Pre-crosslinking gel retarding-swelling microsphere profile control agent and preparation method and application thereof

A pre-crosslinking and profile-modifying agent technology, applied in chemical instruments and methods, drilling compositions, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

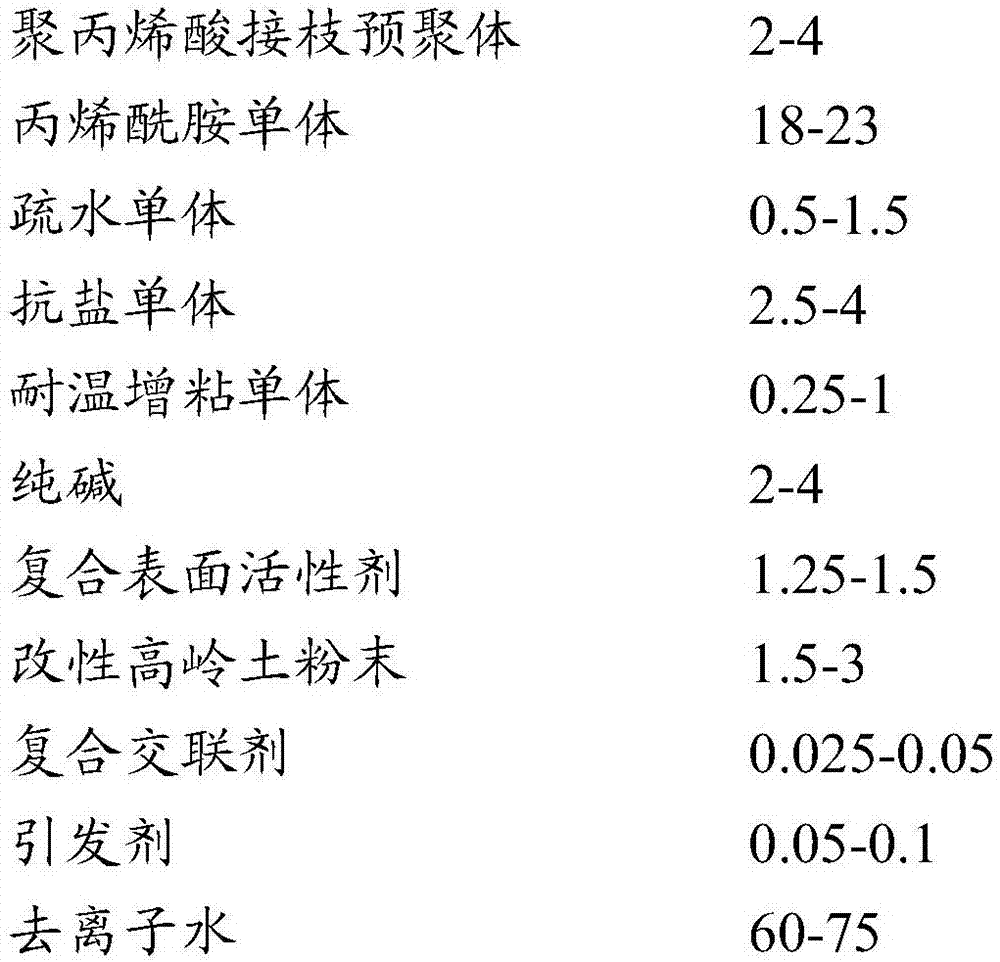

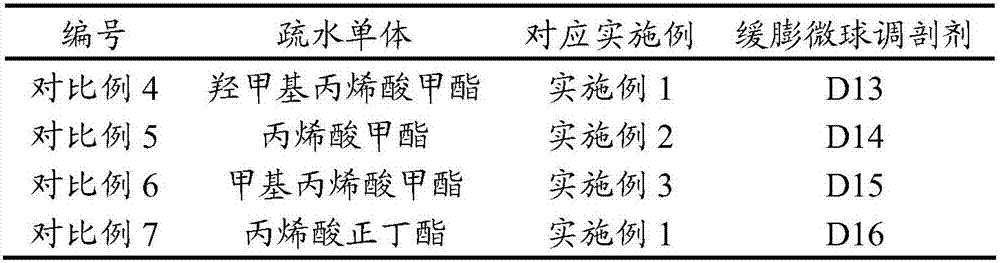

Method used

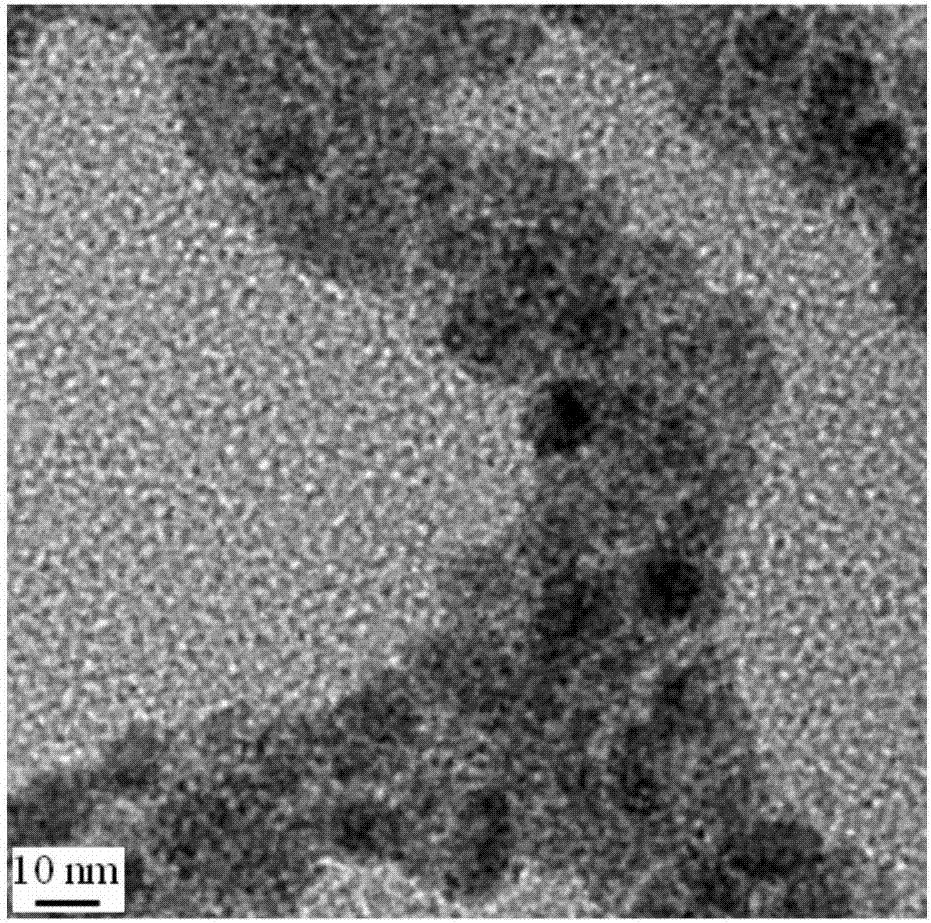

Image

Examples

preparation example 1

[0076] Preparation Example 1: Preparation of Polyacrylic Acid Graft Prepolymer

[0077] A1: Heat the aqueous solution of polyvinyl alcohol with a concentration of 2% by mass to 85°C, add a solution of polyethylene glycol 6000 with a concentration of 0.5% by mass and stir to dissolve (wherein, the aqueous solution of polyvinyl alcohol with a concentration of 2% by mass is mixed with Mass percent concentration is 0.5% polyethylene glycol 6000 aqueous solution weight ratio is 1:2.5), then add the glycerol that is 0.6% polyvinyl alcohol weight and stir to dissolve (the weight of glycerin is the polyvinyl alcohol in the polyvinyl alcohol aqueous solution 0.6% by weight), to obtain mixture I;

[0078] A2: Dilute acrylic acid with deionized water to a mass percent concentration of 9%, add NaOH aqueous solution (wherein the molar ratio of acrylic acid to NaOH is 1:0.6), and react at room temperature for 15 minutes. After the reaction, adjust the reaction system. pH value is 8-9, obta...

