the molecular weight distribution Mw / Mn is 6-20; (3) the content of the molecules with molecular weight over 5 million is greater than or equal to 0.8% by weight; and (4) (Mz+1) / Mn is greater than or equal to 70. The foam material is prepared by premix melting, blending and foaming of the following components in parts by weight: 100 parts of high-melt strength polypropylene and 1-15 parts of foaming agent. The obtained foam material meets the environmental protection requirements of degradability, uniform cell, high physical heat resistance, low production cost and smooth surface, and is suitable for continuous large-scale production.

Owner:CHINA PETROLEUM & CHEM CORP +1

Method for comprehensive utilization of residues from alcohol and starch processing by using tapioca

InactiveCN101773927AImprove the economic efficiency of the industryBroad marketSolid waste disposalNutrientChemistry

The invention provides a method for producing products such as organic fertilizers, biological fertilizers, organic-inorganic compound fertilizers, plant breeding nutrient mediums, soil improvement materials and water retention materials by industrial chemical fermentation processing of residues from alcohol and starch processing by using tapioca. By the method, waste pollutants of chicken manure, pig manure, cow manure, sheep manure, sugar-refinery mud and the like are fully used, the comprehensive treatment and the recycling development of various organic resources are realized, and the problems for the technical treatment and the environmental influence of industrialized tapioca residues are effectively solved; and no three-waste emission occurs in the whole treatment process, the secondary pollution is avoided, and good economic benefits and social benefits are generated.

Owner:GUANGXI LIYUAN NEW RESOURCE DEV

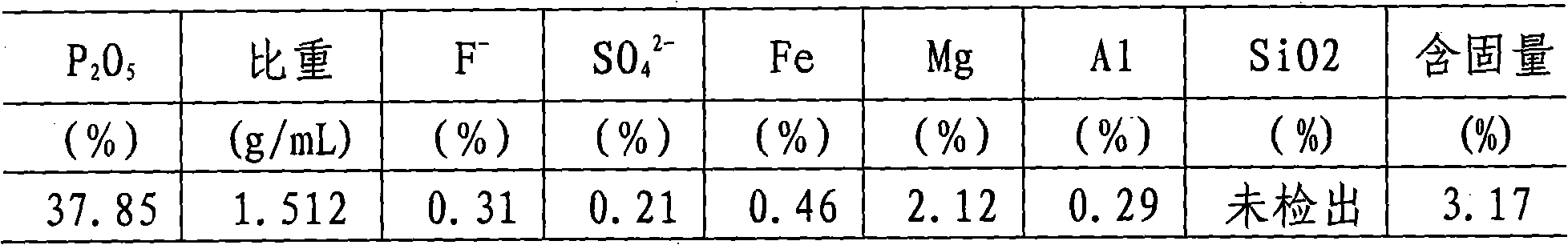

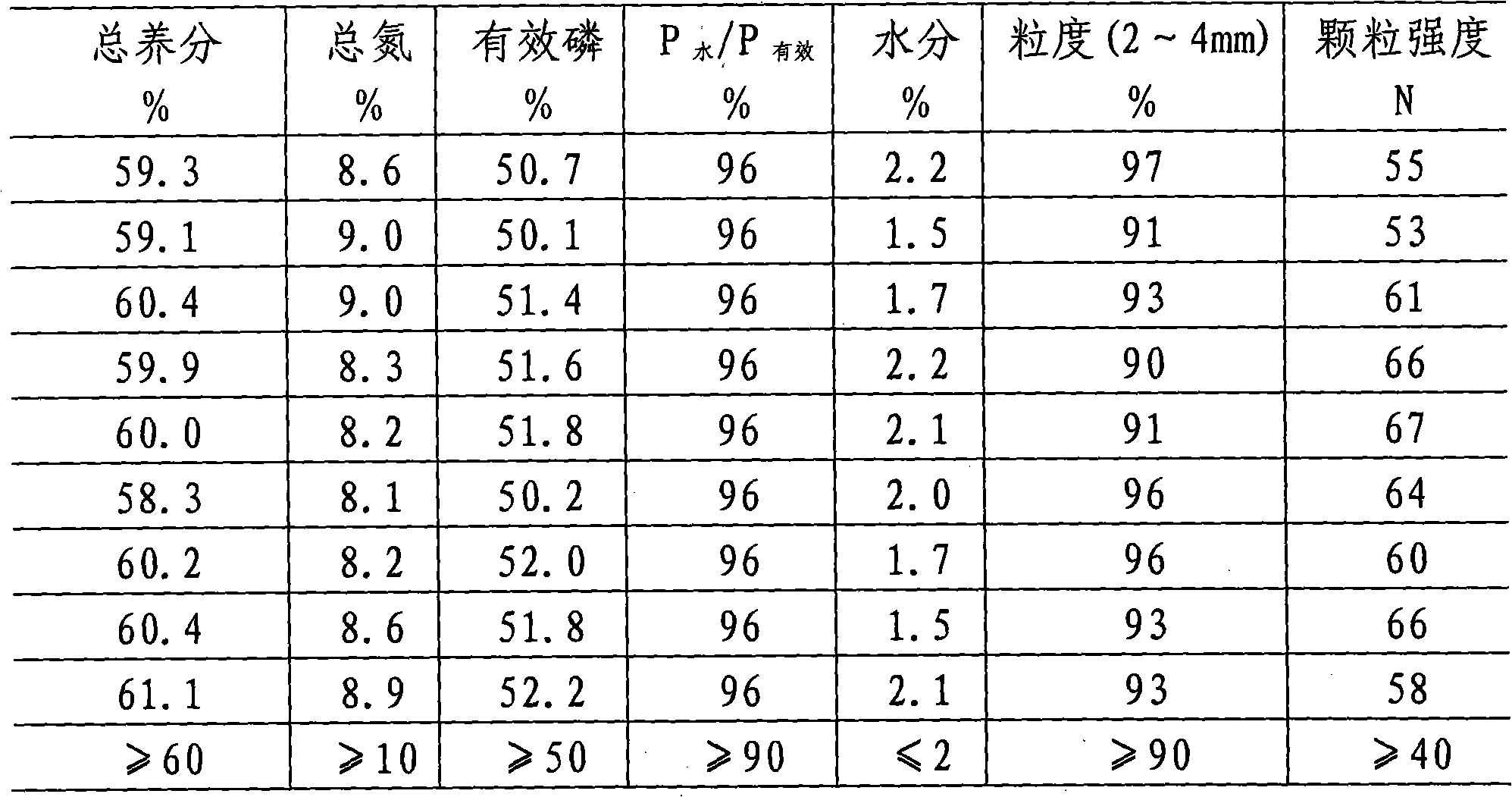

Method for producing granular monoammonium phosphate with raffinate

ActiveCN101891504ADigestive raffinateIncrease concentrationAlkali orthophosphate fertiliserAmmonium orthophosphate fertilisersSpray GranulationPhosphate

The invention provides a method for producing granular monoammonium phosphate with raffinate, wherein, ammonia is neutralized with phosphoric acid to obtain slurry, and the slurry is concentrated and then subjected to spraying granulation to obtain the granular monoammonium phosphate. The method comprises the following steps: (1) mixing wet-process phosphoric acid with the raffinate according to a certain ratio to obtain mixed phosphoric acid, and then lowering the metal ion content in the raw material mixed phosphoric acid; and (2) adjusting the neutralization degree of neutralization reaction between the mixed phosphoric acid and the ammonia to obtain monoammonium phosphate slurry. The granular monoammonium phosphate obtained by the method can meet the requirement for nitrogen nutrients in the product, reach the product strength of no less than 40N, digest the raffinate in a wet-process phosphoric acid purification device, conform to the requirement for the current global recycling economy. The method can improve the concentration of dilute phosphoric acid, reduce steam consumption of a slurrying system, and increase the product strength of the granular monoammonium phosphate.

Owner:WENGFU (GRP) CO LTD

Antistatic polypropylene foam material and preparation method thereof

The invention discloses an antistatic polypropylene foam material and a preparation method thereof. The foam material comprises the following blended components in parts by weight: 100 parts of high-melt-strength polypropylene, 0.1-2 parts of grapheme, 5-15 parts of a foaming agent, 0.125-0.25 parts of a compatilizer and 0.05-0.15 parts of a coupling agent. The method for preparing the antistatic polypropylene foam material comprises the following steps of: melting and blending according to the using amounts; molding and foaming.

Owner:CHINA PETROLEUM & CHEM CORP +1

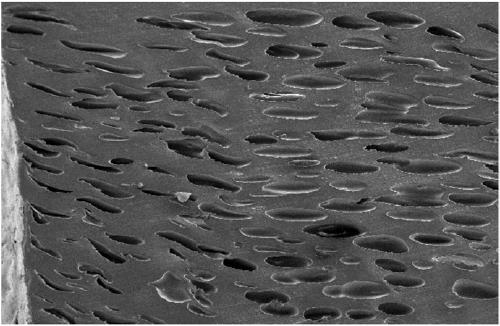

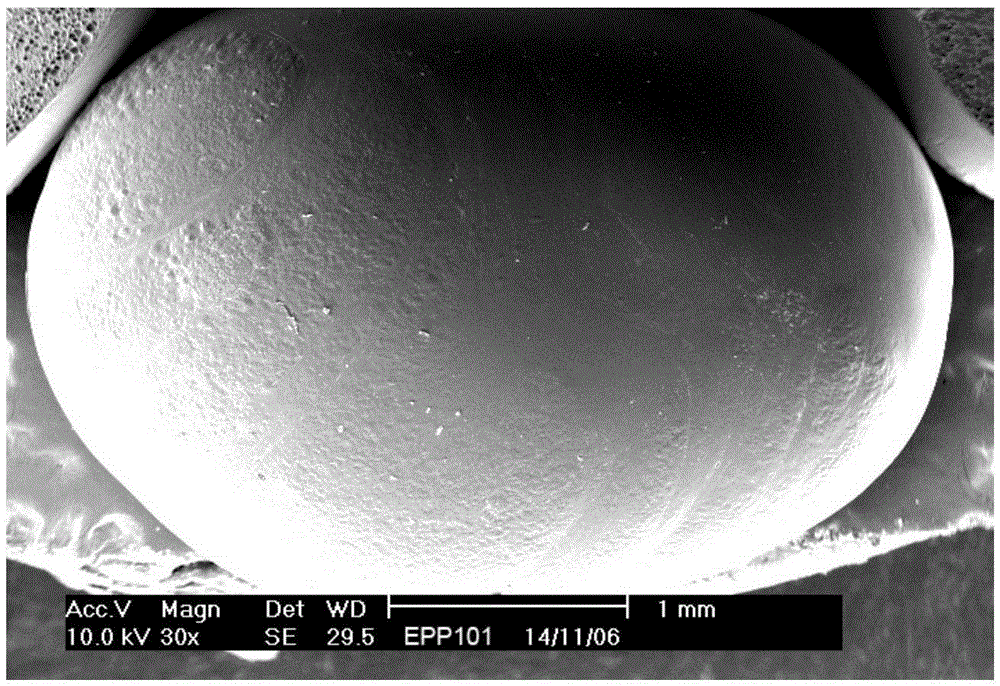

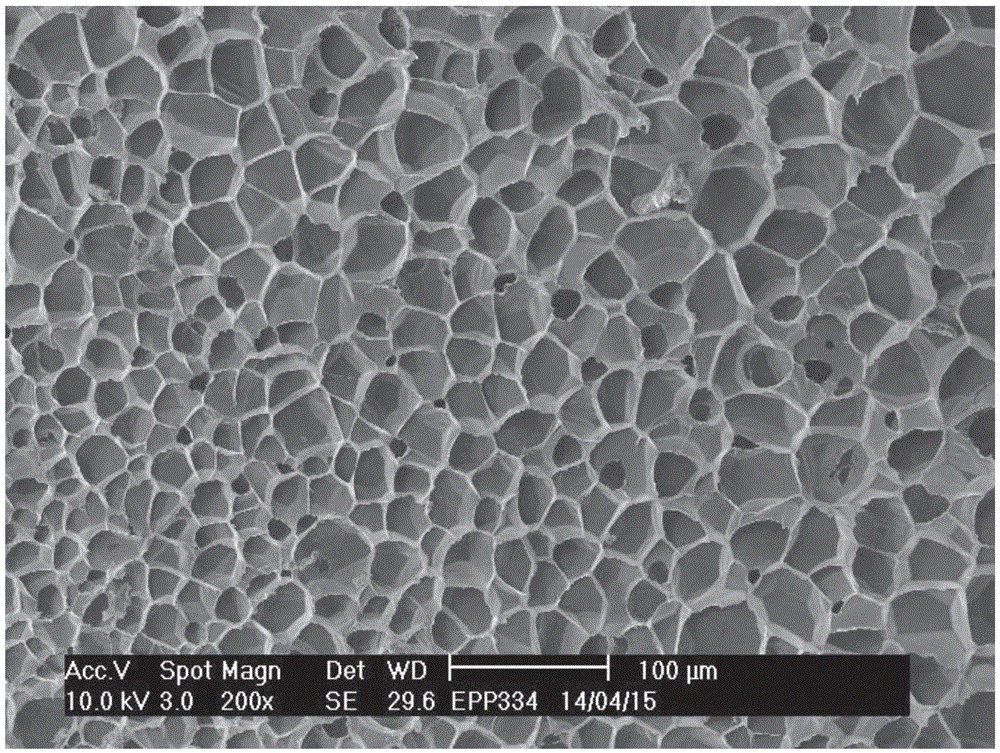

Propylene-ethylene high-melt-strength polypropylene foamed bead and preparation method thereof

