Steam supply apparatus for RH vacuum steel refining furnace

A vacuum refining furnace and steam supply technology, which is applied in the field of RH vacuum refining furnace steam supply device, can solve the problems of unfavorable saving of investment, increase of energy consumption and cost, etc., and achieve the effect of saving investment, saving operating cost and reducing investment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

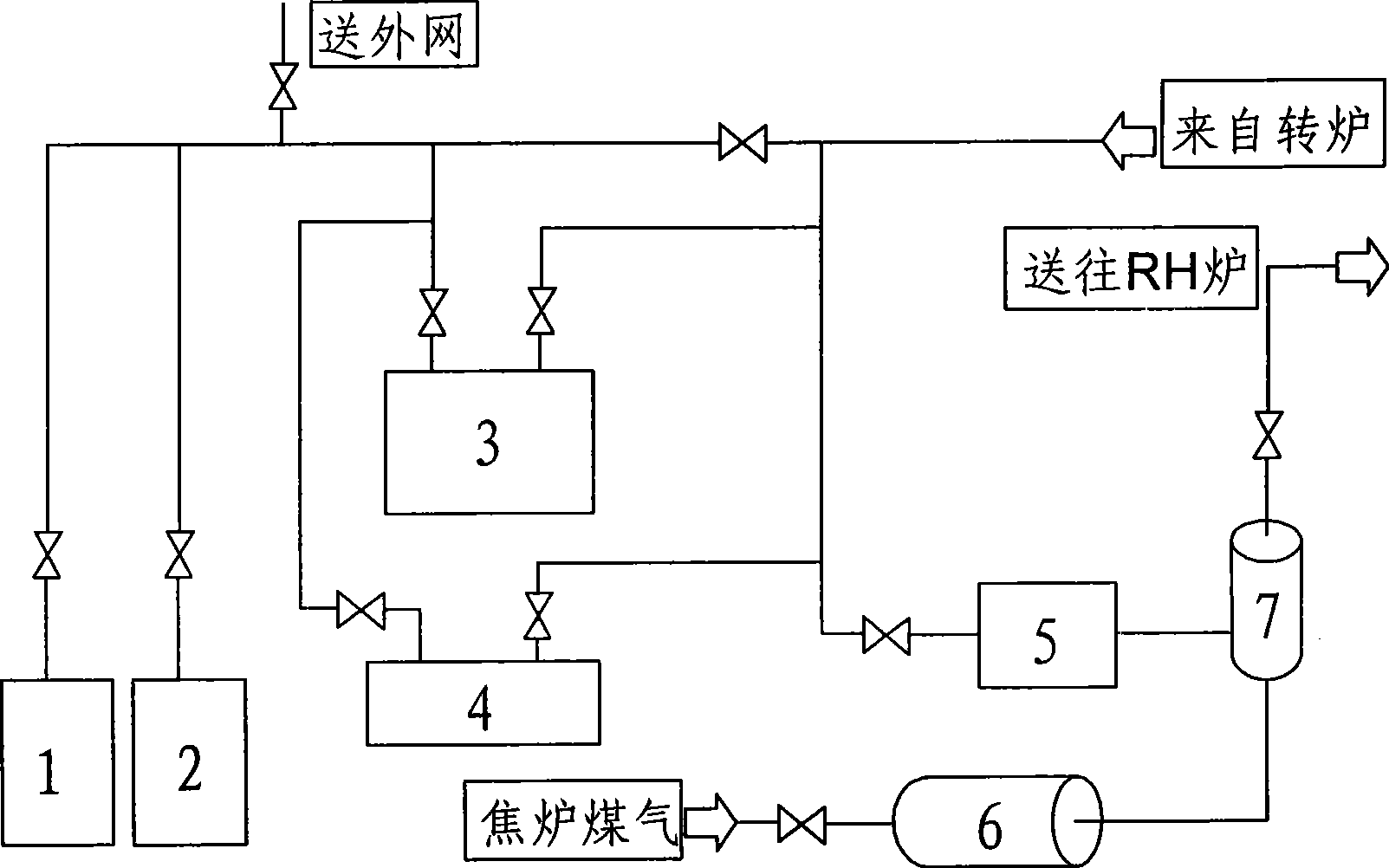

[0017] The connection relationship of this embodiment is as follows figure 1 As shown, a RH vacuum refining furnace steam supply device includes a heat accumulator connected to the steam drum of the converter vaporization cooling system and a gas-fired steam superheating device connected to the RH vacuum refining furnace, the steam inlet end of the heat accumulator and the converter The steam drum of the vaporization cooling system is connected, the steam outlet end of the regenerator is connected with the steam inlet end of the gas-fired steam superheater, and the steam outlet end of the gas-fired steam superheater is connected with the RH vacuum refining furnace. The accumulator consists of 150m 3 Regenerator 1, 150m 3 Regenerator 2, 94m 3 Regenerator 3 and 94m 3 Regenerator 4 composition. Gas-fired steam superheating device includes burner, combustion-supporting fan, pneumatic control valve, automatic ignition device, flameout protection device, adiabatic combustion cha...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com