Comprehensive utilization method for wastewater of ammonium phosphate production

A technology for producing wastewater and ammonium phosphate, applied in chemical instruments and methods, phosphates, phosphorus oxyacids, etc., can solve the problems of recycling ammonia nitrogen wastewater, failing to achieve recycling, etc., to achieve environmental protection and reduce process The effect of water intake

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

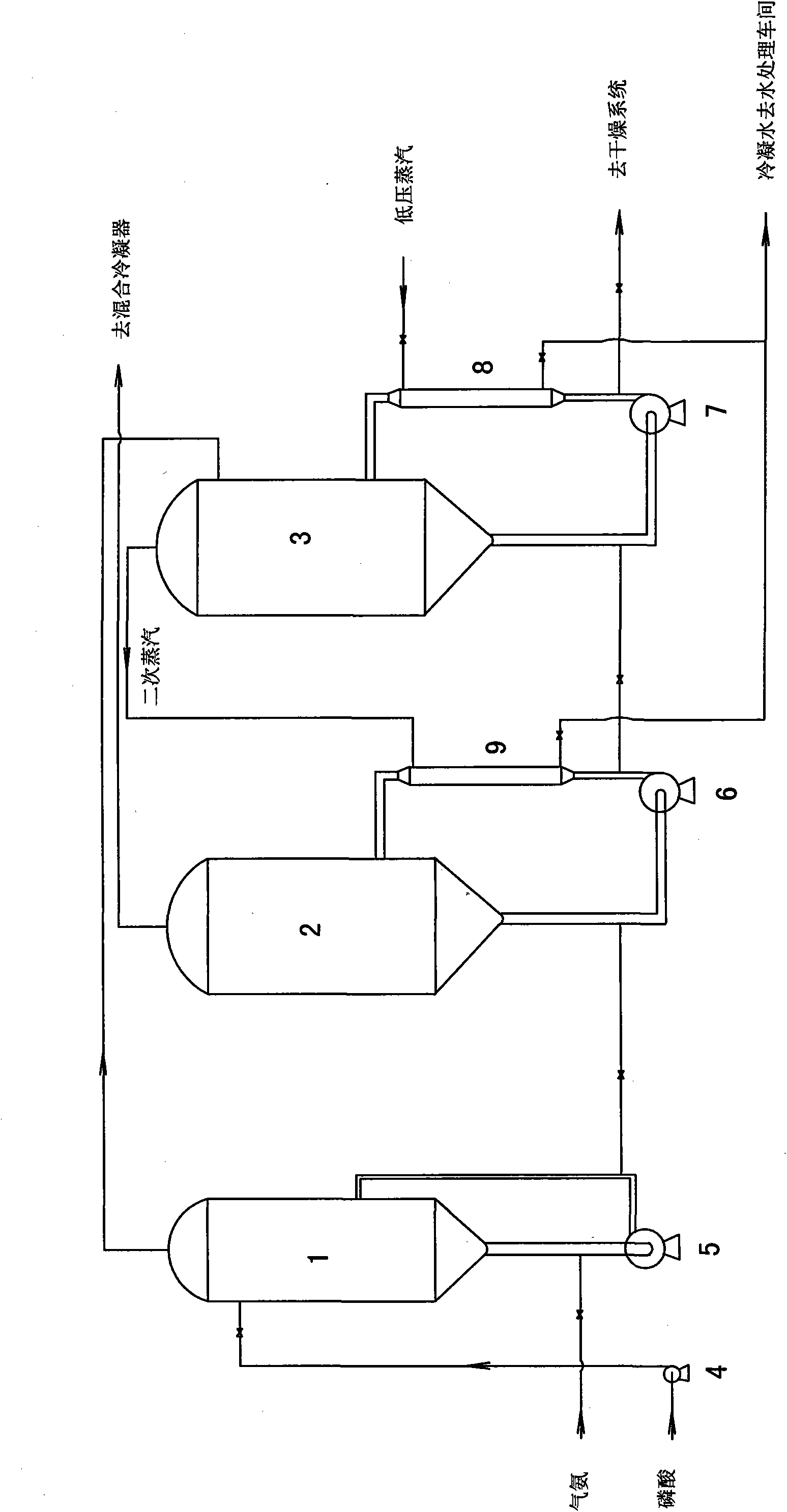

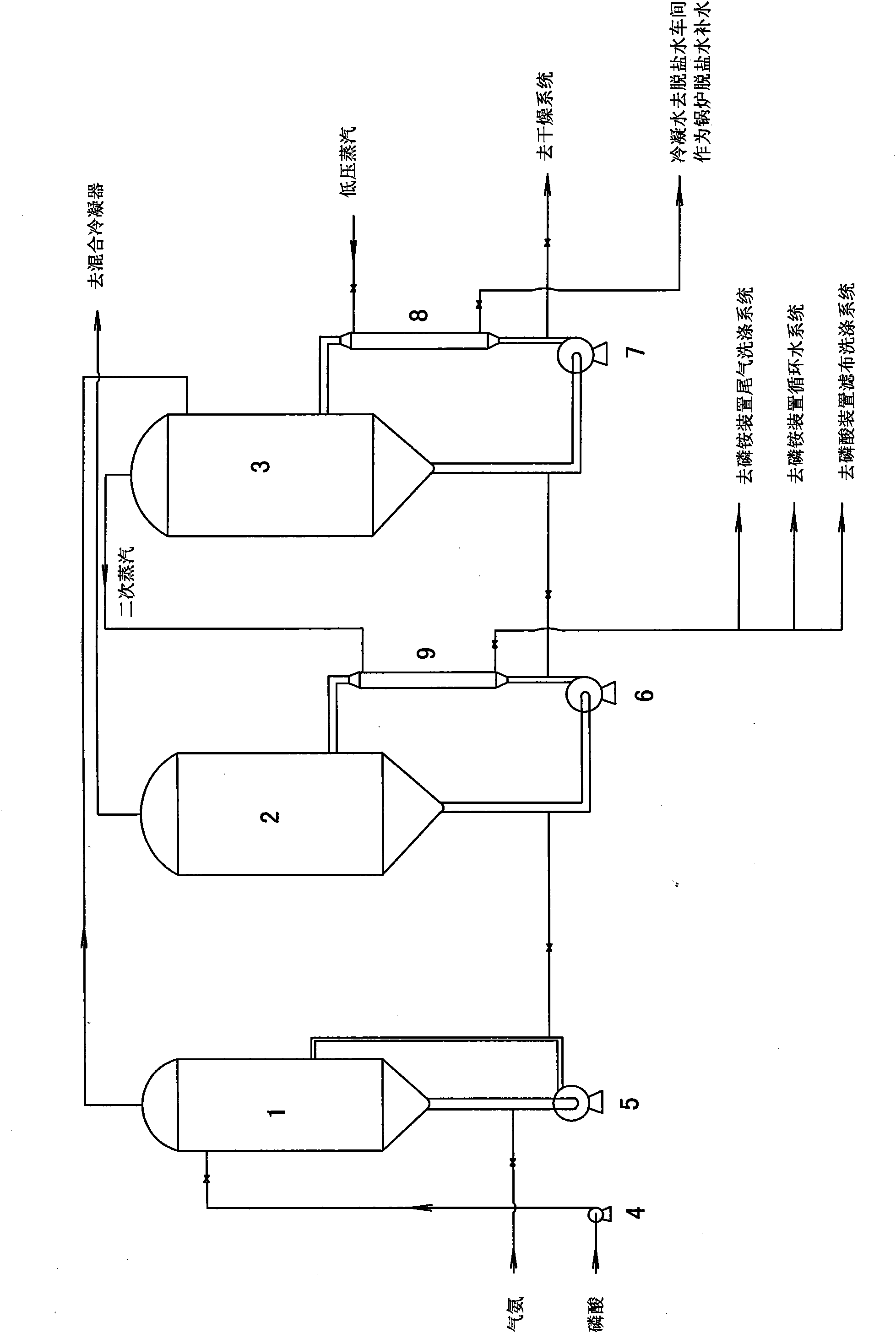

Image

Examples

Embodiment

[0012] The Phosphate Fertilizer Plant of Wengfu Group Company implements the comprehensive recycling of ammonium phosphate production wastewater, and realizes the large-scale recycling of ammonium phosphate wastewater through the ammonium phosphate plant and phosphoric acid plant.

[0013] The monoammonium phosphate and diammonium phosphate plants are separated by waste water, and the process water intake point is cut off except for some domestic water in the plant area.

[0014] The condensed water produced by I effect evaporation is sent to the desalinated water workshop as make-up water for the boiler desalinated water; the ammonia nitrogen wastewater produced by the II effect evaporation is used for tail gas washing make-up water in the ammonium phosphate production process, transmission equipment sealing water, and partly used for phosphoric acid production filter cloth Rinse water. Through the water circulation between different product devices, the ammonium phosphate plant p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com