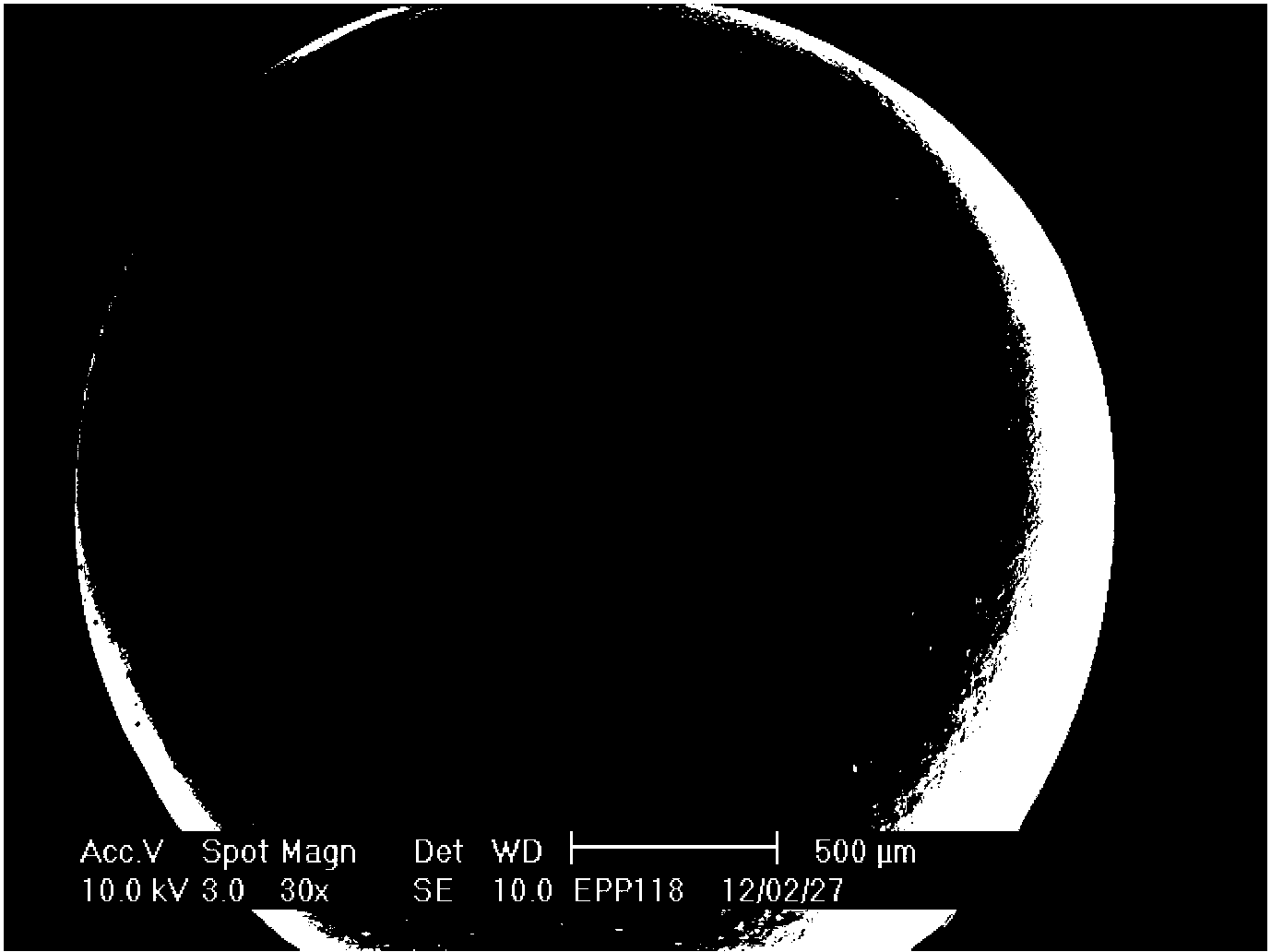

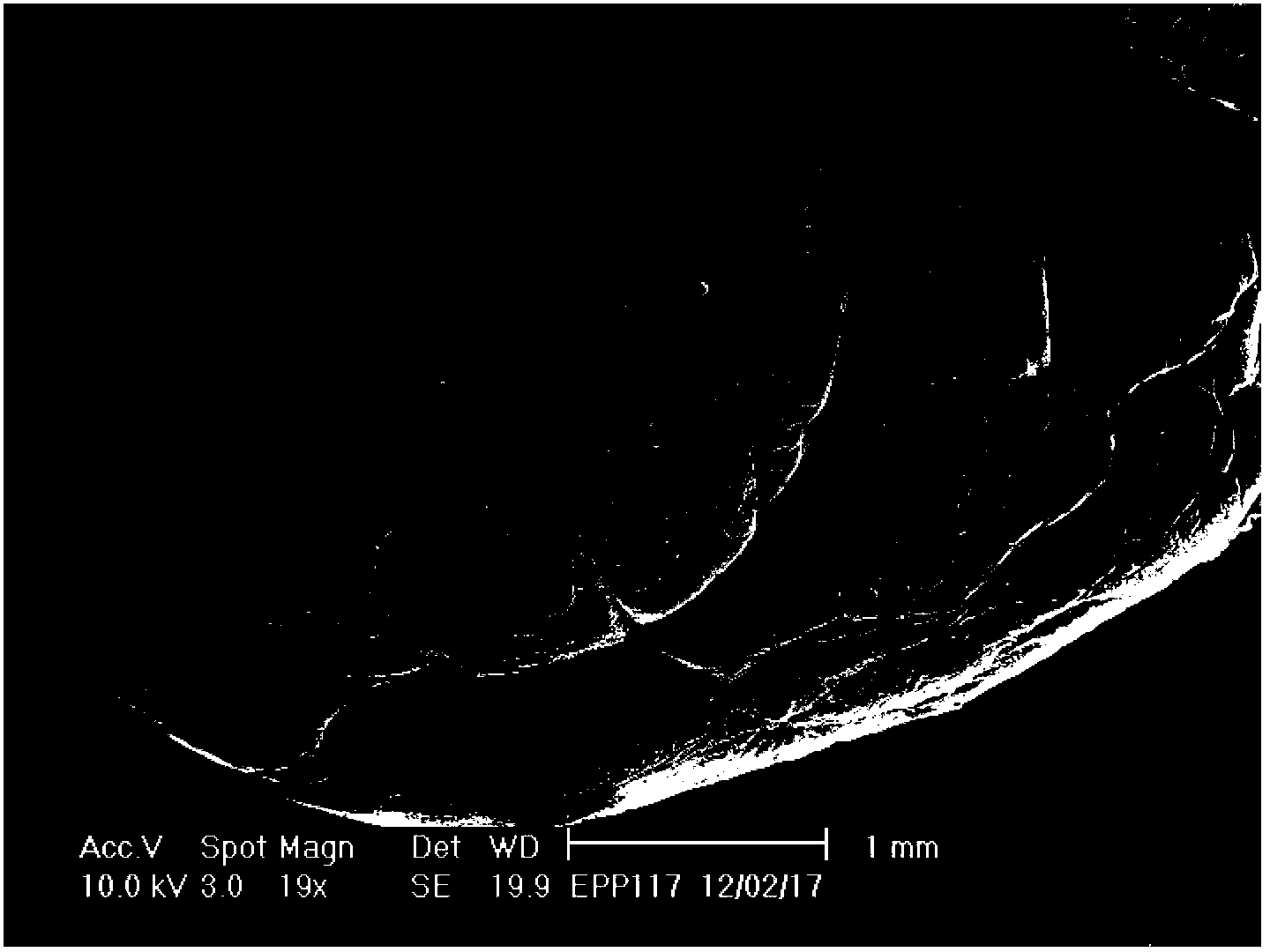

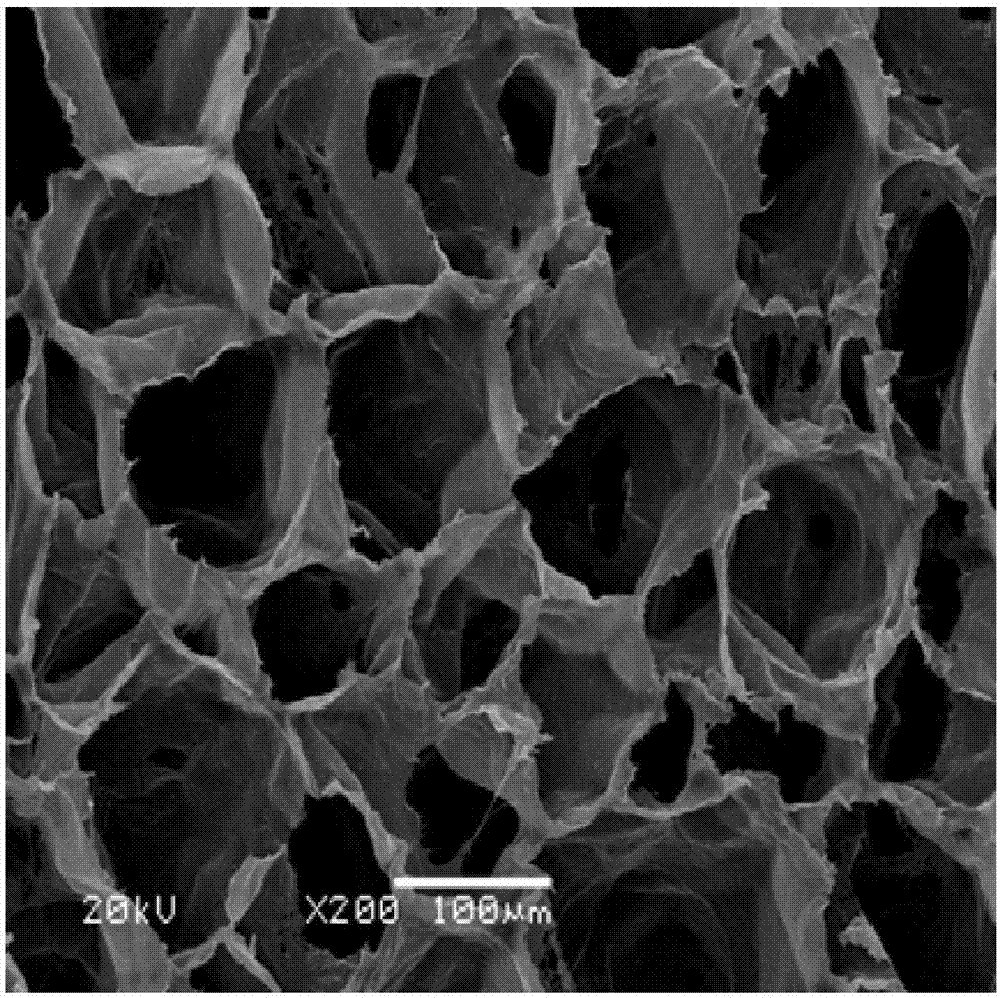

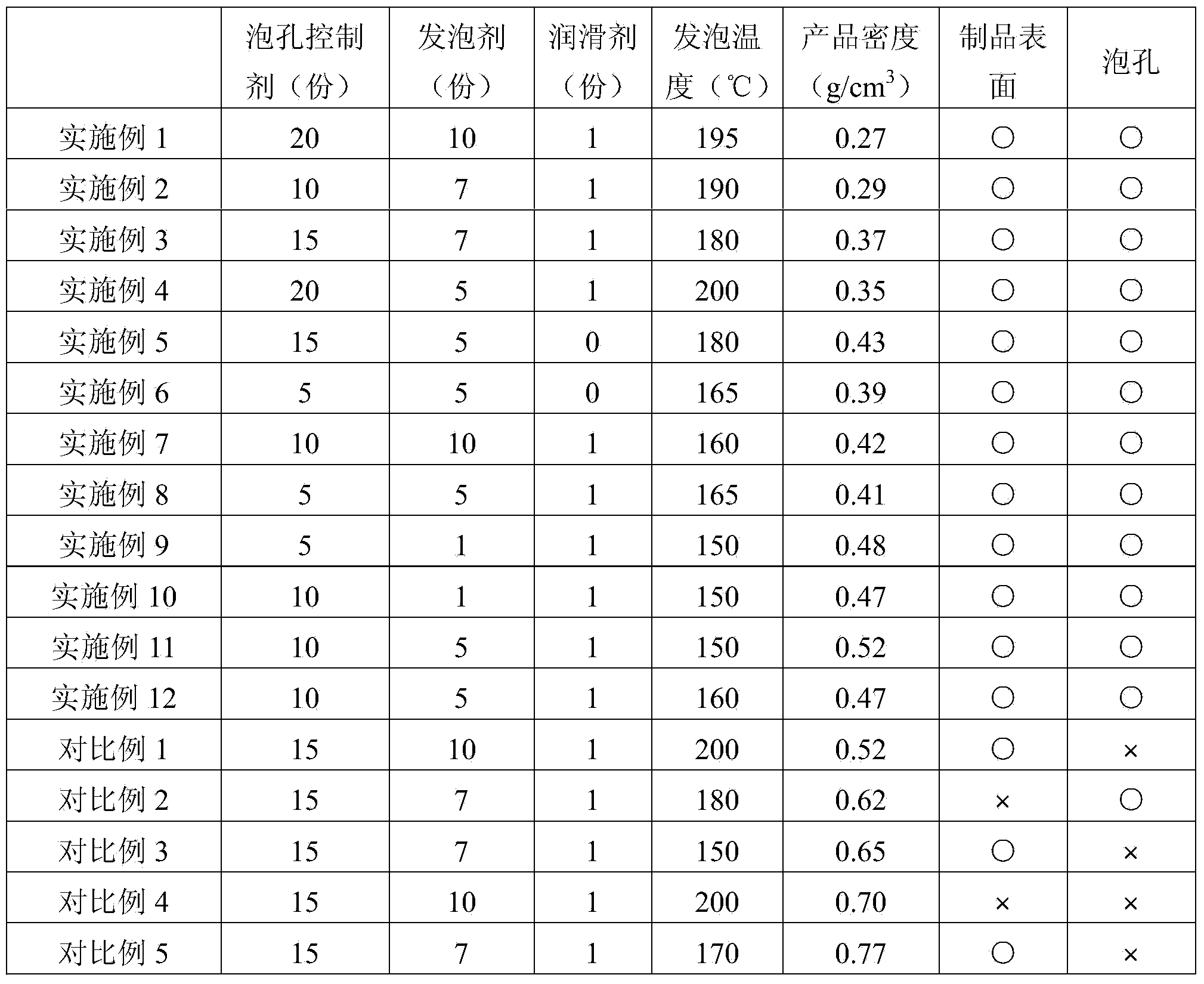

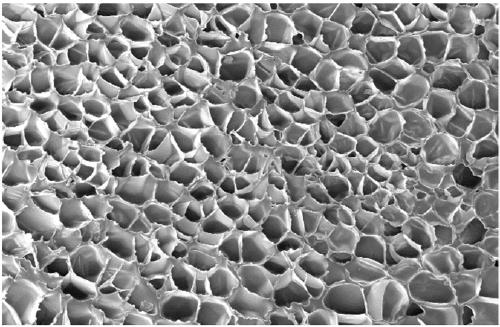

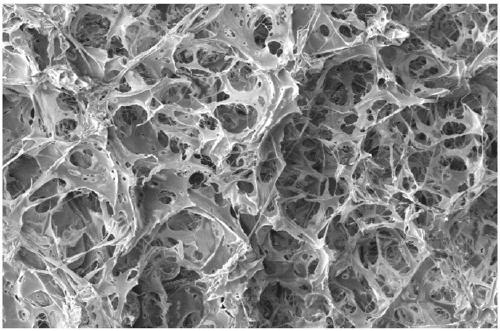

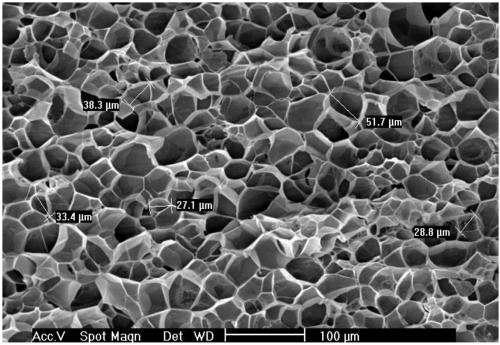

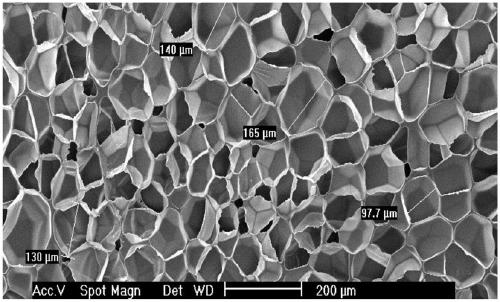

The invention provides a polypropylene foamed bead. The foamed bead is prepared by foaming a base resin high-melt-strength polypropylene with a foaming agent, wherein the high-melt-strength polypropylene has the following characteristics: the melt index MFR is 0.2-10 g / 10 minutes, the molecular weight distribution Mw / Mn is 6-20, the content of substances with the molecular weight of greater than 5 million is greater than or equal to 0.8 wt%, the M[z+1] / Mn is greater than or equal to 70, and the ethylene content is 0.1-20 wt%. The high-melt-strength polypropylene with wide molecular weight distribution is utilized as the raw material to implement stabilization of the polypropylene raw material, so that the foaming window is effectively enlarged, the technique is easy to adjust, and the cost is low; the method can be used for preparing the polypropylene foamed bead with the density of 0.02-0.3 g / cm<3>, which has the advantages of uniform pore diameter, compact pores, uniform pore size distribution and close-pore structure; and the polypropylene foamed bead can be widely used in the fields of thermal insulation tableware, automobile interior ornaments, architectural moldboards, camping supplies, decorating material interlayers, product damping packages and the like.

