Oil displacement type fracturing fluid system and preparation method thereof

A fracturing fluid and oil displacement technology, which is applied in the direction of chemical instruments and methods, drilling compositions, etc., can solve the problems of affecting oil field production, low flowback rate, and high output, and achieves easy on-site rapid preparation, on-site The effect of safe construction and simple preparation method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0041] The oil displacement fracturing fluid system of the present embodiment is composed of the following components in terms of mass percentage:

[0042] Guar gum (CJ2-6) 0.25%; ultra-low interfacial tension surfactant (EOS-3) 0.5%; potassium chloride (KCl) 1.0%; bactericide (CJSJ-3) 0.5%; the balance is water.

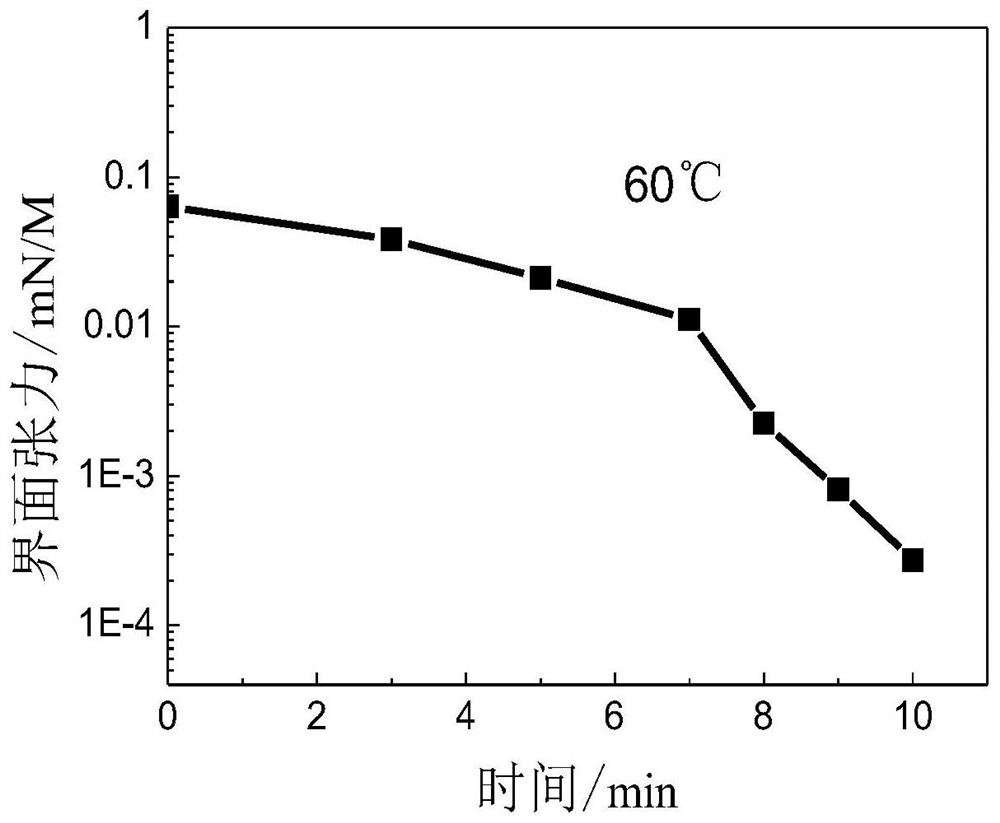

[0043] The preparation method of ultra-low interfacial tension surfactant (EOS-3): mix alkanolamide, sodium dodecylsulfonate and sulfobetaine according to the mass ratio of 2:1:1.6, the mass of the mixture Percentage is 40%, all the other are water, stir then, obtain ultra-low interfacial tension surfactant (EOS-3), its oil-water interfacial tension reaches 1.2 * 10 -3 mN / m.

[0044] The preparation method of the oil displacement type fracturing fluid system in this embodiment 1: according to the above mass percentage, take guar gum, ultra-low interfacial tension surfactant (EOS-3), potassium chloride (KCl), bactericide (CJSJ-3 ) and the remaining amount of water ...

Embodiment 2

[0047] The oil displacement fracturing fluid system of the present embodiment is composed of the following components in terms of mass percentage:

[0048] Guar gum (CJ2-6) 0.25%; ultra-low interface surfactant (EOS-3) 0.5%; potassium chloride (KCl) 3.0%; bactericide (CJSJ-3) 0.5%; the balance is water.

[0049] The preparation method of ultra-low interfacial tension surfactant (EOS-3): mix alkanolamide, sodium dodecylsulfonate and sulfobetaine according to the mass ratio of 2:1:1.6, the mass of the mixture Percentage is 40%, all the other are water, stir then, obtain ultra-low interfacial tension surfactant (EOS-3), its oil-water interfacial tension reaches 1.2 * 10 -3 mN / m.

[0050] The preparation method of the present embodiment 2 oil displacement type fracturing fluid system: according to the above mass percentage, take guar gum, ultra-low interfacial tension surfactant (EOS-3), potassium chloride (KCl), bactericide (CJSJ-3 ) and the remaining amount of water are mixed ...

Embodiment 3

[0053] The oil displacement fracturing fluid system of the present embodiment is composed of the following components in terms of mass percentage:

[0054] Guar gum (CJ2-6) 0.25%; ultra-low interfacial tension surfactant (EOS-3) 0.8%; potassium chloride (KCl) 1.8%; bactericide (CJSJ-3) 0.1%; the balance is water.

[0055] The preparation method of ultra-low interfacial tension surfactant (EOS-3): mix alkanolamide, sodium dodecylsulfonate and sulfobetaine according to the mass ratio of 2:1:1.6, the mass of the mixture Percentage is 40%, all the other are water, stir then, obtain ultra-low interfacial tension surfactant (EOS-3), its oil-water interfacial tension reaches 1.2 * 10 -3 mN / m.

[0056] The preparation method of the oil displacement type fracturing fluid system in this embodiment 3: according to the above mass percentage, take guar gum, ultra-low interfacial tension surfactant (EOS-3), potassium chloride (KCl), bactericide (CJSJ-3 ) and the remaining amount of water ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| interfacial tension | aaaaa | aaaaa |

| depth | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com