Patents

Literature

44results about How to "Advance evenly" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

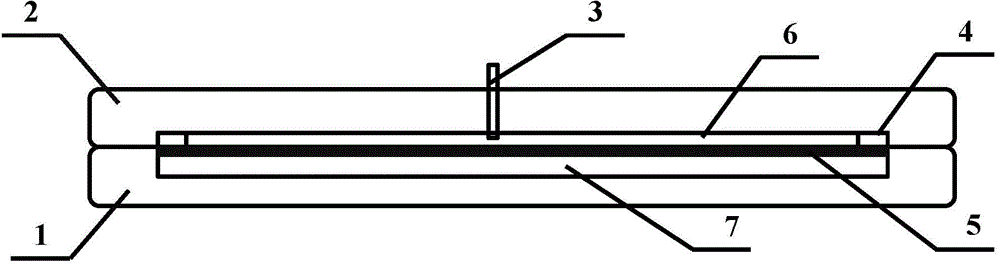

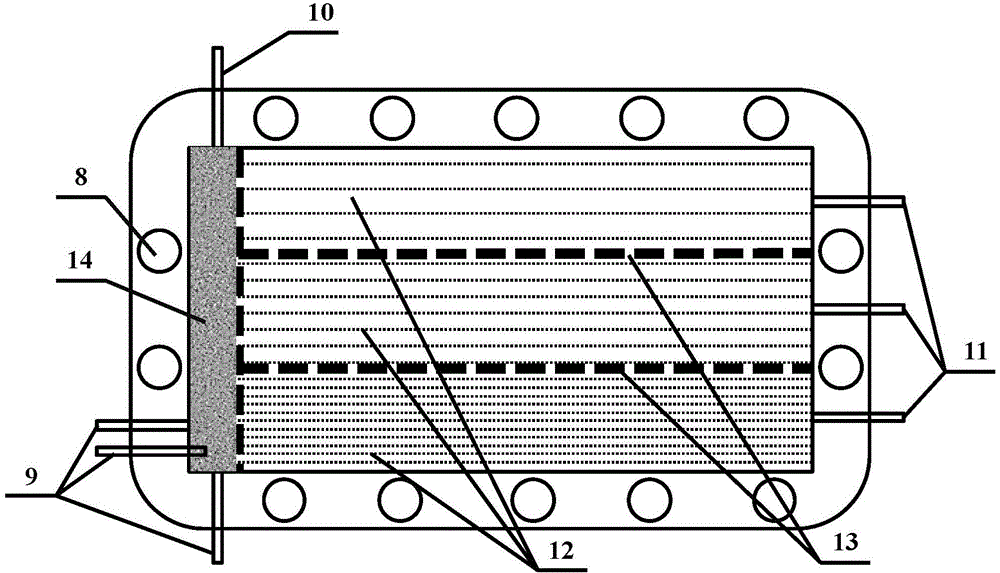

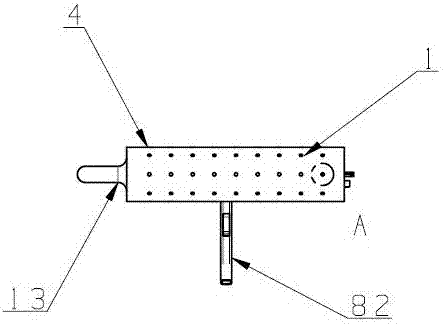

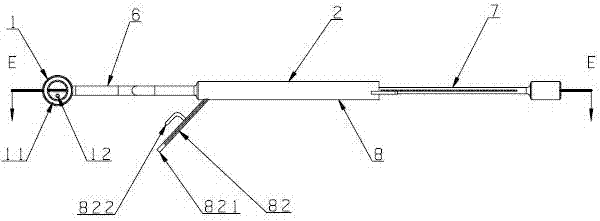

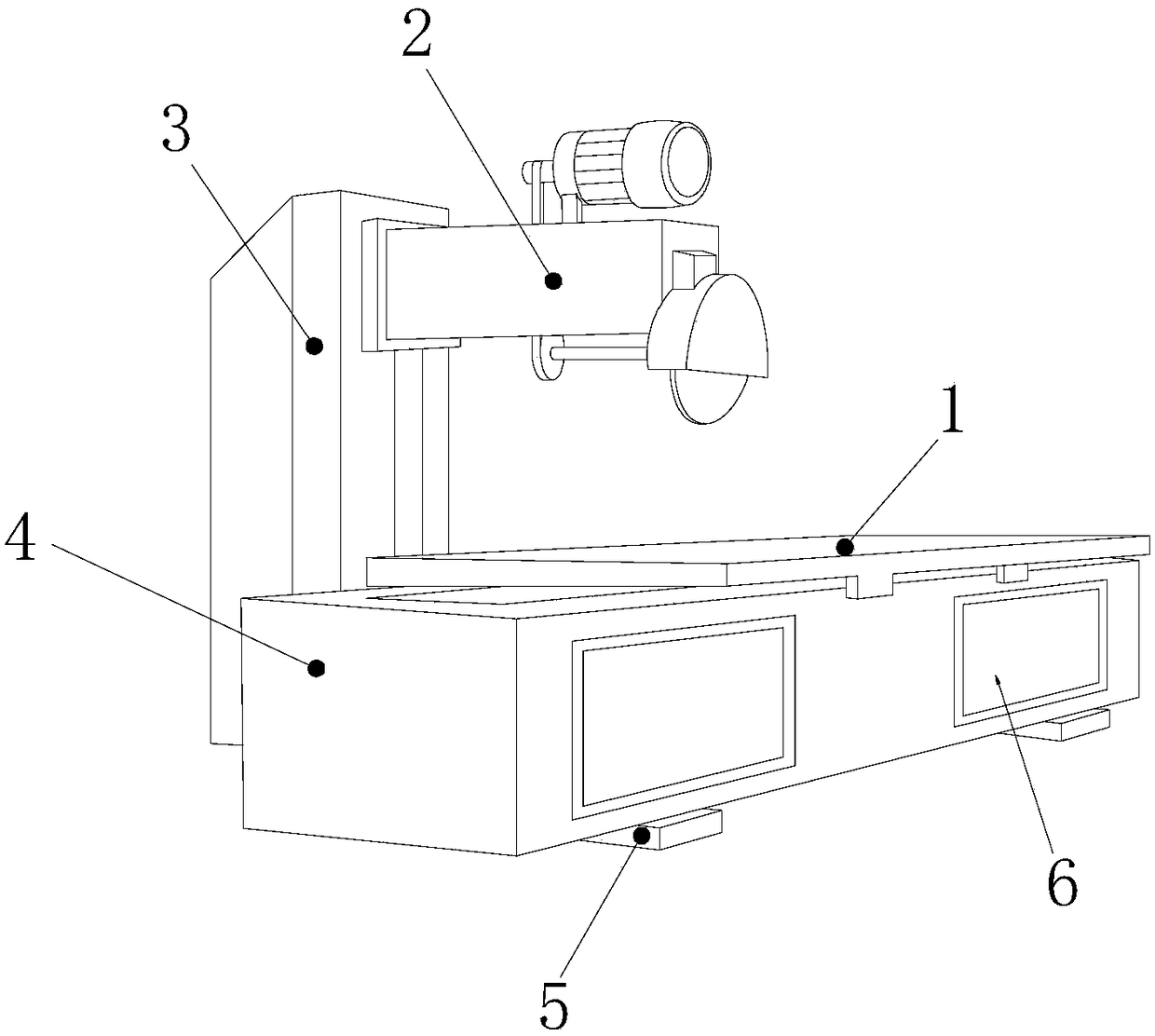

Anisotropic two-dimensional visual sand filling model in simulation layer and two-dimensional visual seepage experimental device

InactiveCN105096719AGuaranteed fluid exchangeDoes not cause migrationEducational modelsEngineeringPressure data

