Antistatic polypropylene foam material and preparation method thereof

A foaming material, polypropylene technology, applied in the field of polymers, can solve the problems of difficult blending of polypropylene base resin, no mention of polypropylene blending and compounding, and low apparent density

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

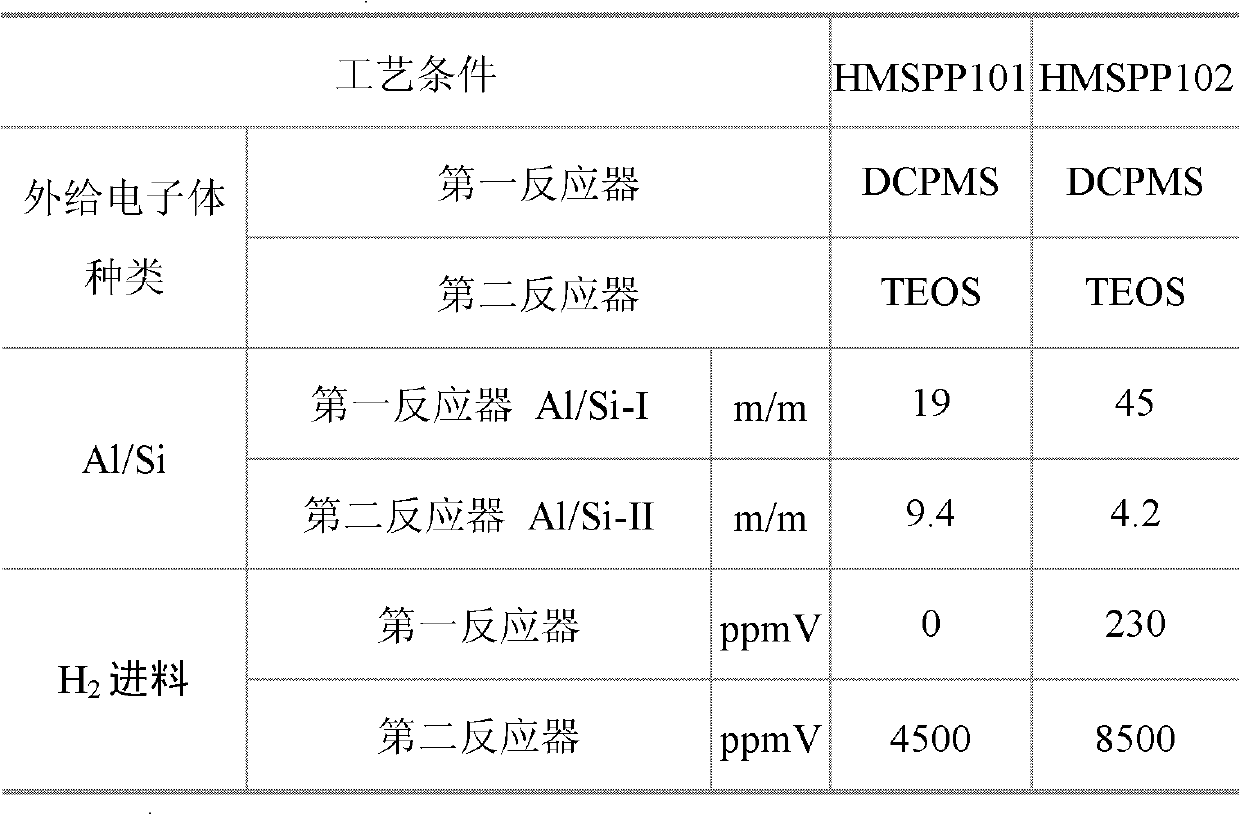

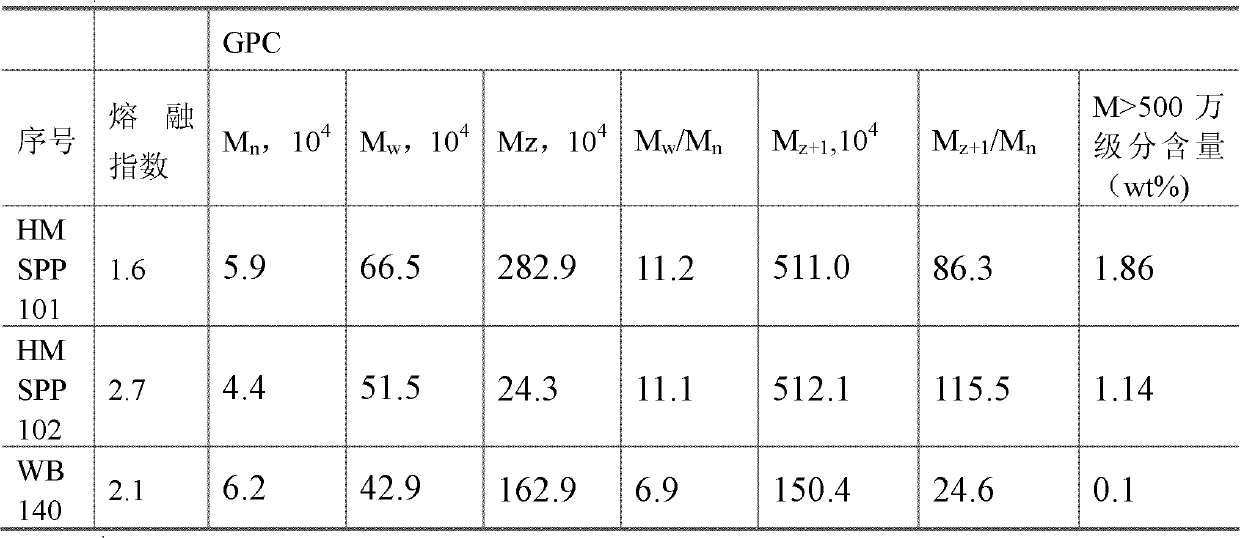

[0110] Preparation of High Melt Strength Polypropylene:

[0111] The polymerization reaction was carried out on a polypropylene pilot plant. Its main equipment includes prepolymerization reactor, first loop reactor and second loop reactor. Polymerization method and steps are as follows:

[0112] HMSPP101

[0113] (1) Prepolymerization reaction:

[0114] The main catalyst (titanium-containing solid catalyst active component) is obtained by the method described in Example 1 of Chinese Patent CN93102795, its Ti content: 2.4wt%, Mg content 18.0wt%, di-n-butyl phthalate content: 13wt %.

[0115] The main catalyst, co-catalyst (triethylaluminum), and the first external electron donor (dicyclopentyldimethoxysilane, DCPMS) were pre-contacted at 10°C for 20 minutes, and then continuously added to the pre-polymerization reactor for pre-polymerization. In the polymerization reactor, the pre-polymerization is carried out in the environment of the propylene liquid phase body, the temp...

Embodiment 1

[0129] 1. Preparation of graphene by chemical exfoliation

