Winding needle

A technology of rolling needles and needle holders, which is applied in the direction of sustainable manufacturing/processing, electrochemical generators, electrical components, etc., can solve the problems of "S-shaped" deformation of batteries, achieve improved S-shaped deformation, and improve long-term cycle Performance and use of safe, easy-to-achieve effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] In order to present the purpose and technical solution of the present invention more clearly to everyone, the following description will further describe the technology of the present invention in detail in conjunction with the accompanying drawings and specific implementation methods.

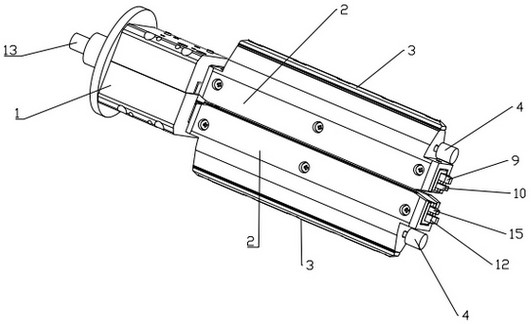

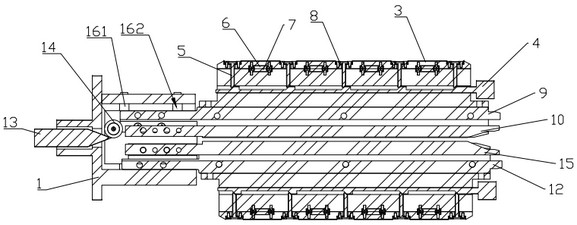

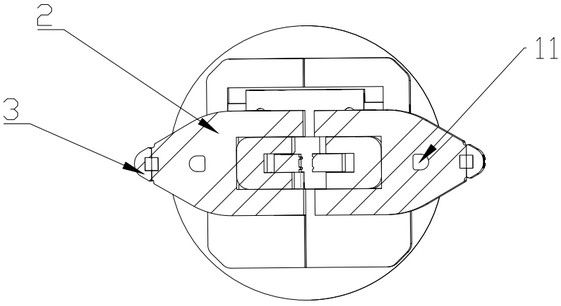

[0027] figure 1 , 2 , 3, 4, and 5, the present invention includes an outer cover 1 and a needle roll cover, the needle roll cover is divided into a needle roll cover main body 2 and a needle roll cover auxiliary body 3, and the inside of the needle cover main body 2 is provided with an outer needle seat, a needle clamp , the above constitutes the main structure of the rolling needle. The needle cover main body 2 is additionally provided with a pin connecting rod 4, and the needle cover auxiliary body 3 is provided with a latch 5, an upper magnet 6, and the latch 5, an upper magnet 6 and the pin connecting rod 4 set in the needle cover main body 2 , Lower magnet 7 constitutes interlock...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com