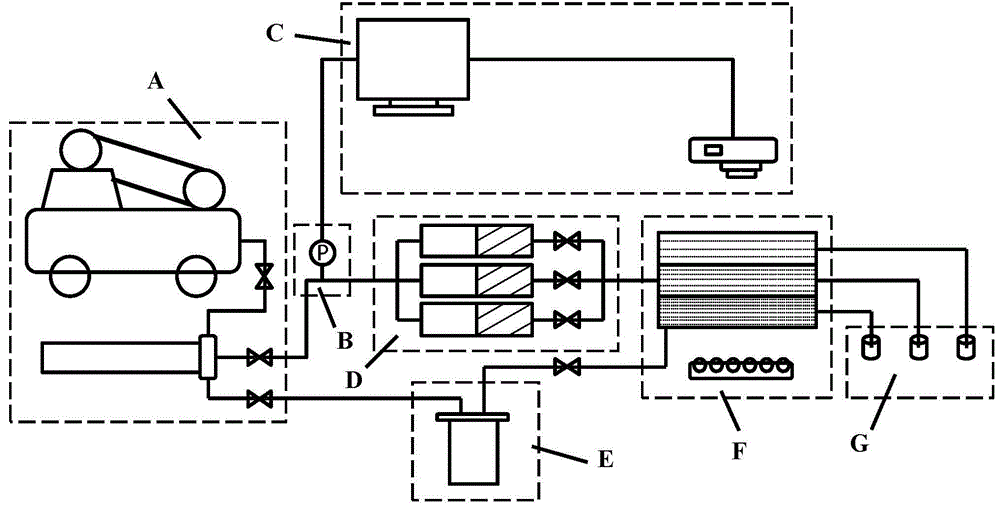

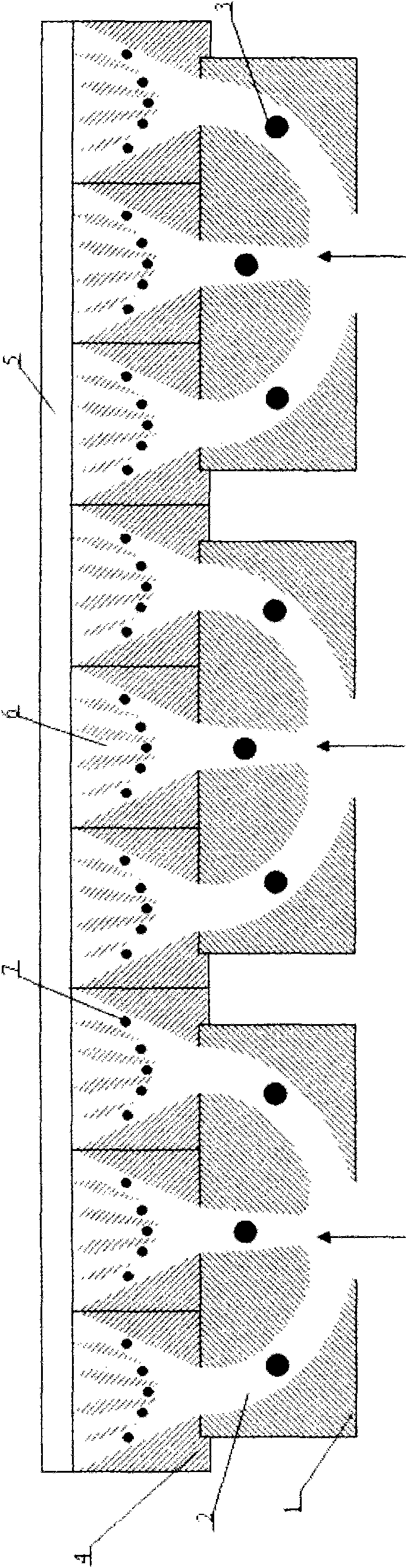

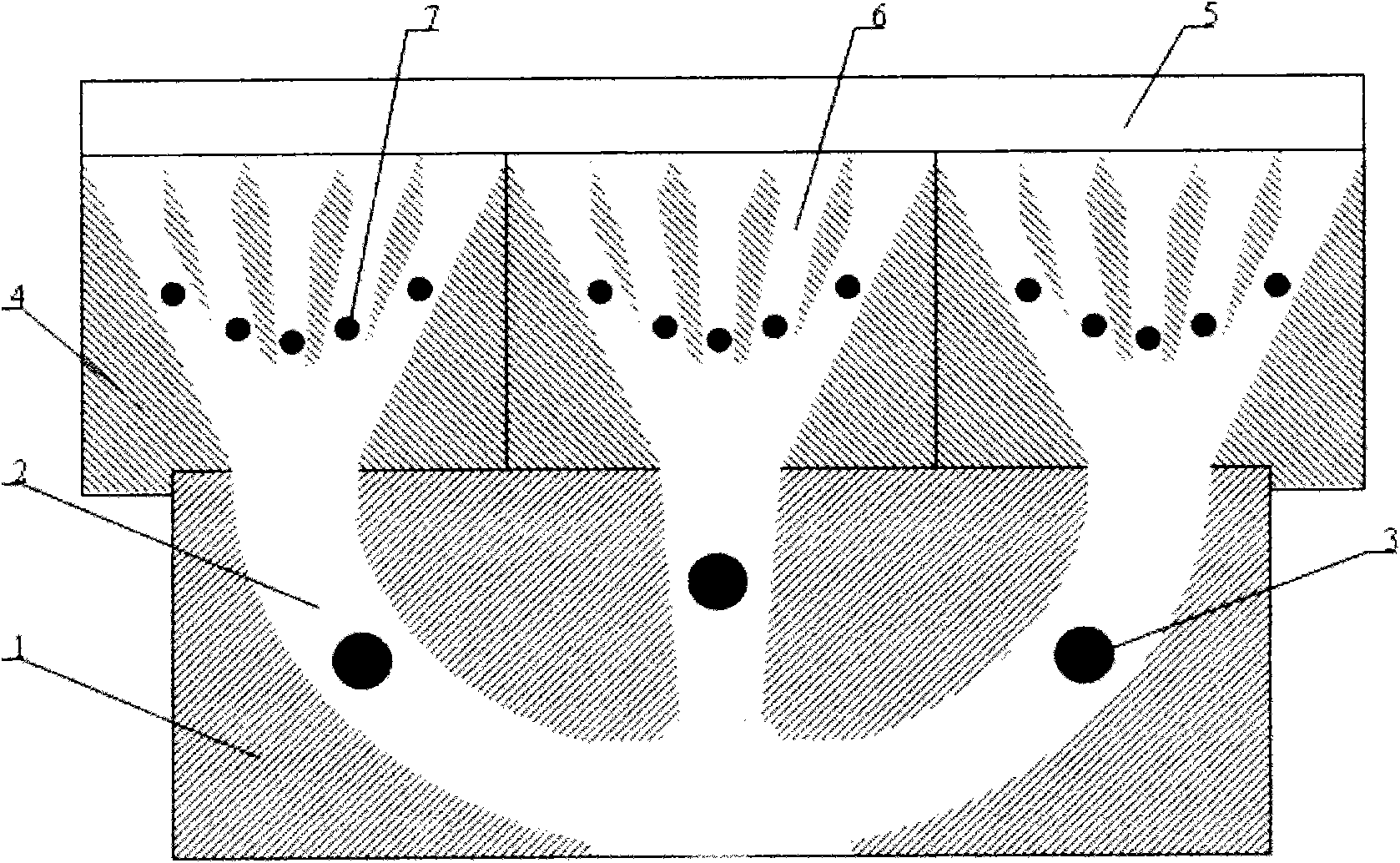

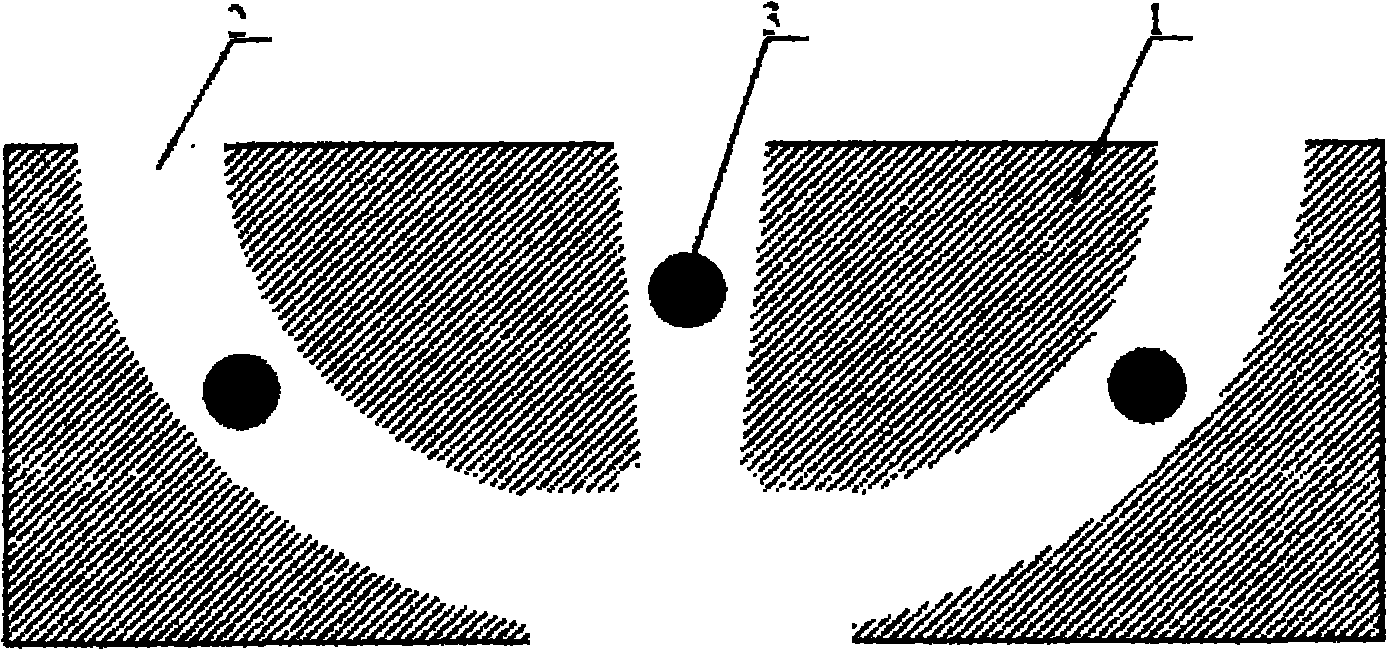

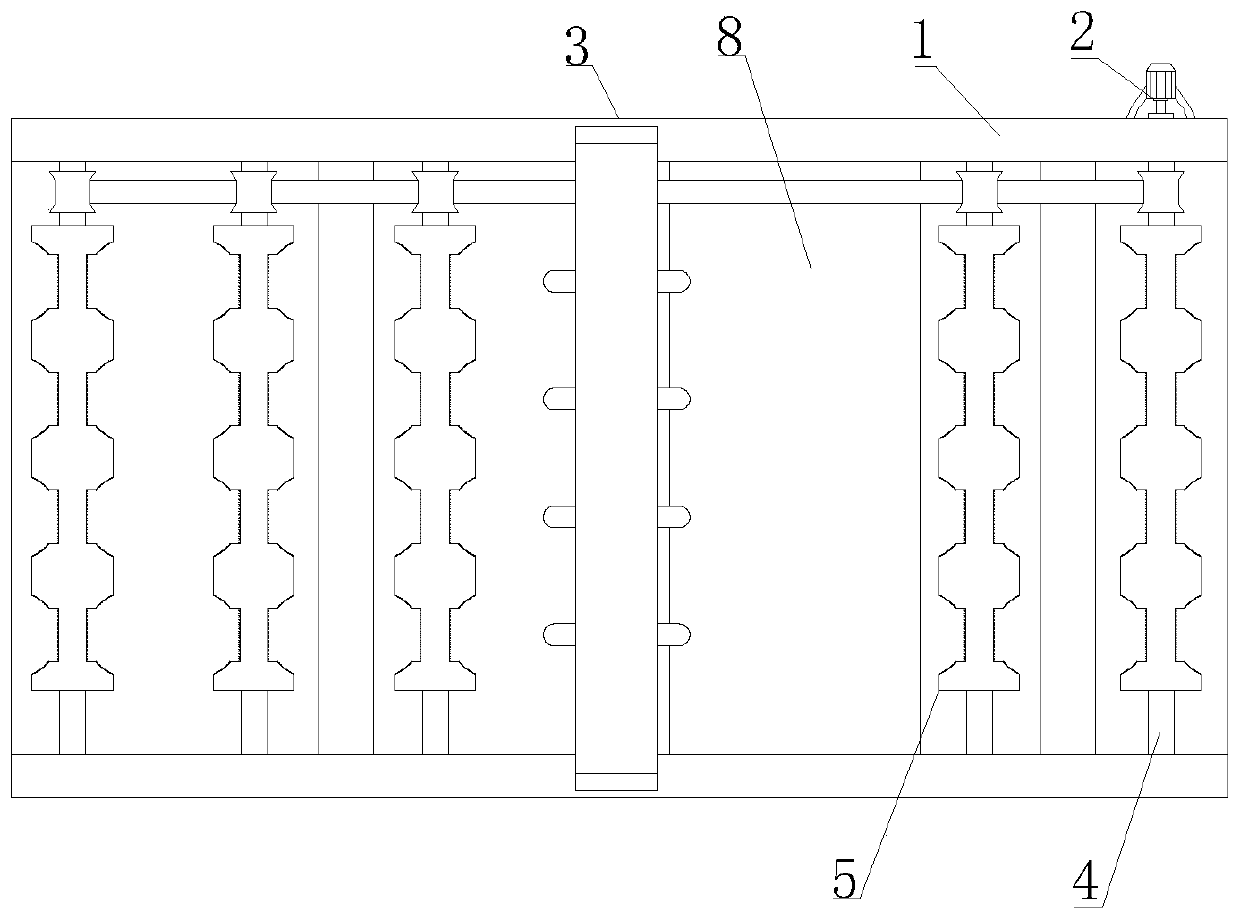

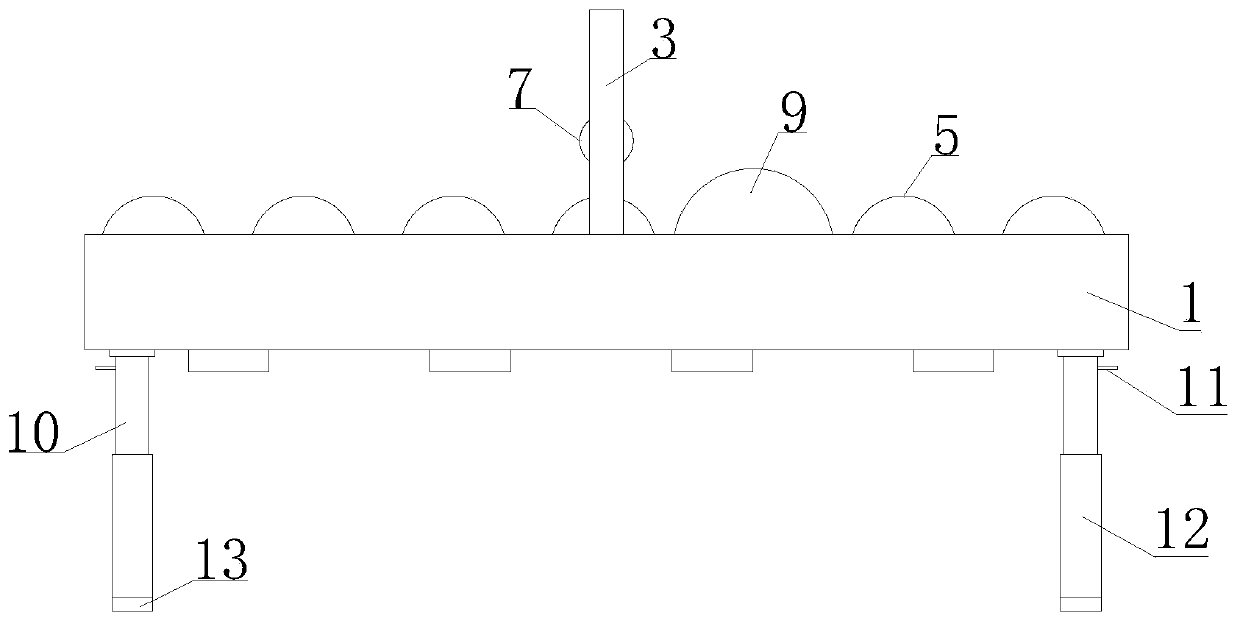

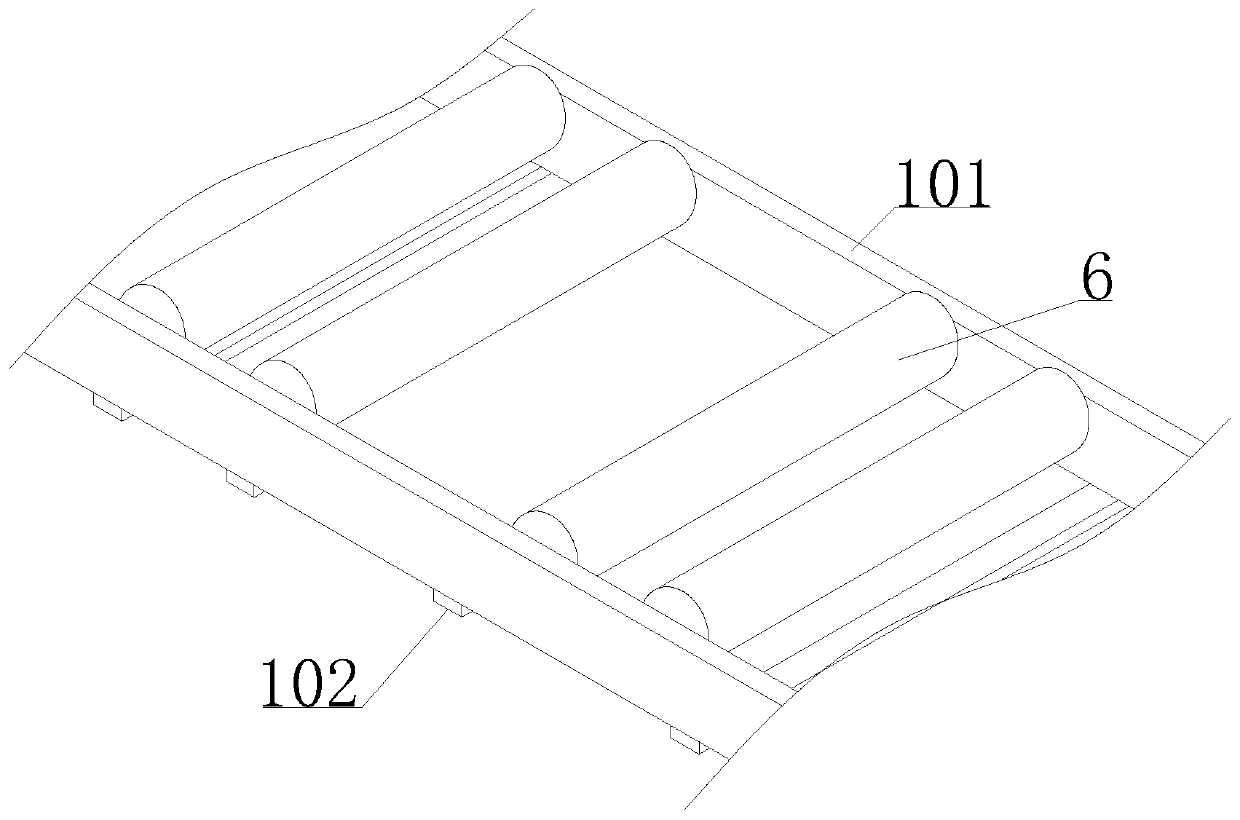

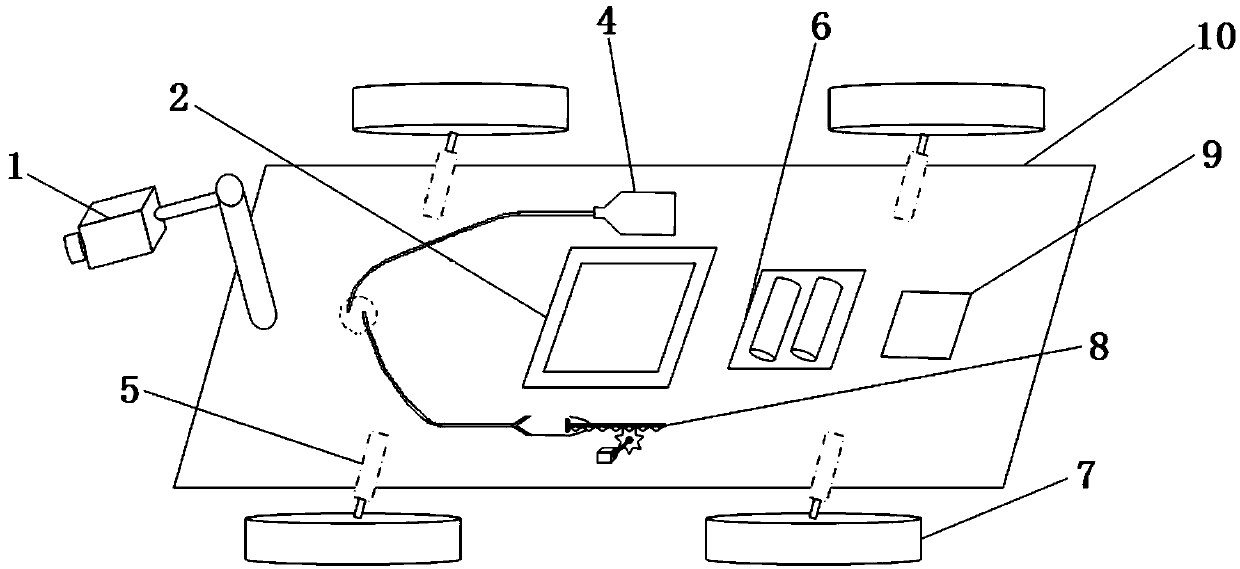

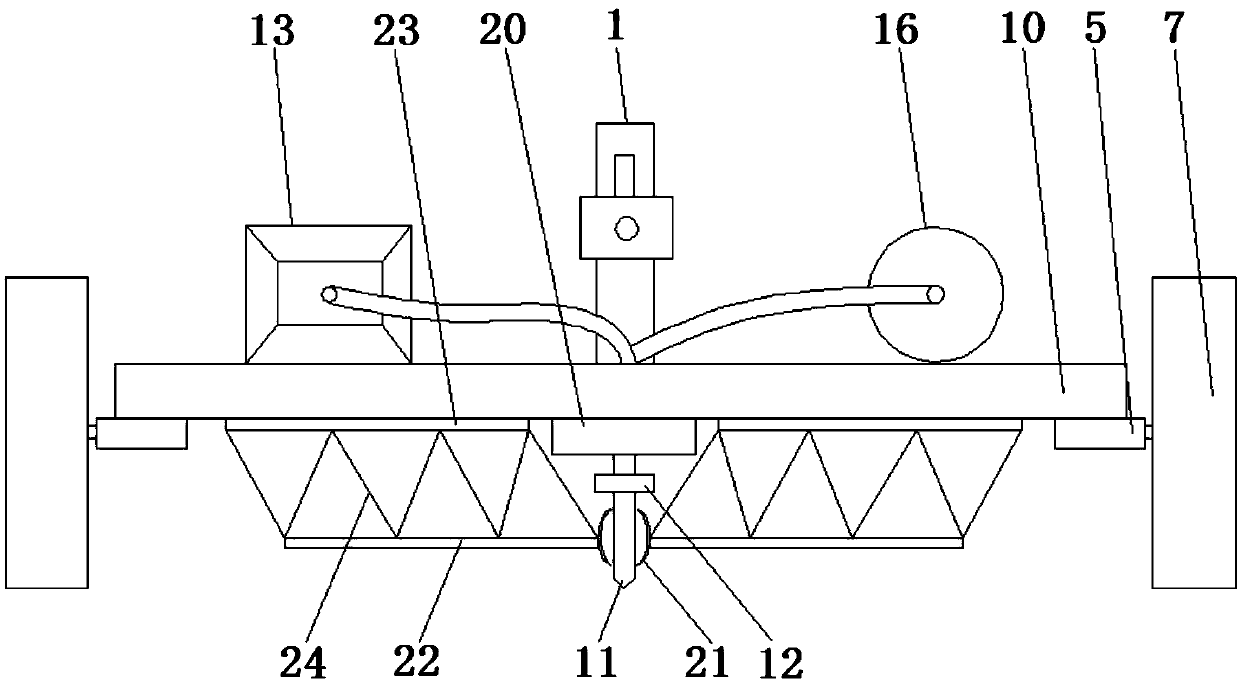

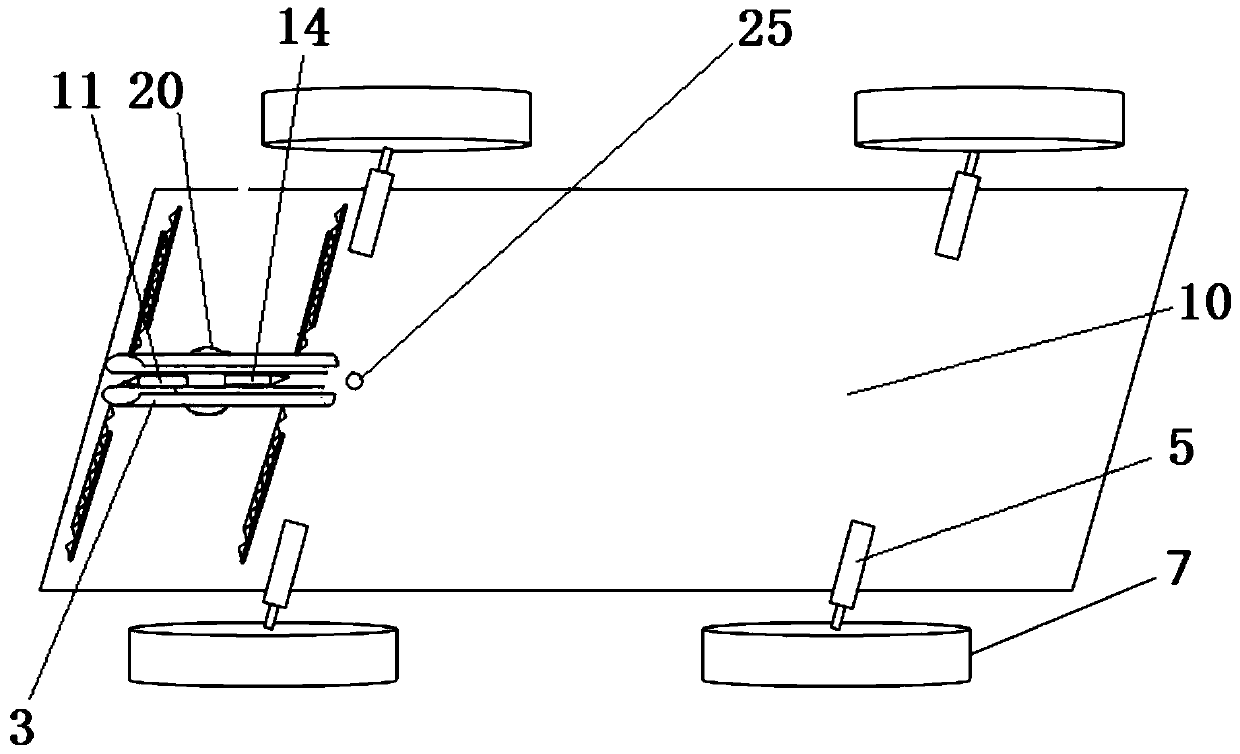

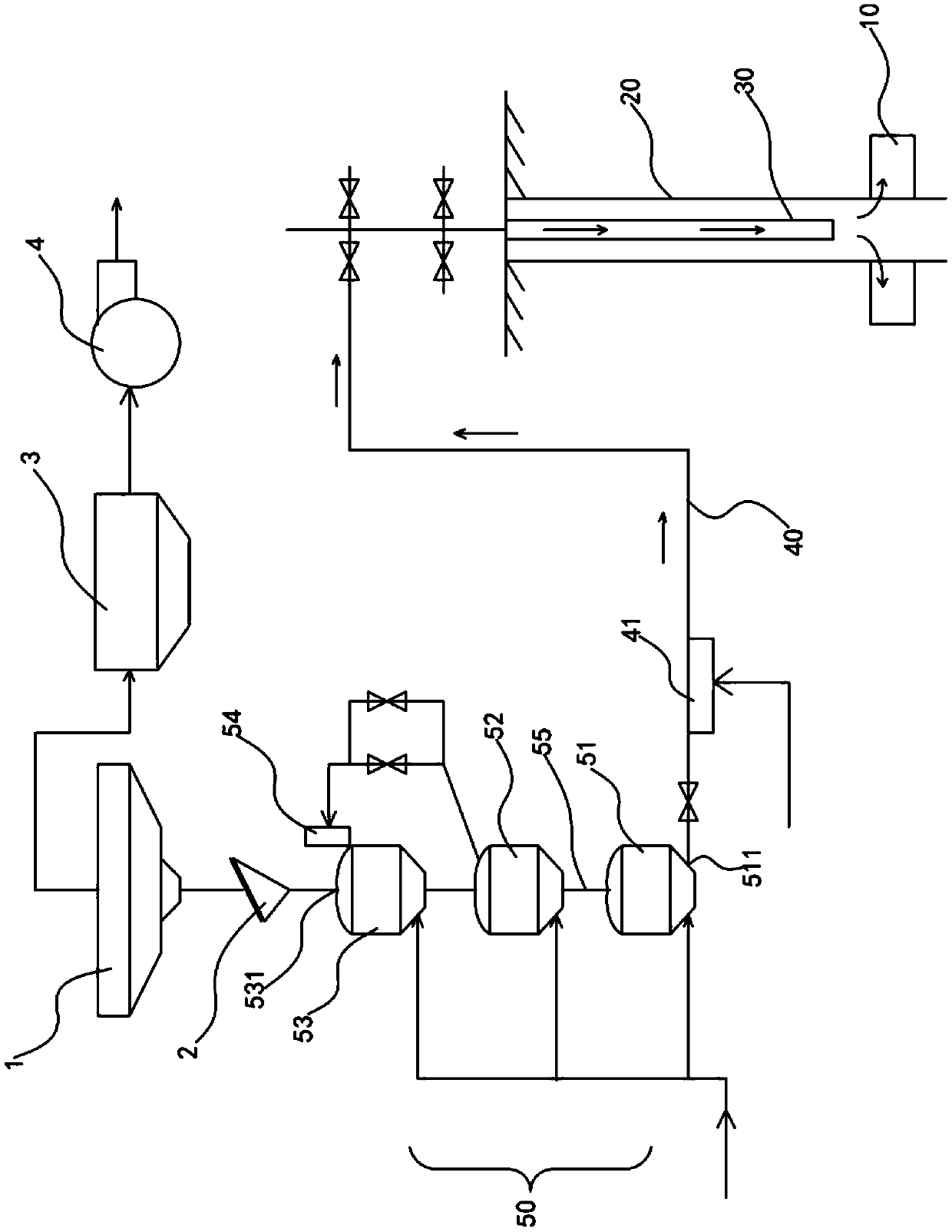

The invention discloses an anisotropic two-dimensional visual sand filling model in a simulation layer and a two-dimensional visual seepage experimental device. The two-dimensional visual sand filling model includes a bottom board and a cover board. The bottom board and the cover board are both made of transparent material. The surfaces of the bottom board and the cover board are in sealing fit and a sealing rubber pad is arranged between the bottom board and the cover board. A cavity between the sealing rubber pad and the cover board is an enclosed cavity and a cavity between the sealing rubber pad and the bottom board is a filling cavity. The bottom board is provided with three sand filling grooves in parallel. The sand filling grooves are arranged in the width direction of the bottom board. One end of the three sand filling grooves is provided with liquid inlets while the other end of the three sand filling grooves is provided with liquid outlets. According to the invention, the two-dimensional visual seepage experimental device includes a pressure providing module, a pressure data collecting module, an image collecting module, an injection module, the two-dimensional visual sand filling model and a metering module. When using the model and the experimental device provided by the invention, core sandstone particles or quartz sand particles of different particle sizes are put into the sand filling grooves, so that permeability difference is formed among different layers. Therefore, different anisotropic oil deposit can be simulated by different sand filling combinations.

