Oil displacement method using anion-cation complex surfactant

A composite surfactant and surfactant technology, applied in chemical instruments and methods, production fluids, earthwork drilling and production, etc., can solve problems such as poor oil displacement efficiency, difficulty in demulsification of corroded equipment and pipelines, damage to formations and oil wells, etc. , to achieve the effects of high interfacial activity, enhanced oil recovery, and expanded swept volume

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

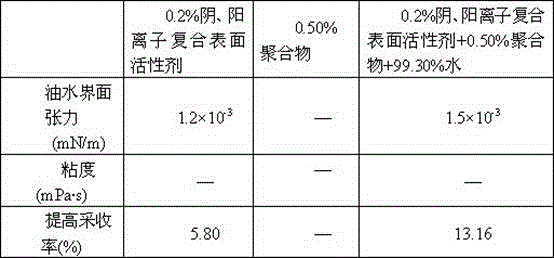

[0024]Dissolve phenyltrimethylammonium chloride and sodium sulfosalicylate in water respectively, and then mix the above two solutions evenly according to the molar ratio of phenyltrimethylammonium chloride and sodium sulfosalicylate 1:0.1 , to obtain anion and cation composite surfactants. Dissolve ultra-high molecular weight polyacrylamide in water to prepare an aqueous solution. Then mix the aforementioned 0.2wt% negative and positive composite surfactant, 0.15wt% ultra-high molecular weight polyacrylamide and 99.65wt% injection water from the offshore block of Shengli Oilfield and stir for 2 hours to obtain a uniform and transparent high-efficiency oil displacement agent .

[0025] The TX-500C spinning drop interfacial tensiometer was used to measure the oil-water interface of anion and cationic composite surfactants (one-component system) and their composites with polymers (poly-surface binary system) and the offshore block IFA-8 of Shengli Oilfield. tension. The measu...

Embodiment 2

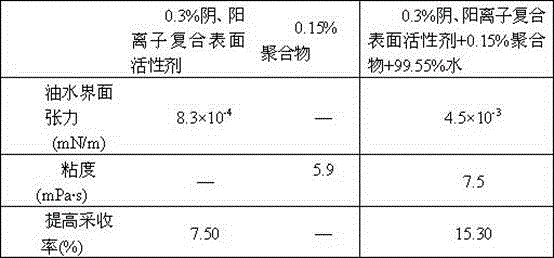

[0032] Dissolve decyltriethylammonium hydroxide and sodium α-olefin sulfonate (carbon chain length is C15-18) in water respectively, and then : 0.4 The above two solutions are mixed uniformly to obtain anion-cation complex surfactant. Dissolve ultra-high molecular weight polyacrylamide in water to prepare an aqueous solution. Then mix the aforementioned 0.05wt% negative and positive composite surfactant, 1.00wt% ultra-high molecular weight polyacrylamide and 98.95wt% injection water from the offshore block of Shengli Oilfield and stir for 2 hours to obtain a uniform and transparent high-efficiency oil displacement agent .

[0033] The TX-500C spinning drop interfacial tensiometer was used to measure the oil-water interface of anion and cationic composite surfactants (one-component system) and their composites with polymers (poly-surface binary system) and the offshore block IFA-8 of Shengli Oilfield. tension. The measured temperature is 60 o C, the salinity is 29858mg / L, C...

Embodiment 3

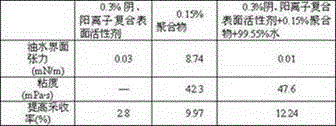

[0040] Dissolve tetraethylammonium chloride and lignosulfonate in water respectively, and then mix the above two solutions evenly according to the molar ratio of tetraethylammonium chloride and lignosulfonate of 1:1.4 to obtain anion-cation composite Surfactant. Dissolve ultra-high molecular weight polyacrylamide in water to prepare an aqueous solution. Then mix and stir the aforementioned 0.2wt% negative and positive composite surfactant, 0.15wt% ultra-high molecular weight polyacrylamide and 99.65wt% Henan Shuanghe Oilfield 5-11 layer injection water for 2 hours to obtain a uniform and transparent Efficient oil displacing agent.

[0041] The TX-500C spinning drop interfacial tensiometer was used to measure the interfacial tension of anion and cationic composite surfactants (one-component system) and their composites with polymers (poly-surface binary system) and the oil-water interfacial tension of the 5-11 layers of Henan Shuanghe Oilfield. . The measured temperature is ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com