Can and production technology

A production process and tank technology, which is applied in the direction of rigid containers, containers, packaging, etc., can solve the problems of releasing harmful substances, impact, and easy breakage, and achieve the effect of simple structural design, not easy to damage, and easy to recycle

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The best embodiment of the present invention will be further described in detail below.

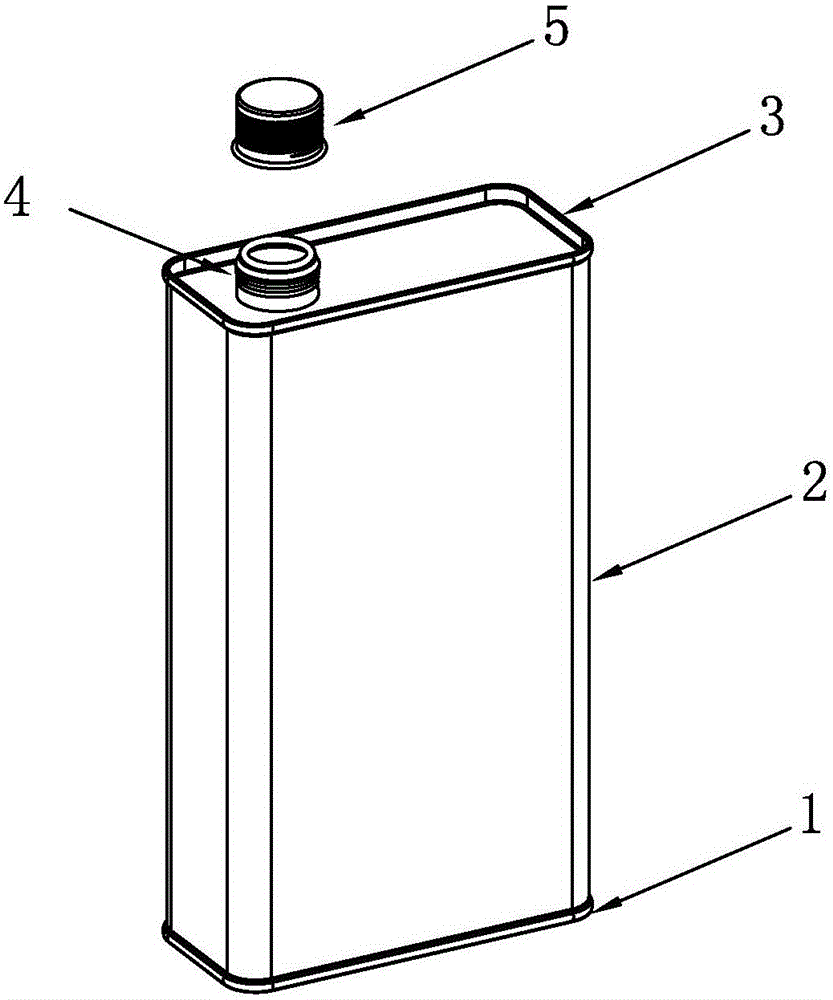

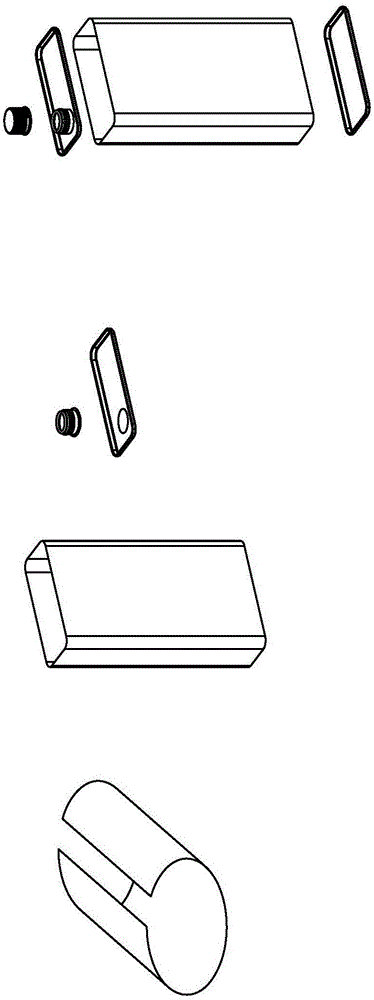

[0024] like figure 1 As shown, the tank body includes a bottom 1, a tank body 2, a cover 3, a mouth 4, and a knob 5. The cross section of the tank body 2 is a transparent body with a square or circular or other shape, and the lower part of the transparent body is sealed. The bottom 1 is set, and the upper part of the transparent body is sealed with a cover 3. The cover 3 is provided with a mouth 4 near the edge, and a knob 5 is sealed on the mouth 4.

[0025] The bottom 1, the tank body 2 and the tank body 2 and the cover 3 are sealed and connected by folding and pressing.

[0026] The face cover 3 is provided with a hole, and the mouth 4 is an inverted T-shaped structure. After the mouth 4 passes through the hole, the bottom of the mouth 4 is closely attached to the lower side of the face cover 3 and pressed tightly to make it tightly connected.

[0027] The outer wall of the mo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com