Halogen-free flame-retardant polypropylene foam material and preparation method thereof

A technology of flame-retardant polypropylene and foam materials, which is applied in the field of polymers and can solve problems such as unreachable, high flame-retardant grades, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

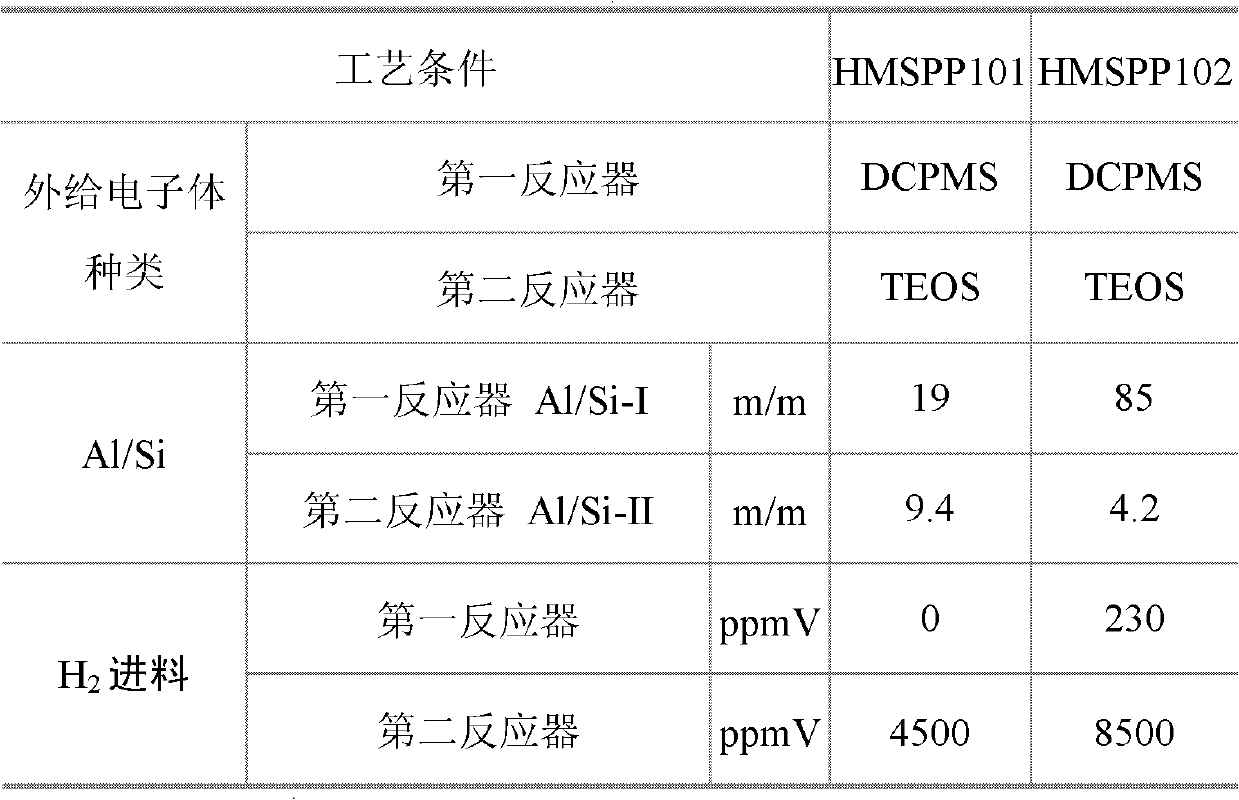

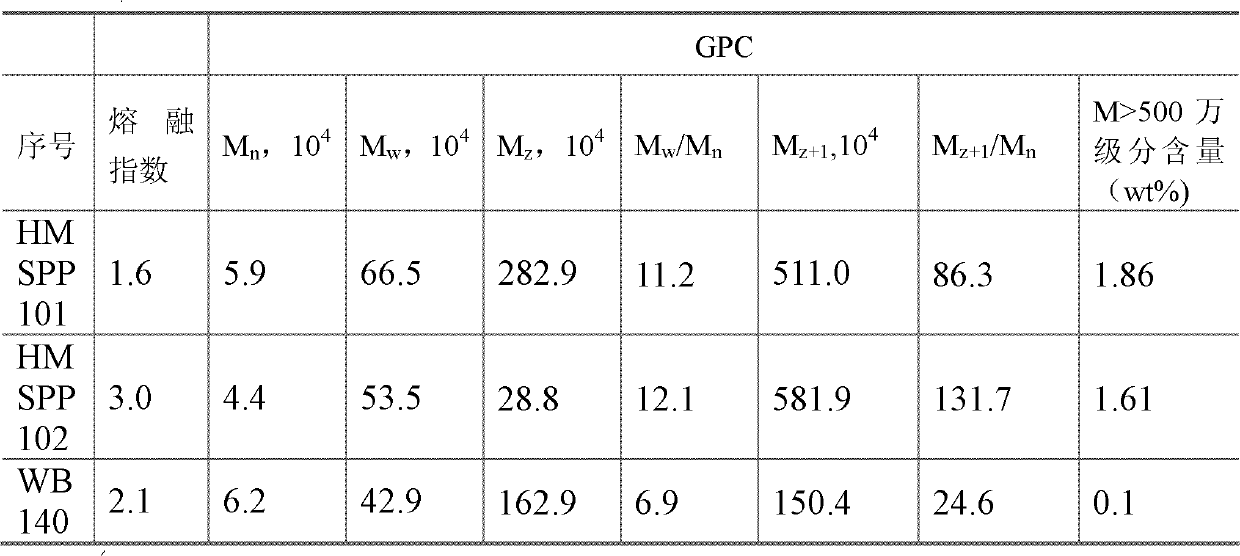

[0090] Preparation of High Melt Strength Polypropylene:

[0091] The polymerization reaction was carried out on a polypropylene pilot plant. Its main equipment includes prepolymerization reactor, first loop reactor and second loop reactor. Polymerization method and steps are as follows:

[0092] HMSPP101

[0093] (1) Prepolymerization reaction:

[0094] The main catalyst (titanium-containing solid catalyst active component) is obtained by the method described in Example 1 of Chinese Patent CN93102795, its Ti content: 2.4wt%, Mg content 18.0wt%, di-n-butyl phthalate content: 13wt %.

[0095]The main catalyst, co-catalyst (triethylaluminum), and the first external electron donor (dicyclopentyldimethoxysilane, DCPMS) were pre-contacted at 10°C for 20 minutes, and then continuously added to the pre-polymerization reactor for pre-polymerization. In the polymerization reactor, the pre-polymerization is carried out in the environment of the propylene liquid phase body, the tempe...

