Polypropylene foam material and preparation method thereof

A foaming material and polypropylene technology, applied in the field of foaming materials, can solve the problems of large cell diameter, insufficient low temperature resistance, poor cell uniformity, etc., and achieve the effect of causing secondary pollution and 100% recycling.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

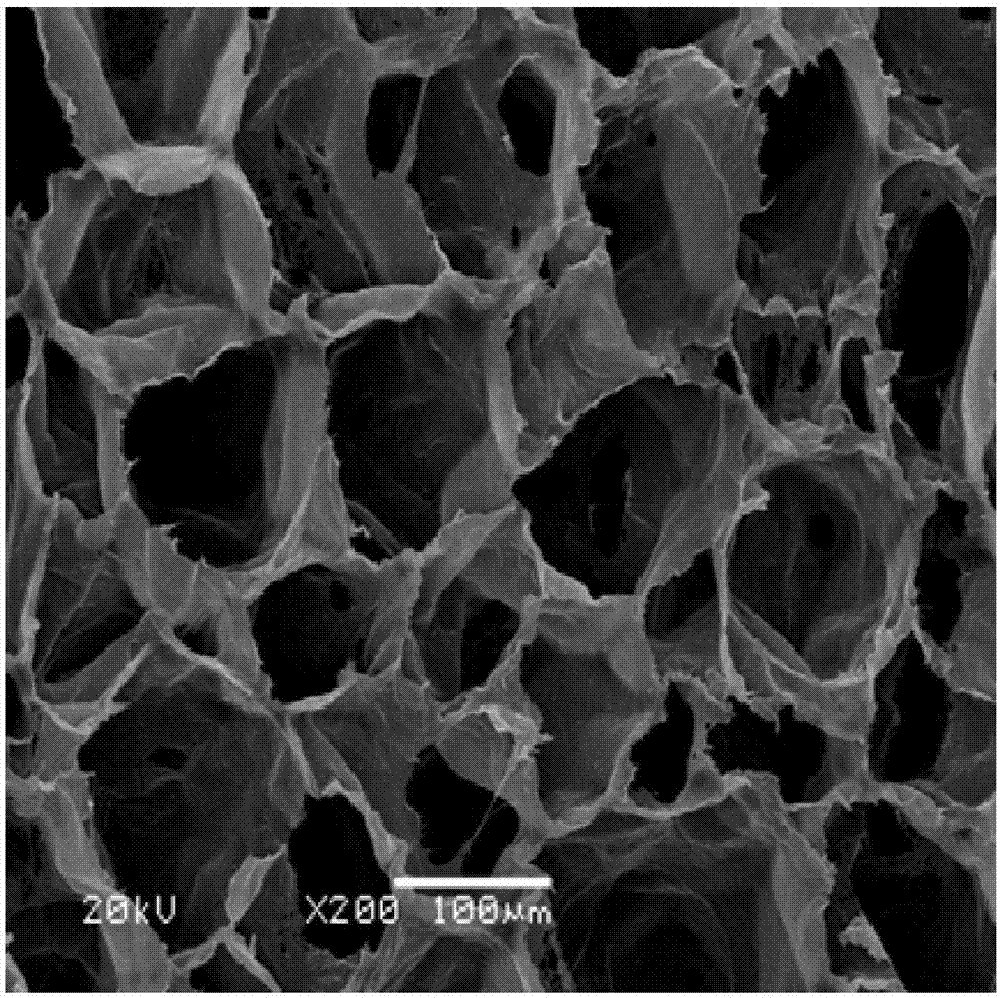

Embodiment 1

[0046] A kind of polypropylene foam material, comprises each component of following parts by weight:

[0047] Matrix resin: 40 parts by weight of high-melt strength polypropylene, 40 parts by weight of polypropylene random copolymer, and 5-30 parts by weight of low-density polyethylene;

[0048] The gas nucleating agent is talcum powder: add 0.2 parts by weight of talcum powder in every 100 parts by weight of matrix resin;

[0049] The physical blowing agent is supercritical butane: add 15 parts by weight of supercritical butane in the base resin of every 100 parts by weight;

[0050] The antioxidant is tetrakis[β-(3,5-di-tert-butyl-4-hydroxyphenyl) propionate] pentaerythritol ester: add 0.6 parts by weight in every 100 parts by weight of the matrix resin;

[0051] The cell stabilizer is monoglyceride: add 1.5 parts by weight per 100 parts by weight of the matrix resin.

