Metal pipe wall thickness detection device and detection method

The technology of a detection device and detection method, which is applied in the field of ultrasonic detection, can solve the problems of detection of metal pipe wall thickness, low energy conversion efficiency, and reduction of eddy current area, so as to achieve the effect of stable measurement process, satisfying measurement and reducing damage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

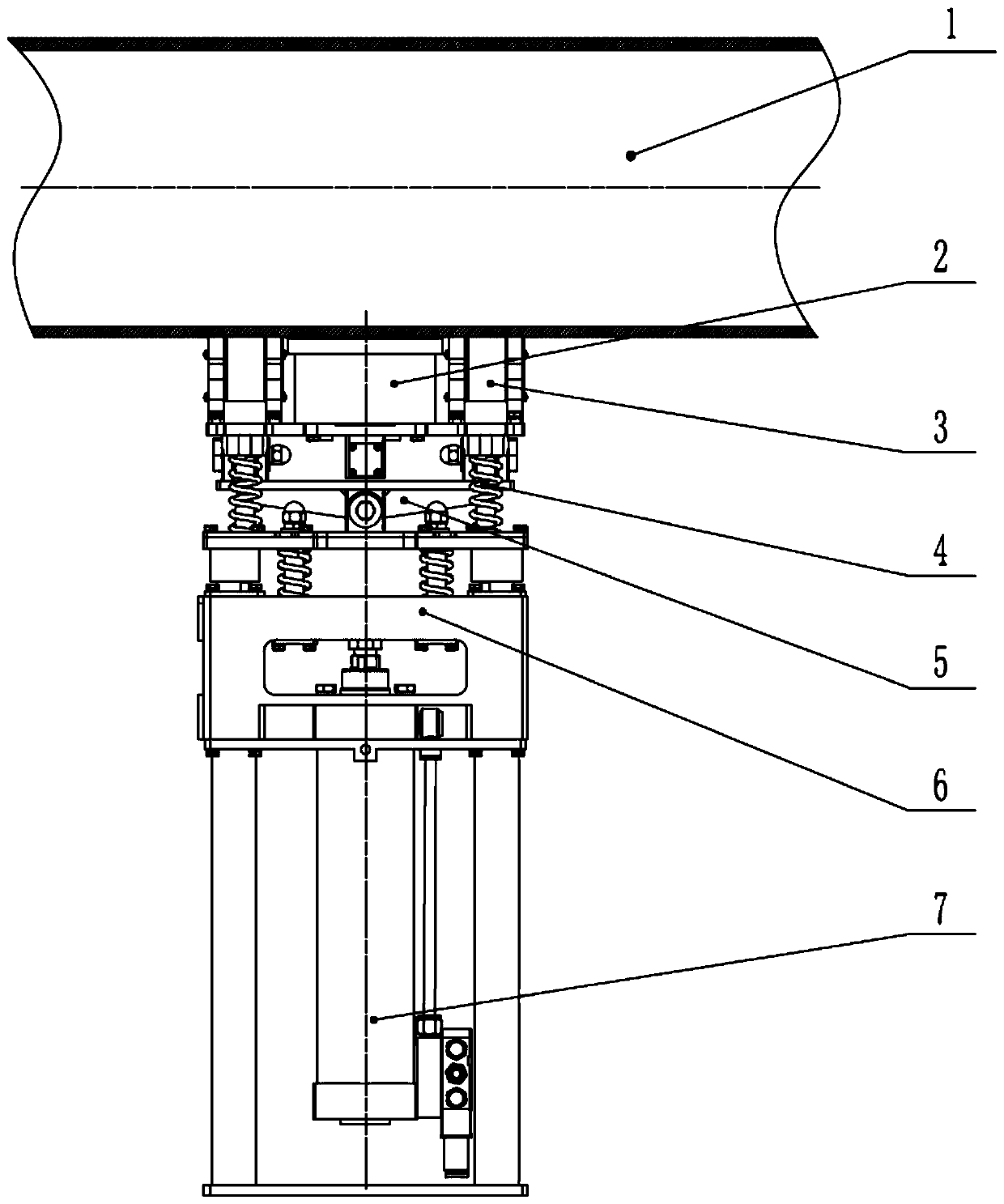

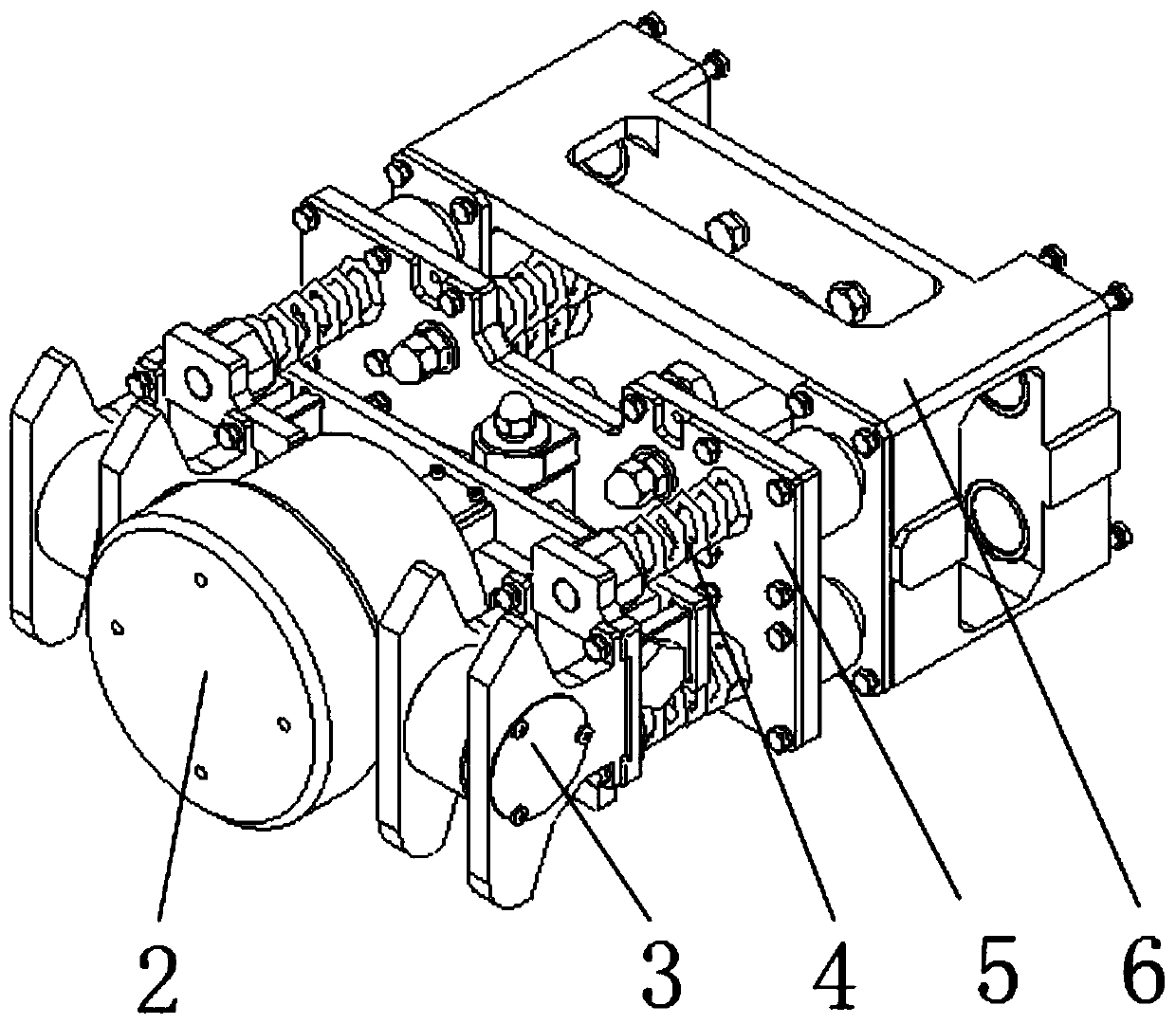