Owner:CHINA NAT OFFSHORE OIL CORP +3

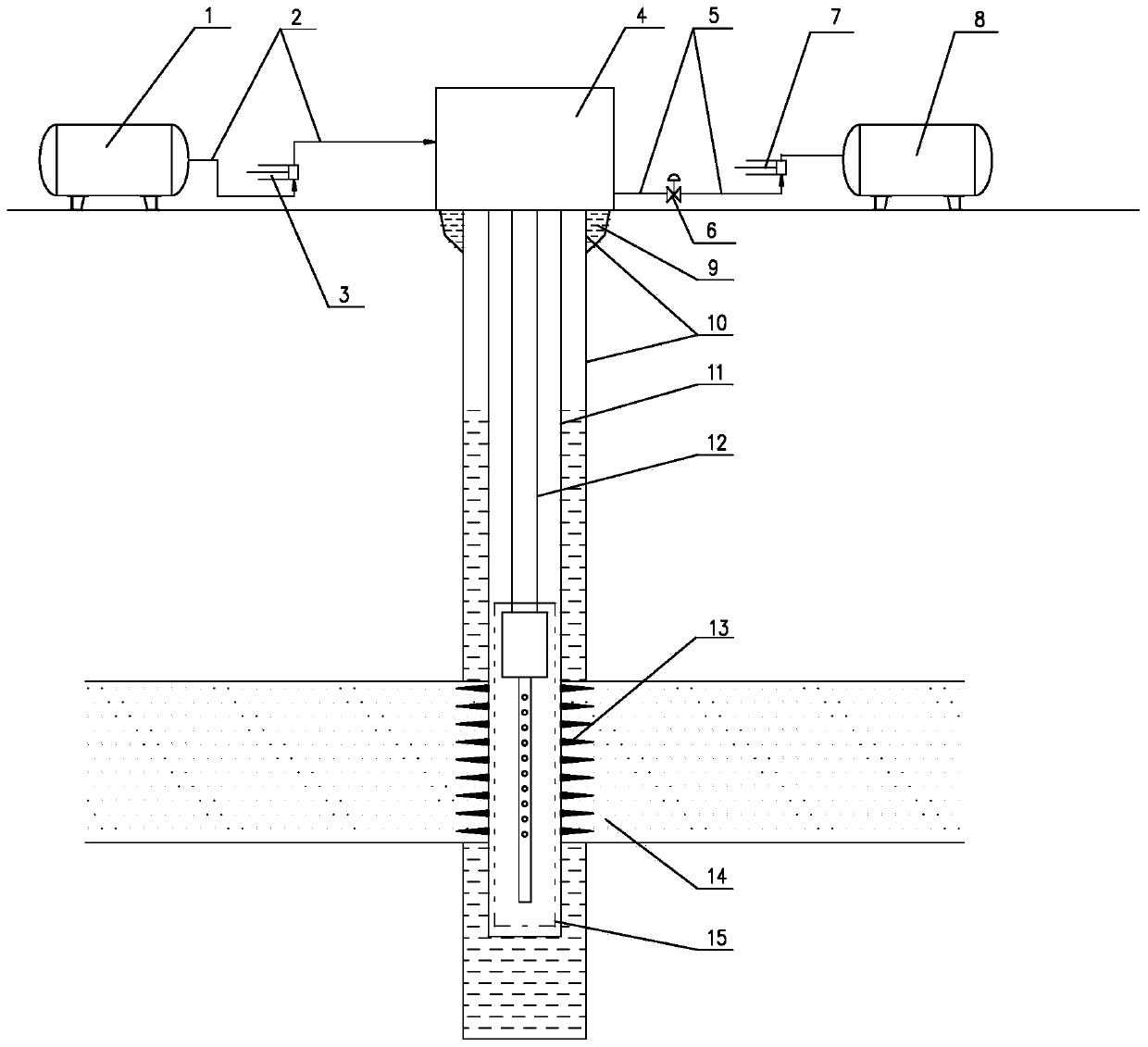

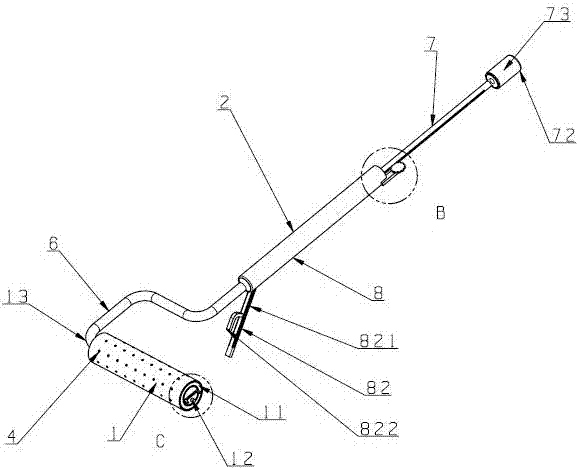

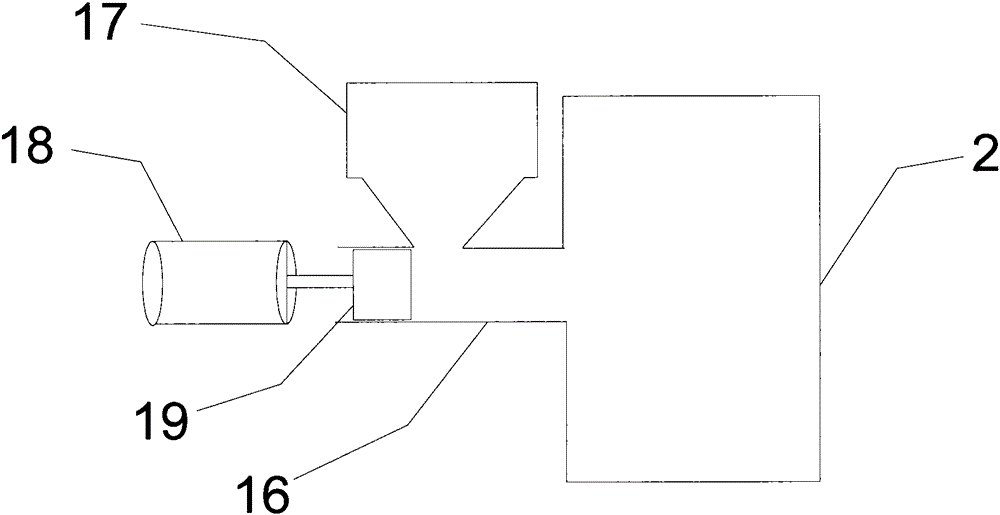

Device for injecting pulverized coal into oil layer and ignition method for in-situ oil combustion

ActiveCN106050207AReduce moisture contentImprove ignition performanceFluid removalCombustionInjection well

The invention provides a device for injecting pulverized coal into an oil layer and an ignition method for in-situ oil combustion and belongs to the field of exploitation through in-situ oil combustion. The device for injecting the pulverized coal into the oil layer comprises an oil pipe arranged in an injection well or a production well, a pulverized coal spray-blowing system arranged on the ground and an injection pipeline, wherein the pulverized coal spray-blowing system is provided with a pulverized coal input port and a spray-blowing port, the spray-blowing port sprays out the pulverized coal, the injection pipeline is connected between the oil pipe and the spray-blowing port of the pulverized coal spray-blowing system, and the pulverized coal sprayed out of the spray-blowing port is delivered to the oil pipe. The device can improve the ignition effect for in-situ oil combustion and can also improve the development effect of the in-situ oil combustion.