preparation example 1-1

[0080] Preparation Example 1-1: Preparation of Polyacrylic Acid Graft Prepolymer

[0081] Except that no sodium metabisulfite was added in step A3, other operations remained unchanged, so the operation of Preparation Example 1 was repeated, and the obtained polyacrylic acid grafted prepolymer was named JBX1.

preparation example 2

[0082] Preparation Example 2: Preparation of Modified Kaolin Powder

[0083] B1: Calcining kaolin at 550° C. for 50 minutes, then naturally cooling to room temperature, and crushing to a particle size of 10-15 nm to obtain heat-treated kaolin powder;

[0084] B2: Spray atomized simethicone oil into heat-treated kaolin powder (wherein the mass ratio of heat-treated kaolin powder to atomized simethicone oil is 1:0.08), and fully mix to obtain oil-based kaolin, then The oil-based kaolin is added to an appropriate amount of absolute ethanol, and then the coupling agent succinyl-bis(trimethoxysilylpropyl sulfide) is added (wherein, the mass ratio of the heat-treated kaolin powder to the coupling agent is 1: 0.02), and fully stirred at 40°C for 35 minutes, and stood overnight to obtain a mixed solution;

[0085] B3: Centrifuge the mixed solution, and wash the obtained solid with ethyl acetate and acetone for 2-3 times in sequence, and then vacuum-dry to obtain the modified nano-kao...

PUM

| Property | Measurement | Unit |

|---|---|---|

| shear viscosity | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com