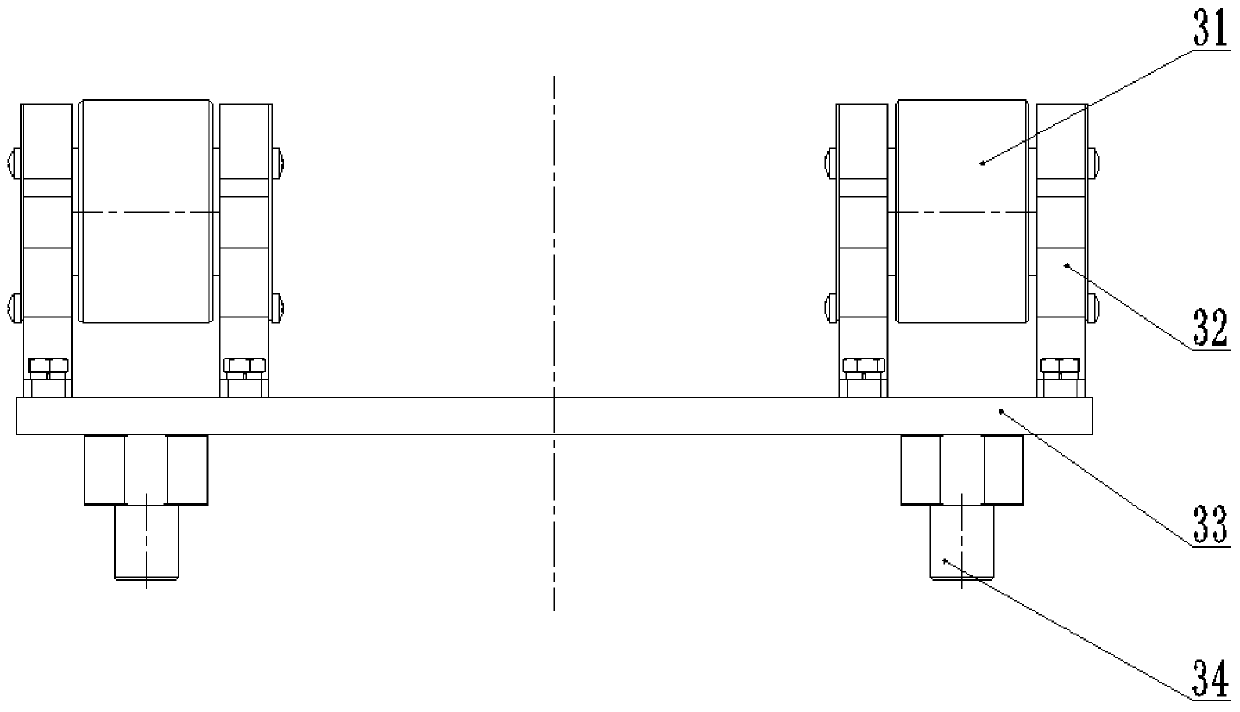

[0033] Such as Figure 1-7As described above, the present invention provides a metal pipe wall thickness detection device, including an electromagnetic ultrasonic sensor 2 for detecting the metal pipe wall thickness and a mounting part 33 for installing the electromagnetic ultrasonic sensor 2, and the present invention also includes a pusher for moving the electromagnetic ultrasonic sensor 2 6. The pushing member 6 is connected to the mounting member 33 through the buffer assembly 5 .

[0034] The electromagnetic ultrasonic sensor 2 of the present invention can be respectively connected with the signal generator and the signal processing electromechanical, and can also separately set up the signal receiving probe; 1, to detect the thickness of the pipe wall; during work, the signal generator provides an excitation signal to the electromagnetic ultrasonic sensor 2, and the signal processor collects and processes the signal of the thickness of the pipe wall induced by the electr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com