Owner:CHINA PETROLEUM & CHEM CORP +1

Polypropylene foaming bead formed body and preparation method thereof

The invention provides a polypropylene foaming bead formed body and a preparation method thereof. The preparation method comprises the following steps: mixing polypropylene foaming beads having different foaming rates and prepared by using wide-molecular-weight-distribution high-melt-strength polypropylene as a raw material in proportion, and carrying out thermal molding of the above obtained mixed foaming beads to obtain the foamed body with good surface flatness and tight adhesion. The formed body can be widely applied to the heat insulation tableware field, the automobile interior decorative part field, the finishing material interlayer field, the product damping packaging field and the like. Additionally, the molded body can be recycled, causes no secondary pollution, and accords with circular economy requirements.

Owner:CHINA PETROLEUM & CHEM CORP +1

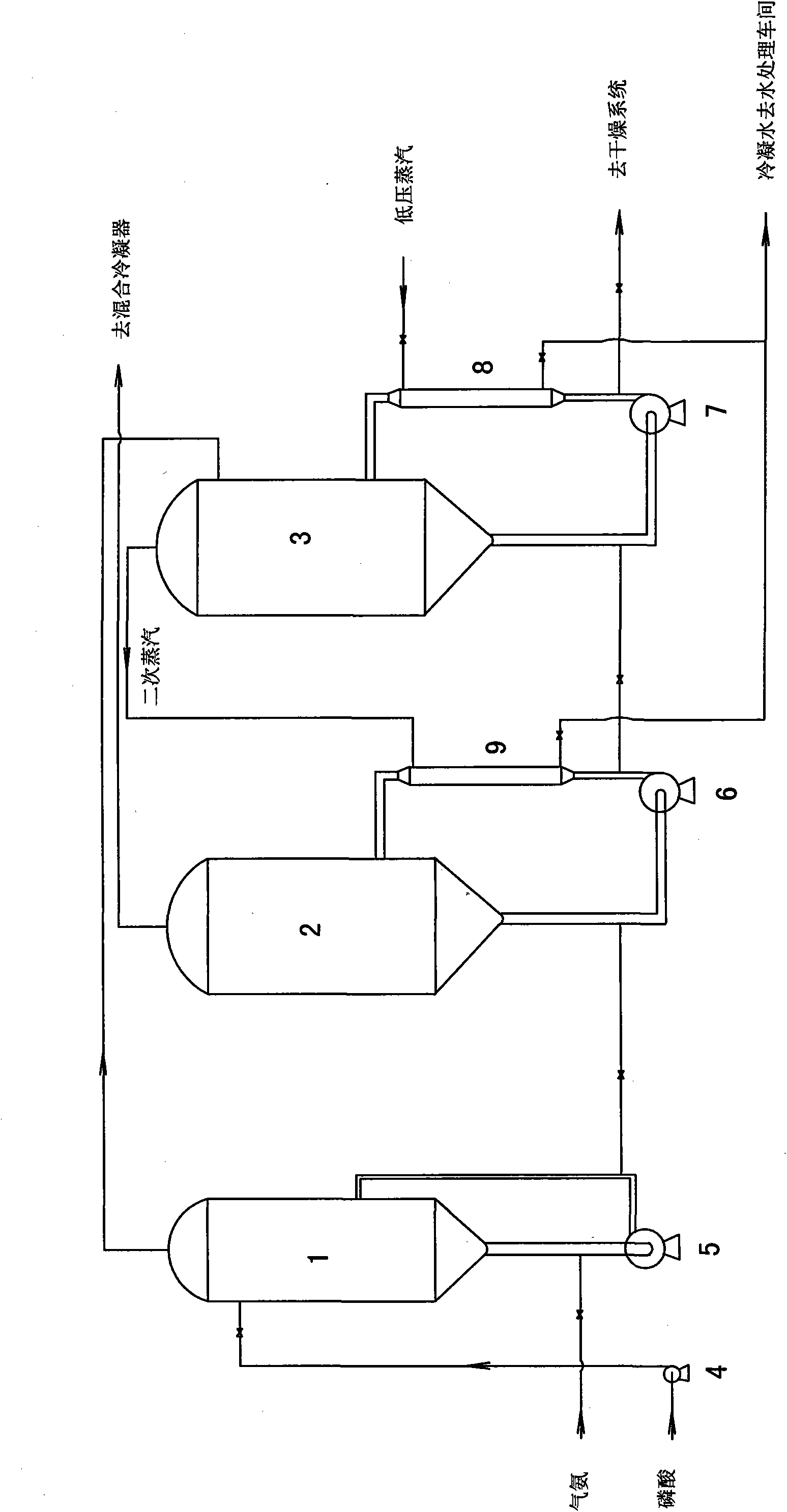

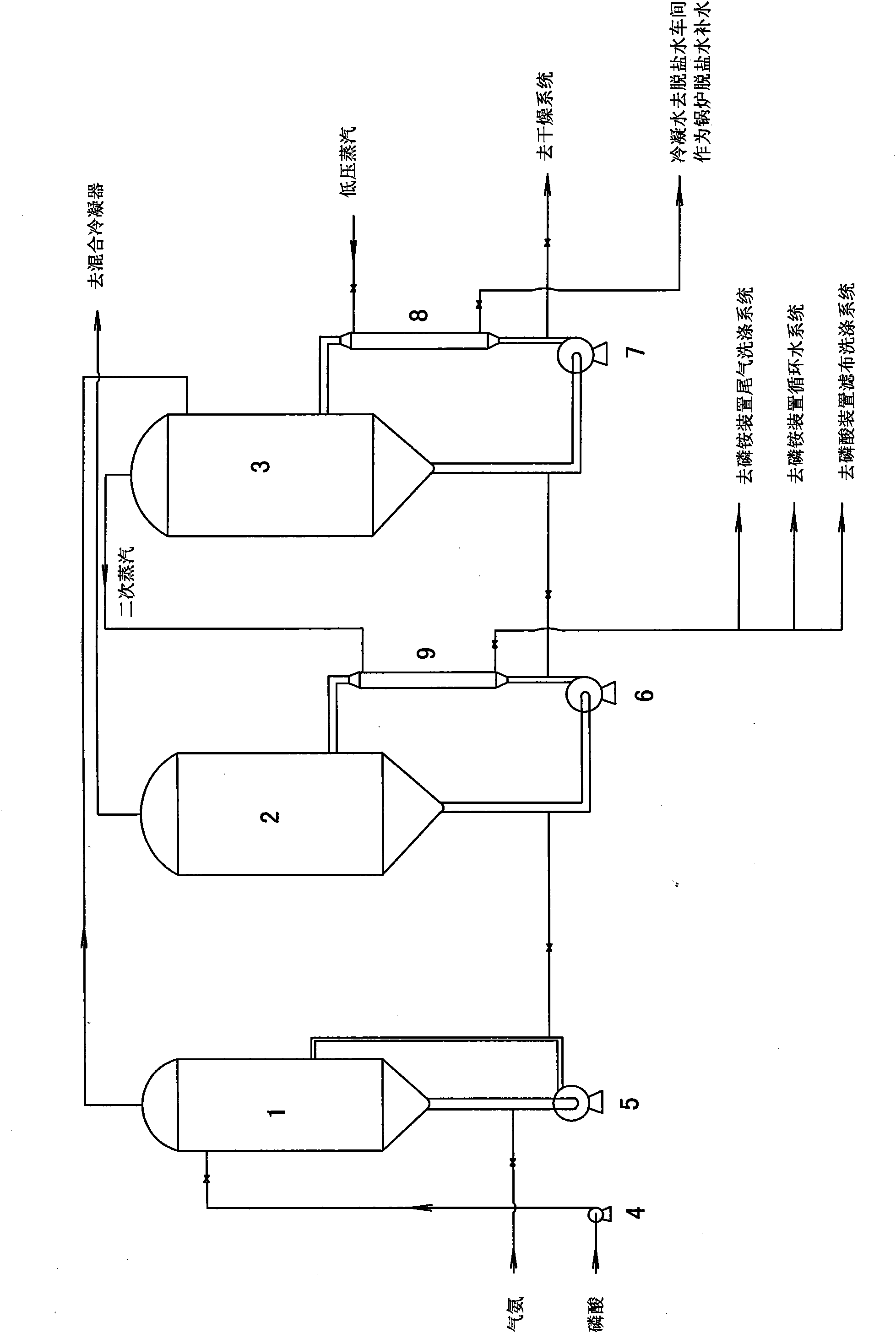

Comprehensive utilization method for wastewater of ammonium phosphate production

ActiveCN101928046AImprove protectionReduce process water intakePhosphatesWater/sewage treatmentSaline waterEvaporation

The invention discloses a comprehensive utilization method for wastewater of ammonium phosphate production. By distributing the wastewater, the wastewater is blended in other production links for recycling according to different ammonia nitrogen contents so as to realize zero emission. Condensed water generated by I-effect evaporation is relatively clean, and is delivered to a desalted water workshop to serve as supply water for desalted water of a boiler; and secondary steam generated by the I-effect evaporation is used in II-effect evaporation, condensed water is wastewater containing ammonia nitrogen, by adopting a treatment method of breaking up the whole into parts, a part of the wastewater is delivered to a tail gas washing system of a ammonium phosphate device and is added to serve as tail gas washing water, another part of wastewater is delivered to a circulating system of the ammonium phosphate device to serve as transmission equipment sealing water or adding water, and the other part of wastewater is delivered to a filter of the ammonium phosphate device to serve as filter cloth washing water. The method has the advantages of realizing zero emission of ammonia nitrogen wastewater of a large ammonium phosphate device, contributing to environmental protection, reducing process water quantity, realizing liquid-phase circular production, meeting the requirement of circular economy, and being suitable for the large ammonium phosphate device.

Owner:WENGFU (GRP) CO LTD

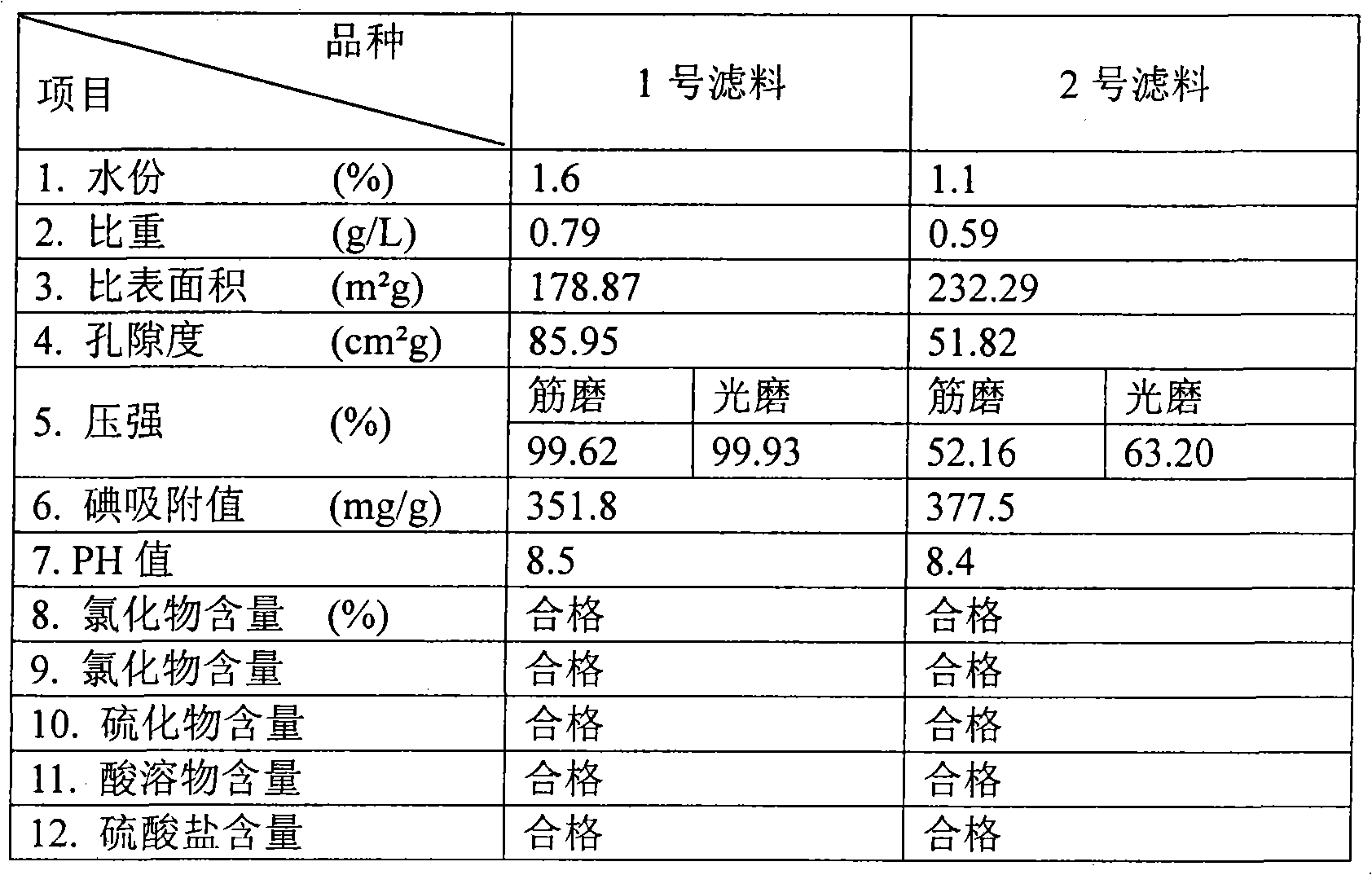

Composite filtering material for activating and regenerating coal ash and production method thereof

InactiveCN101274172ALow costReduce processingOther chemical processesFiltration separationFiltrationGranularity

The invention discloses a fly ash activation regeneration composite filtration material and a manufacture method of the filtration material, belonging to the field of water treatment technique. The fly ash activation regeneration composite filtration material consists of 80 to 90 portions of fly ashes or furnace ashes (by weight) with the grain diameter not less than 80 meshes and 10 to 20 portions of porous aluminosilicate mixed powders (by weight); the fly ash or the furnace ash are bonded as grain shape with the granularity less than 8mm; the porous aluminosilicate mixed powders are enwrapped on the surface of the fly ashes or the furnace ashes and burned so as to form a ceramic layer which is provided with an adsorption micro-hole which is communicated with an internal core. The fly ash activation regeneration composite filtration material is fabricated and formed by the steps of raw material mixing, primary granulation, secondary granulation, drying, roasting, etc., and has the advantages of low cost and good purification effect.

