Method for separating arsenic and recycling copper from arsenious high-copper dross

A technology for recycling copper and high copper, which is applied in the field of mineral processing, can solve the problems of high energy consumption, explosion risk, and low iron utilization rate, and achieve the effects of reducing solution acidity, eliminating potential safety hazards, and reducing solubility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

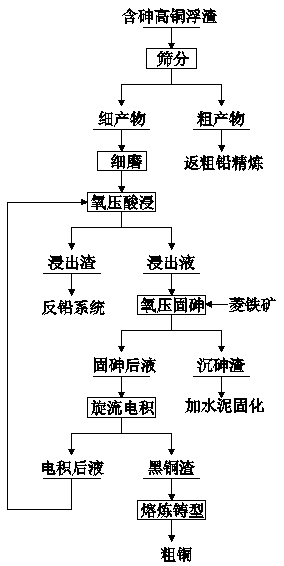

Method used

Image

Examples

Embodiment Construction

[0017] 1 Composition of arsenic-containing high-copper dross

[0018] Pb is 74.48% (mass percentage), As is 4.31% (mass percentage), Cu is 7.46 (mass percentage), Fe is 0.1015% (mass percentage), Au is 17.4g / t, and Ag is 3868g / t.

[0019] 2 Pretreatment of arsenic-containing and high-copper scum

[0020] Use a 40-mesh sieve to sieve the arsenic-containing and high-copper scum. The fine products under the sieve are further ground, and more than 96% of the materials are required to pass through the 120-mesh sieve.

[0021] The crude product on the sieve is then returned to crude lead fire refining to produce arsenic-containing high-copper scum.

[0022] 3 oxygen pressure acid leaching

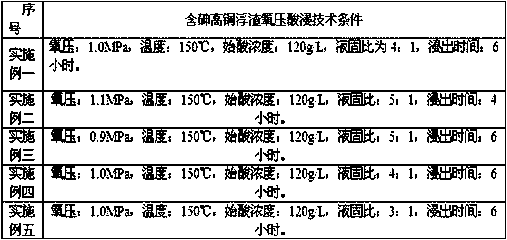

[0023] 3.1 Technical conditions of oxygen pressure acid leaching

[0024] Sulfuric acid is used as the acid solution.

[0025]

[0026] The solid-to-liquid ratio is the mass-to-volume ratio, that is, mL:g.

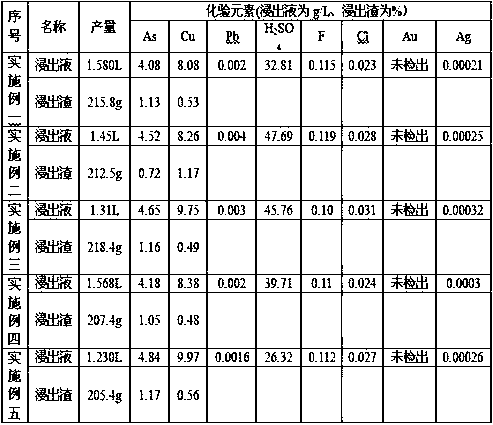

[0027] 3.2 Oxygen pressure acid leaching test results

[0028] 3.2.1 Oxygen pre...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com