Toluene-containing tail gas recycling process in refractory mica tape production

A technology for refractory mica and tail gas recovery, applied in the fields of resource recycling and environmental protection, can solve problems such as inflammable, explosive, unsafe, and achieve the effect of solving production safety problems, simple treatment process and good absorption effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

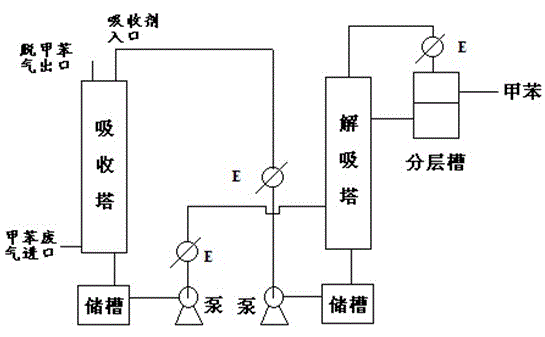

Image

Examples

Embodiment 1

[0022] Contains toluene 1250mg / m 3 The exhaust gas enters the absorption tower, with 9% (mass percentage) sodium citrate aqueous solution (adding sodium silicate in an appropriate amount), with 4.5kg 吸收液 / kg 气 At 40°C and 0.1MPa, the gas-liquid countercurrent contact is carried out to complete the toluene absorption process; after absorption by the absorption liquid, the toluene concentration in the toluene-removed gas is 42.3 mg / m 3 The toluene-containing absorption liquid enters the storage tank, and the toluene-containing absorption liquid is heated by a heater to enter the desorption tower for desorption, and the toluene-water azeotrope is obtained at the top of the desorption tower. Rich in toluene, toluene is obtained after drying; the desorbed absorption liquid enters the storage tank, and the absorption liquid is cooled by a cooler with a pump and then transported to the top of the absorption tower for absorption and reuse.

Embodiment 2

[0024] Contains toluene 850mg / m 3 The tail gas enters the absorption tower, with 5% (mass percentage) sodium acetate aqueous solution (adding appropriate amount of sodium p-toluene sulfonate), with 4.0kg 吸收液 / kg 气 The liquid-gas ratio, at 35°C and 0.1MPa, conduct gas-liquid countercurrent contact to complete the toluene absorption process; after absorption by the absorption liquid, the toluene concentration in the toluene-removed gas is 22.3 mg / m 3 The toluene-containing absorption liquid enters the storage tank, and the toluene-containing absorption liquid is heated by a heater to enter the desorption tower for desorption, and the toluene-water azeotrope is obtained at the top of the desorption tower. Rich in toluene, toluene is obtained after drying; the desorbed absorption liquid enters the storage tank, and the absorption liquid is cooled by a cooler with a pump and then transported to the top of the absorption tower for absorption and reuse.

Embodiment 3

[0026] Contains toluene 650mg / m 3 The tail gas enters the absorption tower, with 4% (mass percentage) sodium xylene sulfonate aqueous solution (sodium carbonate is added in an appropriate amount), with 3.6kg 吸收液 / kg 气 The liquid-to-gas ratio, at 25°C and 0.1MPa, conduct gas-liquid countercurrent contact to complete the toluene absorption process; after absorption by the absorption liquid, the toluene concentration in the toluene-removed gas is 16.3 mg / m 3 The toluene-containing absorption liquid enters the storage tank, and the toluene-containing absorption liquid is heated by a heater to enter the desorption tower for desorption, and the toluene-water azeotrope is obtained at the top of the desorption tower. Rich in toluene, toluene is obtained after drying; the desorbed absorption liquid enters the storage tank, and the absorption liquid is cooled by a cooler with a pump and then transported to the top of the absorption tower for absorption and reuse.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com