Owner:江苏正本净化节水科技实业有限公司

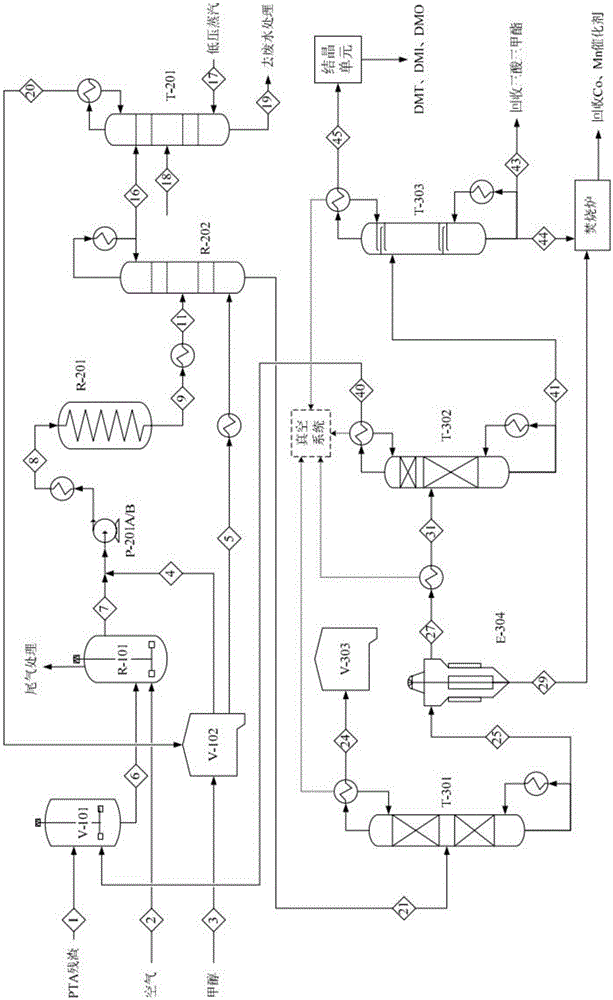

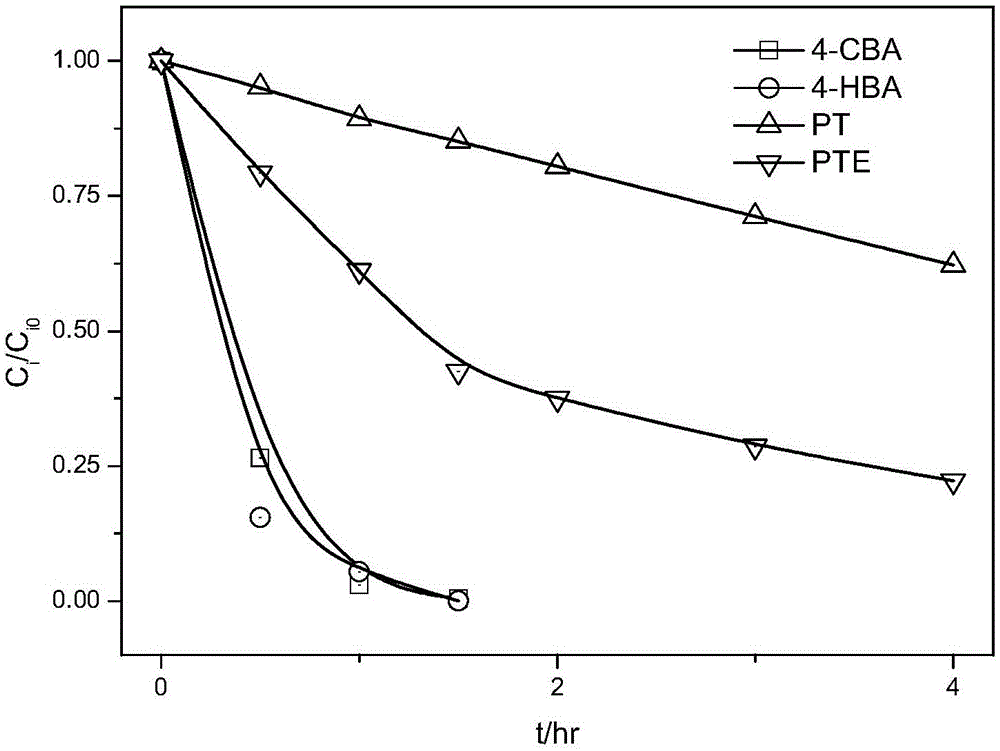

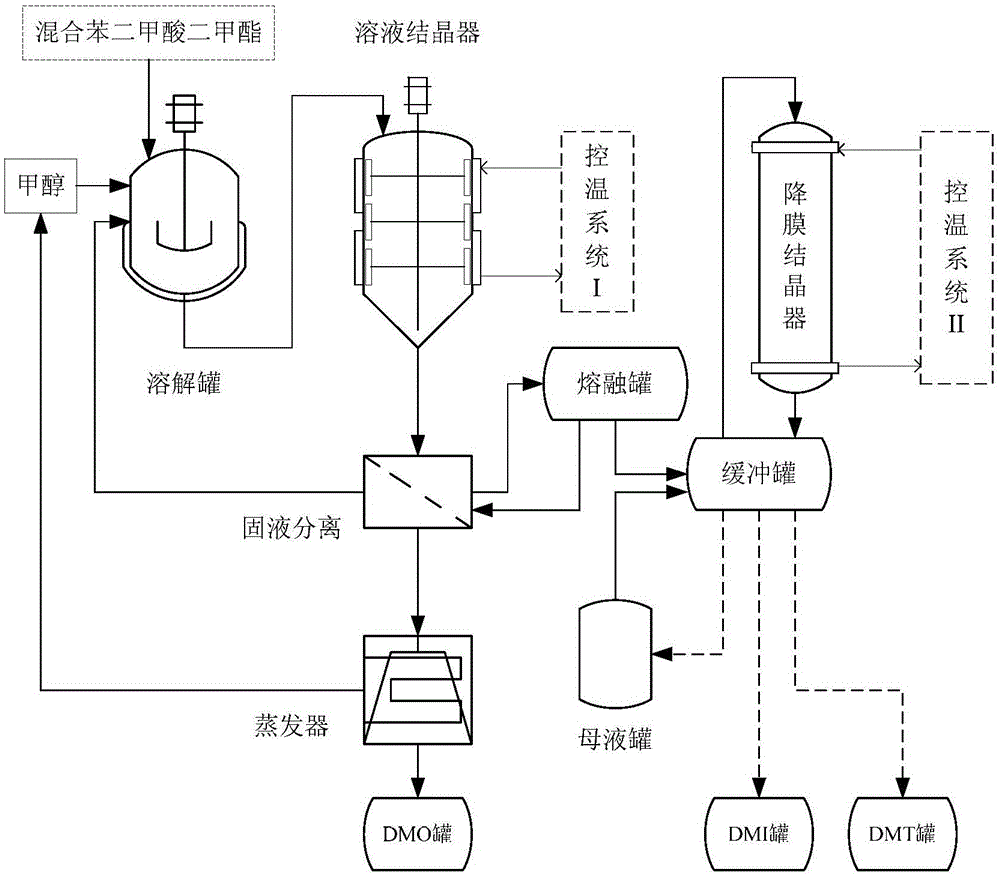

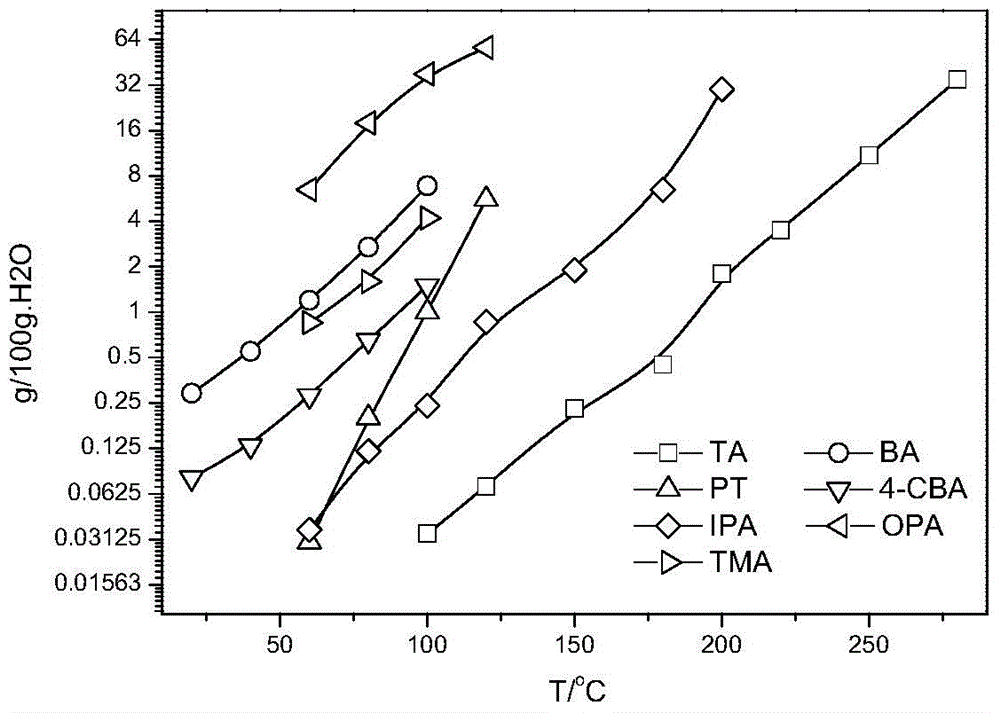

Method for methyl esterification recovery and recycle of PTA oxidation residue

InactiveCN105017022ARealize resource utilizationHigh purityOrganic compound preparationCarboxylic acid esters preparationDimethyl terephthalateMethyl benzoate

The invention discloses a method for methyl esterification recovery and recycle of PTA oxidation residue. The method comprises 1, primary oxidation treatment, 2, secondary methyl esterification treatment, and 3, tertiary rectification treatment, wherein methyl benzoate is recovered by primary reduced pressure rectification, methyl toluate is recovered by secondary reduced pressure rectification, mixed benzenedicarboxylic acid dimethyl ester is recovered by tertiary reduced pressure rectification, and dimethyl terephthalate, dimethyl isophthalate and dimethyl phthalate are respectively recovered by mixed benzenedicarboxylic acid dimethyl ester crystallization treatment. The method effectively recovers BA, IPA, TA, PT, 4-CBA, 4-HBA, OPA and TMA of the PTA oxidation residue, can produce high purity methyl benzoate, mixed benzenedicarboxylic acid dimethyl ester and trimethyl trimellitate products and realizes separation and recovery of DMT, DMI and DMO products from mixed benzenedicarboxylic acid dimethyl ester by crystallization.

Owner:ZHEJIANG UNIV

Method for recycling PTA oxidation residue

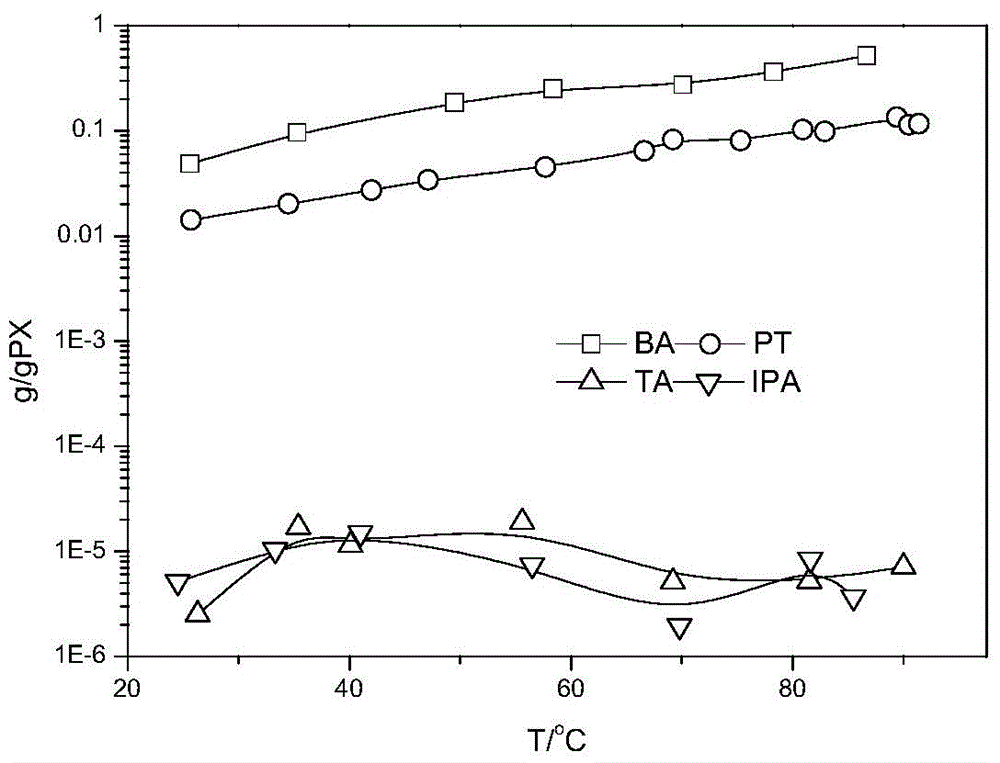

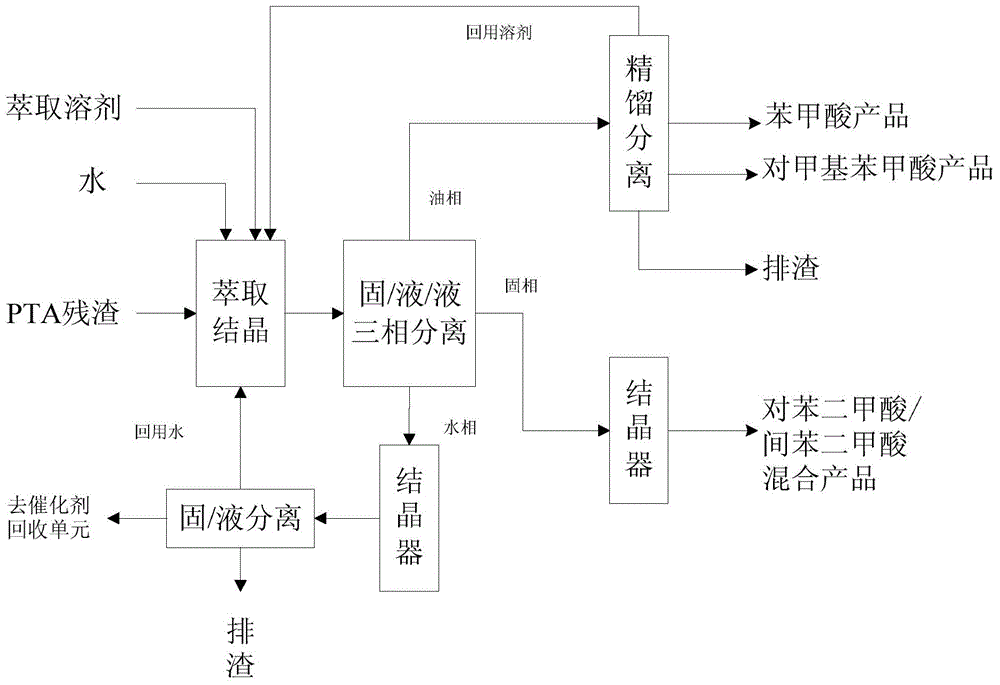

ActiveCN104418720ARealize resource utilizationMeet the requirements of circular economyCarboxylic compound separation/purificationBenzoic acidOil phase

The invention discloses a method for recycling a PTA oxidation residue. The method sequentially comprises the following steps: 1) mixing the PTA oxidation residue, water and an oil-phase extracting agent, pulping for 0.1-5 hours, and then extracting for 0.1-5 hours at 20-200 DEG C, so as to obtain a material of which a soil phase, an oil phase and a water phase are separated from one another; 2) respectively separating the solid phase, the oil phase and the water phase of the material obtained in the step 1); 3) rectifying the oil phase obtained in the step 2), respectively obtaining benzoic acid and p-toluylic acid, and recycling the rectified oil phase; 4) re-crystallizing the solid phase which is obtained in the step 2) to obtain a mixture of isophthalic acid and terephthalic acid; and 5) removing cobalt and manganese metal ions catalysts from the water phase which is obtained in the step 2), carrying out flash separation on aromatic acid, recycling the processed water phase. Through the method, a PTA oxidation residue system can be recycled; and the components of benzoic acid, isophthalic acid, terephthalic acid and p-toluylic acid can be recycled.

