Piezoelectric device, liquid discharging head, and liquid discharging apparatus

一种压电器件、压电元件的技术,应用在压电/电致伸缩/磁致伸缩器件、压电器件的或电致伸缩器件的零部件、电气元件等方向,能够解决龟裂、振动板出现裂纹、妨碍振动板位移等问题

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 approach

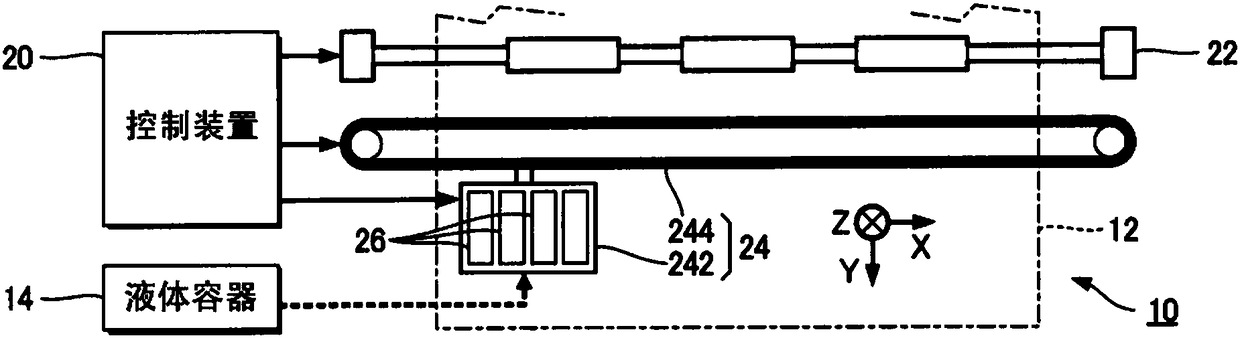

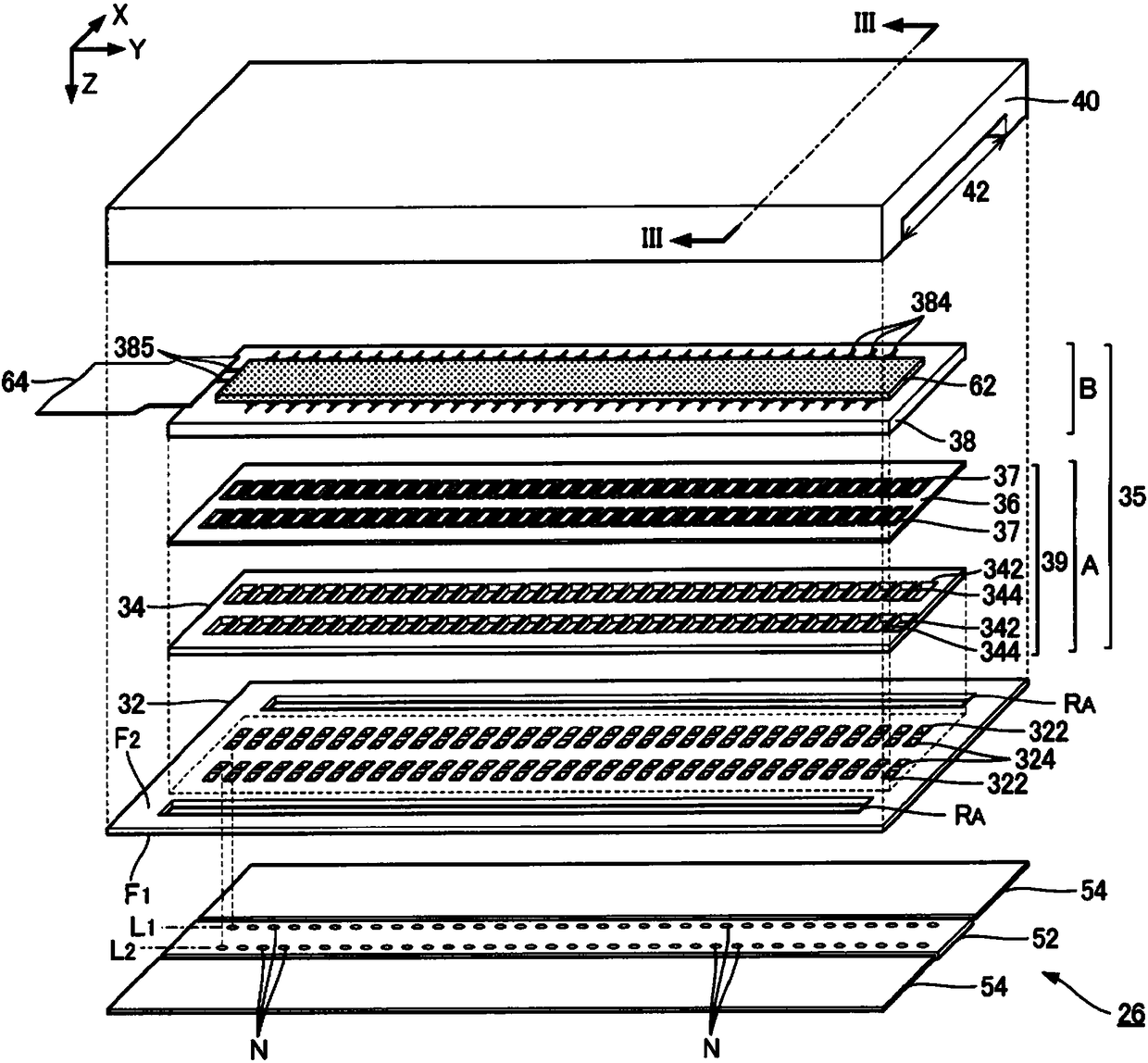

[0034] figure 1 It is a configuration diagram illustrating an example of the liquid ejection device 10 according to the first embodiment of the present invention. The liquid ejection device 10 of the first embodiment is an inkjet printing device that ejects ink as an example of a liquid onto a medium 12 . The medium 12 is typically printing paper, but any printing target such as a resin film or cloth can also be used as the medium 12 . like figure 1 As shown, a liquid container 14 for storing ink is fixed in the liquid ejection device 10 . As the liquid container 14 , for example, an ink cartridge detachable from the liquid ejection device 10 , a pouch-shaped ink pack formed of a flexible film, or an ink tank capable of replenishing ink can be used. A plurality of inks of different colors are stored in the liquid container 14 .

[0035] like figure 1 As shown, the liquid ejection device 10 includes a control device 20 , a transport mechanism 22 , a moving mechanism 24 , a...

no. 2 approach

[0087] A second embodiment of the present invention will be described. In each of the embodiments exemplified below, the symbols used in the description of the first embodiment are used for the elements having the same functions or functions as those of the first embodiment, and detailed descriptions thereof are appropriately omitted. While the first embodiment exemplifies the case where the vibration plate 36 is formed from a single crystal silicon substrate whose crystal plane is the (100) plane, the second embodiment exemplifies the case where the crystal plane is the (110) plane A case where the vibration plate 36 is formed of a single crystal silicon substrate (the crystal plane orientation perpendicular to the crystal plane is [110]).

[0088] Figure 10 It is a graph showing an example of the anisotropy of Young's modulus in the (110) plane of a single crystal silicon base material whose crystal plane is the (110) plane. exist Figure 10 middle, Figure 10 is a pola...

