Self-adjusting type steel bar winding device

A winding device and self-adjusting technology, applied in the field of steel bars, can solve the problems of inconvenient disassembly of steel bars and different weights of steel bars, and achieve the effects of preventing steel bars from falling, reducing human accidents and reducing costs.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

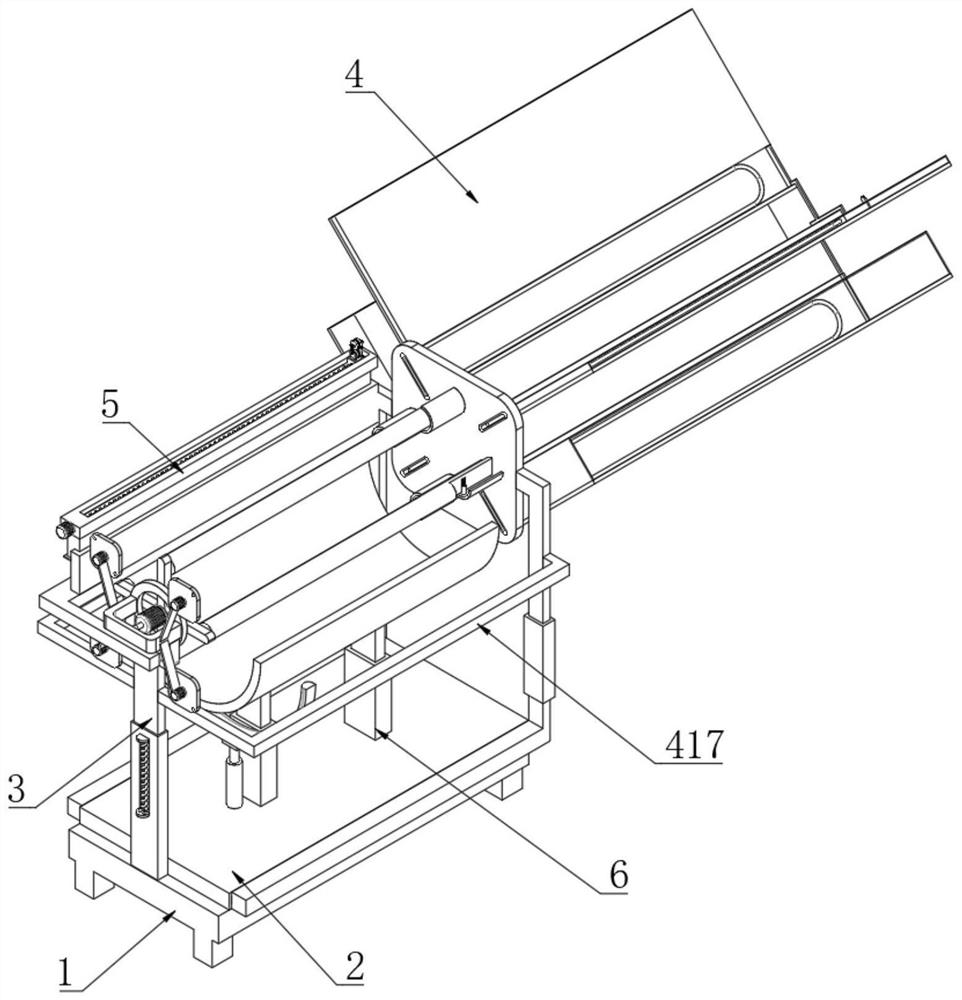

[0043] Example: such as Figure 1-9 As shown, the present invention provides a technical solution, a self-adjusting steel bar winding device, including a support frame 1, and a mounting plate 2 is fixedly installed on the top surface of the support frame 1;