Owner:CHINA PETROLEUM & CHEM CORP +1

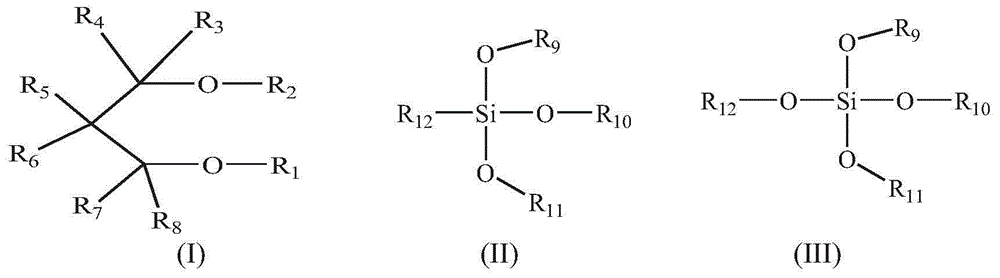

Recovery method of silicone rubber

InactiveCN103626796AEvenly heatedIncrease heat transfer rateSilicon organic compoundsRecovery methodCircular economy

The invention relates to a recovery method of silicone rubber by alkali solvent cracking. In a high temperature resistant inert solvent medium, an alkaline compound is employed to carry on cracking on silicone rubber. The cracking products are subjected to separation and purification to obtain organic siloxane ring monomers and silica. The method does not generate new wastes, and is consistent with the requirements of circular economy.

Owner:杨晓林

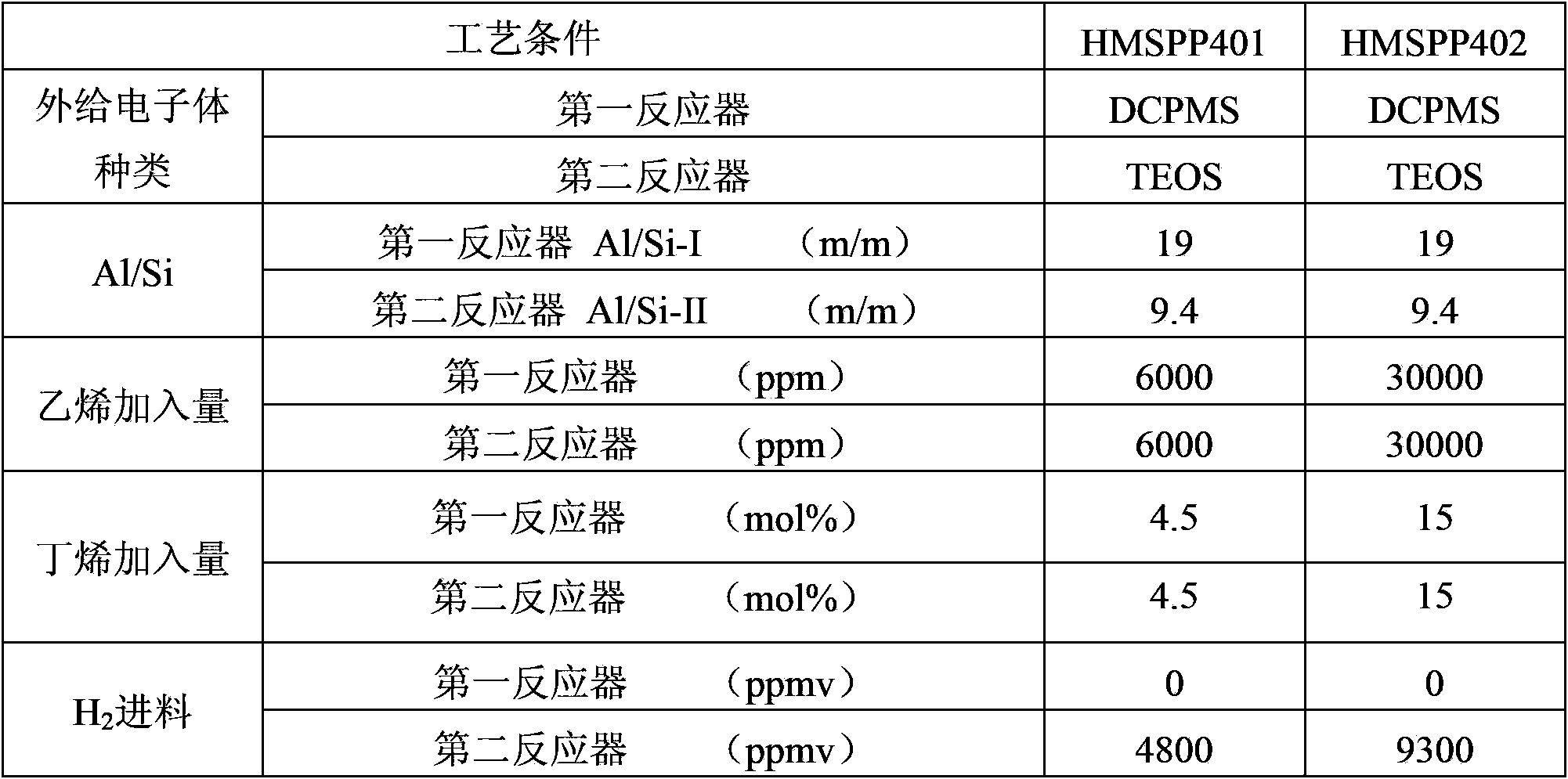

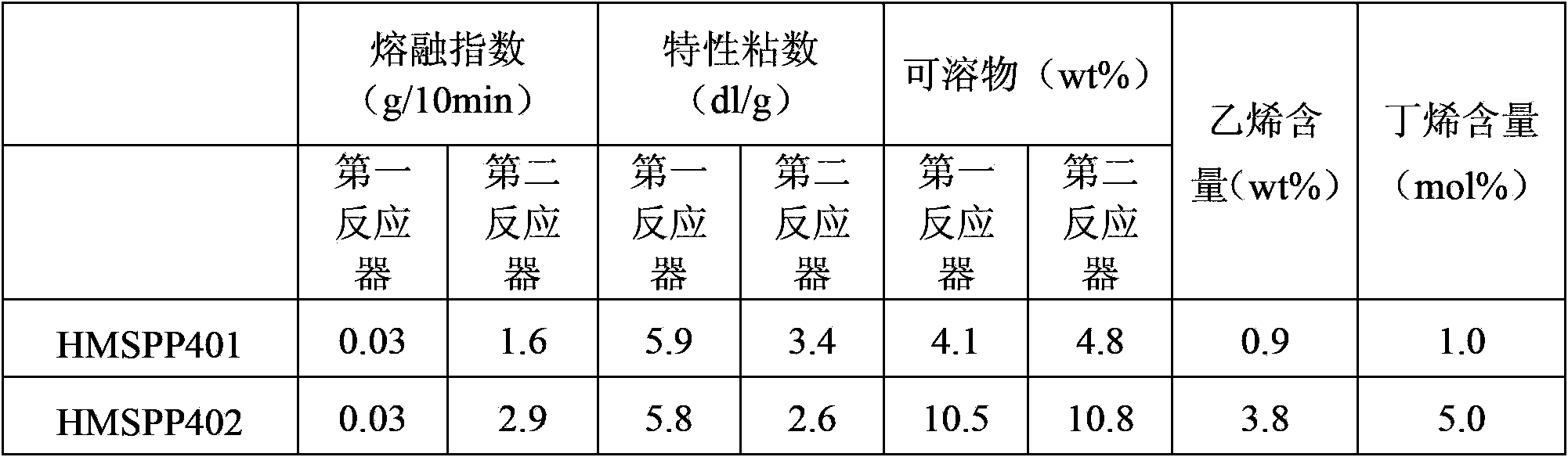

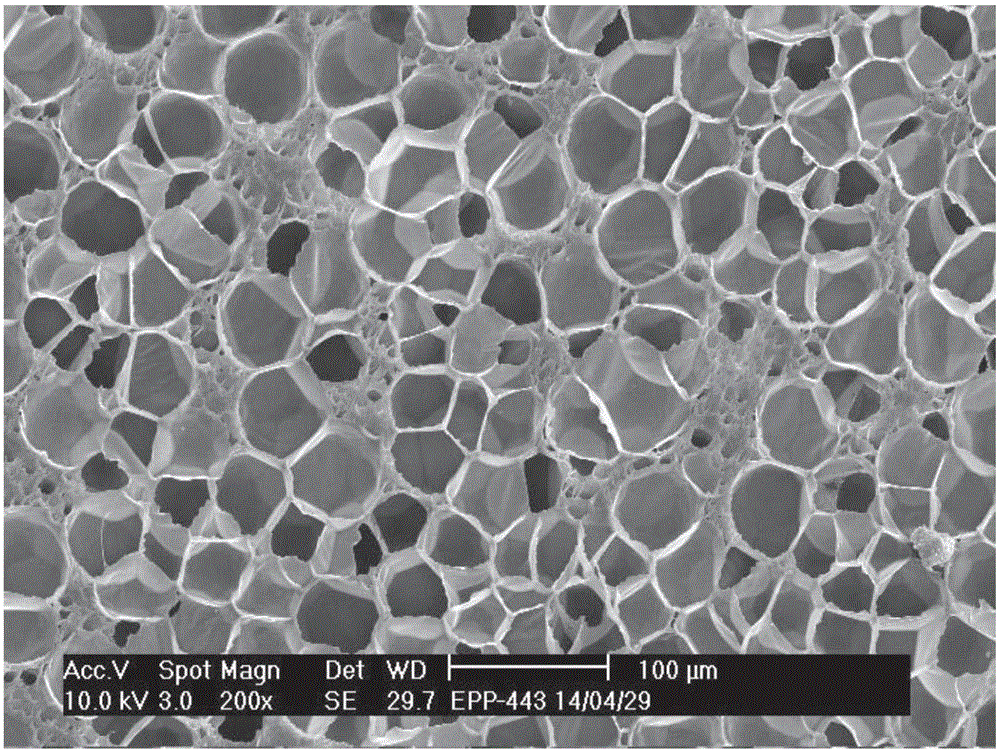

Propylene-ethylene-butylene high-melt-strength polypropylene foamed bead and preparation method thereof

The invention provides a polypropylene foamed bead. The foamed bead is prepared by foaming a base resin high-melt-strength polypropylene with a foaming agent, wherein the high-melt-strength polypropylene has the following characteristics: the melt index MFR is 0.2-10 g / 10 minutes, the molecular weight distribution Mw / Mn is 6-20, the content of substances with the molecular weight of greater than 5 million is greater than or equal to 0.8 wt%, the M[z+1] / Mn is greater than or equal to 70, the ethylene content is 0.1-15 wt%, and the butylene content is 0.1-15 wt%. The high-melt-strength polypropylene with wide molecular weight distribution is utilized as the raw material to implement stabilization of the polypropylene raw material, so that the foaming window is effectively enlarged, the technique is easy to adjust, and the cost is low; the method can be used for preparing the polypropylene foamed bead with the density of 0.02-0.3 g / cm<3>, which has the advantages of uniform pore diameter, compact pores, uniform pore size distribution and close-pore structure; and the polypropylene foamed bead can be widely used in the fields of thermal insulation tableware, automobile interior ornaments, architectural moldboards, camping supplies, decorating material interlayers, product damping packages and the like.

Owner:CHINA PETROLEUM & CHEM CORP +1

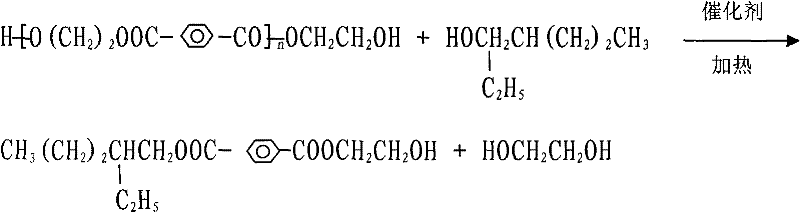

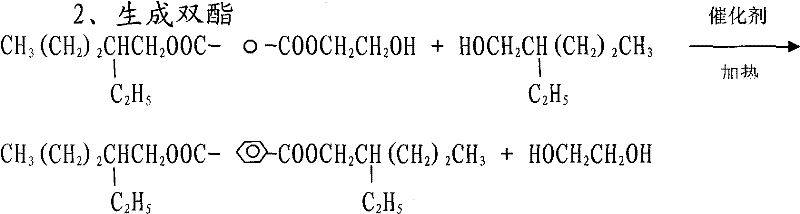

Method for producing dioctyl terephthalate from polyester waste

InactiveCN102241592AAvoid disadvantagesWide variety of sourcesPreparation by ester-hydroxy reactionHydroxy compound separation/purificationPolyesterIndustrial waste water

The invention provides a method for producing dioctyl terephthalate from PET (Polyester) waste, belonging to the technical field of plasticizers. The method is implemented by the following steps of: coarsely crushing PET waste, cleaning and drying to obtain a clean PET material; adding the clean PET material and industrial octanol into a reaction kettle in a certain ratio and undergoing an ester exchange reaction under the action of a catalyst; returning the industrial octanol into the reaction kettle by dealcoholization for recycling to obtain crude dioctyl terephthalate; and adding a decoloring agent and a filter aid, fully stirring and filtering with a filter press to obtain finished dioctyl terephthalate. In the method, PET waste is taken as a raw material, the raw material is readily available, a new measure is provided for the recycling of the PET waste, and the requirement for recycling economy is met; and alkali neutralizing and water washing procedures are eliminated in the process flow, the defect of the production of a large amount of industrial waste water in the reaction process existing in the prior art is overcome, the production process is simple and the cost is low.

