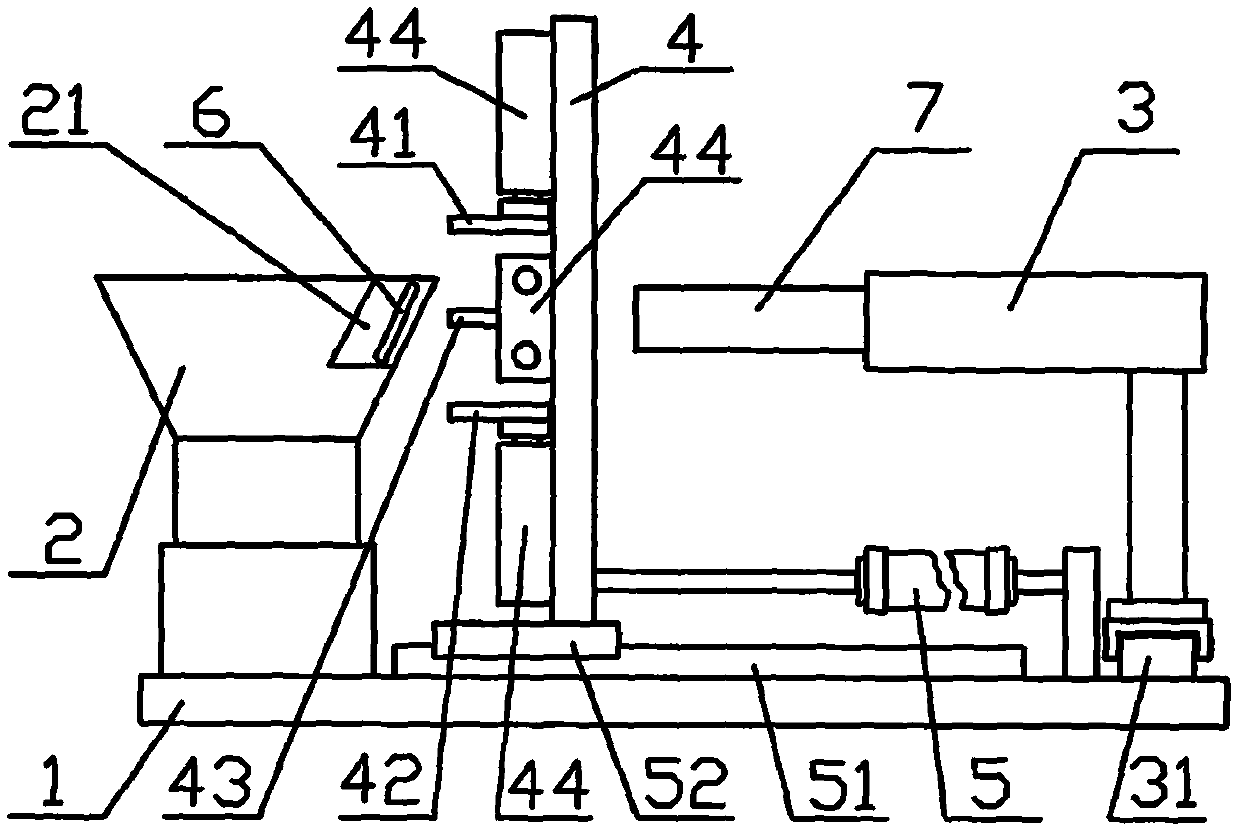

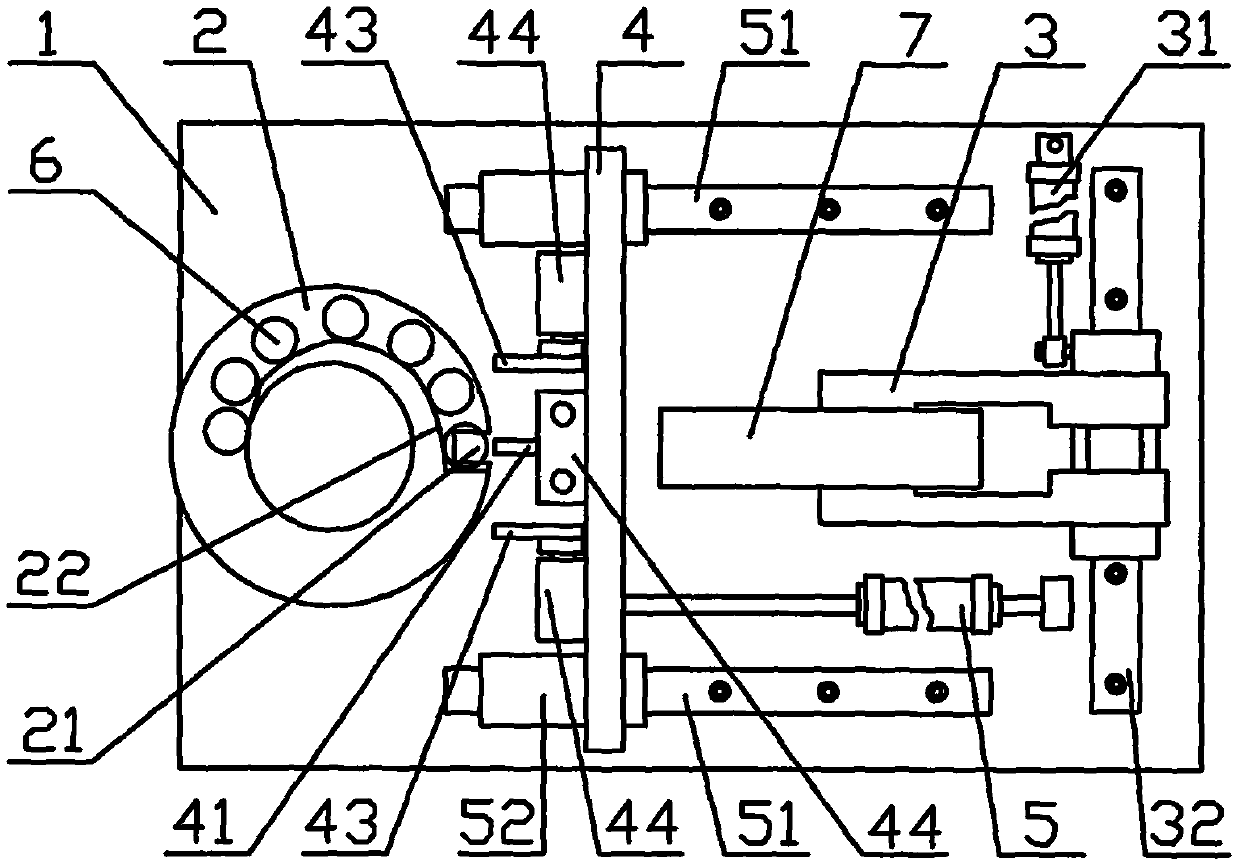

Plastic bag bundling machine and bundling method thereof

A technology of plastic bags and strapping machines, which is applied to the parts, strapping objects, and strapping materials of strapping machinery, etc., can solve problems such as difficulty in adapting to the market, inability to be tightened, and shaking.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