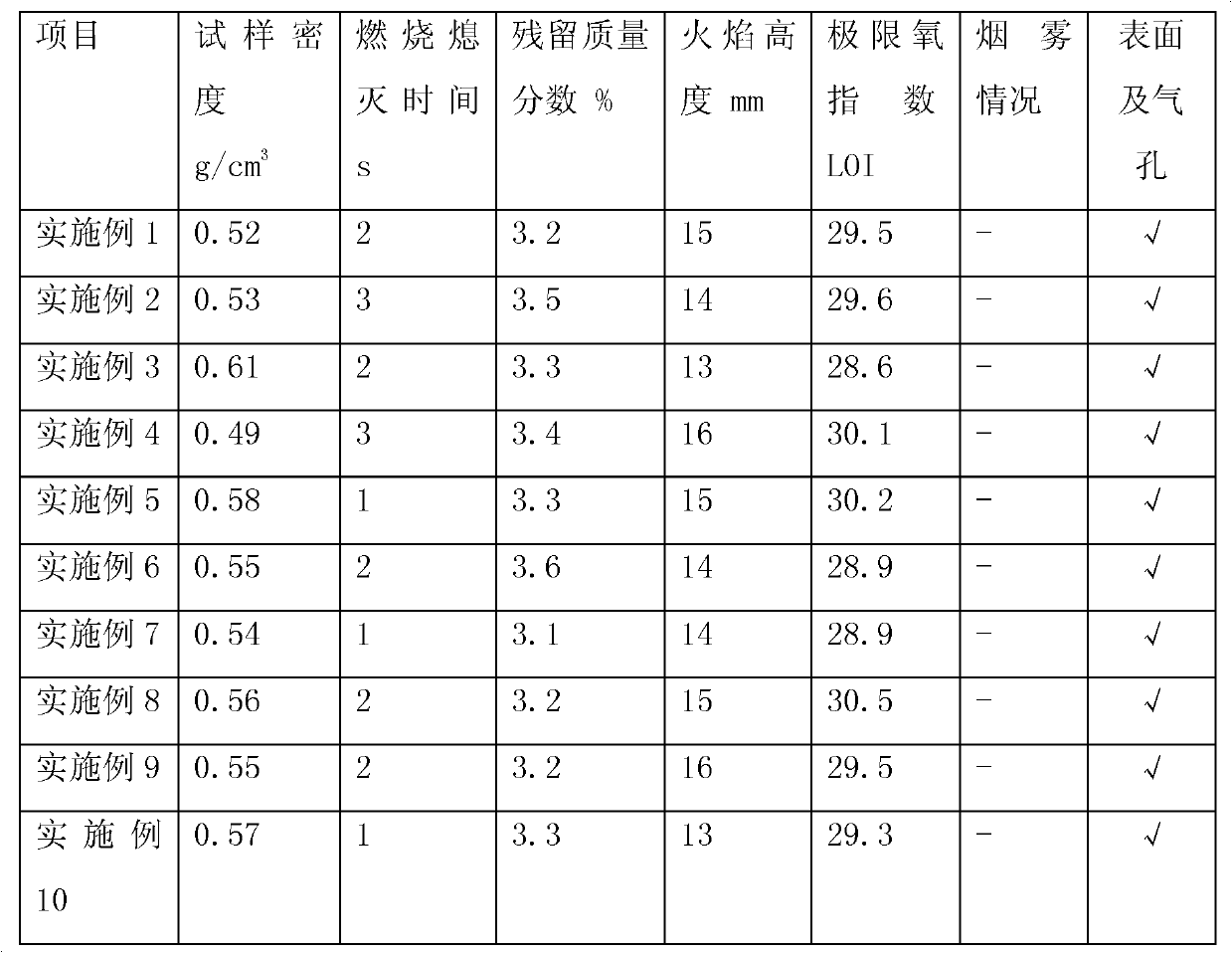

Embodiment 1

[0109] Preparation of hydrotalcite

[0110] Step A: 53.0g (0.5mol) of solid Na 2 CO 3 and 100.0 g (2.5 mol) of solid NaOH were dissolved in 225 mL of H 2 O, another 101.7g (0.5mol) of solid MgCl 2 6H 2 O and 120.7 g (0.5 mol) of solid AlCl 3 6H 2 O dissolved in 225 mL H 2 In O, put alkali solution and salt solution in the reactor at room temperature to nucleate rapidly, cool and crystallize the obtained slurry at 100°C, place it for 10h, centrifuge, wash the obtained sample until the pH value is less than 8, and dry at 70°C 24h, get Mg-Al-HCO 3 LDHs, its Mg 2+ / Al 3+ =2:1.

[0111] Step B: Weigh 35.8g (0.1mol) Na 2 HPO 4 12H 2 O, prepared as 1.0M phosphate solution.

[0112] Step C: Add 9.6 g (0.02 mol) of LDHs obtained in Step A into a container containing 100 mL of deionized water, and stir magnetically at room temperature to obtain a hydrotalcite suspension.

[0113] Step D: While stirring, add the phosphate solution to the LDHs suspension, and then add 0....

Embodiment 2

[0116] Preparation method as described in embodiment 1, process parameter changes as follows:

[0117] The ratio of sheet extrusion is updated to 100:10:5:2.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com