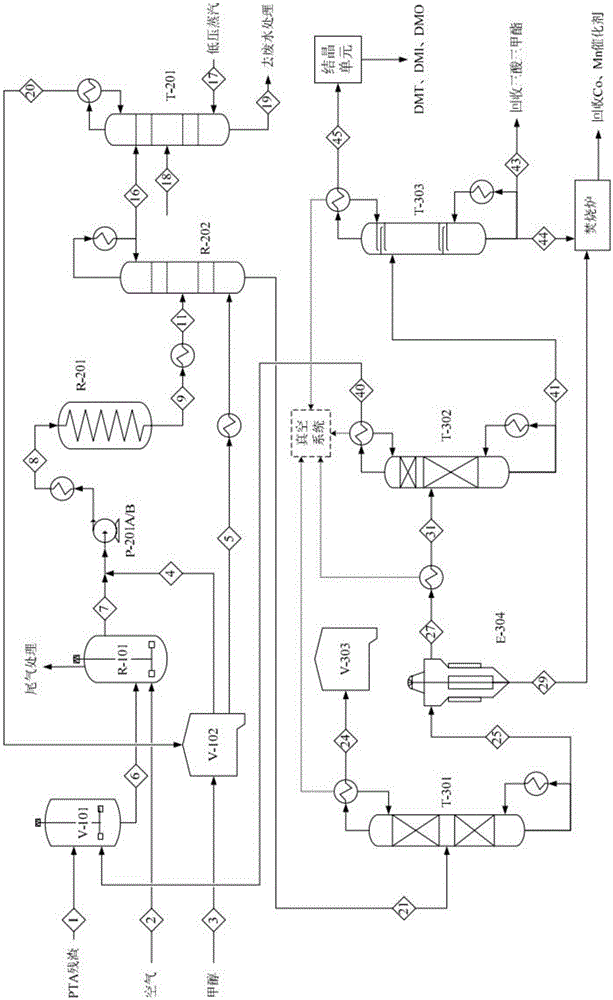

Method for methyl esterification recovery and recycle of PTA oxidation residue

A methyl esterification and residue technology, which is applied in the field of methyl esterification recycling PTA oxidation residue, can solve the problem of not considering the impact

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

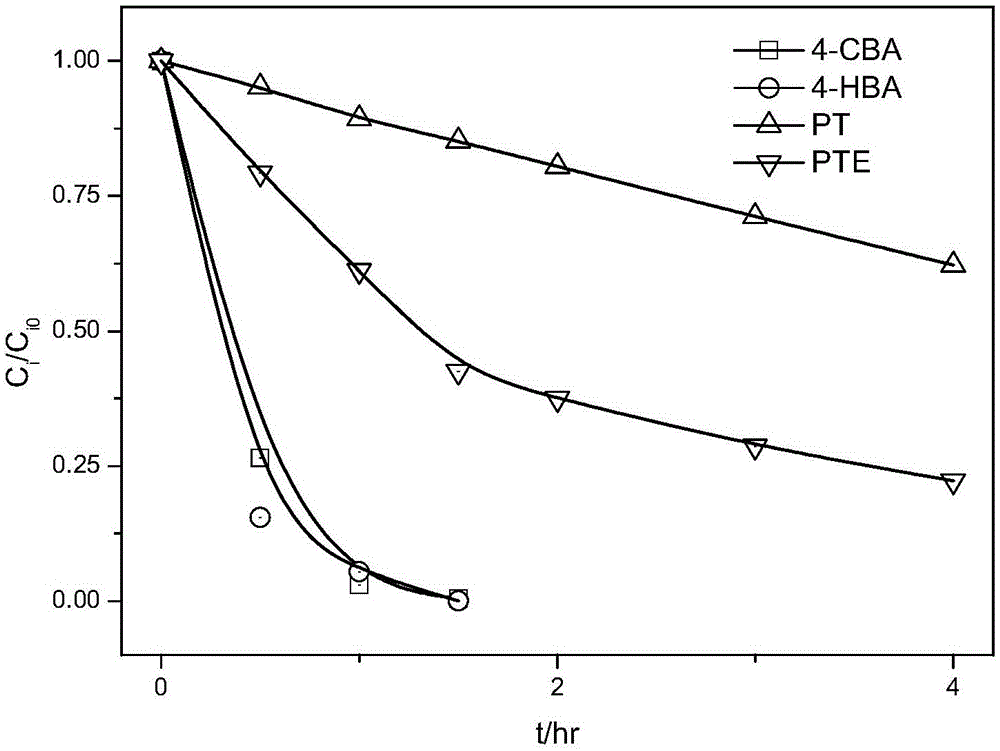

Embodiment 1

[0067] A 1.0L high-pressure reactor was used for air oxidation treatment of PTA oxidation residue. The high-pressure reactor is equipped with electric heating and internal cooling oil coil, and the temperature is controlled by PID; the gas phase outlet of the reactor is equipped with a stop valve, a condenser, and a back pressure valve. The condensate in the condenser can return to the reactor, and the back pressure valve can Control the reaction pressure; it is also equipped with an online detection system for intake flow and tail oxygen concentration. The residue A is used as a raw material, and the residue A is first dried until the water content is less than 5.0%, and the dried residue contains 1200 ppm Co and 300 ppm Mn as measured by ICP. Quantitatively take residue A after 150.0g dry treatment, 5.0g PT acid methyl ester (PTE) and 600.0g methyl benzoate solvent and add autoclave; Pass into nitrogen in stirring process, pressurization and heat up; When pressure rises to ...

