Aluminum wire bundling machine for bundling aluminum ingots and operation method thereof

A technology of strapping machine and aluminum wire, which is applied to the parts, packaging, and strapping materials of strapping machines, and can solve the problem that steel straps or rubber straps cannot be reused, the flexibility of steel straps is not high, and the use is large, etc. question

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

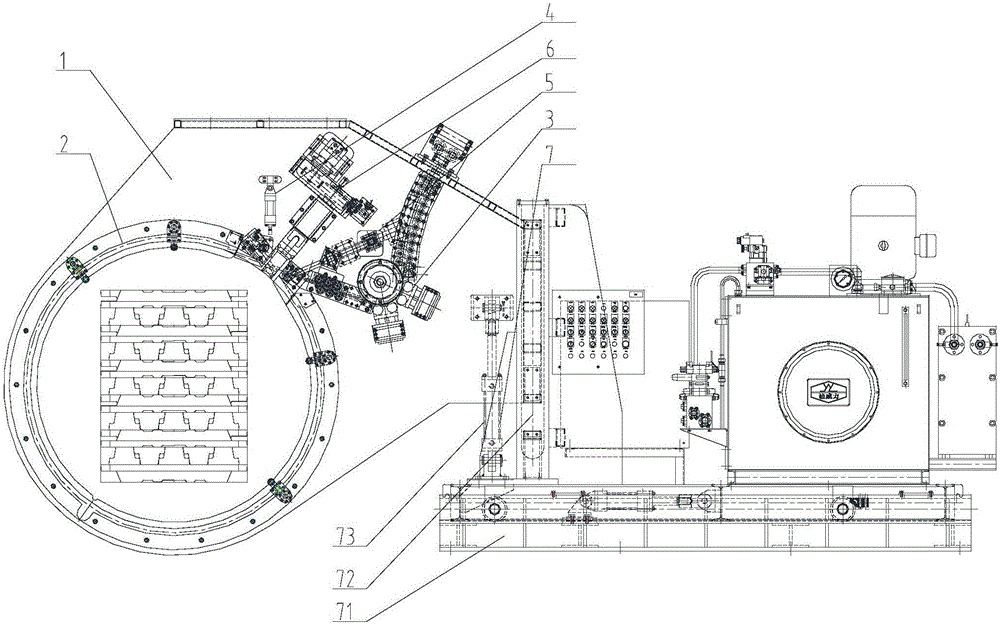

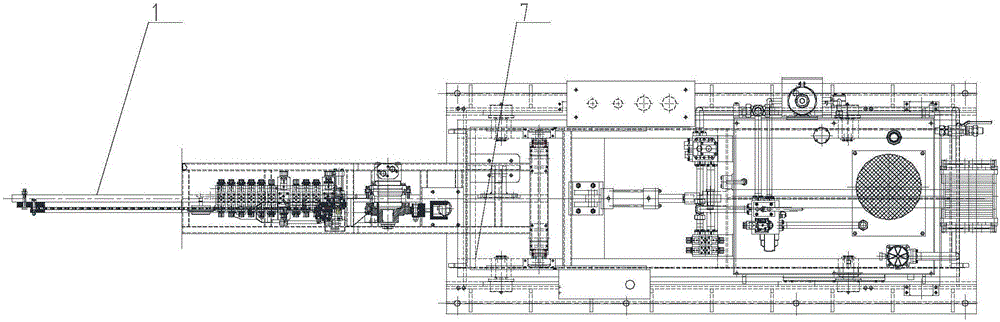

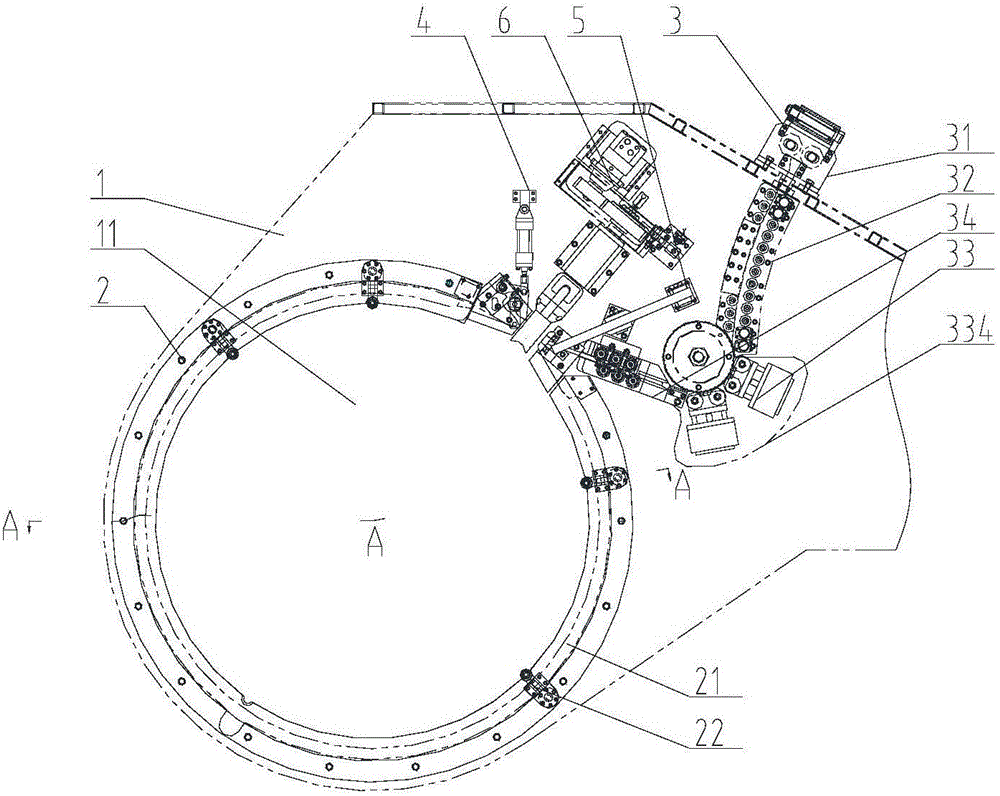

[0082] The present invention as Figure 1-26 As shown, it includes a binding base plate 1, a wire guide assembly 3, a wire guide assembly 2, a wire clamping assembly 4, a wire cutting assembly 5 and a knotting assembly 6. The binding base plate 1 is vertically arranged, and a circular shaped through hole 11, the guide wire assembly 2 is fixedly connected to one side of the circular through hole 11, and the guide wire assembly 3, the wire cutting assembly 5, the knotting assembly 6, the clamp wire assembly 4 and the guide wire assembly 2 are all connected to the same end surface of the bundled substrate 1;

[0083] The wire guide assembly 2 includes an annular guide rail 21 with a gap and several guide wheel assemblies 22. The annular guide rail 21 is fixedly connected to one end surface of the binding substrate 1 and is C-shaped. The annular guide rail 21 The inner side is provided with a guide groove; several guide wheel assemblies 22 are arranged radially along the annular ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com