Method of producing triple superphosphate by using raffinate acid resulted from phosphoric acid purification

A technology of heavy superphosphate and raffinate, which is applied in chemical instruments and methods, phosphorus compounds, inorganic chemistry, etc., to achieve the effects of rational utilization and smooth process flow

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

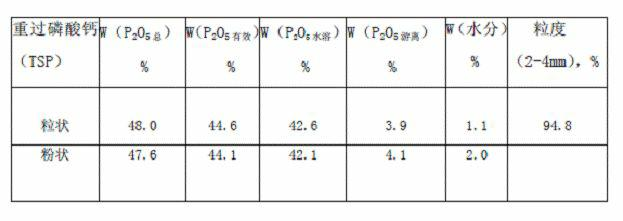

Image

Examples

Embodiment 1

[0011] Raw materials: 1) raffinate phosphoric acid: the chemical composition is as follows (by mass percentage)

[0012] composition P 2 o 5 F SO 4 Fe Mg Al SiO 2 Solid content % 42.0 0.38 0.60 0.55 1.80 0.30 0.02 2.5

[0013] 2) Phosphate rock powder: the chemical composition is as follows (by mass percentage)

[0014]

[0015] Take 50kg of residual phosphoric acid, add 0.02kg of mixed additives, measure it through a flow meter, and feed steam to make the temperature of phosphoric acid reach 60 0 C, then add 25.2kg of phosphate rock powder, mix and react with raffinate phosphoric acid in a mixer for 3min, the slurry flows into the belt forming room for curing, the curing time is 25min, and the curing temperature is 80 0 c. The cutter cuts the solidified fresh heavy superphosphate, breaks it and sends it to the curing warehouse for curing. The curing temperature is 45 0 C. After aging for 12 days, add water to the powdery ma...

Embodiment 2

[0018] Raw materials: 1) raffinate phosphoric acid: the chemical composition is as follows (by weight)

[0019] composition P 2 o 5 F SO 4 Fe Mg Al SiO 2 Solid content % 44.5 0.48 0.80 0.65 2.30 0.35 0.08 3.5

[0020] 2) Phosphate rock powder: the chemical composition is as follows (by weight)

[0021]

[0022] Take 25 kg of residual phosphoric acid, add 0.01 kg of mixed additives, measure through a flow meter, and feed steam to make the temperature of phosphoric acid reach 55 0 C, then add 13.4kg of phosphate rock powder, mix and react with raffinate phosphoric acid in a mixer for 3min, the slurry flows into the belt forming room for curing, the curing time is 25min, and the curing temperature is 80 0 c. The cutter cuts the solidified fresh heavy superphosphate, breaks it and sends it to the curing warehouse for curing. The curing temperature is 45 0 C. After aging for 10 days, the powdery material is granulated by adding w...

Embodiment 3

[0025] Raw materials: 1) raffinate phosphoric acid: the chemical composition is as follows (by weight)

[0026] composition P 2 o 5 F SO 4 Fe Mg Al SiO 2 Solid content % 46.0 0.66 1.2 0.79 2.55 0.47 0.14 6.0

[0027] 2) Phosphate rock powder: the chemical composition is as follows (by weight)

[0028]

[0029] Take 25 kg of residual phosphoric acid, add 0.01 kg of mixed additives, measure through a flow meter, and feed steam to make the temperature of phosphoric acid reach 45 0 C, then add 13.8kg of phosphate rock powder, mix and react with raffinate phosphoric acid in the mixer for 2min, the slurry flows into the belt forming room for curing, the curing time is 20min, and the curing temperature is 80 0 c. The cutter cuts the solidified fresh heavy superphosphate, breaks it and sends it to the curing warehouse for curing. The curing temperature is 40 0 C. After aging for 8 days, the powdery material is granulated by adding w...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com