Owner:PETROCHINA CO LTD

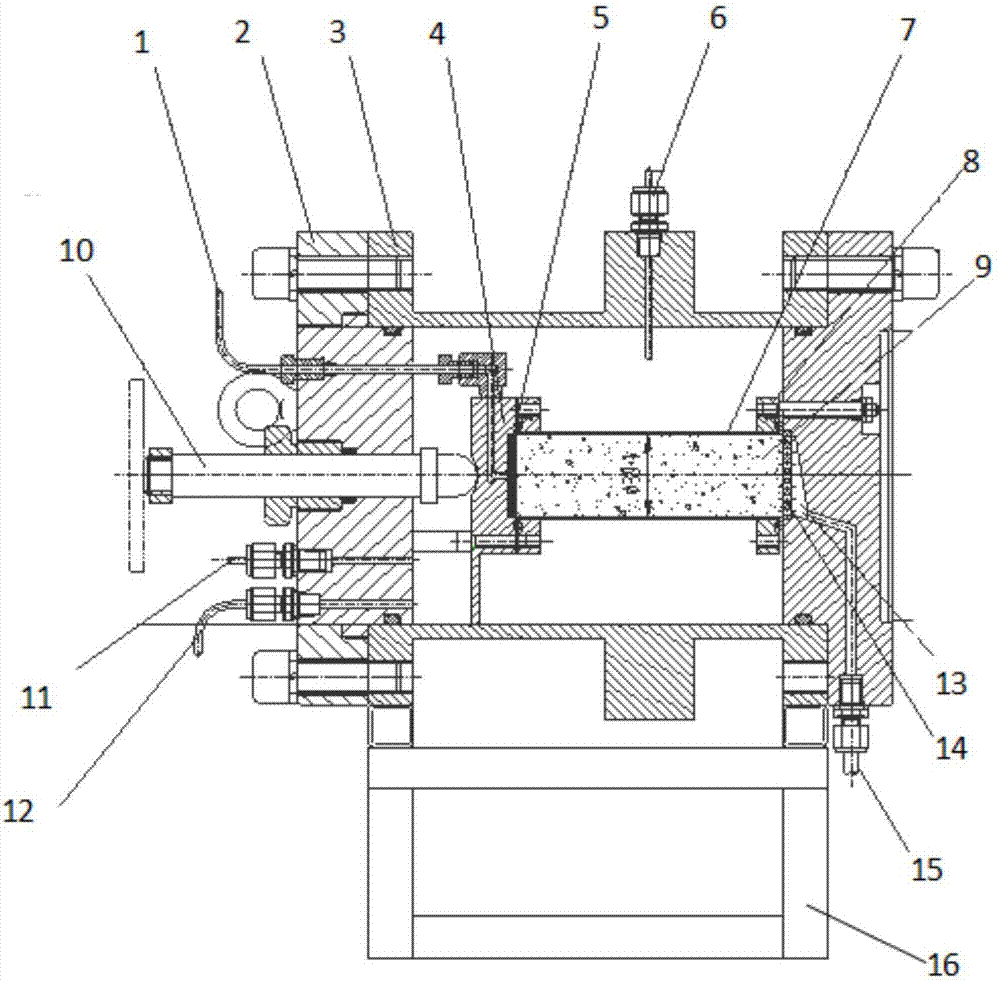

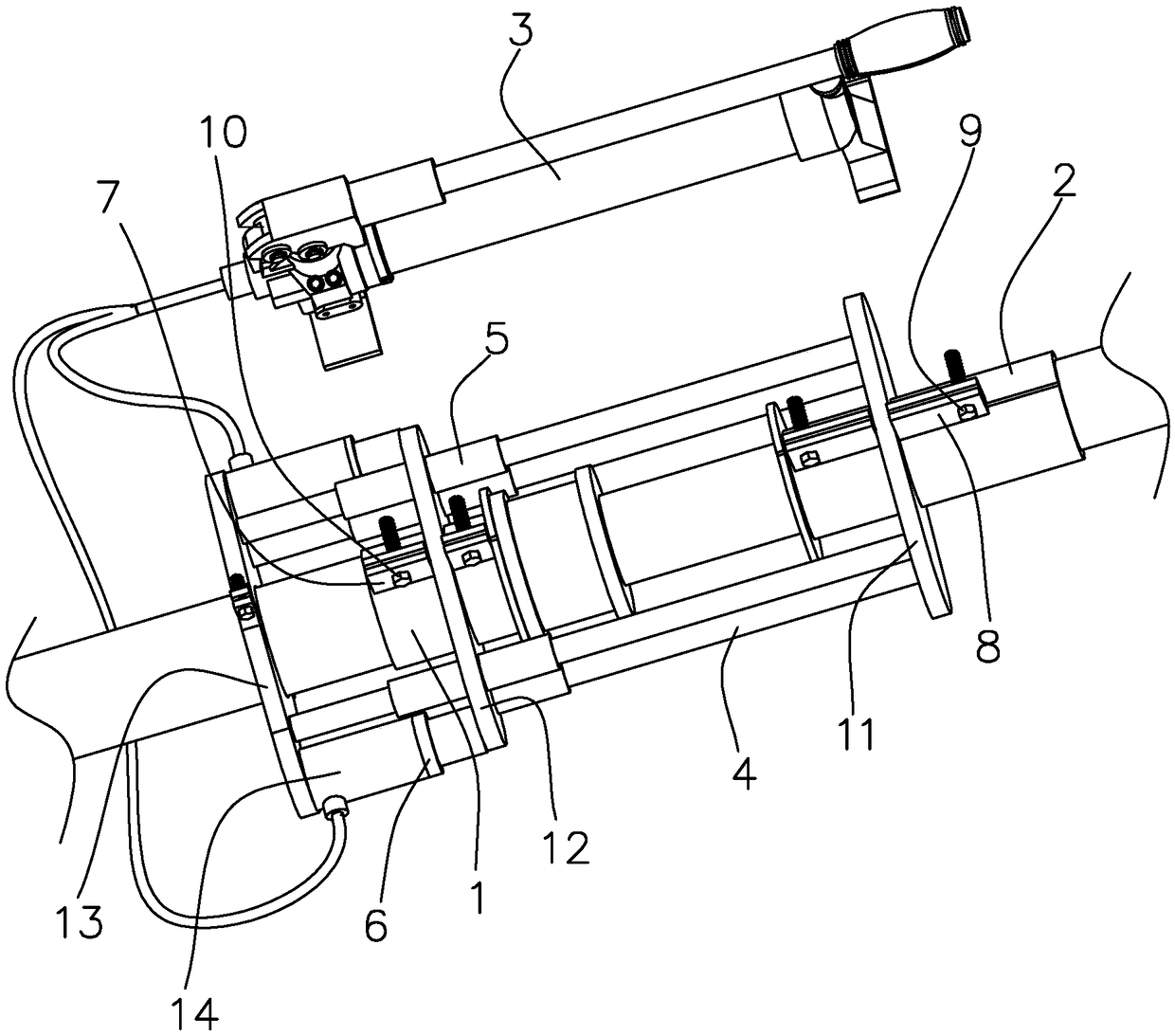

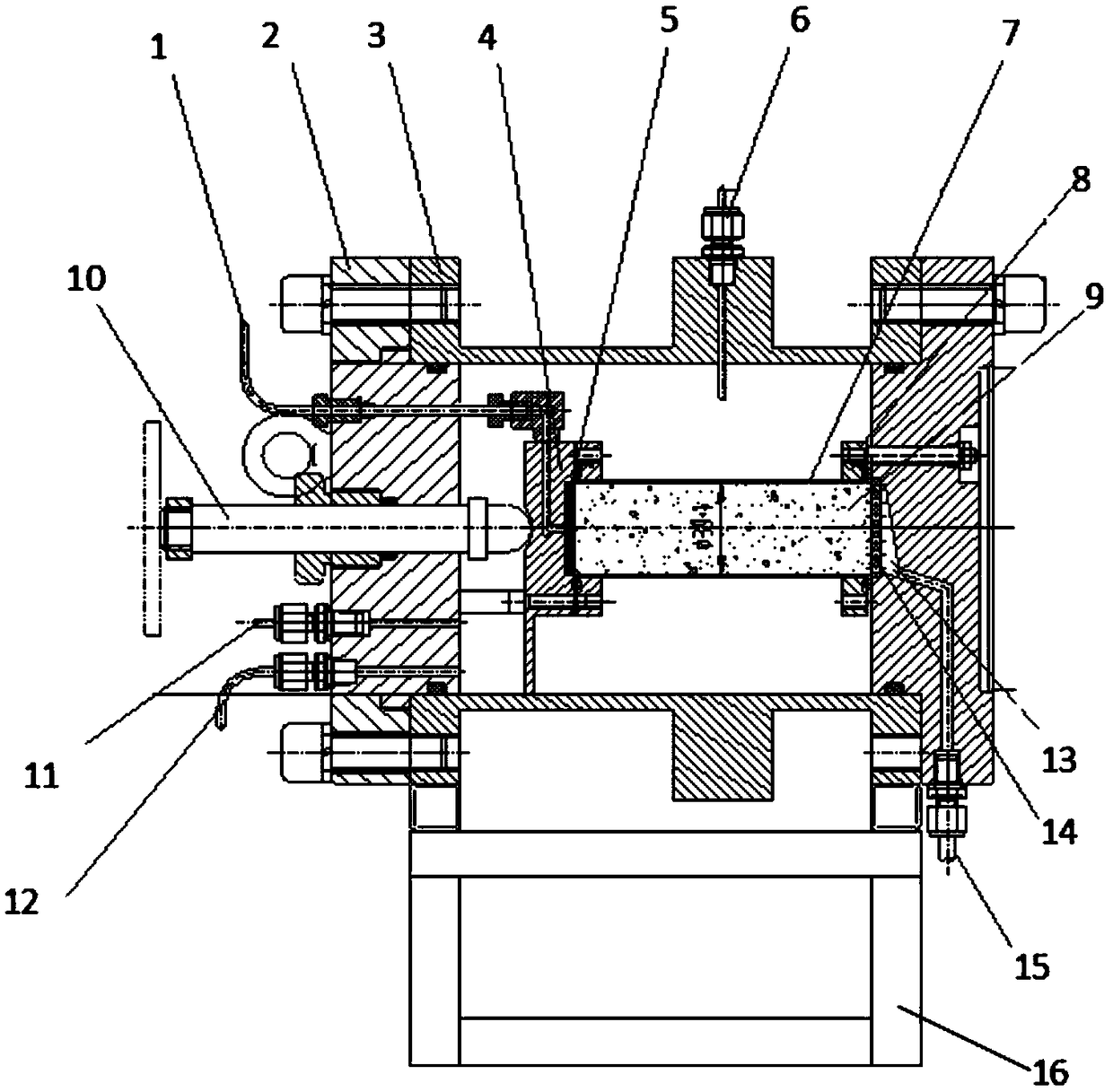

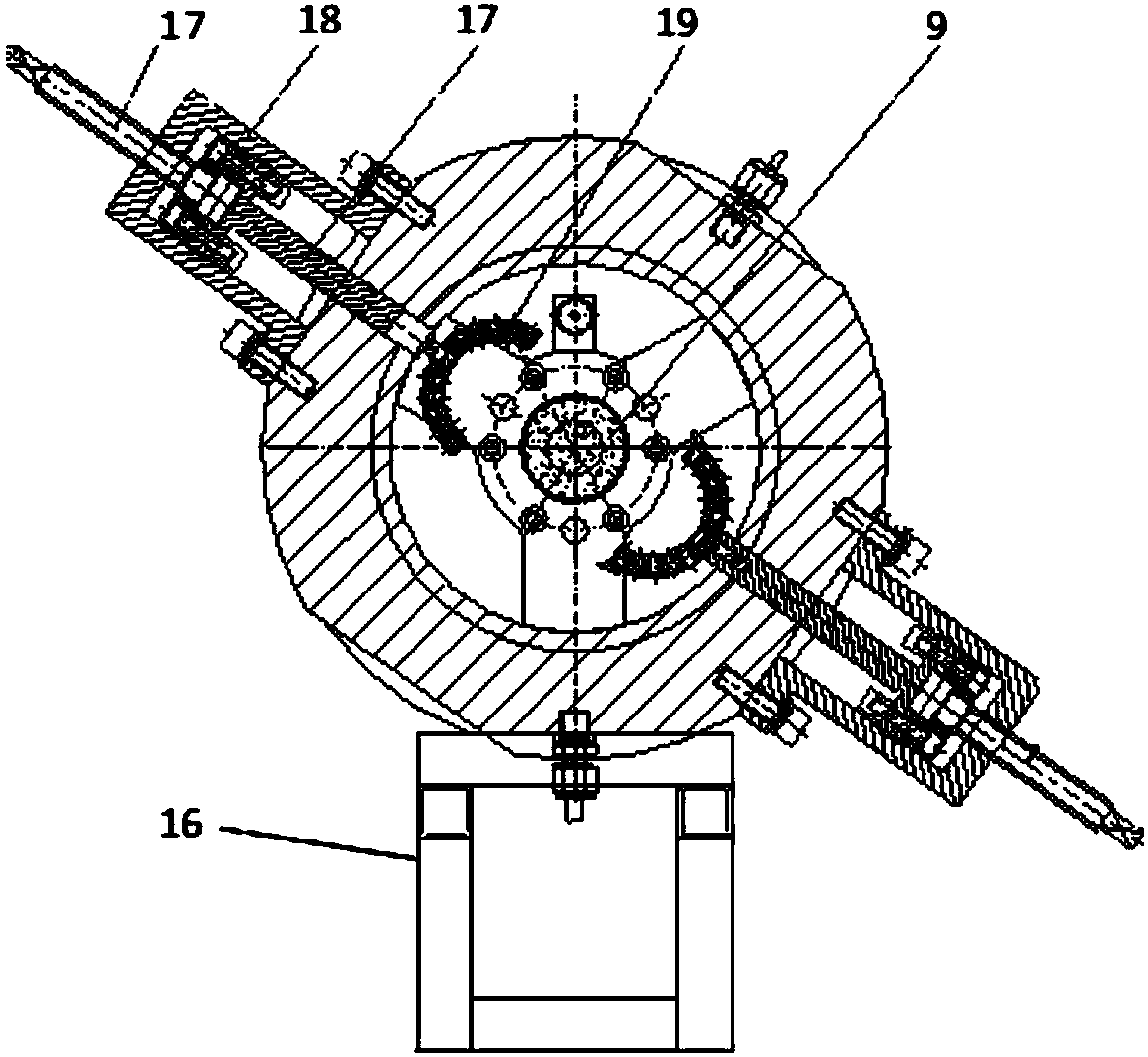

Special reaction kettle for simulating sand production process of hydrate-containing sediment and testing method thereof

ActiveCN106950153AAchieving a stressful environmentSolve the technical problem of "standing" difficultyFlow propertiesParticle size analysisStress conditionsTest sample

The invention belongs to the technical field of marine gas hydrate resource exploitation engineering and in particular relates to a special reaction kettle capable of simulating a dynamic variation rule of parameters in a sand production process of a hydrate-containing sediment under a true stress condition and a testing method thereof. The reaction kettle comprises a pressurizing kettle device and a holding device. The pressurizing kettle device comprises a reaction kettle body, a sediment clamping rubber gasket, an upper flange disc, a supporting flange, a lower flange cover and a piston pressurizing ejector rod. The sediment clamping rubber gasket and the supporting flange are arranged in the reaction kettle body, the supporting flange slides along the inner wall of the reaction kettle body, and a flowing channel where a confining pressure liquid circulates is arranged between the supporting flange and the inner wall of the reaction kettle body; one end of the piston pressurizing ejector rod penetrates through the upper flange cover and is in contact with the supporting flange, and a groove in contact with the piston pressurizing ejector rod is arranged on the end surface of the corresponding supporting flange. An in-situ forming demand of a hydrate sediment test sample is met, and sand production dynamic simulation in a condition of hydrate saturated degree of actual stratum is achieved.

