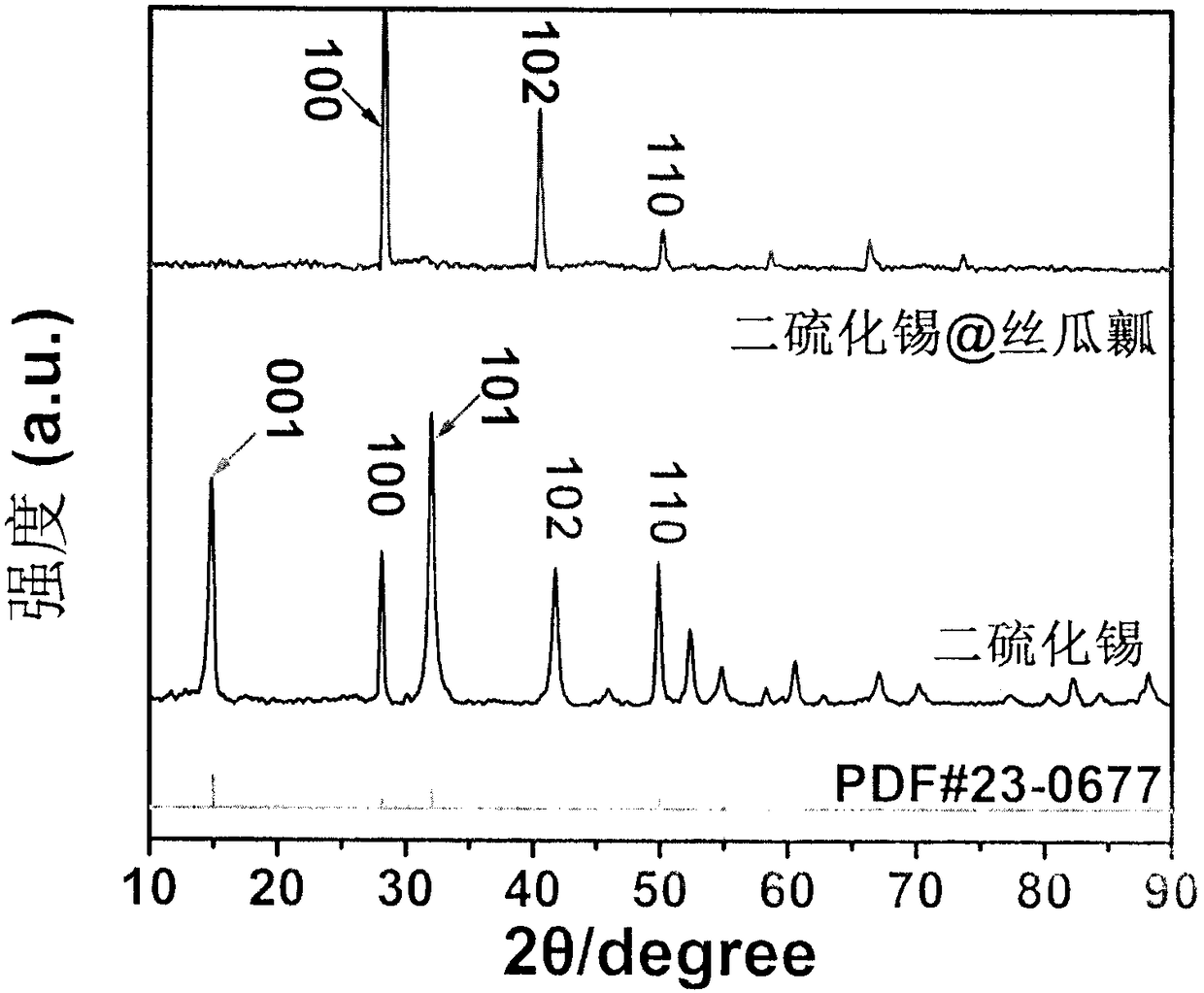

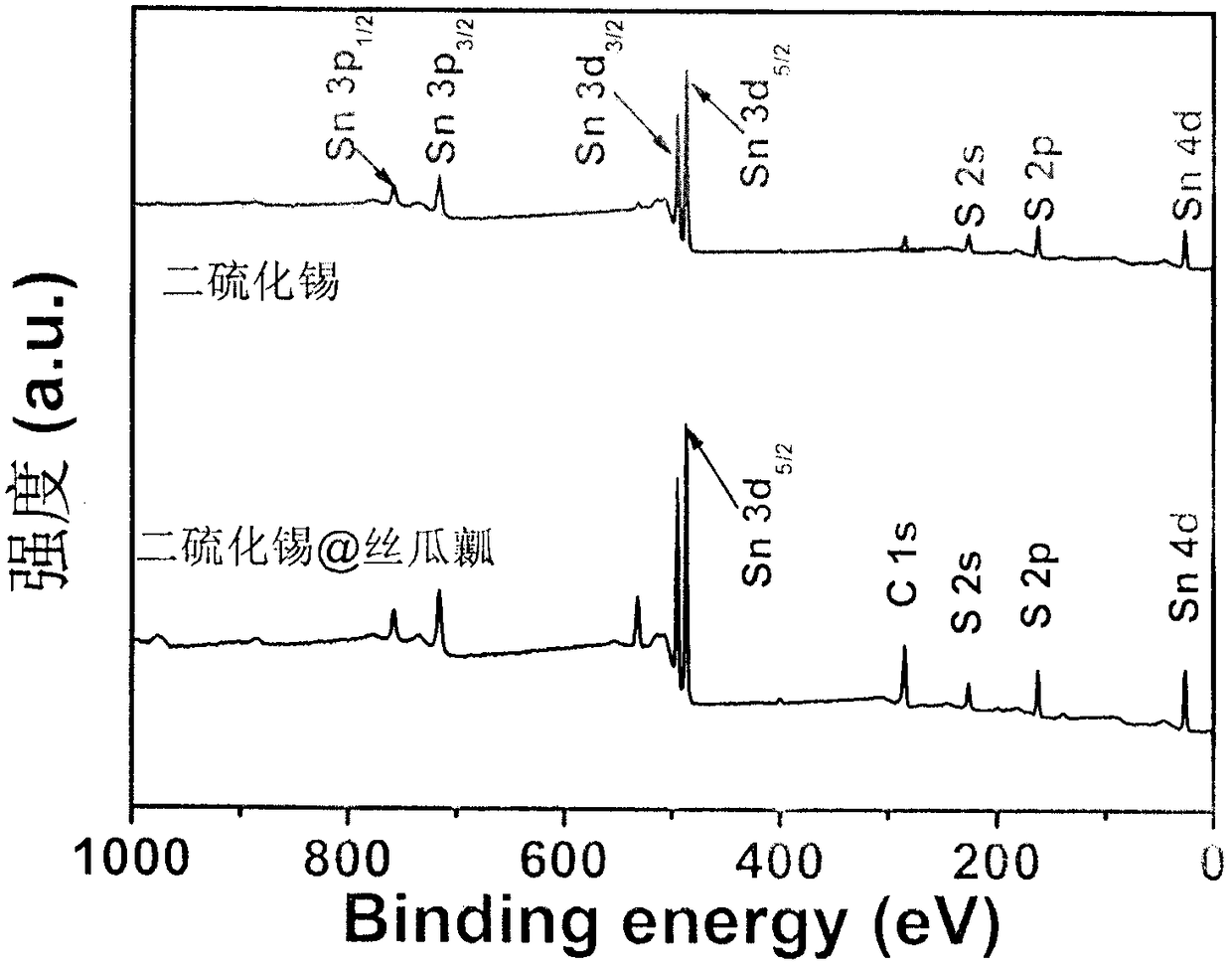

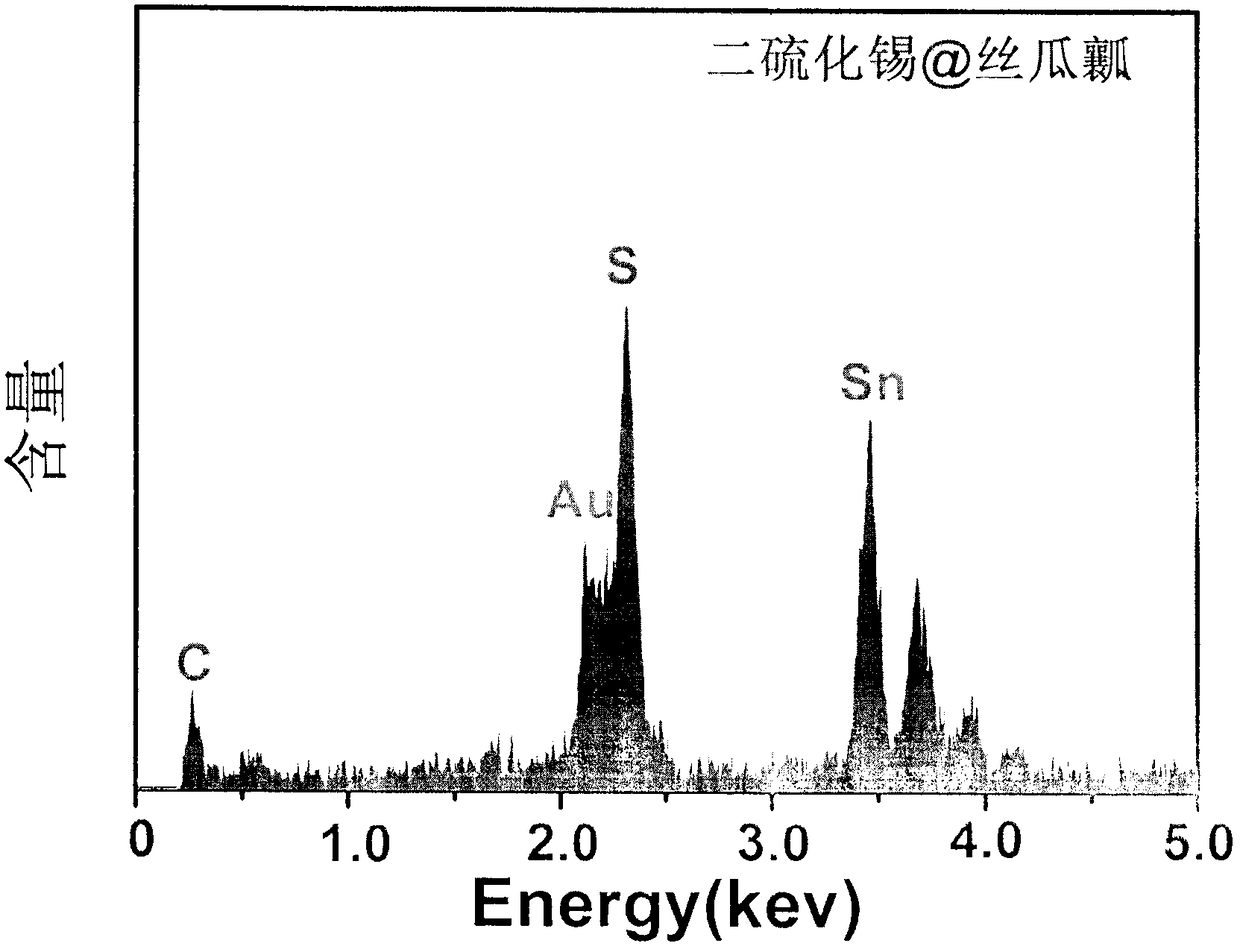

Preparation method of tin sulfide/vegetable sponge nanocomposite

A nano-composite material, tin disulfide technology, applied in catalyst activation/preparation, chemical instruments and methods, chemical/physical processes, etc., can solve the problems of low visible light utilization rate, easy agglomeration, etc., and achieve excellent synergistic catalytic effect and degradation. The effect of high activity and lower production cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0023] Preparation of loofah pulp: Soak 2 grams of natural loofah pulp in acetone and absolute ethanol for ultrasonic vibration, then soak the loofah pulp in tin tetrachloride solution for 10 minutes, and then put it in an oven at 110 degrees Celsius for 20 minutes.

