Water-gathering co-well layering co-charging process tubular column

A technology for process strings and outer tubing, applied in the direction of drilling pipes, casings, drilling equipment, etc., can solve problems such as the greater influence of interlayer thickness, the greater influence of oil field production, and the reduction of subsequent water flooding production contributions, etc., to achieve The effect of improving displacement efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0010] The present invention will be further described below in conjunction with accompanying drawing:

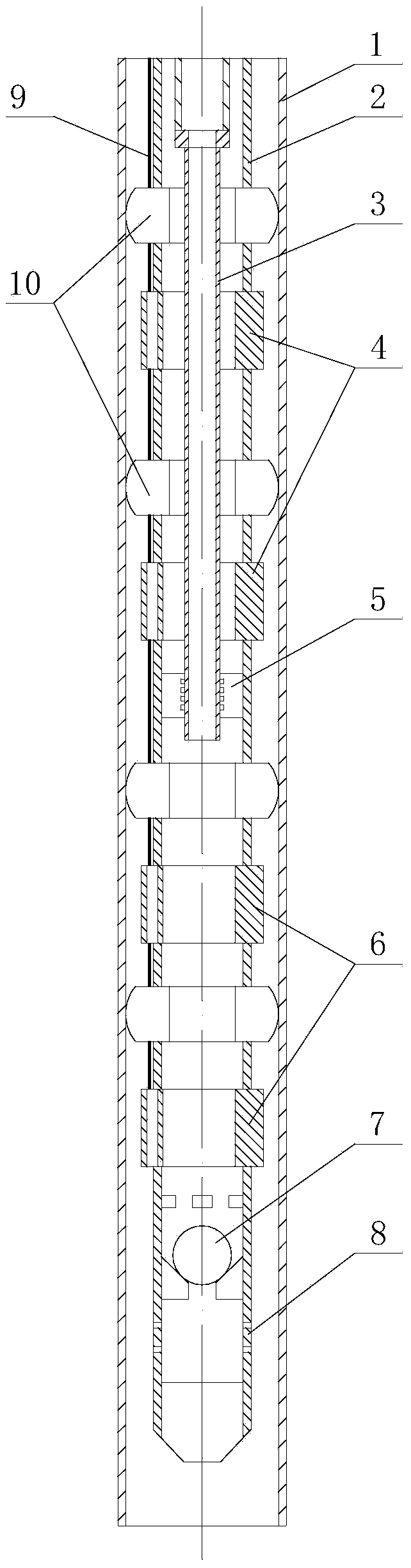

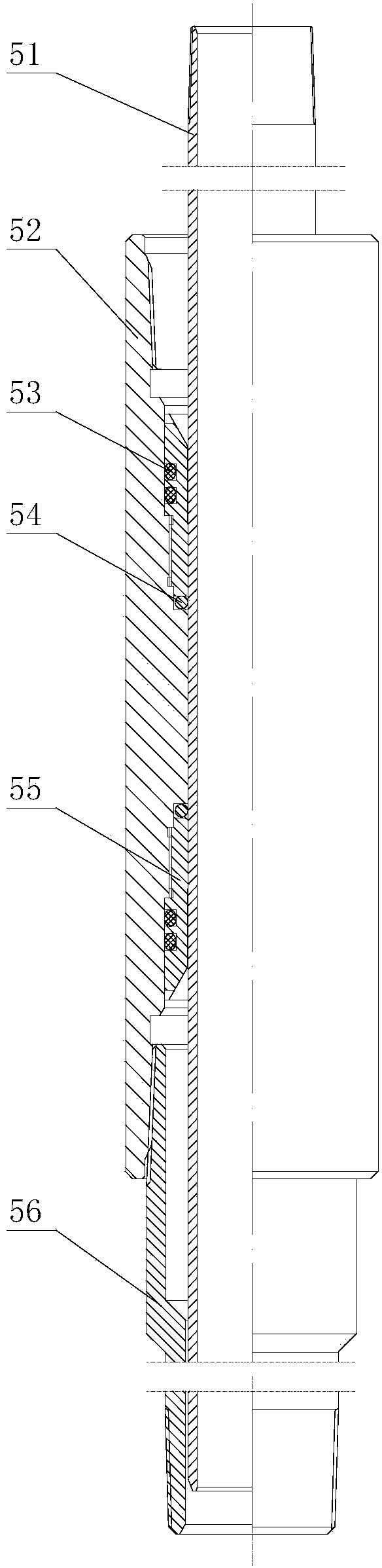

[0011] Depend on figure 1 , figure 2 As shown, a string of water-accumulating and co-well delamination and simultaneous injection process includes a casing 1, and an outer tubing 2 is arranged inside the casing 1, and the outer tubing 2 is a 2-inch semi-flat tubing, and the casing 1 The annular space between the outer tubing 2 and the outer tubing 2 is divided into different layers by several washable cable packers 10, and the cable 9 can pass through the above-mentioned washable cable packers 10, and each layer All of them are equipped with eccentric polymer injectors 4 correspondingly, and the polymer injectors 4 are electronically controlled. The inner oil pipe 3 is built inside the outer oil pipe 2, and a plug-in sealing device 5 is arranged between the bottom end of the inner layer oil pipe 3 and the outer layer oil pipe 2, and an eccentric water distribution device...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com