Inner semi-ring connected oil cylinder dismantling tool

A connected, inner half-ring technology, which is applied in the field of mechanical engineering, can solve problems such as the uneven and synchronous advancement of the piston rod guide sleeve, improper operation, cylinder blockage, and damage to key parts, so as to improve safety performance and work efficiency. Protects the inner wall of the cylinder and improves the effect of static friction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

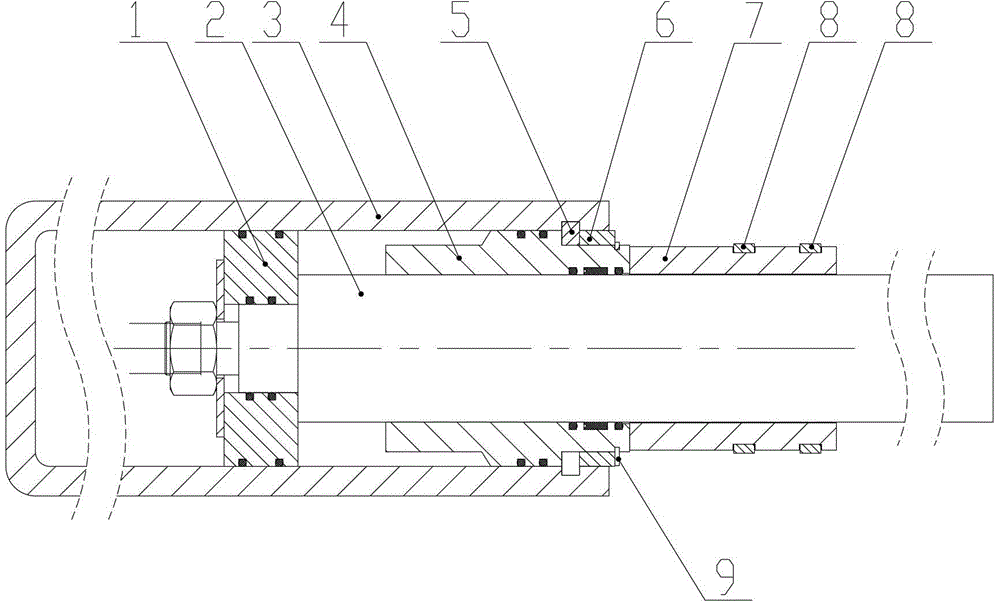

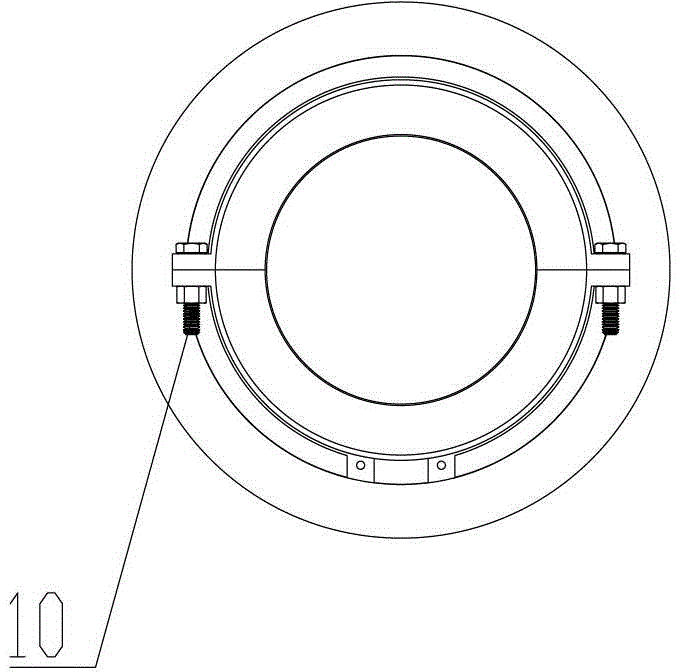

[0024] A dismantling tool for an inner half-ring connection type oil cylinder, including a jacking sleeve, a jacking sleeve locking ring and fasteners; the jacking sleeve is composed of two pieces, and the two pieces of the jacking sleeve are fastened on the piston rod Above; the jacking sleeve is provided with a locking ring of the jacking sleeve, and the locking ring of the jacking sleeve is equipped with fasteners for clamping.

[0025] There are two sets of jacking sleeve locking rings, each set consists of two pieces, the diameter of the inner hole of the jacking sleeve is slightly larger than the outer diameter of the piston rod by 0.1-3mm, and the outer diameter of the jacking sleeve is slightly smaller than the outer diameter of the piston rod guide sleeve The diameter of the outer circle at the center is 0.1-3mm; the fastener is a locking bolt, and the two locking rings of each set are fastened and installed together through the locking bolt. The inner hole of the jac...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com