Method for achieving interval waterflood swallowing-spitting oil exploitation among multi-stage fracturing horizontal well fractures

A technology for horizontal wells and fracturing, which can be used in the development of fluids, earth-moving drilling, wellbore/well components, etc., and can solve the problems of no utilization, low production efficiency, and increased oil production.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0060] In order to further understand the content of the present invention, the present invention will be described in detail below in conjunction with specific examples.

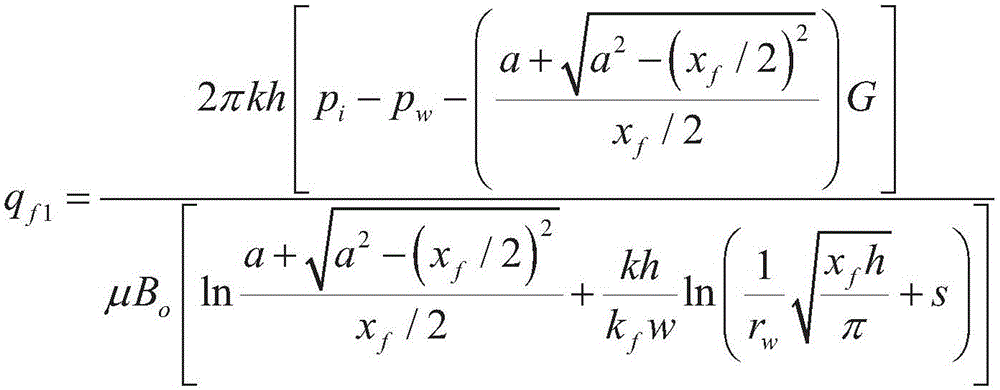

[0061] According to the multi-stage fracturing horizontal well fracture interval water injection huff and puff production method of the present invention, it comprises the following steps in sequence:

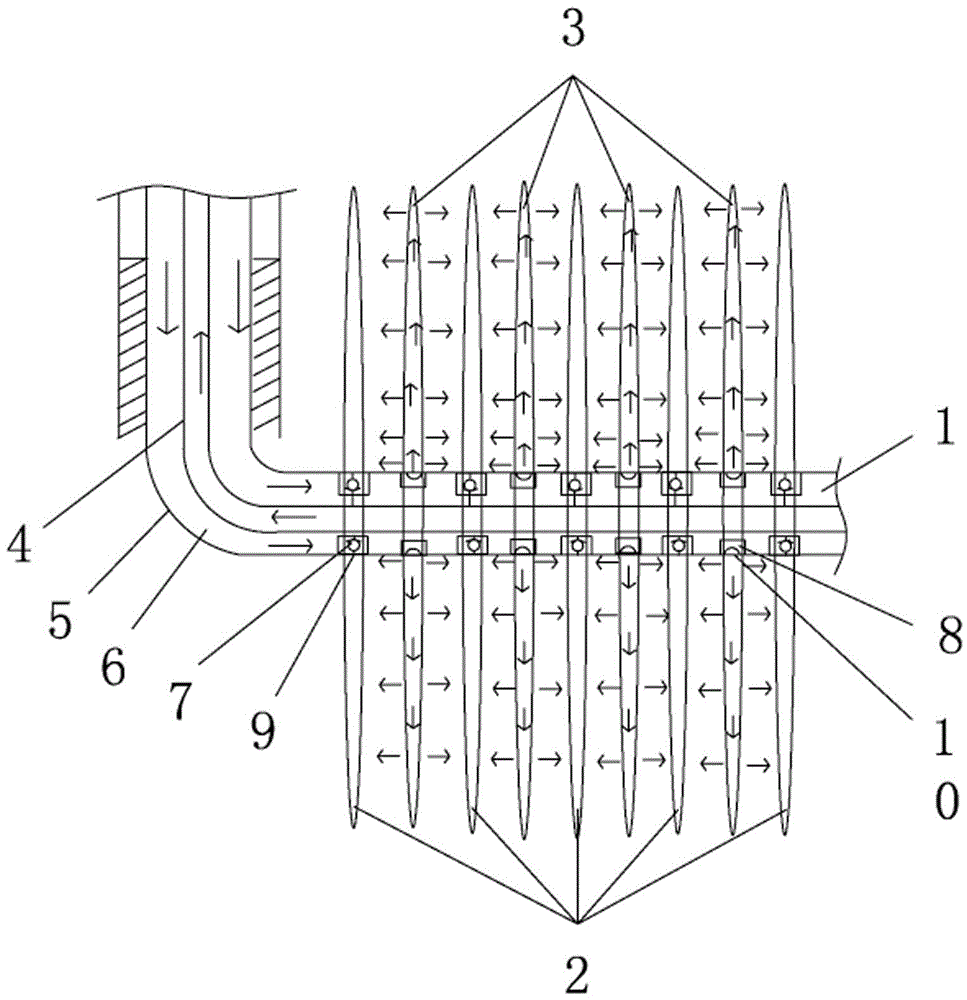

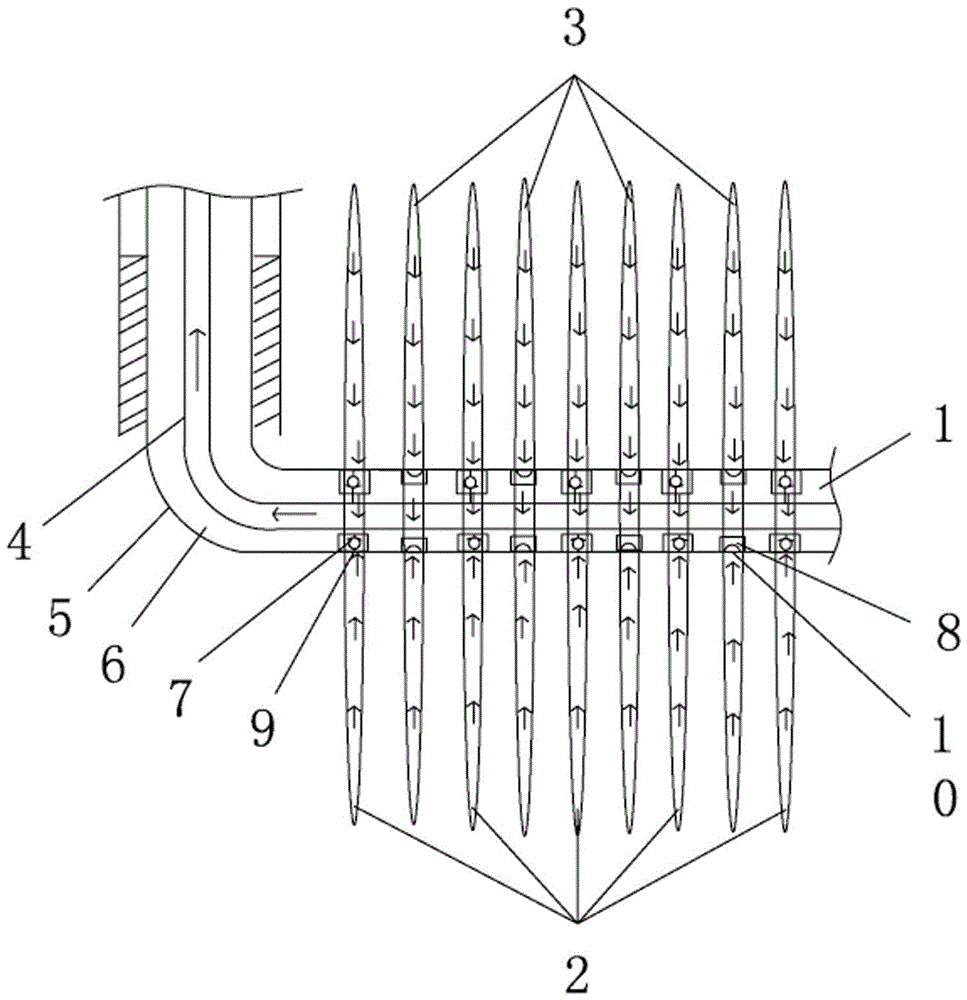

[0062] Step 1: Fracturing the wellbore of the horizontal well in stages to form multiple fracturing fractures perpendicular to the wellbore of the horizontal well;

[0063] Step 2: Set a one-way valve at the position of each odd-numbered crack, and set a dispensing valve at each even-numbered crack;

[0064] Step 3: In the early stage of production, use natural energy to mine for a period of time until the bottom hole pressure drops to the bubble point pressure;

[0065] Step 4: Use fracture interval water injection huff and puff to mine, automatically close the one-way valve, automatically open the dispens...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com