A kind of nanocomposite oil displacement agent and its preparation method and application

A technology of nano-composite and oil-displacing agent, which is applied in chemical instruments and methods, drilling compositions, heat-exchange materials, etc., can solve the problem of increasing oil production workload, oil production raw materials and time costs, increase in interfacial tension, performance It can improve the displacement efficiency, reduce the interfacial tension, and reduce the cost of oil production.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

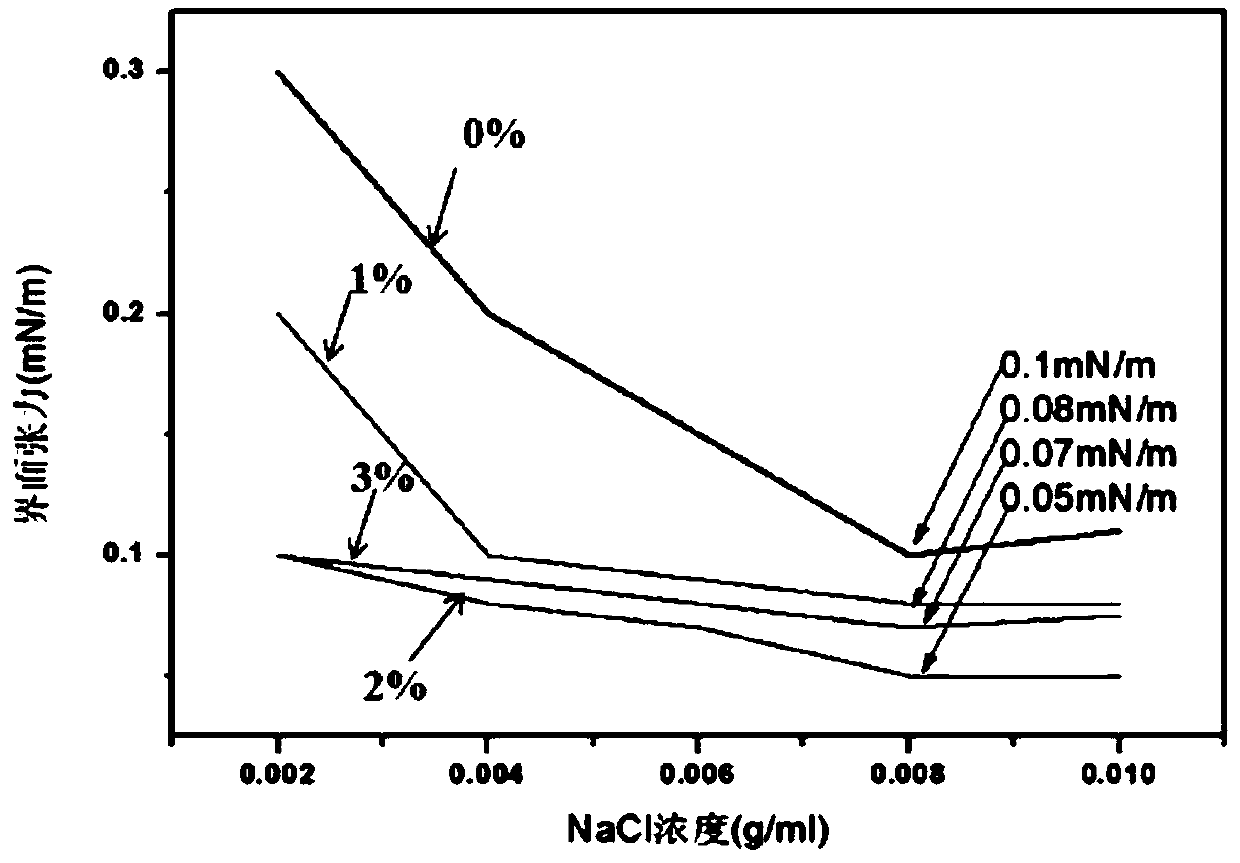

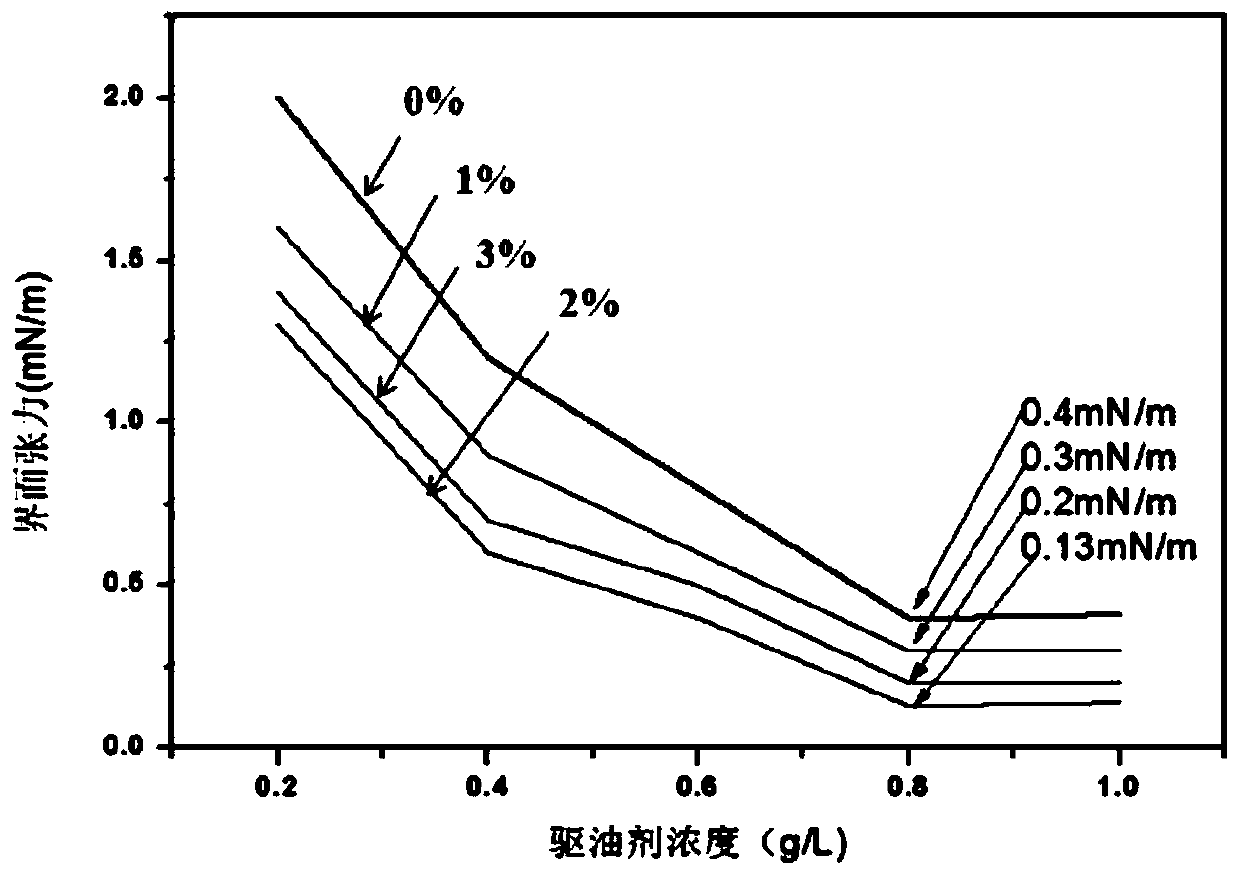

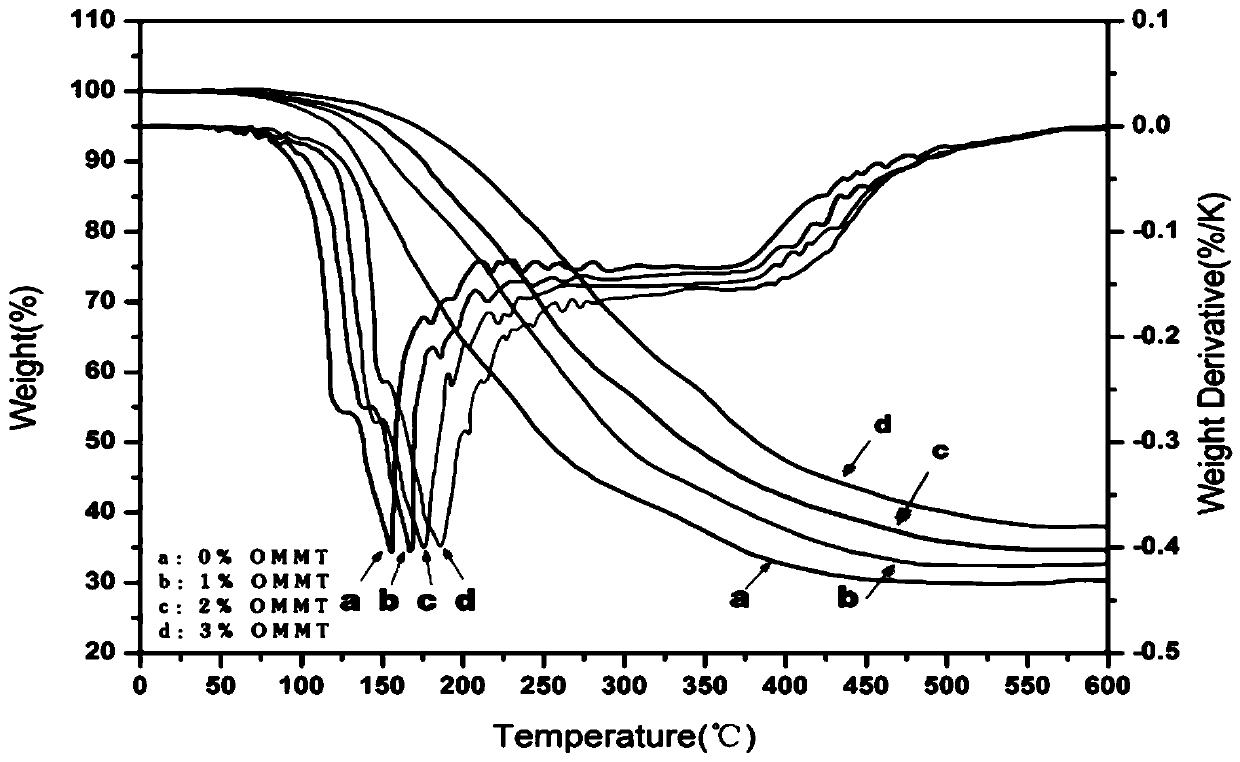

[0057] The present embodiment provides a kind of nanocomposite oil displacement agent, and its preparation method is as follows:

[0058] 1. Preparation of inorganic nano intermediates