[0052] The preparation method of polypropylene foam material in the present embodiment is:

[0053] (1)...

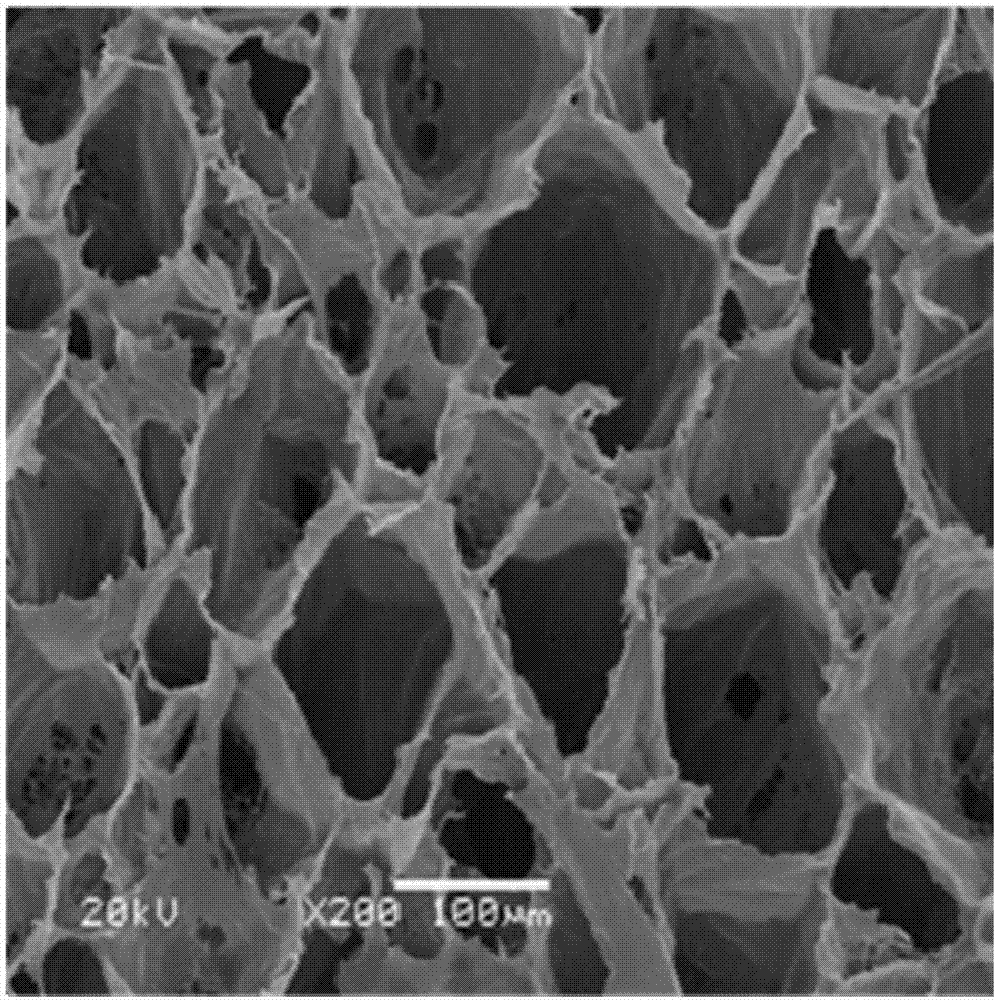

Embodiment 2

[0058] A kind of polypropylene foam material, comprises each component of following parts by weight:

[0059] Matrix resin: 50 parts by weight of high-melt strength polypropylene, 45 parts by weight of polypropylene random copolymer, and 5 parts by weight of low-density polyethylene;

[0060] The gas nucleating agent is a 1:4 mixture of silicon dioxide and talcum powder: add 0.2 parts by weight in every 100 parts by weight of the matrix resin;

[0061] The physical blowing agent is a mixture of supercritical carbon dioxide and supercritical butane 1:6: add 3 parts by weight in the base resin of every 100 parts by weight;

[0062] The antioxidant is β-(3,5-di-tert-butyl-4-hydroxyphenyl) n-octadecyl propionate: add 0.6 parts by weight per 100 parts by weight of the base resin;

[0063] The cell stabilizer is monoglyceride: 1.1 parts by weight is added per 100 parts by weight of the matrix resin.