[0130] A: Weigh 5.5g artificial graphite (industrial grade, particle distribution is 10-20μm, specific surface area is 4m 2 / g), join 95mL, in the mixed solution of the vitriol oil (concentration 98%) of 4 ℃ and the concentrated nitric acid (concentration is 65-67%) of 47.5mL, add 5 gram potassium chlorate subsequently every 5 minutes, add up to 55 grams, Control the reaction temperature at 0-4°C. After the reaction lasts for 90 hours, wash with 0.1mol / L dilute hydrochloric acid and then deionized water repeatedly until no chlorine ions are detected and the pH value reaches neutral. Graphite oxide powder was obtained after vacuum drying at 40°C.

[0131] B: put the graphite oxide powder into the crucible and put it into a muffle furnace with an air atmosphere at 1000°C for rapid heat treatment for 20 seconds (that is, leave it for 20 seconds) to obtain exfoliatable graphite.

[0132] C: Using an ultrasonic cleaning ...

Embodiment 2

[0143] Preparation method as described in embodiment 1, process parameter changes as follows:

[0144] The composition of the masterbatch is changed to: PP: GNSs: compatibilizer: coupling agent = 100: 1.0: 1.5: 1.5

[0145] Coupling agent: vinyl silane;

[0146] Foaming agent: AC foaming agent;

[0147] Using a high-speed stirrer, the above self-made high melt strength polypropylene HMSPP101, graphene / polypropylene masterbatch, AC foaming agent, cell control agent (talcum powder), and lubricant (MB50-002) were mixed at a ratio of 100:10 : 8: 10: 2 for mixing to obtain the premix of polypropylene foam board, put the premix into the hopper of the extruder, the temperature of the extruder rises to 150-220°C, and the temperature is controlled at the die mouth At 170°C, extrude the foamed sheet.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com