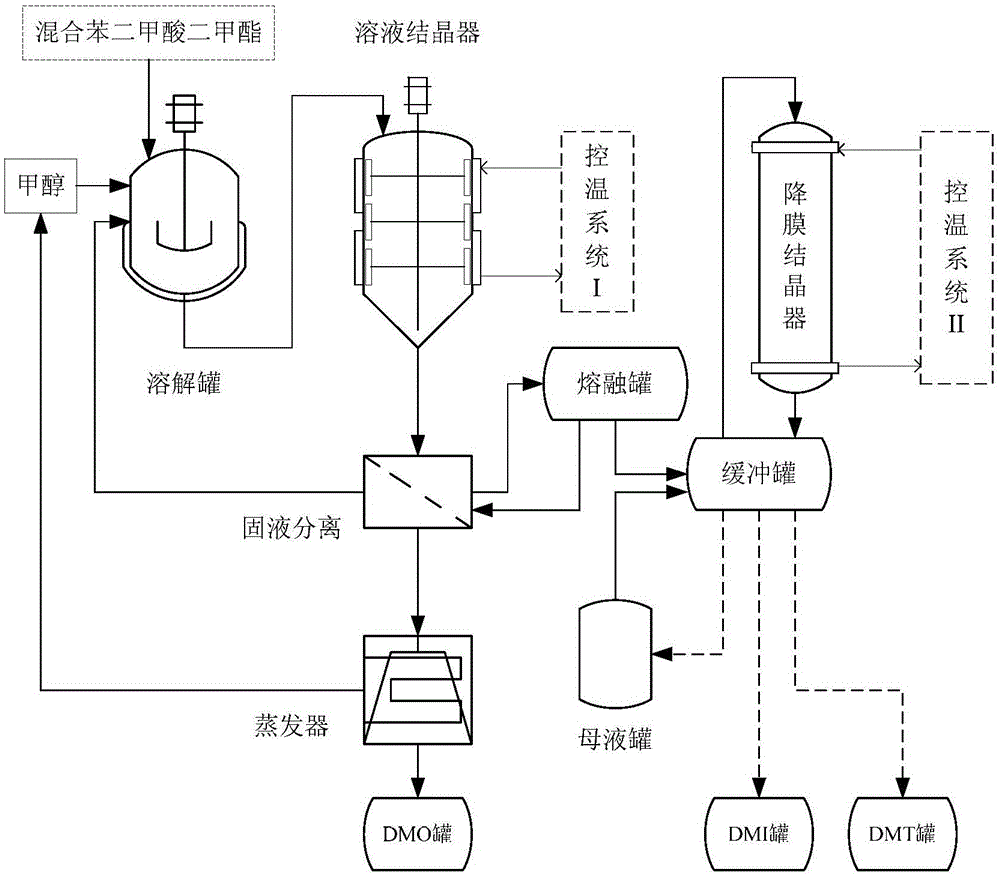

Embodiment 2

[0071] A 1.0L autoclave was used for methyl esterification of PTA oxidation residue. The autoclave used was similar to Example 1, the temperature was controlled by PID, and the gas phase outlet of the reactor was equipped with a stop valve, a condenser, a back pressure valve, etc. The difference is that the condensate in the gas phase condenser of the reactor is not directly refluxed, but recovered by a solvent tank. The residue A after the drying treatment is used as the raw material for the methyl esterification reaction, and the residue is dried and has a water content of less than 5.0%. First quantitatively weigh 250.0g of residue A and 500.0g of methanol into the autoclave; feed nitrogen during the stirring process, then close the gas phase outlet stop valve; heat up to 240°C, and the pressure in the reactor is 8.0MPa; After stirring for 3 hours, lower the temperature and lower the pressure, take a sample to measure the acid value of the reaction liquid phase, and then ca...

Embodiment 3

[0073] Carry out the methyl esterification reaction as in Example 2, the difference is that the dry residue B is used as a raw material, the reactor feed is 200.0g residue B and 600.0g methanol, the esterification temperature is 250°C, the pressure is 10.0MPa, and the esterification time for 2 hours. After the reaction was finished, by NaOH titration, the acid value of the reaction product was measured to be 105.8 mgKOH / g (calculated as residue), and the methyl esterification rate of carboxylic acid in the residue was calculated to be about 83.6%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| acid value | aaaaa | aaaaa |

| acid value | aaaaa | aaaaa |

| purity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com