Owner:WUDI YONGXIN BIO ENG

Sintered brick and preparation method thereof

ActiveCN104150861ASatisfy the production operationMeet handlingSolid waste managementBrickMaterials science

The invention discloses a sintered brick prepared by taking tailings as main raw materials and a preparation method of the sintered brick. According to the method, coal slime and coal gangue are doped into fine grained tailings according to a certain ratio to serve as raw materials, so that the content of SiO2 in the mixture is between 50 and 70 percent, the content of Al2O3 is between 6 and 20 percent, the content of CaO is lower than 6 percent, the content of MgO is lower than 6 percent, and the heating value is controlled to be 1.465-1.780MJ / Kg, and therefore, the mixture is reasonable in grading, and the requirements on plasticity and heating value needed by the sintered brick are met. The sintered brick and the preparation method thereof provided by the invention have the effects that the defects of the tailings, the coal slime and coal gangue respectively serving as raw materials of the sintered brick are overcome due to the mixture, the mineral composition and physical characteristics of the raw materials are optimized, comprehensive utilization of the fine grained tailings is realized, and the cost of the sintered brick is reduced.

Owner:NANJING IRON & STEEL CO LTD

Method for producing diammonium phosphate by using extract spent acid resulted from phosphoric acid purification

The invention relates to a method for producing diammonium phosphate by using extract spent acid resulted from phosphoric acid purification. The method comprises the following steps: adding a modified frequency modulator on an extract spent acid conveying pump and ensuring the conveying amount of the extract spent acid to be constant; mixing the extract spent acid with common raw material phosphoric acid, and causing the content of sesquioxide in the complex acid to be lower than 3 percent; adding surfactant in the complex acid to increase the fluidity and the surface activity of a reaction slurry and reduce the viscosity of the reaction slurry; and according to a conventional method, using ammonia to neutralize the complex acid so as to obtain the diammonium phosphate. The method is a precedent in realizing the recovery of high-content impurity acid and the production of fine-quality diammonium phosphate products meeting national standards, when compared with a conventional process. The procedures in the method are unhindered, thereby being favorable for reasonably utilizing the phosphorus resource and conforming to the requirement of recycling economy. The method is suitable for enterprises producing the diammonium phosphate of purified phosphoric acid by using extracting agent.

Owner:WENGFU (GRP) CO LTD

Polypropylene foam material and preparation method thereof

The invention provides a polypropylene foam material and a preparation method thereof. The polypropylene foam material comprises matrix resin which is composed of, by weight, 30 to 70 parts of polypropylene with high melt strength, 10 to 50 parts of a polypropylene random copolymer and 5 to 30 parts of low-density polyethylene; and the polypropylene foam material further comprises, on the basis of 100 parts by weight of the matrix resin, 0.1 to 0.5 part by weight of a gas nucleating agent, 5 to 16 parts by weight of a physical foaming agent, 0.5 to 1 part by weight of an antioxidant and 1 to 10 parts by weight of a cell stabilizer. The polypropylene foam material provided by the invention has the advantages of good cell homogeneity, large cell density and no secondary environmental pollution.

Owner:TIANJIN DALIN NEW MATERIAL TECH

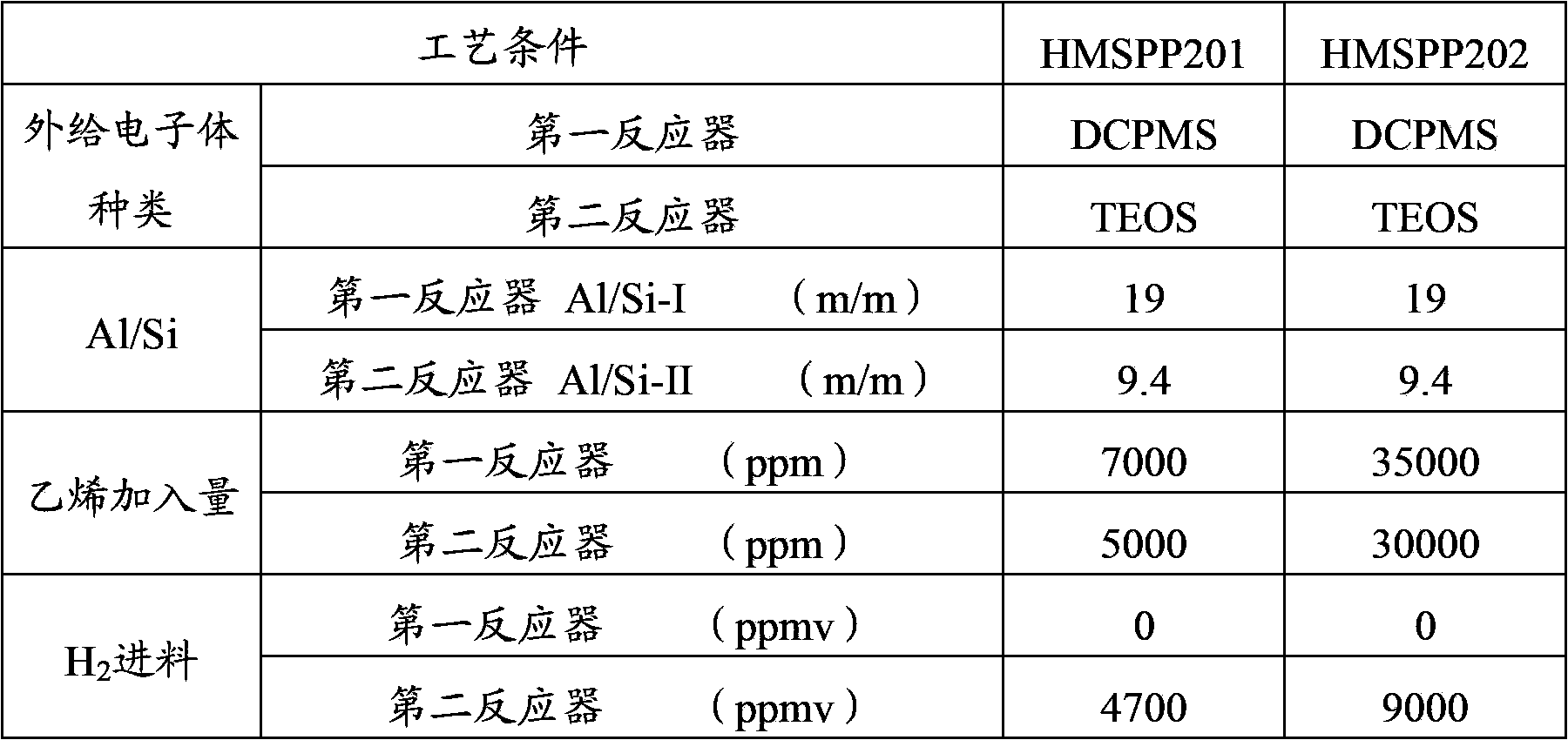

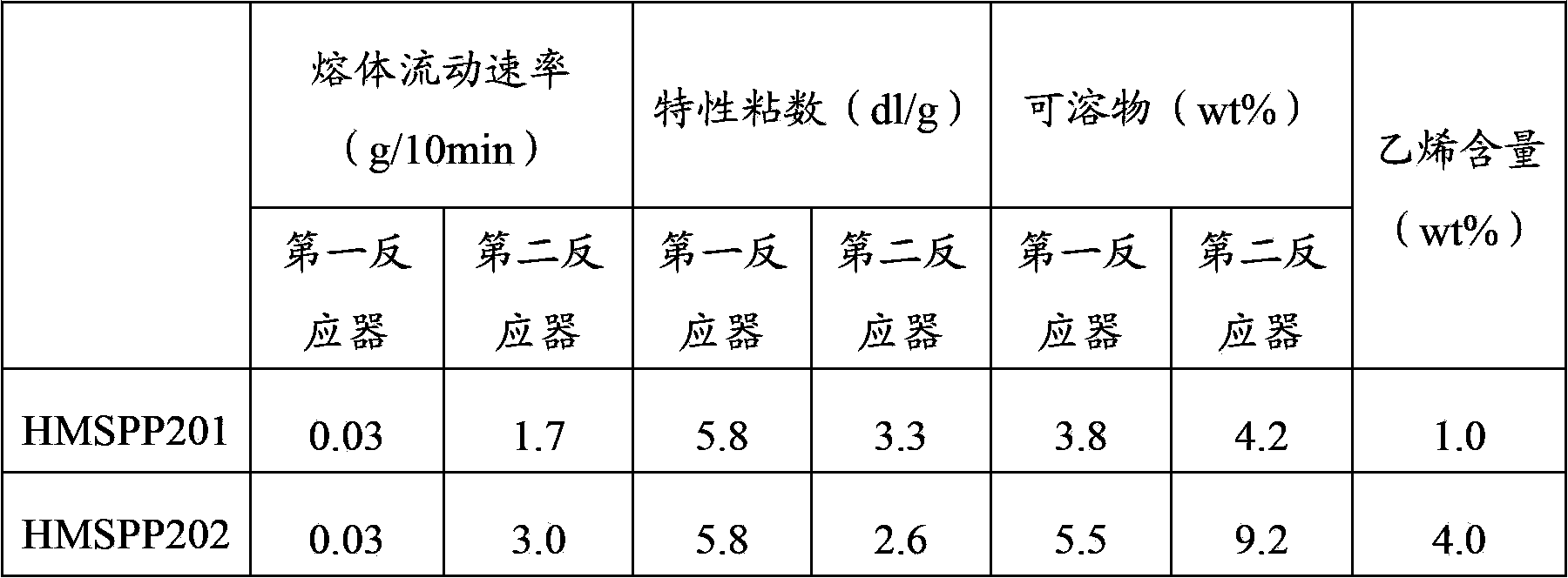

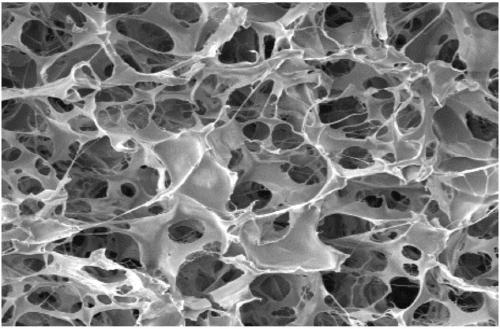

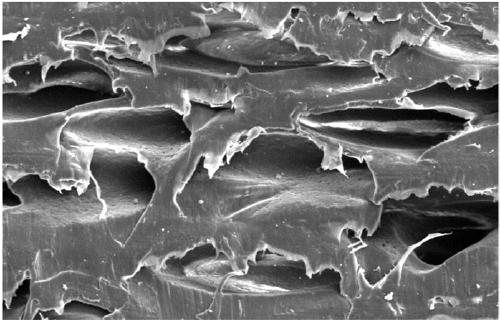

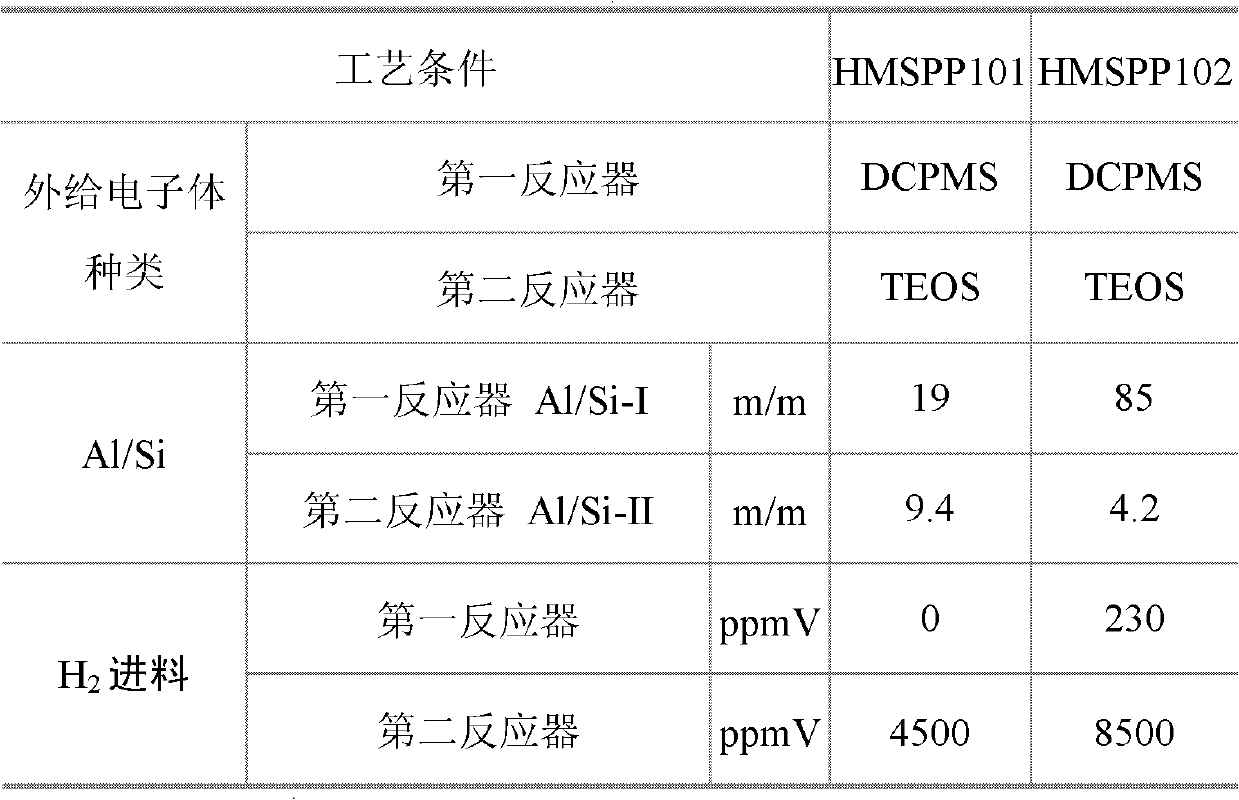

Preparation method of polypropylene foaming plate or sheet

The present invention provides a preparation method of a polypropylene foaming plate or sheet. According to the preparation method, high melt strength homopolymerization polypropylene is adopted as a matrix resin and a foaming agent is adopted to foam to prepare the polypropylene foaming plate or sheet, wherein the homopolymerization polypropylene preparation method comprises: in two or more than two reactors having the series connection operation, carrying out a two-stage or multi-stage propylene homopolymerization reaction, wherein the external electron donors used in the two-stage reaction are respectively a silane compound and a diether compound. According to the present invention, the high melt strength polypropylene having the wide molecular weight distribution is adopted as the raw material to achieve the stabilization of the polypropylene raw material, such that the foaming window is effectively expanded, the process is easy to adjust, the polypropylene foaming plate or sheet having the smooth self-skinning, the uniform foam hole diameter, the closed hole rigid structure, the density of 0.2-0.9 g / cm<3> and the thickness of 0.1-400 mm can be prepared, and the polypropylene foaming plate or sheet can be widely used in the fields of heat-insulation tableware, automotive interiors, building templates, camping supplies, decoration material sandwiches, product vibration reduction packaging and the like.

