Two-tower ammonia method desulfurization device and method

The technology of ammonia desulfurization and desulfurization tower is applied in the field of ammonia desulfurization flue gas. , the effect of reducing the formation of aerosols

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

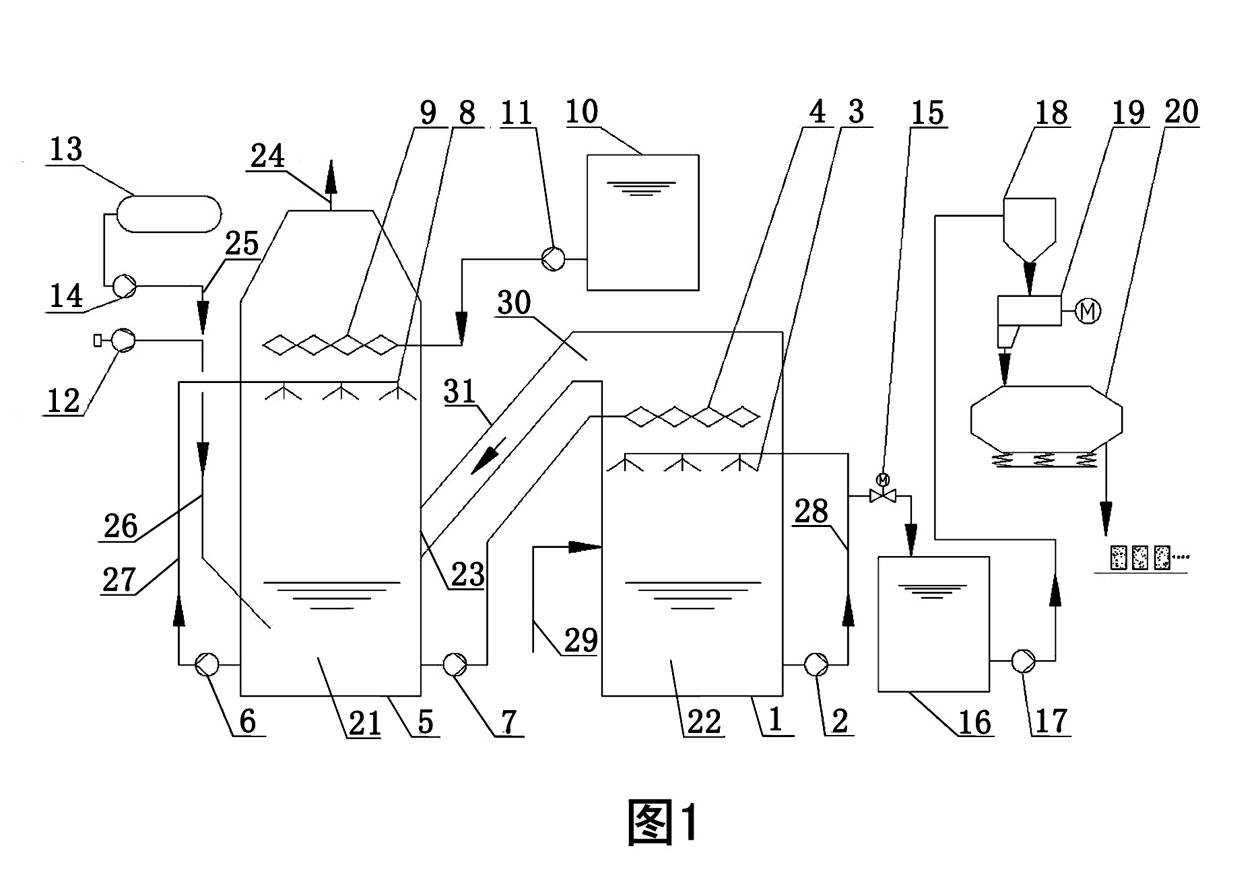

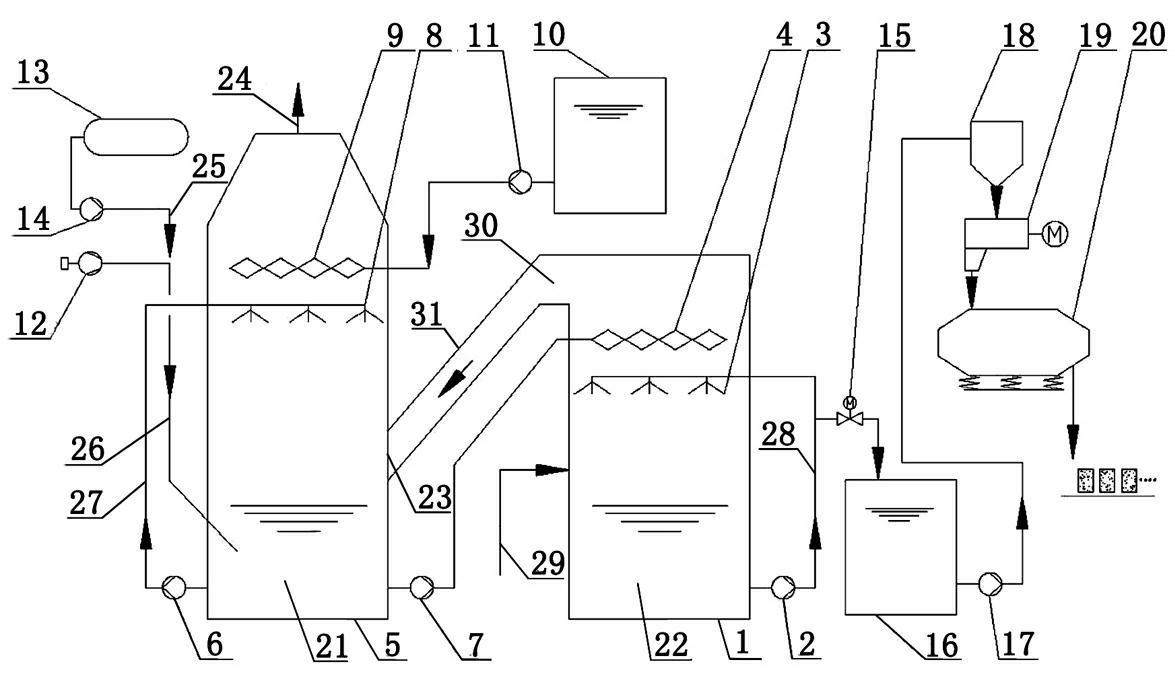

[0026] Examples see figure 1 As shown, this double-tower ammonia desulfurization device includes a flue gas purification part, an absorbent supply part and an ammonium sulfate dehydration part; the flue gas purification part is composed of a desulfurization tower 5 and a pre-washing tower 1; the lower part of the desulfurization tower 5 is There is a desulfurization tower slurry pool 21, the upper section has a desulfurization tower spray layer 8 and a desulfurization tower demister 9, and the circulation pipeline I27 connected to the outside of the spray pipe of the desulfurization tower spray layer 8 is connected to the desulfurization tower slurry pool 21. The circulation pump 6 is connected to the pipeline I27, and the demister 9 of the desulfurization tower is arranged above the spray layer 8 of the desulfurization tower. The road is connected with a process water pump 11, and the top of the desulfurization tower 5 has a clean flue gas outlet 24, and a flue gas inlet 23 i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com