Flame-retardant and antistatic polypropylene fiber composition and fibers and non-woven fabrics prepared therefrom

A polypropylene composition, flame retardant and antistatic technology, applied in the field of fiber and non-woven fabrics, can solve problems such as electronic equipment malfunction, and achieve the effects of low cost, high melting point and crystallization temperature, and high mechanical strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0194] Preparation of Polypropylene Base Resin HPP

[0195] 1. Preparation of polypropylene base resin HPP101

[0196] 1) Raw material

[0197] Preparation of the main catalyst: Fully replace the 16L pressure-resistant reactor with a stirrer with nitrogen, then add 10L ethanol, 300mL 2-ethylhexanol, 11.2g iodine, 8g magnesium chloride and 640g magnesium powder into the reactor and stir to mix Evenly, while stirring, the system was heated to 75°C and refluxed until no more hydrogen gas was released. Stop the reaction, wash with 3L of ethanol, filter and dry to obtain dialkoxymagnesium carrier. Its D50 is 30.2 μm, its SPAN is 0.81, and its m value is 0.015. Take 650 g of the above-mentioned dialkoxymagnesium carrier, 3250 mL of toluene and 65 mL of di-n-butyl phthalate (DNBP) to prepare a suspension. In a 16L pressure-resistant reactor that has been repeatedly replaced by high-purity nitrogen, add 2600 mL of toluene and 3900 mL of titanium tetrachloride, raise the temperatur...

Embodiment 1

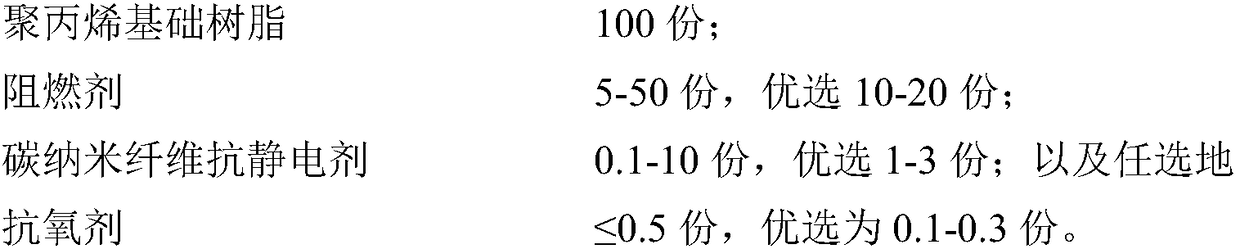

[0248] 1. Preparation of flame retardant and antistatic polypropylene fiber composition

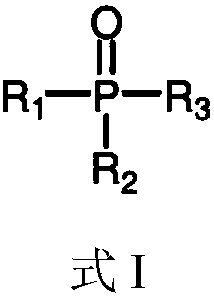

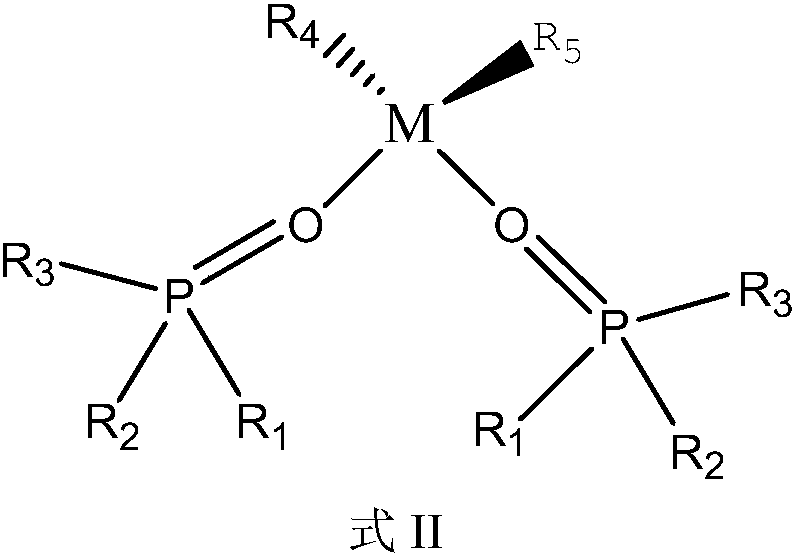

[0249] The raw material ratio and reaction conditions of the flame retardant and polypropylene composition prepared in this example are listed in Table 2 and Table 3. Wherein, the flame retardant component A is phosphine oxide, the flame retardant component B is a transition metal salt, and the flame retardant component C is an inorganic flame retardant component.

[0250] 1) Preparation of (halogen-free) flame retardant

[0251] Add triphenylphosphine oxide and cobalt nitrate into ethanol, stir at a rate of 100rpm, and then use microwave to heat the mixture under stirring, with a heating power of 50W, a temperature of 40°C, and a heating time of 4h. The material after microwave heating reaction is carried out supercritical drying, obtains the complex Co(OPPh of the formation of triphenylphosphine oxide and cobalt nitrate 3 ) 2 (NO 3 ) 2 .

[0252] The above-prepared complex Co(OPPh...

Embodiment 2

[0264] 1. Preparation of flame retardant and antistatic polypropylene fiber composition

[0265] 1) The preparation method of flame retardant, carbon nanofiber antistatic agent, and flame retardant antistatic polypropylene composition is the same as that of Example 1, except that the raw material formulation and reaction conditions shown in Table 2 and Table 3. For example, this embodiment uses HPP102, and the halogen-free flame retardant formed is the complex Ni(OPOt) formed by trioctylphosphine oxide and nickel nitrate. 3 ) 2 (NO 3 ) 2 , the prepared carbon nanofiber antistatic agent contains nickel 3wt%.

[0266] 2) Preparation of flame retardant and antistatic polypropylene fiber composition

[0267] 90 parts by weight of the above-mentioned flame-retardant antistatic polypropylene composition, 10 parts by weight of general-purpose LDPE, and 0.06 parts by weight of slip agent oleic acid amide. After being mixed by a high-speed mixer, it is obtained by blending with a ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| crystallization temperature | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com