[0059] a. Using co-precipitation method, mix montmorillonite and water in a 1 cubic meter multifunctional reaction kettle at a mass ratio of 1:15, and swell for 20 to 30 minutes at a stirring rate of 30 to 35 Hz to obtain a swelling system ;

[0060] b. Heat up the swelling system obtained above to 80°C, then add an intercalation agent cetyl ammonium bromide equivalent to 10% of the mass of the swelling system into the multifunctional reactor, set the mixer frequency to 30hz, and react for 12h;

[0061] c. Pour the reaction product obtained above into a cooling tank, wait for the temperature to drop to 30°C, and perform vacuum filtration;

[0062] d. The solid powder obtained by suction filtration was placed in a drying oven and dried at 65° C. to obtain an inorganic nano-intermediate, which...

Embodiment 2

[0077] Example 2 provides a nanocomposite oil displacement agent, the preparation process of which is basically the same as that of Example 1, the only difference being that in step 3-b, the added mass of the inorganic nano-intermediate is controlled to be 2% of the total mass of the mixed solution.

[0078] After testing, when the nanocomposite oil displacement agent product is dispersed in water, more than 95% (volume fraction) of the particle size distribution is within the range of 100-120nm.

Embodiment 3

[0080] Example 3 provides a nanocomposite oil displacement agent, the preparation process of which is basically the same as that of Example 1, the only difference being that in step 3-c, the added mass of inorganic nano intermediates is controlled to be 3% of the total mass of the mixed solution.

[0081] After testing, when the nanocomposite oil displacement agent product is dispersed in water, more than 95% (volume fraction) of the particle size distribution is within the range of 100-120nm.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com