Method for producing dioctyl terephthalate from polyester waste

A technology for dioctyl phthalate and waste, which is applied in the field of producing dioctyl terephthalate by using PET polyester waste, can solve the problems of complex production process, difficult processing and high production cost, and achieves a simple production process , Overcome the effect of industrial waste water and low production cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

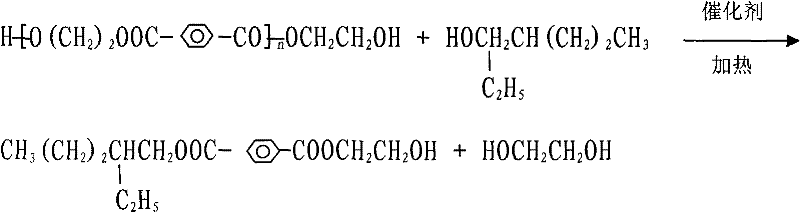

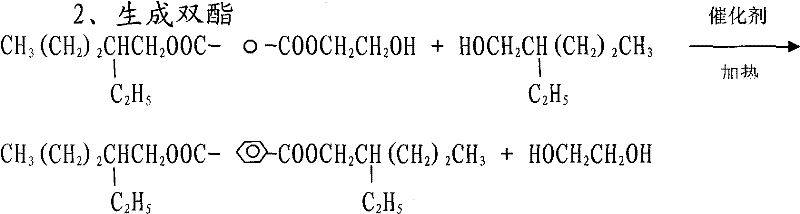

Method used

Image

Examples

Embodiment 1

[0022] The non-polyester materials in the polyester waste are picked out and crushed to obtain polyester flakes; the above polyester flakes are processed by cleaning and drying equipment to obtain clean polyester materials; the above clean polyester materials are mixed with industrial octanol Add it into the reaction kettle, the molar ratio of clean polyester material and industrial octanol is 1:3 according to the clean polyester material: industrial octanol, stir and heat up to 180°C, and when the pressure of the reactor is controlled to -0.03MPa, add The catalyst degrades the clean polyester material and undergoes a transesterification reaction with industrial octanol. The catalyst is a titanate lipid, and the amount of the catalyst is 0.1% of the clean polyester material. The reaction continues until the acid value of the sample in the kettle is equal to or less than 0.05 mgKOH / g, the degradation-transesterification reaction is completed; then the pressure in the reactor is ...

Embodiment 2

[0024] The non-polyester materials in the polyester waste are picked out and crushed to obtain polyester flakes; the polyester flakes are processed by cleaning and drying equipment to obtain clean polyester materials; the clean polyester materials and industrial octanol are added to the In the reaction kettle, the mol ratio of the clean polyester material added and industrial octanol is 1: 6 by clean polyester material: industrial octanol is 1: 6, and stirring is heated up to 240 ℃, when the control reactor pressure is-0.01MPa, add catalyst to make The clean polyester material is degraded and transesterified with industrial octanol. The catalyst is titanate, and the amount of the catalyst is 3% of the clean polyester material. The reaction time lasts until the acid value in the kettle is equal to or less than 0.05mgKOH / g, the degradation-transesterification reaction is completed; after the degradation-transesterification reaction is completed, the pressure in the reactor is co...

Embodiment 3

[0026] The non-polyester materials in the polyester waste are picked out and crushed to obtain polyester flakes; the polyester flakes are processed by cleaning and drying equipment to obtain clean polyester materials; the clean polyester materials and industrial octanol are added to the In the reaction kettle, the mol ratio of the clean polyester material added and industrial octanol is 1: 3 by clean polyester material: industrial octanol is 1: 3, and stirring is heated up to 240 ℃, when the control reactor pressure is-0.03MPa, add catalyst to make The clean polyester material is degraded and transesterified with industrial octanol. The catalyst is titanate, and the amount of the catalyst is 3% of the clean polyester material. The reaction time lasts until the acid value in the kettle is equal to or less than 0.05mgKOH / g, the degradation-transesterification reaction is completed; after the degradation-transesterification reaction is completed, the pressure in the reactor is co...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com