Roll paper conveying and cutting device and method

A roll paper and cutting technology, which is applied in the field of paper feeding and cutting, and roll paper feeding and cutting devices, can solve the problems of limited operation, difficulty in adjusting the size of the package, blocking the sight of the operator, etc., and achieves tightness. Uniform, saving packaging paper, reliable effect of breaking

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

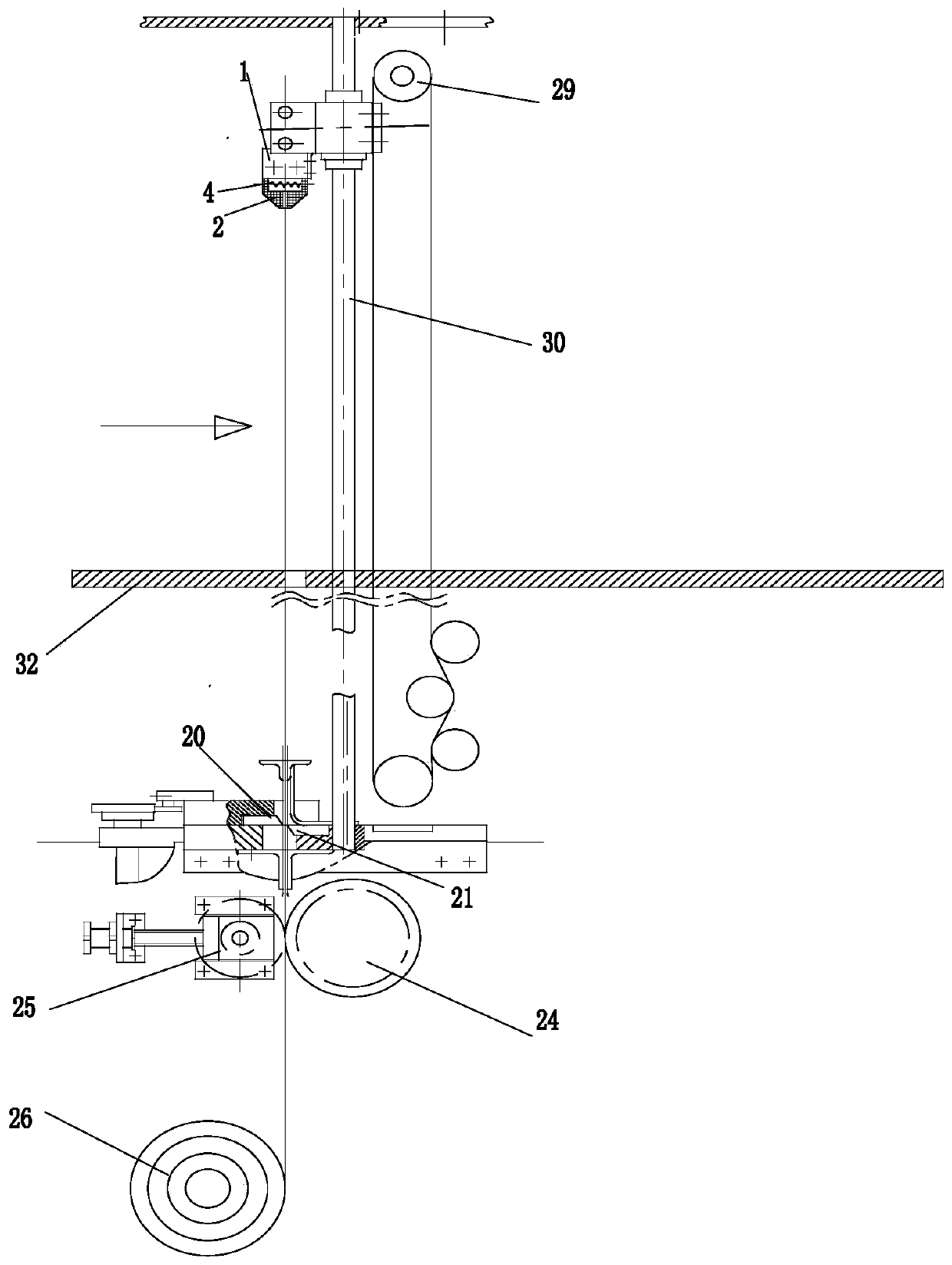

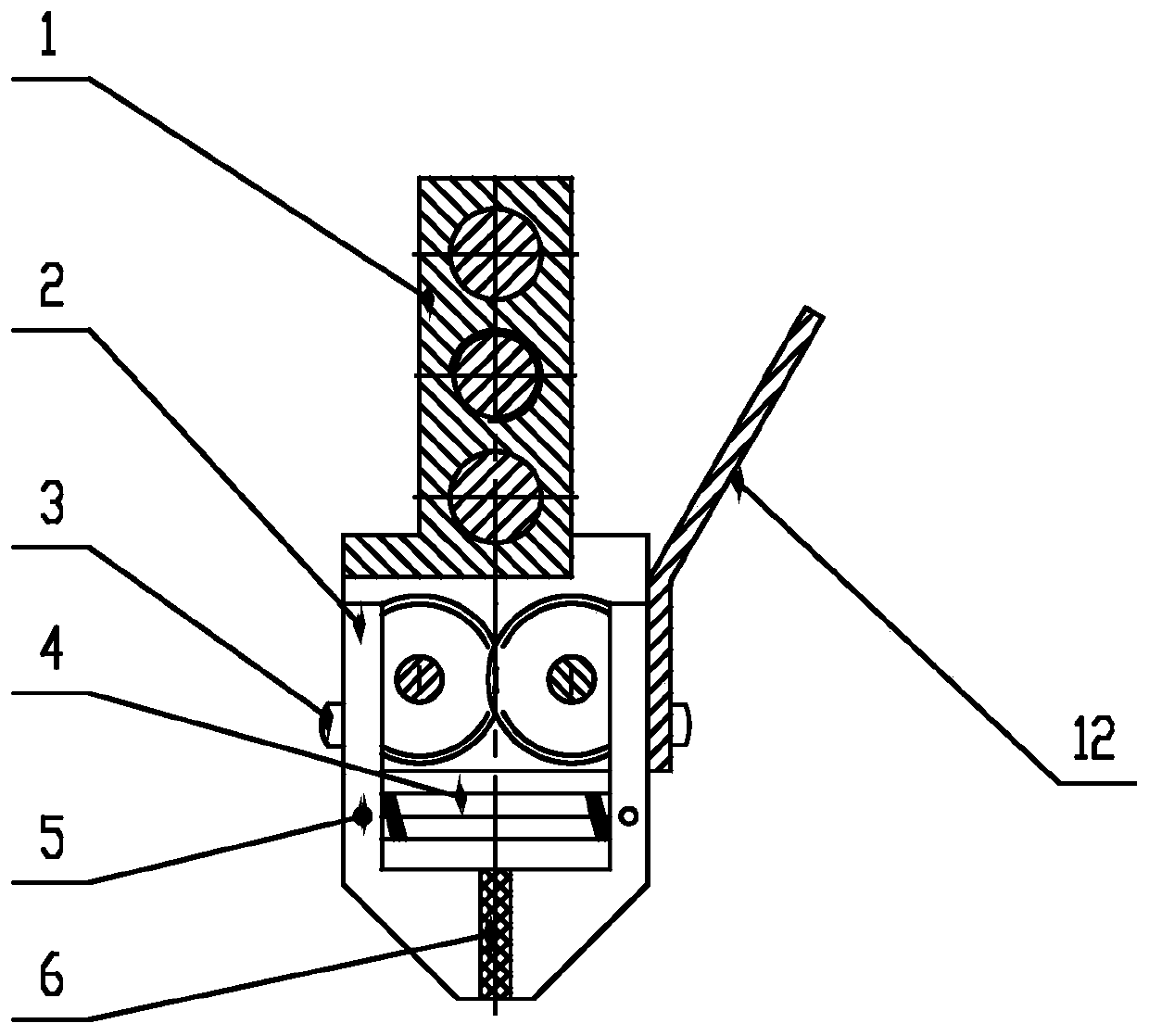

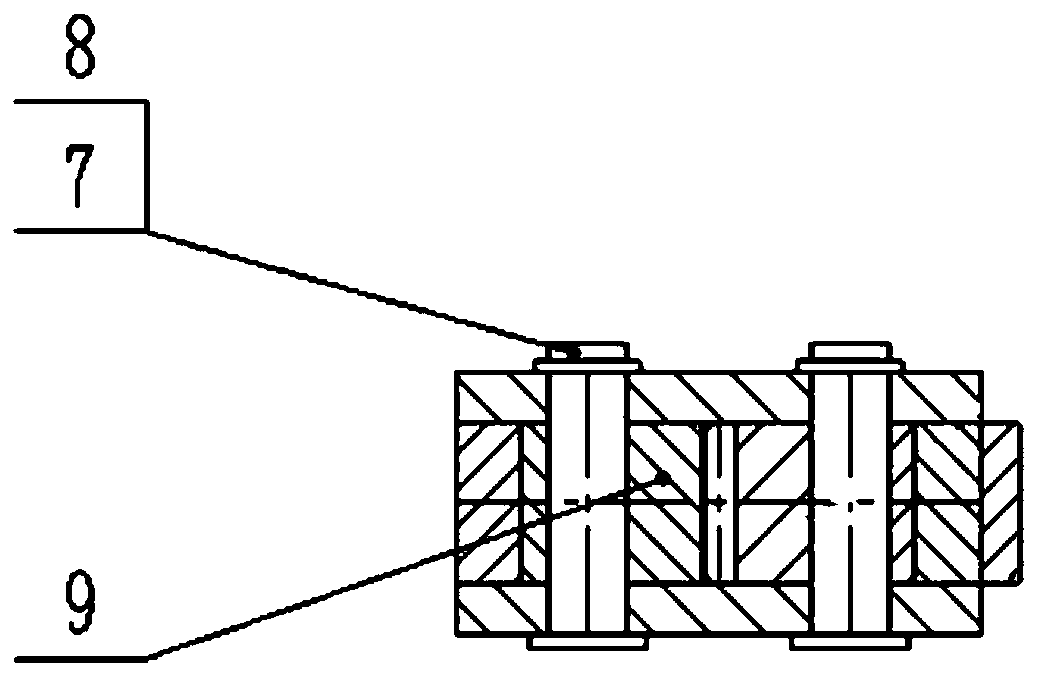

[0035] The structure of a web feeding and cutting device of the present invention is as follows: figure 1 As shown, it includes a guide shaft 30 vertically fixed below the frame and a workbench 32 perpendicular to the guide shaft 30. The workbench 32 is located at the lower section of the guide shaft 30, and a cutting device is fixedly installed at the lower end of the guide shaft 30. The guide shaft 30 is provided with an opening and closing teeth clamping transmission device that can slide up and down along the guide shaft 30. The opening and closing teeth clamping transmission device is controlled by the synchronous pulley group 29 to slide up and down. The upper part of the cutting device is equipped with a lower tooth opening device, the upper tooth opening device and the lower tooth opening device can control the opening and closing of the opening and closing teeth clamping transmission device; the cutting position of the cutting device is facing the opening and closing t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com