A method for removing arsenic in nickel electrolytic mixed acid system

A technology of nickel electrolysis and mixed acid, applied in the field of nickel electrolysis, can solve problems such as increase and affect the economic benefits of electronickel, and achieve the effect of stabilizing chemical quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

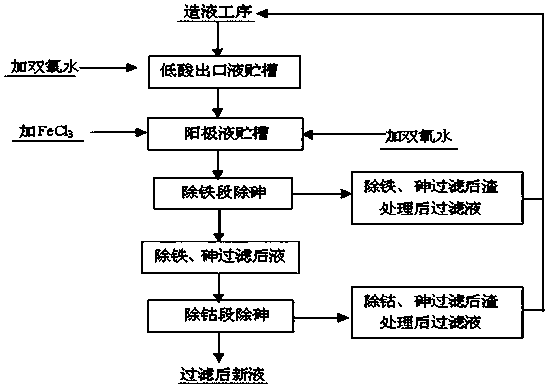

Image

Examples

Embodiment 1

[0018] The nickel electrolytic mixed acid system contains 65g / l of chloride ions, 0.2g / l of iron, and 0.06g / l of arsenic. The method for removing arsenic in the nickel electrolytic mixed acid system includes the following steps:

[0019] A. In the nickel sulfide soluble anode electrolysis process, copper and arsenic are removed by electrochemical deposition in the liquid-making process, and after impurity removal, H is added to the low-acid outlet liquid storage tank for liquid making 2 o 2 solution to oxidize trivalent arsenic in the low-acid outlet liquid of effusion to pentavalent arsenic, which is beneficial to the removal of arsenic, and H 2 o 2 The solution is industrial H with a mass fraction of 30% 2 o 2 The solution diluted 1:1 with water is added in an amount of 0.2% of the mass of the liquid-making low-acid outlet liquid; during the process of electrochemical deposition-induced arsenic removal in the liquid-making process, the anode is a nickel anode plate, and t...

Embodiment 2

[0026] The nickel electrolytic mixed acid system contains 70g / l of chloride ions, 0.3g / l of iron, and 0.03g / l of arsenic. The method for removing arsenic in the nickel electrolytic mixed acid system includes the following steps:

[0027] A. In the nickel sulfide soluble anode electrolysis process, copper and arsenic are removed by electrochemical deposition in the liquid-making process, and after impurity removal, H is added to the low-acid outlet liquid storage tank for liquid making 2 o 2 solution to oxidize trivalent arsenic in the low-acid outlet liquid of effusion to pentavalent arsenic, which is beneficial to the removal of arsenic, and H 2 o 2 The solution is industrial H with a mass fraction of 30% 2 o 2 The solution diluted 1:1 with water is added in an amount of 0.2% of the mass of the liquid-making low-acid outlet liquid; during the process of electrochemical deposition-induced arsenic removal in the liquid-making process, the anode is a nickel anode plate, and t...

Embodiment 3

[0034] The nickel electrolytic mixed acid system contains 68g / l of chloride ions, 0.2g / l of iron, and 0.04g / l of arsenic. The method for removing arsenic in the nickel electrolytic mixed acid system includes the following steps:

[0035] A. In the nickel sulfide soluble anode electrolysis process, copper and arsenic are removed by electrochemical deposition in the liquid-making process, and after impurity removal, H is added to the low-acid outlet liquid storage tank for liquid making 2 o 2 solution to oxidize trivalent arsenic in the low-acid outlet liquid of effusion to pentavalent arsenic, which is beneficial to the removal of arsenic, and H 2 o 2 The solution is industrial H with a mass fraction of 30% 2 o 2 The solution diluted 1:1 with water is added in an amount of 0.2% of the mass of the liquid-making low-acid outlet liquid; during the process of electrochemical deposition-induced arsenic removal in the liquid-making process, the anode is a nickel anode plate, and t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com