Novel arc air gouging device

A new type of arc gouging technology, applied in the field of mechanical processing equipment, can solve the problems of large overall weight of copper tungsten gouging device, easy oxidation of pure tungsten electrode tip, high divergence, etc., to avoid consumables and dust problems, and overcome production safety Problems, the effect of a simple overall structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

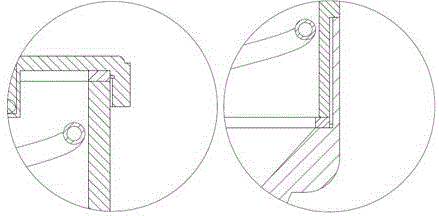

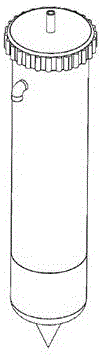

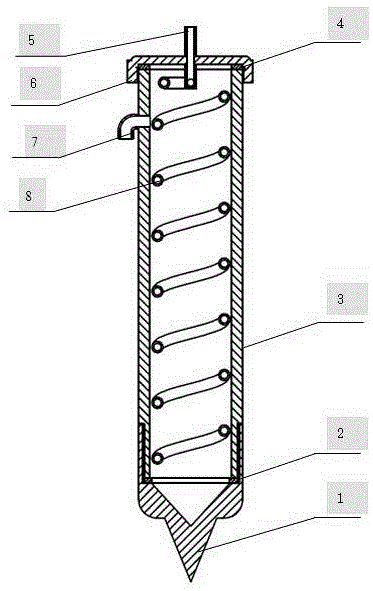

[0020] like figure 1 As shown, a new type of arc gouging device, including tungsten-molybdenum alloy electrode head 1, lower sealing ring 2, copper pipe body 3, upper sealing ring 4, air intake pipe 5, upper cover body 6, air injection pipe 7, and spiral passage pipe 8. The electrode head 1 is made of tungsten-molybdenum alloy. The tungsten-molybdenum alloy electrode head is provided with an inner hole along the axial direction. The upper end of the electrode head is a cylinder, the lower end is a cone, and the upper and lower joints are rounded. Body shell, the upper end of the copper pipe is connected with the upper cover 6, and the lower end is connected with the electrode head 1; the upper end of the upper cover 6 closes the lower opening, and the closed end of the upper cover is provided with an air inlet pipe 5, and the air inlet pipe 5 is connected to the spiral pipe 8 Connected; the spiral tube 8 is a hollow copper spiral tube; the lower end of the copper tube body 3 i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com