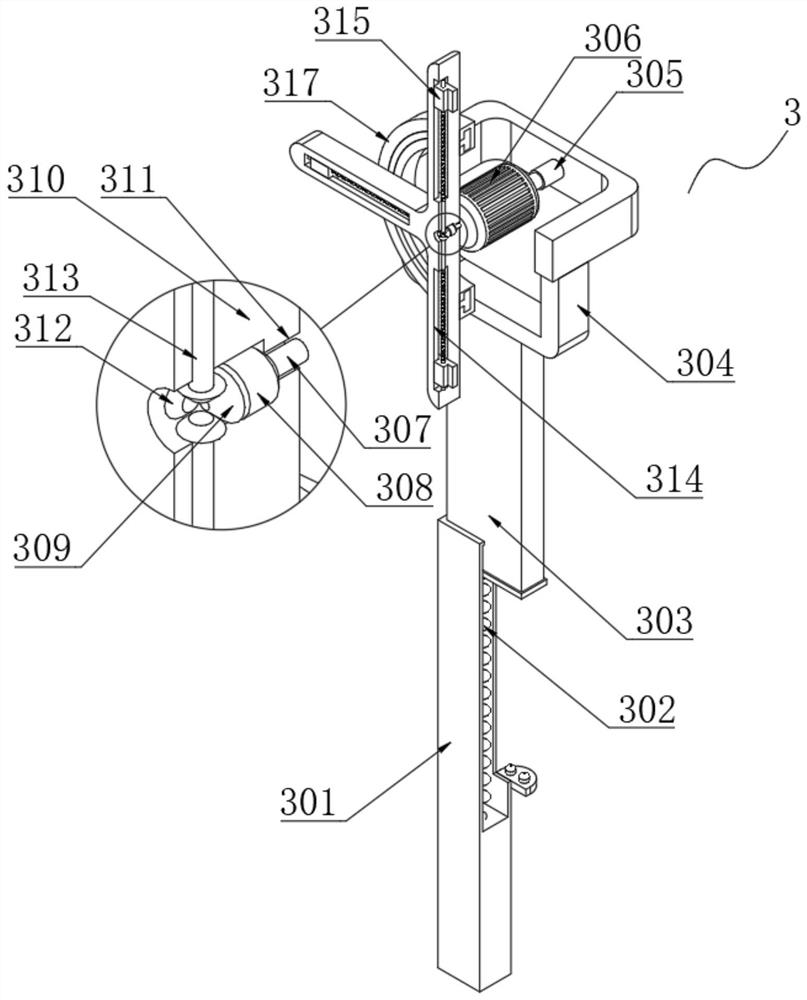

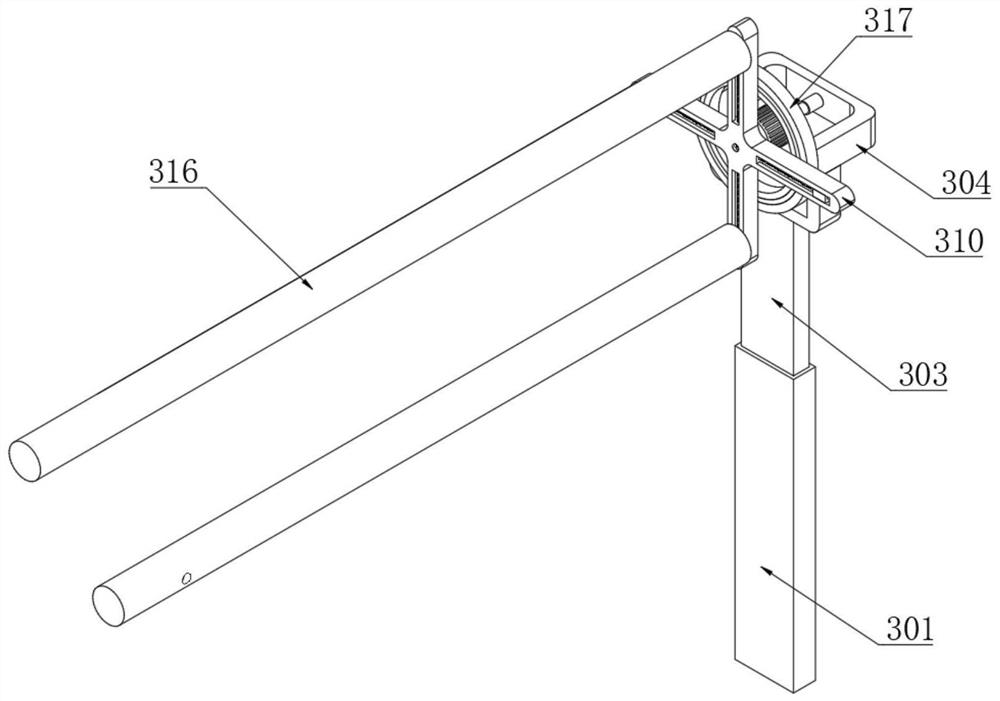

[0044] One end of the top surface of the mounting plate 2 is fixedly installed with an adjustable rewinding assembly 3, which is convenient for unloading the rebar after rewinding, and can realize the self-stop function, thereby ensuring the consistency of rewinding the rebar;

[0045] The other end of the mounting plate 2 is fixedly installed with a self-propelled binding assembly 4, which realizes automatic binding of the reeled steel bars, thus avoiding manual binding, thereby improving the efficiency of binding;

[0046] One end of the adjustable rewinding assembly 3 is equipped with a self-lifting traction assembly 5, which can rewind the steel bars during the rolling process, thereby avoiding the problem of mutual w...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com