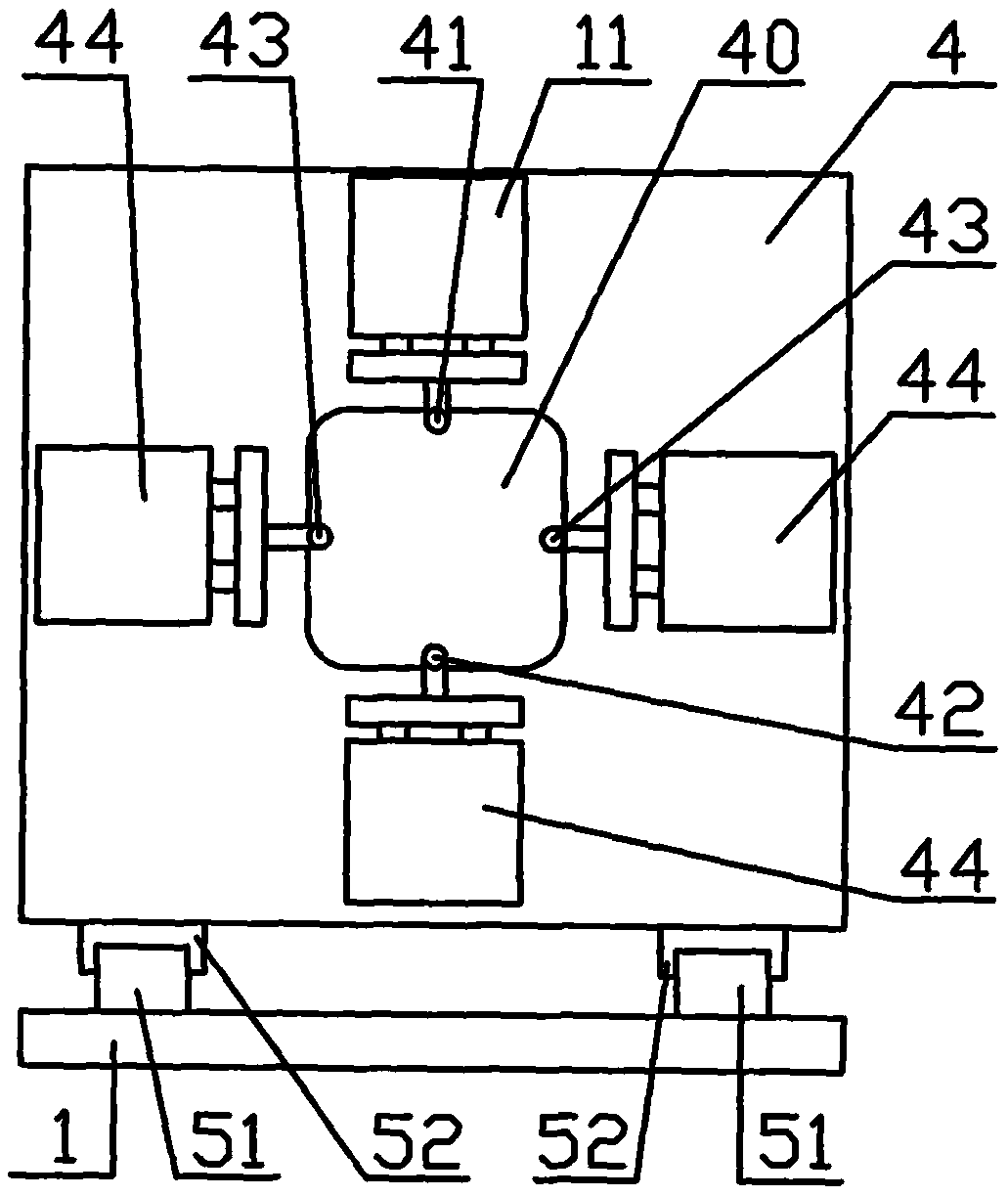

Examples

Embodiment 2

[0042] Embodiment two, such as Figure 12 Shown: the main difference between the second embodiment and the first embodiment is that one side of the support 4 is hinged on the frame 1, and the insertion movement mechanism is a swing cylinder 53; the second is the The opening direction of the U-shaped notch 21 is obliquely arranged, and the rubber band 6 is square after being strutted. One side of support 4 is equipped with hinged column 54 (referring to Figure 14 ), the support 4 is hinged on the frame 1 through the hinge column 54, a swing cylinder 53 is installed on the hinge column 54 and the frame 1 support, the vibrating plate device 2 is installed on the front right side of the support 4, and the U-shaped notch 21 is located at The left side of the vibrating plate device; the guide rail 32 of the plastic bag conveying device and the forward and backward direction of the conveying cylinder 31 are installed on the frame.

[0043] The specific work process of embodiment t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com