Novel braiding machine spindle

A knitting machine and spindle technology, which is used in knitting, textiles, and papermaking, can solve the problems that the lever cannot be reset in time, the yarn output is different in tightness, and the yarn tube is easy to move up and down, and achieves simple structure and tightness. Uniform, easy-to-use results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

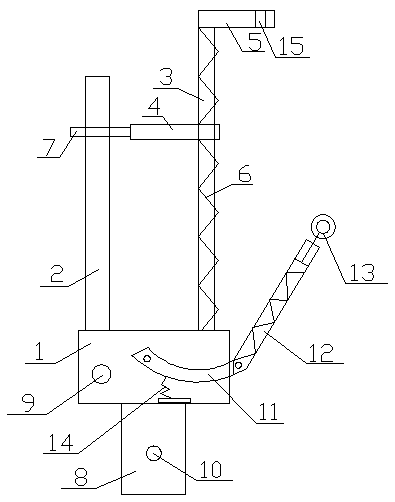

[0013] A new type of braiding machine spindle, comprising a spindle base 1, the upper end of the spindle base 1 is provided with a bobbin shaft 2 and a spindle support bar 3 parallel to each other, the spindle support bar 3 is covered with a moving sleeve 4, and the upper end of the spindle support bar 3 is provided with There is a horizontal plate 5, springs 6 are respectively arranged between the horizontal plate 5 and the moving sleeve 4 and between the moving sleeve 4 and the spindle base 1, and a pressure ring 7 is arranged on the side wall of the moving sleeve 4, and the pressure ring 7 sets On the bobbin shaft 2, the lower end of the spindle base 1 is provided with a rotating shaft 8, the side wall of the spindle base 1 is provided with an oil injection hole 9, the side wall of the rotating shaft 8 is provided with an oil outlet hole 10, and the spindle base 1 and the rotating shaft 8 are provided with communication The channel of the oil injection hole 9 and the oil out...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com