Owner:CHINA PETROLEUM & CHEM CORP +1

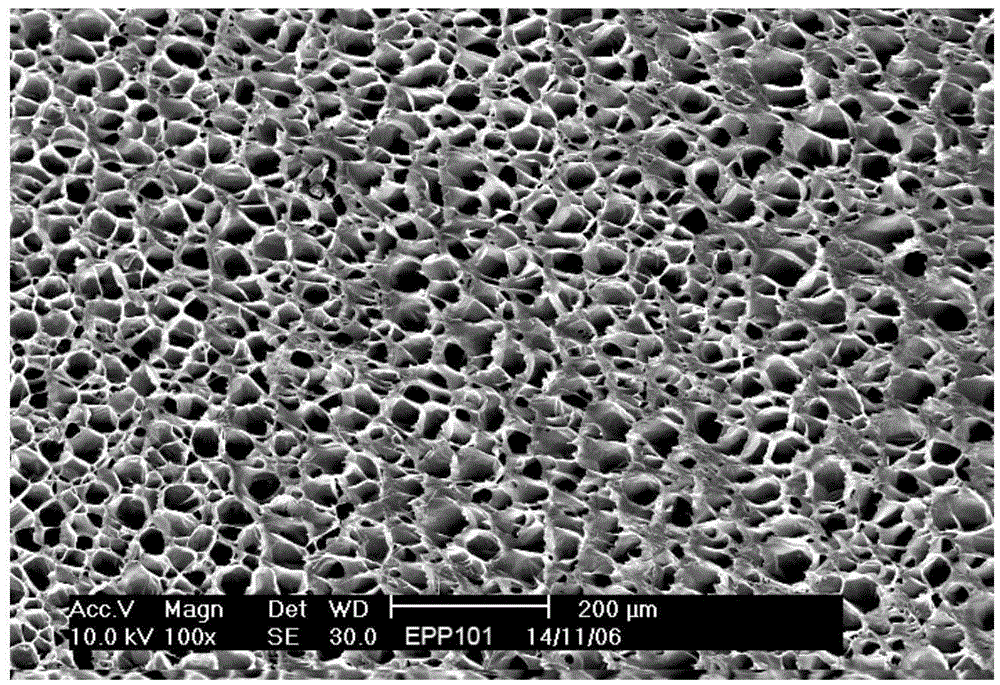

Flame-retardant thermoplastic polyurethane composition and foaming beads thereof

ActiveCN109705563AAdd lessHigh flame retardant efficiencyElectroconductive/antistatic filament manufactureAntistatic agentAntioxidant

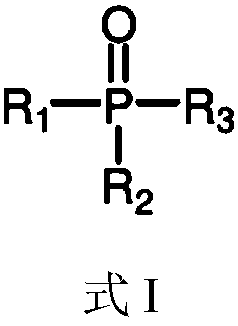

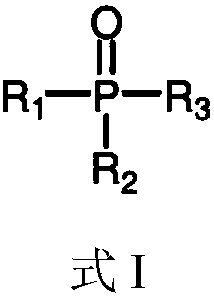

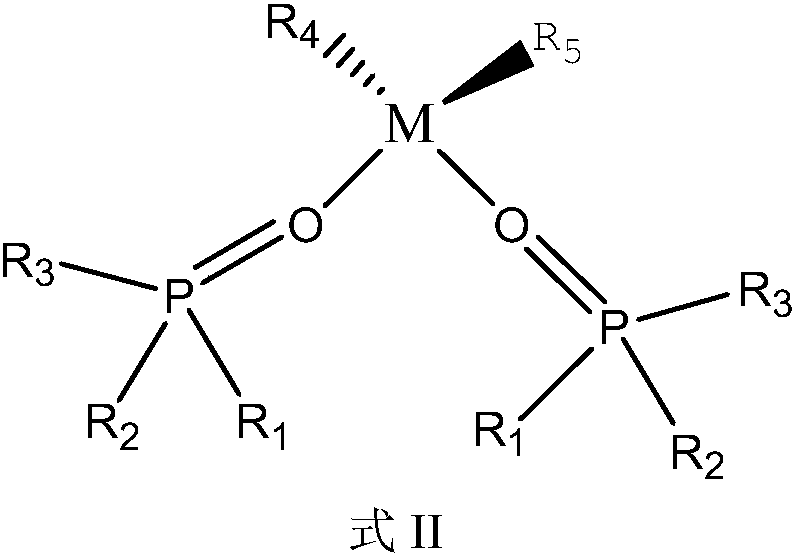

The invention provides a flame-retardant thermoplastic polyurethane composition which comprises thermoplastic polyurethane base resin, a flame retardant and an optional antioxidant, wherein the flameretardant comprises a complex formed by phosphine oxide and a transition metal salt. Foaming beads prepared from the thermoplastic polyurethane base resin are dense and uniform in foam pores, and thecompression strength of a prepared foamed bead molded body is very high; meanwhile, when the thermoplastic polyurethane composition provided by the invention is used in cooperation with a specific flame retardant and a specific antistatic agent, the flame retardant and the antistatic agent can generate a synergistic effect, and meanwhile, the flame retardancy and the antistatic property are improved. The foaming beads prepared from the flame-retardant thermoplastic polyurethane composition disclosed by the invention have good low-temperature impact resistance, static resistance, flame resistance, simple and convenient process, high closed pore rate and controllable density.

Owner:CHINA PETROLEUM & CHEM CORP +1

Flame-retardant polyester composition and foaming beads and plate thereof

ActiveCN109705542AAdd lessHigh flame retardant efficiencyFibre chemical featuresPolyesterAntistatic agent

The invention provides a flame-retardant polyester composition which comprises polyester base resin, a flame retardant and an optional antioxidant, wherein the flame retardant comprises a complex formed by phosphine oxide and a transition metal salt. Foaming beads prepared from the polyester base resin are dense and uniform in foam pores, and the compression strength of a prepared foamed bead molded body is very high; meanwhile, when the polyester composition provided by the invention is used in cooperation with a specific flame retardant and a specific antistatic agent, the flame retardant and the antistatic agent can generate a synergistic effect, and meanwhile, the flame retardancy and the antistatic property are improved. The foaming beads and a plate prepared from the flame-retardantpolyester composition disclosed by the invention have good high-temperature impact resistance, static resistance, flame resistance, simple and convenient process, high closed pore rate and controllable density.

Owner:CHINA PETROLEUM & CHEM CORP +1

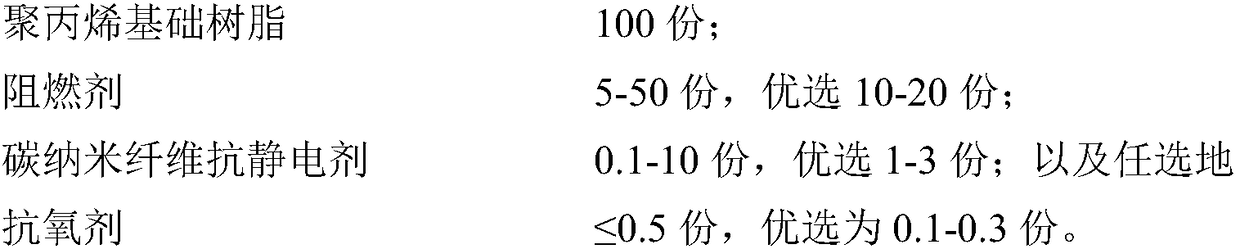

Halogen-free flame-retardant polypropylene foam material and preparation method thereof

The invention discloses a halogen-free flame-retardant polypropylene foam material and a preparation method thereof. The foam material comprises the following blended components in parts by weight: 100 parts of high-melt-strength polypropylene, 10-15 parts of phosphorus-series houghite and 3-15 parts of a foaming agent. The method for preparing the halogen-free flame-retardant polypropylene foam material comprises the following step of: melting according to the using amounts, blending and foaming. The foam material disclosed by the invention has the advantages of consistence with the environmental protection requirement, recyclability, non-crosslinking, uniform foam holes, high physical heat resistance, low production cost, smooth surfaces and suitability for continuous mass production.

Owner:CHINA PETROLEUM & CHEM CORP +1

Flame-retardant polylactic acid composition and foamed beads thereof

The invention provides a flame-retardant polylactic acid composition which comprises polylactic acid base resin, a flame retardant, a cell nucleating agent and an optionally selected antioxidant, wherein the flame retardant comprises a complex formed by phosphine oxide and a transition metal salt. The foamed beads prepared from the polylactic acid base resin provided by the invention are dense anduniform in cell, and a prepared foamed bead molded body has a very high compressive strength; meanwhile, when the flame-retardant polylactic acid composition provided by the invention is used in combination with a specific flame retardant and a specific antistatic agent, a synergistic effect is achieved between the flame retardant and the antistatic agent, and at the same time, the flame retardancy and the antistatic properties are improved. The foamed beads prepared from the flame-retardant polylactic acid composition provided by the invention have the characteristics of excellent high-temperature impact resistance, antistatic properties, flame retardancy, simple process, high closed cell ratio and controllable density.

Owner:CHINA PETROLEUM & CHEM CORP +1

Flame-retardant and antistatic polypropylene fiber composition and fibers and non-woven fabrics prepared therefrom

ActiveCN108930072ANo secondary pollutionMeet the requirements of circular economyElectroconductive/antistatic filament manufactureFlame-proof filament manufactureElastomerPolyolefin

The invention provides a flame-retardant and antistatic polypropylene fiber composition. The composition includes, by weight, 75-95 parts of a flame-retardant and antistatic polypropylene composition,5-25 parts of a polyolefin and / or elastomer, and 0.01-0.25 part of a slipping agent. The flame-retardant and antistatic polypropylene composition includes a flame retardant, and the flame retardant includes a coordination compound formed by phosphine oxide and transition metal salts. The invention simultaneously provides flame-retardant antistatic polypropylene fibers prepared from the flame-retardant and antistatic polypropylene fiber composition provided by the invention through a spunbonding spinning method, and provides flame-retardant and antistatic polypropylene non-woven fabrics prepared from the fibers. The flame-retardant and antistatic polypropylene non-woven fabrics have the characteristics of good filtering performance, and small residual deformation, and have a good touch sense, and flame retardant and antistatic properties.

Owner:CHINA PETROLEUM & CHEM CORP +1

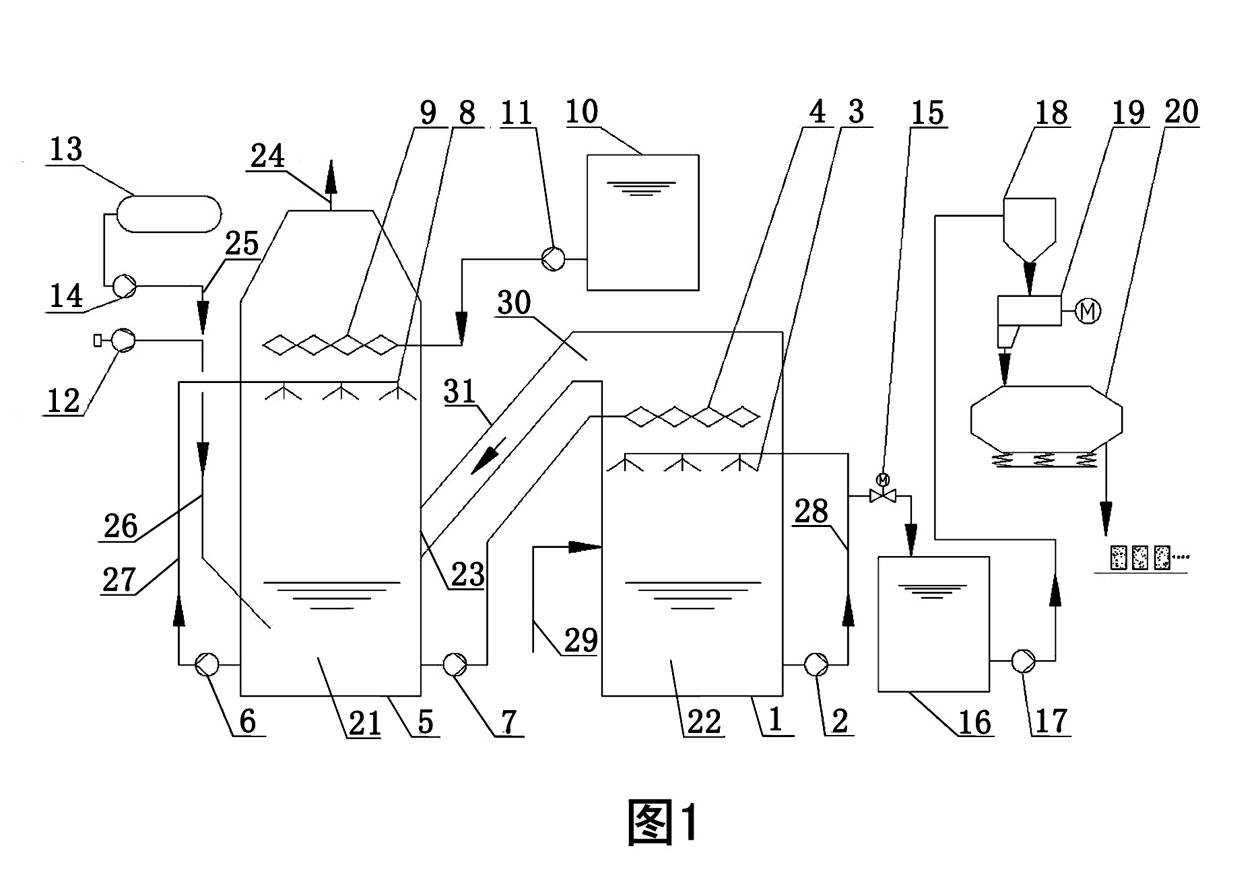

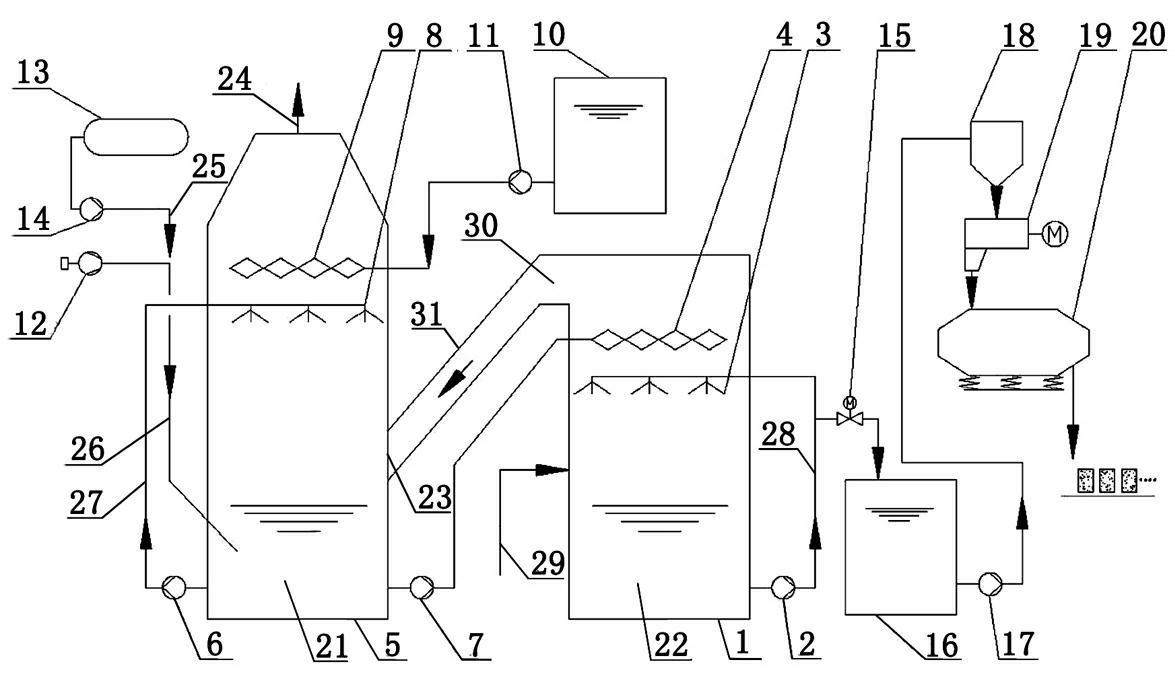

Method for wastewater treatment by using mechanical compression evaporation crystallizer system