no. 3 approach

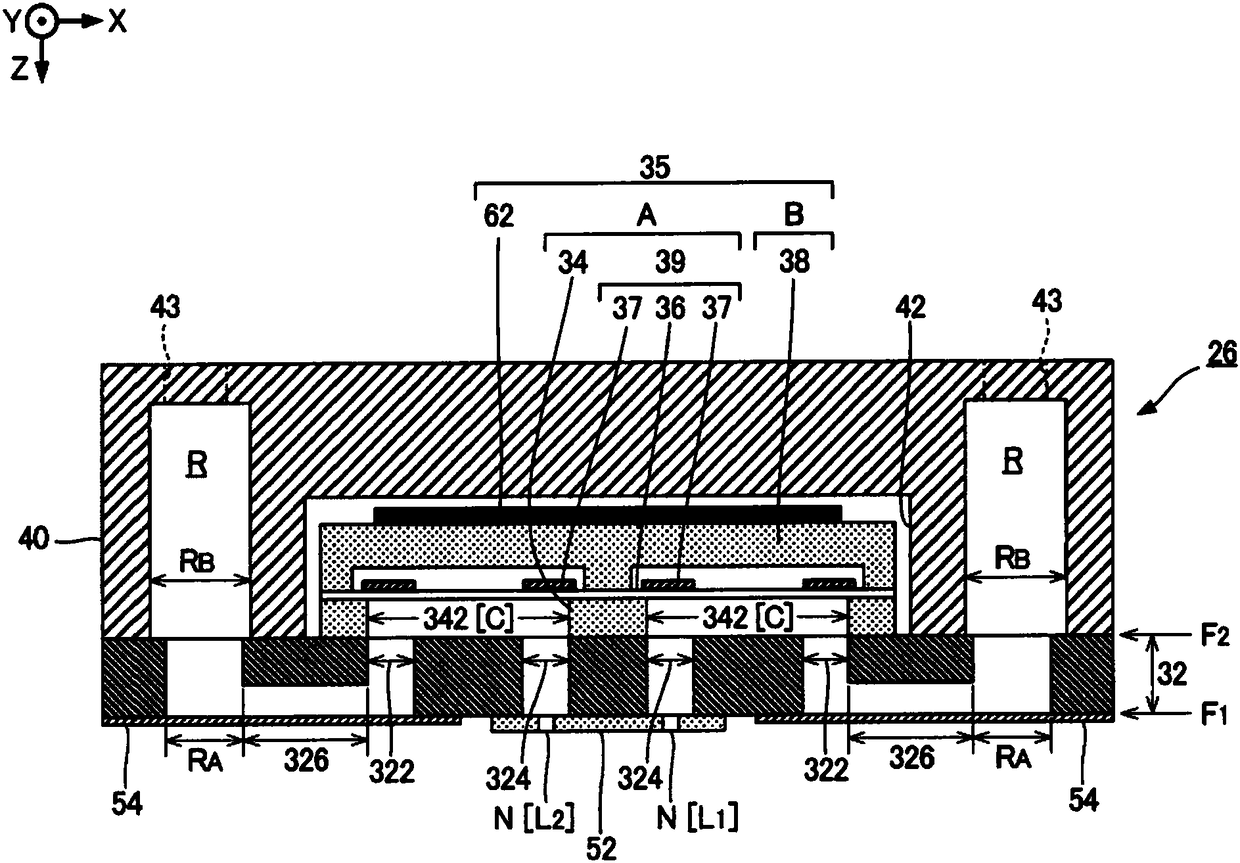

[0107] A third embodiment of the present invention will be described. While in the first and second embodiments, the case where the outer edge 37B of the piezoelectric element 37 has a shape similar to the shape of the inner edge 37A was exemplified, in the third embodiment, the piezoelectric element 37 is exemplified The shape of the outer edge 37B is not a shape similar to the shape of the inner edge 37A.

[0108] The width T of the piezoelectric element 37 is the width between the inner edge 37A and the outer edge 37B. For example, if Figure 4 As shown, the width T of the piezoelectric element 37 can be divided into the width Ta of the portion overlapping the above-mentioned pressure chamber C in plan view and the width Tb of the portion overlapping the side wall 344 of the pressure chamber C in plan view. . The width Ta of the piezoelectric element 37 is the width of the inner peripheral portion 372a, and the width Tb is the width of the outer peripheral portion 372b. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com