[0024] Preparation of tin disulfide: 2 grams of tin tetrachloride, 1.5 grams of thioacetamide and 400 milliliters of absolute ethanol were mixed evenly, and put into an oven at 160 degrees Celsius to react for 12 hours to obtain a solid-liquid mixture. Wash twice successively with 100 milliliters of distilled water and 100 milliliters of absolute ethanol, and the solid is taken out with ethanol, and dried in vacuum at 60 degrees Celsius for 24 hours.

Embodiment 2

[0026] Soak 2.2 grams of natural loofah pulp in acetone and absolute ethanol in turn for ultrasonic vibration, then soak the loofah pulp in tin tetrachloride solution for 12 minutes, and then put it in an oven at 110 degrees Celsius for 22 minutes. Subsequently the sponge gourd pulp of drying, 3 grams of tin tetrachloride, 1.8 grams of thioacetamide and 400 milliliters of dehydrated alcohol are mixed homogeneously, put into 160 degree centigrade baking oven and react 12 hours, obtain solid-liquid mixture. Washed twice with 100 ml of distilled water and 100 ml of absolute ethanol in turn, the solid was taken out with ethanol, and dried in vacuum at 60 degrees Celsius for 24 hours.

Embodiment 3

[0028] Soak 2.4 grams of natural loofah pulp in acetone and absolute ethanol in turn for ultrasonic vibration, then soak the loofah pulp in tin tetrachloride solution for 14 minutes, and then put it in an oven at 110 degrees Celsius for 24 minutes. Subsequently, the loofah pulp of drying, 4 grams of tin tetrachloride, 2.1 grams of thioacetamide and 100 milliliters of dehydrated alcohol were mixed homogeneously, and were put into an oven at 160 degrees Celsius to react for 12 hours to obtain a solid-liquid mixture. Washed twice with 100 ml of distilled water and 100 ml of absolute ethanol in turn, the solid was taken out with ethanol, and dried in vacuum at 60 degrees Celsius for 24 hours.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com