InactiveCN102992555AHigh precisionMeet environmental protection requirementsMultistage water/sewage treatmentEvaporationEngineering

The invention provides a method for wastewater treatment by using a mechanical compression evaporation crystallizer system and belongs to the technical field of industrial wastewater treatment. A storage tank of the mechanical compression evaporation crystallizer system is connected with a balance tank which is connected with a tubular preheater, the tubular preheater is connected with an evaporation separation crystallization device and a condensation water tank, and the evaporation separation crystallization device is connected with a centrifugal separator which is connected with the storage tank. The treatment method includes: pretreated wastewater is pumped in the storage tank and enters a heat exchanger to perform heat exchange after buffering of the balance tank, material temperature rises by 5-8 DEG C, the wastewater enters the evaporation separation crystallization device to be evaporated and crystallized, high-speed separation is performed on crystal mush in a centrifugal machine, separated saturated solution returns to the evaporation crystallizer system again to be evaporated, and separated solid particles are packed. The method for the wastewater treatment by using the mechanical compression evaporation crystallizer system achieves effects regulated by the state of zero emission, circular economy and waste recovery, and evaporated distilled water can achieve the national first class discharging standard.

Owner:黑龙江鑫达晟机械科技有限公司

Two-tower ammonia method desulfurization device and method

ActiveCN102151475AImprove purification effectEmission reductionDispersed particle separationAmmonia compoundsEconomic benefitsCircular economy

The invention discloses a two-tower ammonia method desulfurization device and method. A smoke purifying part of the device comprises a desulfurization tower and a pre-scrubbing tower, the lower section inside the desulfurization tower is provided with a desulfurization tower slurry pool, the upper section inside the desulfurization tower is provided with a desulfurization tower spraying layer and a desulfurization tower mist eliminator, the lower section inside the pre-scrubbing tower is provided with a pre-scrubbing tower slurry pool, and the upper section inside the pre-scrubbing tower is provided with a pre-scrubbing tower spraying layer and a pre-scrubbing tower mist eliminator; an absorbing agent supply part comprises a liquid ammonia storage tank, an ammonia supply device and an oxidization fan; and an ammonium sulfate dewatering part comprises an ammonium sulfate slurry discharge valve, a neutralization tank, an ammonium sulfate slurry pump, a swirler, a centrifugal machine and a drying bed. The ammonia method desulfurization device comprises the two towers, system heat source can be effectively utilized through the pre-scrubbing tower, slurry is heated through high-temperature raw smoke so that the purpose of concentration is achieved, and smoke can be primarily purified through circulation of the slurry in the two towers, the emission of aerosol is further reduced, side products with considerable economic benefit can be produced while desulfurization efficiency is ensured, and wastes are changed into valuable, and requirements on circular economy is met.

Owner:BEIJING GUODIAN LONGYUAN ENVIRONMENTAL ENG

Antibacterial polypropylene composition, microporous antibacterial polypropylene foamed sheet, preparation method thereof and foamed sheet

The invention belongs to the field of antibacterial materials and products thereof, and discloses an antibacterial polypropylene composition, a microporous antibacterial polypropylene foamed sheet, apreparation method thereof and a foamed sheet. The antibacterial polypropylene composition contains polypropylene base resin, a guanidine salt composite antibacterial agent and an auxiliary agent, wherein the auxiliary agent contains a cell nucleating agent and an antioxidant, and based on 100 parts by weight of the polypropylene base resin, the content of the guanidine salt composite antibacterial agent is 0.05-2.0 parts by weight, the content of the cell nucleating agent is 0.01-10 parts by weight, and the content of the antioxidant is 0.01-10 parts by weight. The prepared foamed board / sheethas the characteristics of being easy to slice, excellent in mechanical property, antibacterial, simple and convenient in preparation process, large in multiplying power adjustable range, good in thermal insulation property and the like.

Owner:CHINA PETROLEUM & CHEM CORP +1

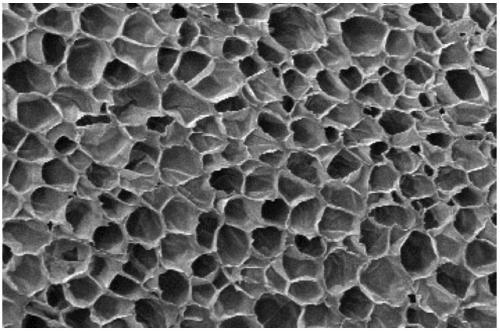

High-melt strength high-impact polypropylene foaming expanded beads and preparation method thereof

The invention provides polypropylene foaming expanded beads and a preparation method thereof. The foaming expanded beads take high-melt strength high-impact polypropylene as a basic resin, and are prepared by foamed impregnation; wherein, the high-melt strength high-impact polypropylene comprise a propylene homopolymer component and a propylene-ethene copolymer component, molecular weight distribution ratio of Mw to Mn is less than or equal to 10 and greater than or equal to 4; the ratio of Mz+1 to Mw is greater than 10 and less than 20; the content of a room temperature xylene soluble substance is greater than 10 weight% and less than 30 weight%; and the ratio of Mw of a room-temperature trichloro-benzenes soluble substance to Mw of a room-temperature trichloro-benzenes insoluble substance is greater than 0.4 and less or equal to 1 The polypropylene foaming expanded beads have the advantages of uniform size and distribution of foaming pore and aperture, high percentage of close area, good high / low temperature high-impact performance, and high melt-strength; and can be widely used for the fields of automobile part, food, electronic package and building decoration; the preparation method is simple, operation is easy, and the cost is low.

Owner:CHINA PETROLEUM & CHEM CORP +1

Composite foaming agent and polypropylene foam material prepared from same

The invention discloses a composite foaming agent and a polypropylene foam material prepared from the same. The foaming agent comprises the following components in parts by weight: 100 parts of azodicarbonamide, 10-20 parts of N,N'-dimethyl-N,N-dinitrosoterephthalamide, 10-30 parts of zinc oxide and 10-30 parts of sodium citrate. The polypropylene foam material comprises the following blended components in parts by weight: 100 parts of high-melt strength polypropylene and 3-15 parts of composite foaming agent. The composite foaming agent disclosed by the invention has controllable foaming temperature, uniform foam cell, smooth surface and high physical heat resistance; and the polypropylene foam material prepared from the composite foaming agent meets the environmental protection requirement, is degradable and low in production cost, and is suitable for continuous large-scale production.

Owner:CHINA PETROLEUM & CHEM CORP +1

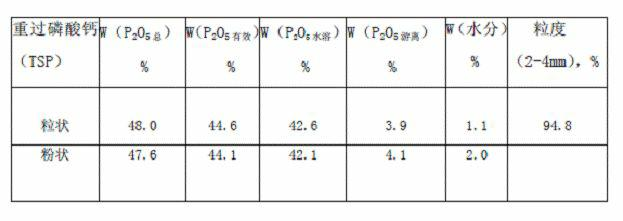

Method of producing triple superphosphate by using raffinate acid resulted from phosphoric acid purification

ActiveCN102583289AAchieve recyclingEasy to usePhosphorus compoundsO-Phosphoric AcidPhysical chemistry

The invention discloses a method of producing triple superphosphate by using raffinate acid resulted from phosphoric acid purification. Affinate phosphoric acid serves as a raw material and additives are added. The method comprises steps of introducing steam so as to maintain the raffinate phosphoric acid temperature between 45 DEG C and 650 DEG C through measurement of a flow meter, adding phosphate rock powders in accordance with proportion, reacting the phosphate rock powders with the raffinate phosphoric acid for 2 to 3 minutes in a mixing device, enabling slurry to flow into a belt formation chamber for solidifying at the formation temperature of 80 DEG C for 20-25 minutes, stockpiling and curing the mixture, adding water to powder materials for granulating, drying and sieving the powder materials, and obtaining products. According to the method, the traditional art can be used for recycling phosphoric acid containing high impurities and the product such as triple superphosphate can reach national premium grade standard. The method has a smooth art process, is beneficial to utilize phosphorus resources reasonably, achieves usage of affinate phosphoric acid containing many impurities of purified phosphoric factories, and meets requirements of cycling economy.

Owner:WENGFU (GRP) CO LTD

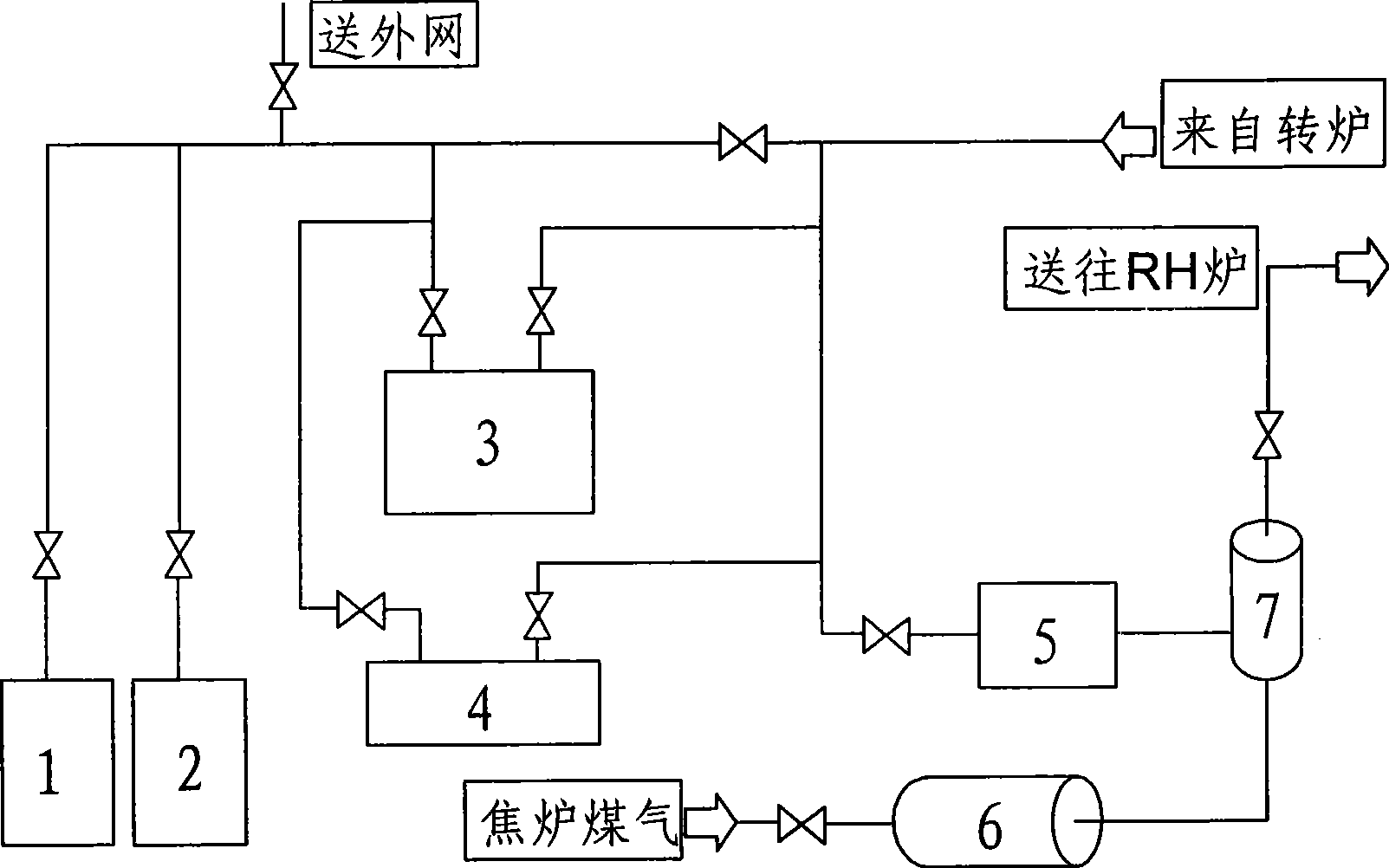

Steam supply apparatus for RH vacuum steel refining furnace

The invention relates to a steam supplying device in the field of metallurgy, in particular to a steam supplying device of an RH vacuum refining furnace, which comprises a heat accumulator connected with a steam header of an evaporation cooling system of a converter, and a fuel gas type steam overheating device connected with the RH vacuum refining furnace; the steam inlet end of the heat accumulator is connected with the steam header of the evaporation cooling system of the converter; the steam outlet end of the heat accumulator is connected with the steam inlet end of the fuel gas type steam overheating device; and the steam outlet end of the fuel gas type steam overheating device is connected with the RH vacuum refining furnace. The steam supplying device fully utilizes steam produced by the converter; and secondary energy source is used in the steam supplying device of the RH furnace, thereby saving investment, reducing energy consumption, saving operating cost and meeting the requirement of circular economy.

Owner:NANJING IRON & STEEL CO LTD

High-melt-strength anti-impact polypropylene foamed board and preparation and application thereof

The invention relates to a high-melt-strength anti-impact polypropylene foamed board. The foamed board is prepared through foaming with high-melt-strength anti-impact polypropylene as matrix resin. The high-melt-strength anti-impact polypropylene comprises a random copolymerization polypropylene continuous phase and a rubber dispersed phase of propylene-ethylene copolymer, wherein the content of room temperature dimethylbenzene soluble substances of the high-melt-strength anti-impact polypropylene is larger than 10 wt% and smaller than 35 wt%, and the ratio of Mw of room temperature trichlorobenzene soluble components to Mw of room temperature trichlorobenzene insoluble components is larger than 0.4 and smaller than 1. The invention further relates to a preparation method of the foamed material. The foamed material has higher melt strength, so foamed products with higher foaming ratio and better surface smoothness can be obtained, and the foamed material also has the characteristics of being high in rigidity, high in toughness and the like. Meanwhile, the foamed board has the advantages of being good in high-and-low-temperature anti-impact performance, high in physical heat resistance, high in percentage of close area, good in heat insulation and sound isolation performance, controllable in foaming ratio and foam pore structure and the like.

Owner:CHINA PETROLEUM & CHEM CORP +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com