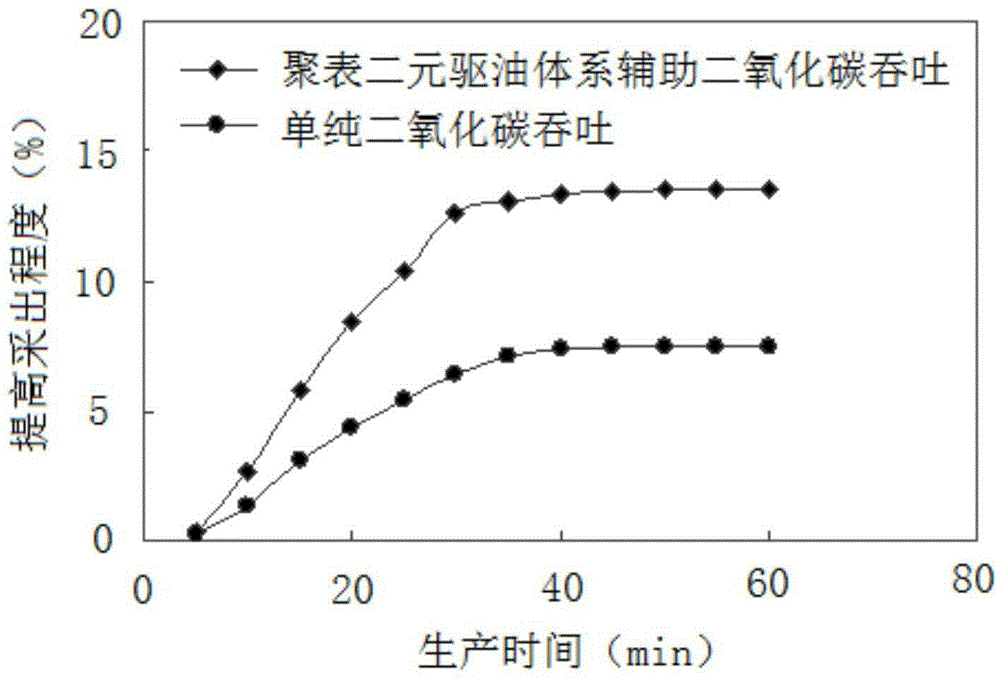

Oil extraction method with polymer-surfactant binary oil displacement system assisting in carbon dioxide huff and puff

A carbon dioxide and binary flooding technology, applied in chemical instruments and methods, production fluids, earthwork drilling, etc., can solve the problems of remaining crude oil not being produced, not being able to improve oil recovery, narrowing the scope of swept, etc. The effect of crude oil recovery, preventing the return of the original road, and improving the utilization rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0045] In this example, due to the small volume of the core used in the indoor core simulation experiment, in Example 1, the pre-slug of the poly-surface binary flooding system, the main carbon dioxide slug, and the post-position of the poly-surface binary flooding system The injection volumes of slugs, plugging agent slugs, and water are proportionally reduced.

[0046] 1. Prepare the pre-slug of the poly-surface binary flooding system, the main slug of carbon dioxide and the post-slug of the poly-surface binary flooding system

[0047] 1. Prepare the pre-slug of the poly-surface binary flooding system and the post-slug of the poly-surface binary flooding system

[0048] First add 99.45g of clear water to the liquid mixing tank, and then add 0.35g of it in turn with a viscosity average molecular weight of 2.5×10 6 Polyacrylamide, 0.04g lauryl dimethyl betaine and 0.16g hexadecyl trimethyl ammonium bromide, stir until completely dissolved to obtain the pre-slug of poly-surfac...

PUM

| Property | Measurement | Unit |

|---|---|---|

| viscosity | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| porosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com