Owner:QINGDAO INST OF MARINE GEOLOGY

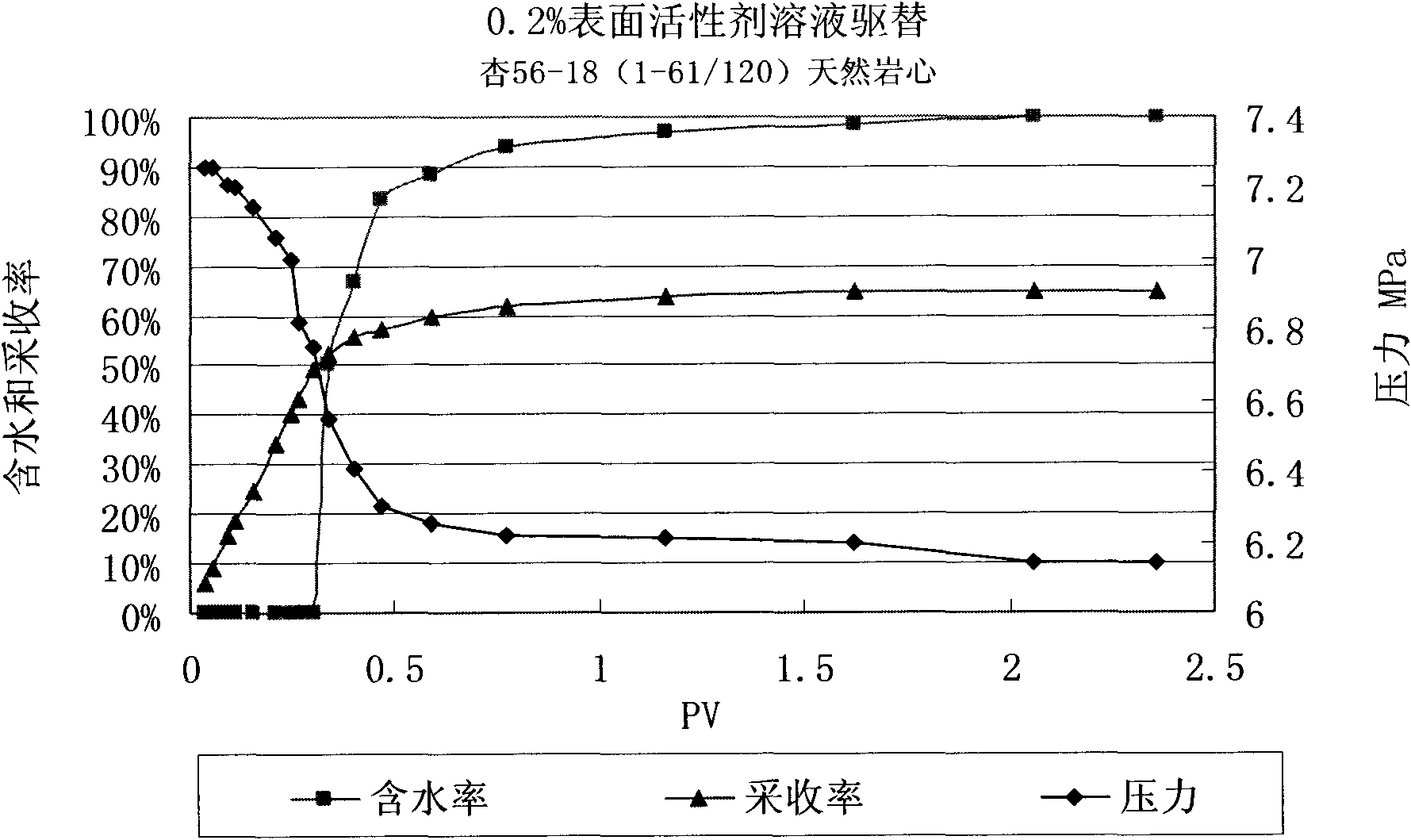

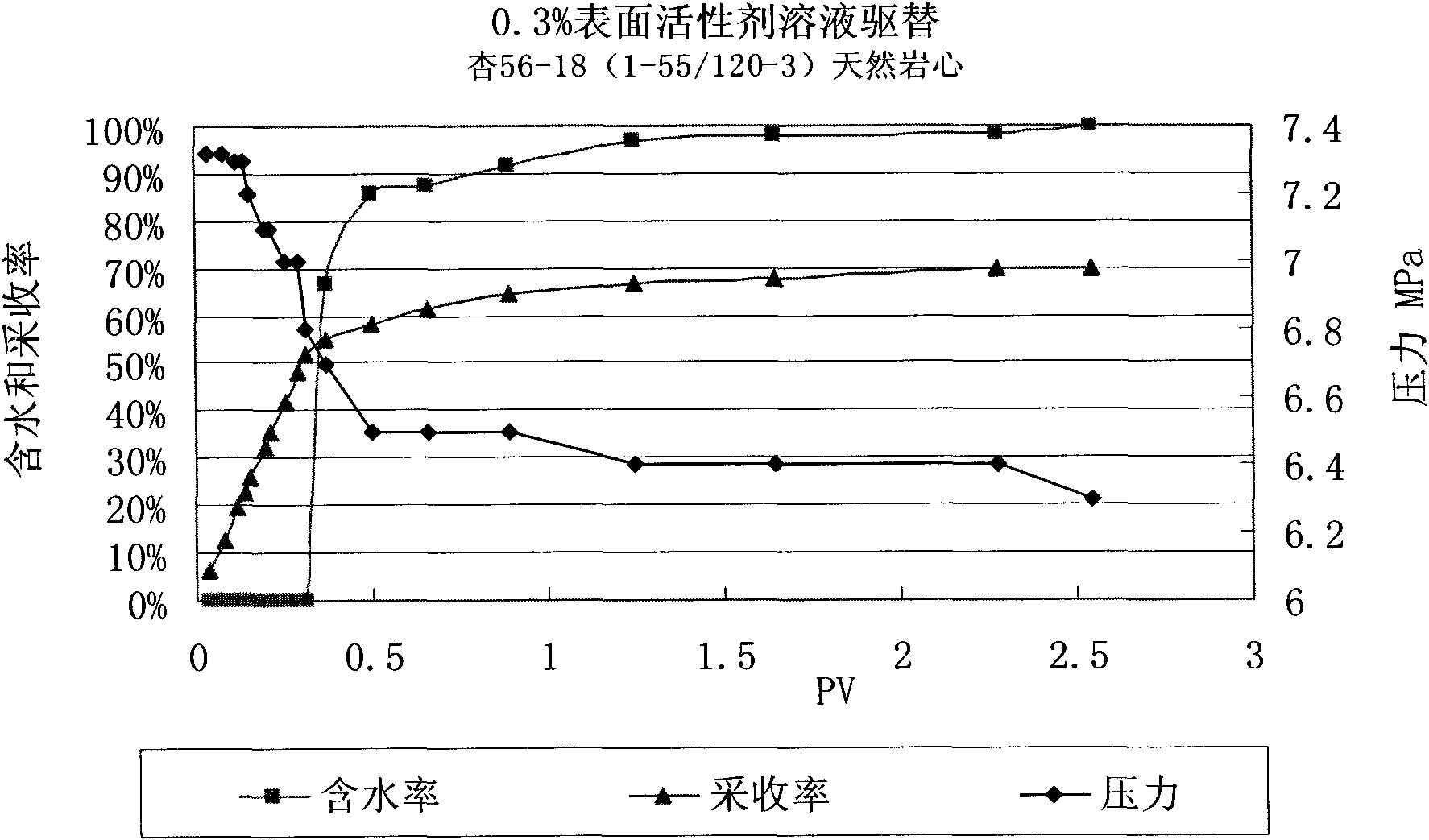

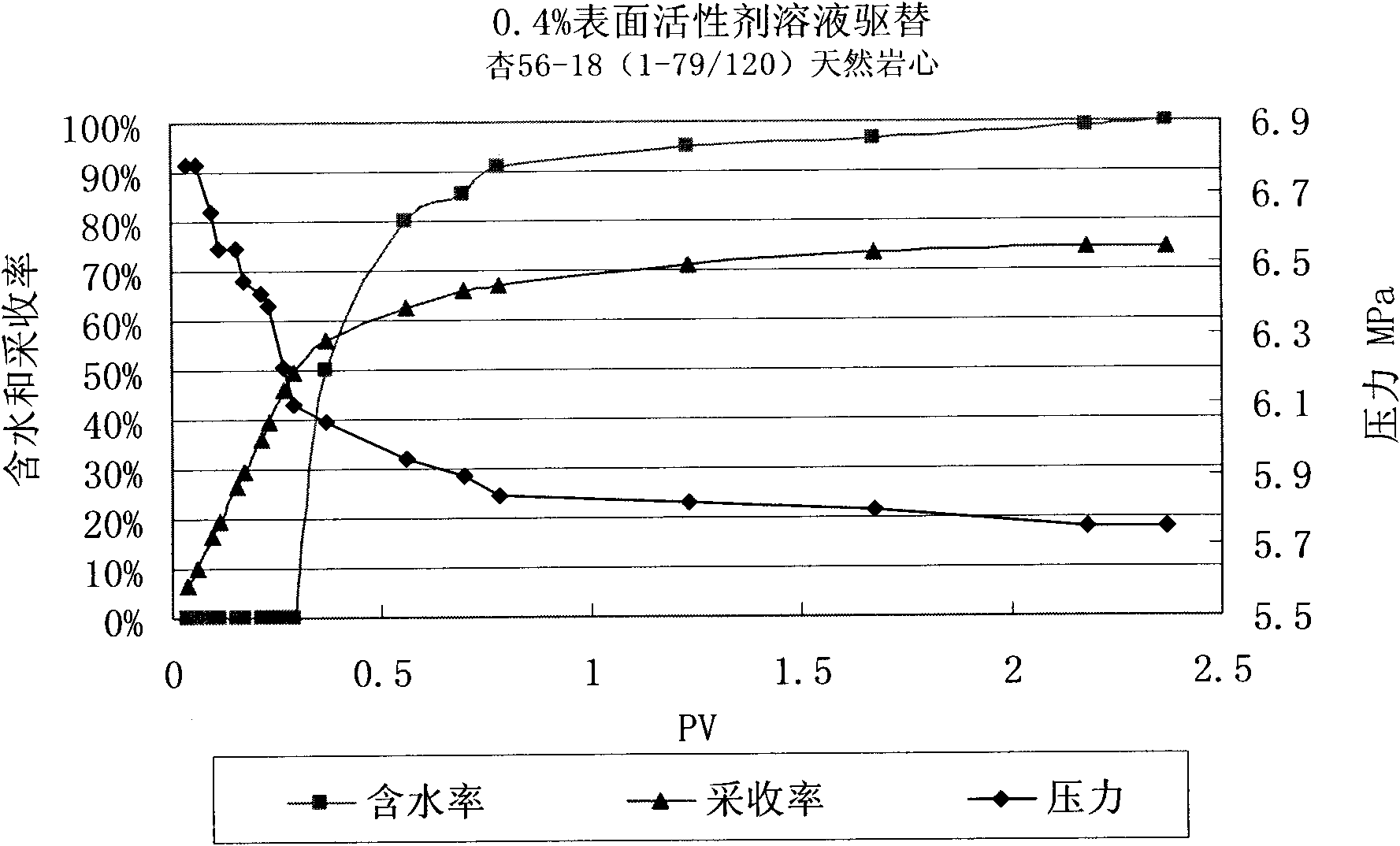

Oil-field largest swept volume chemical-flooding oil production method

The invention relates to an oil-field largest swept volume chemical-flooding oil production method, which is applied to the technical field of oil production in oil fields. The method is applicable to all reservoirs which can be exploited by water flooding but are not exploited by water flooding. When oil is exploited, the self energy of the strata of a reservoir is first utilized to carry out flowing production or swabbing production; when an oil field adopting flowing production or swabbing production reaches the economic benefit limit of production, flowing production or swabbing production is ended, subsequent water-flooding production is not carried out any more, but chemical flooding injecting surfactant as main agent is directly adopted to intensify oil production. The method has the following advantages that: at the moment, the swept volume of the displacement of the chemical displacing fluid is the largest, which is best favorable for the exertion of the oil-washing effect ofthe surfactant, and thereby the yield of oil production can be increased to the max.