[0064] The preparation method of polypropylene foam material in the present embo...

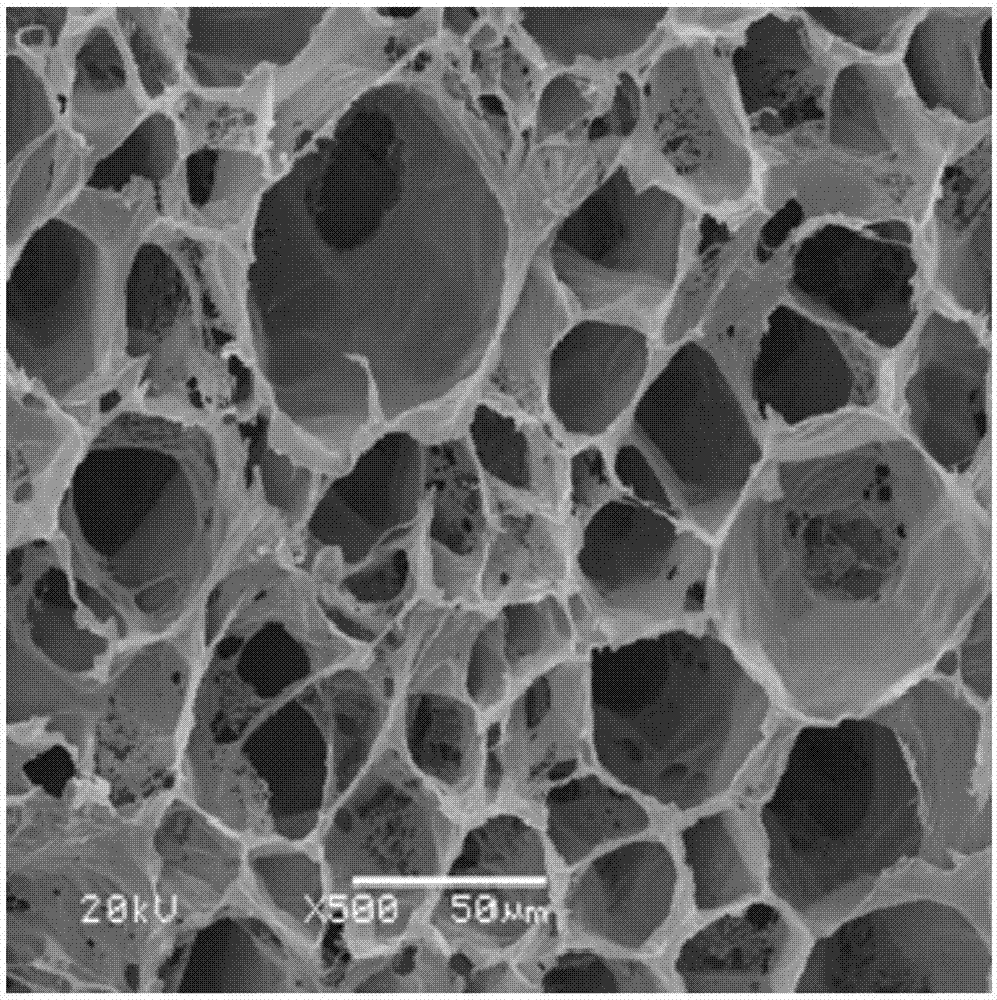

Embodiment 3

[0070] A kind of polypropylene foam material, comprises each component of following parts by weight:

[0071] Matrix resin: 60 parts by weight of high melt strength polypropylene, 30 parts by weight of polypropylene random copolymer, and 10 parts by weight of low density polyethylene;

[0072] The gas nucleating agent is talcum powder: add 0.3 parts by weight in every 100 parts by weight of matrix resin;

[0073] The physical blowing agent is supercritical nitrogen: add 5 parts by weight of supercritical nitrogen in every 100 parts by weight of matrix resin;

[0074] The antioxidant is tetrakis[β-(3,5-di-tert-butyl-4-hydroxyphenyl) propionate] pentaerythritol ester: add 0.6 parts by weight in every 100 parts by weight of the base resin;

[0075] The cell stabilizer is monoglyceride: add 1.8 parts by weight per 100 parts by weight of the matrix resin.

[0076] The preparation method of polypropylene foam material in the present embodiment is:

[0077] (1) Add the high melt s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com