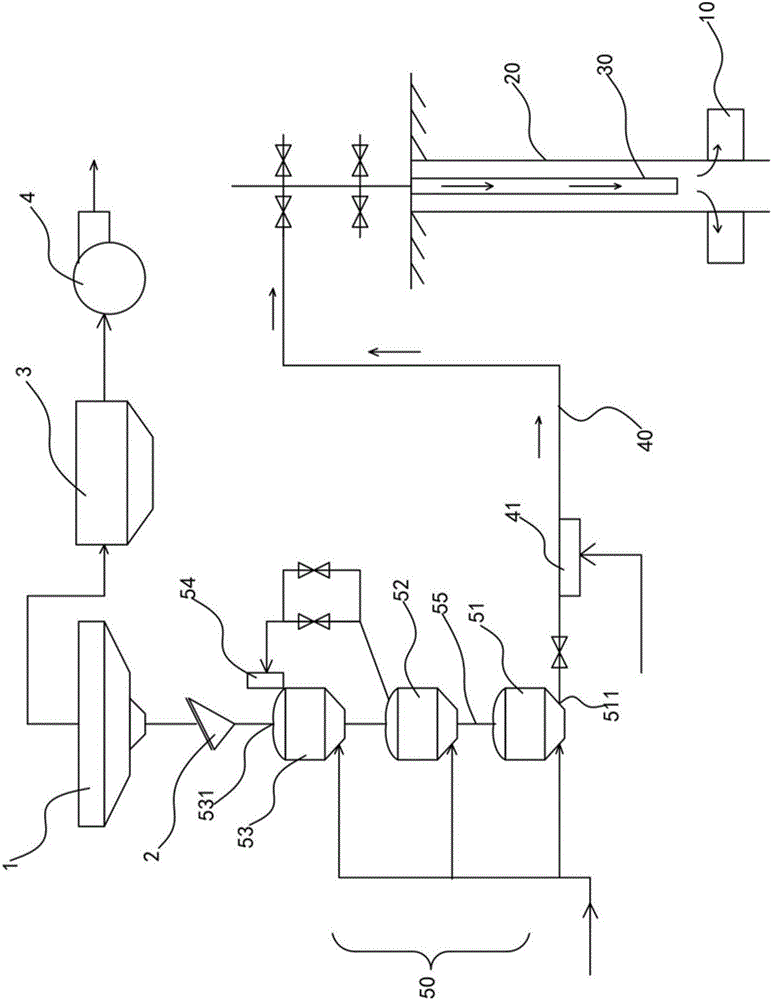

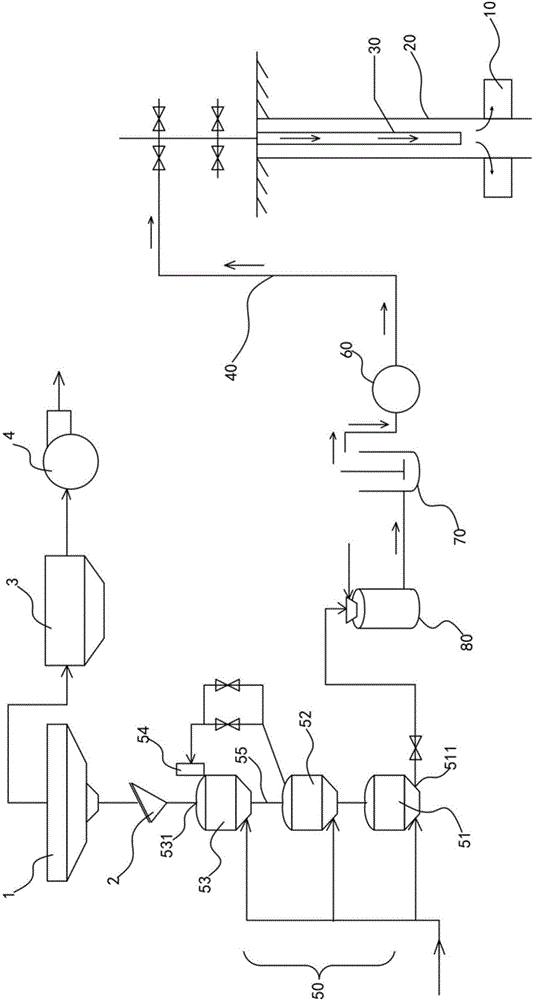

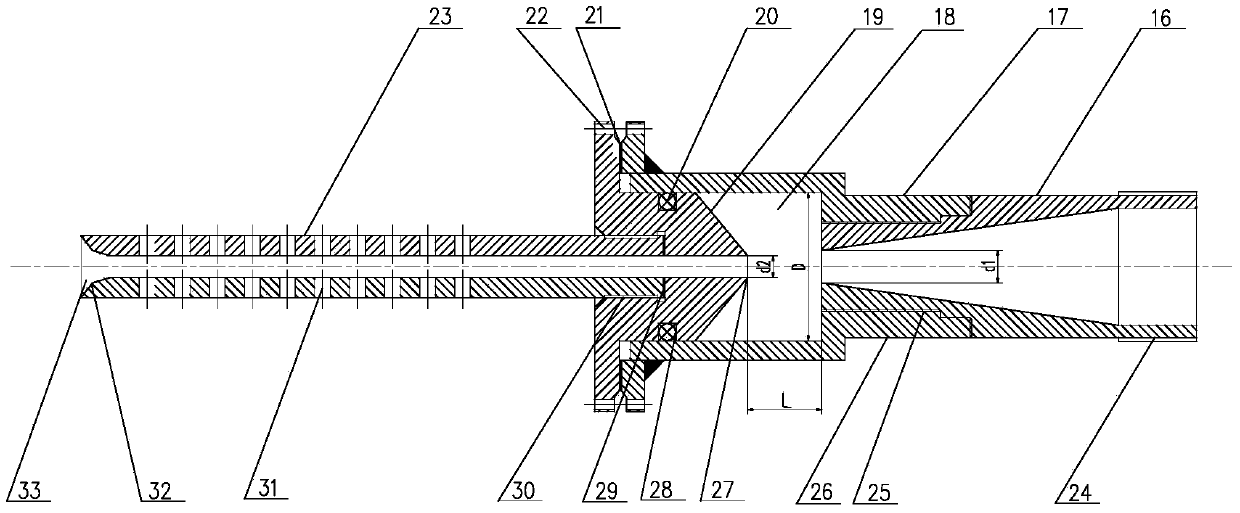

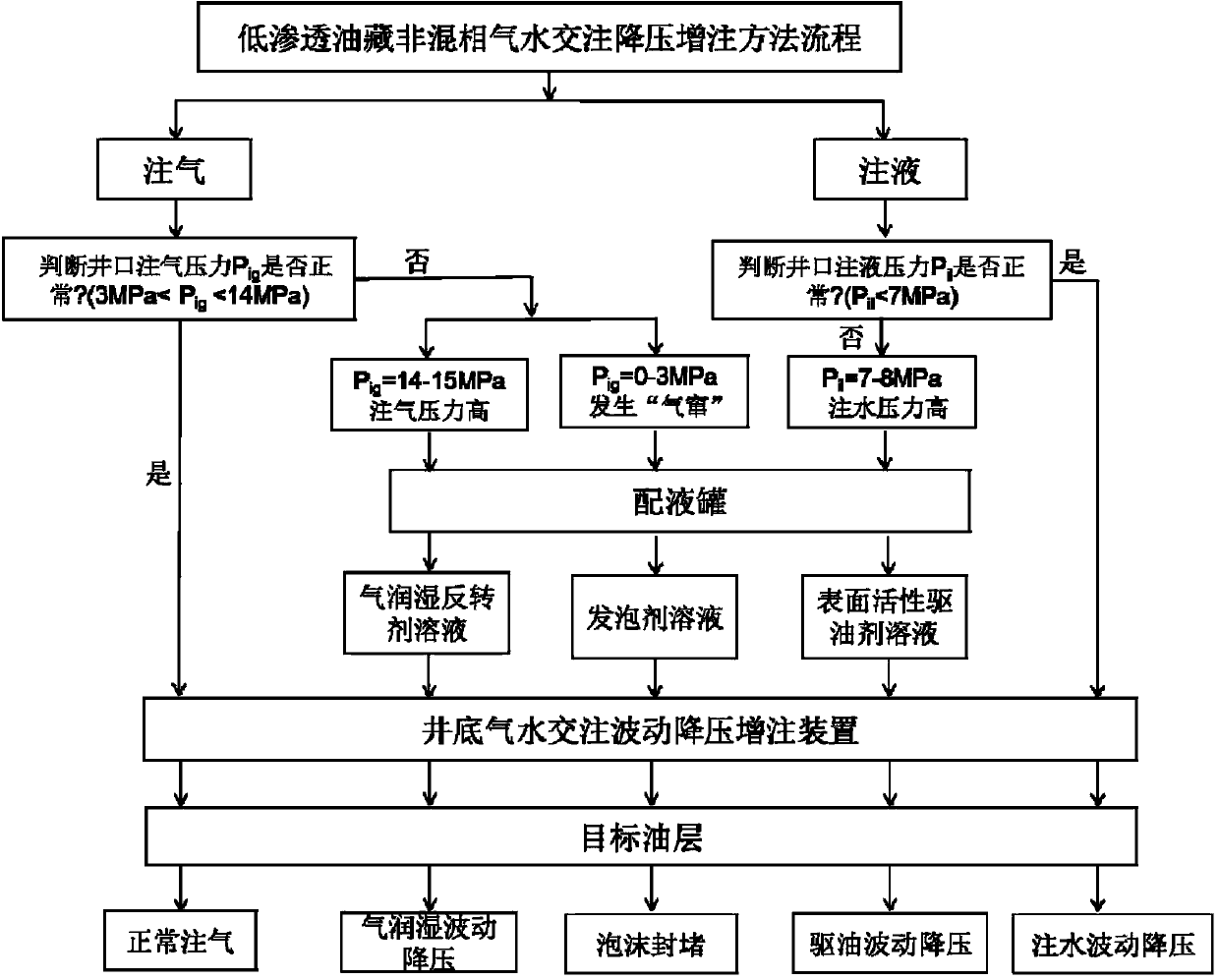

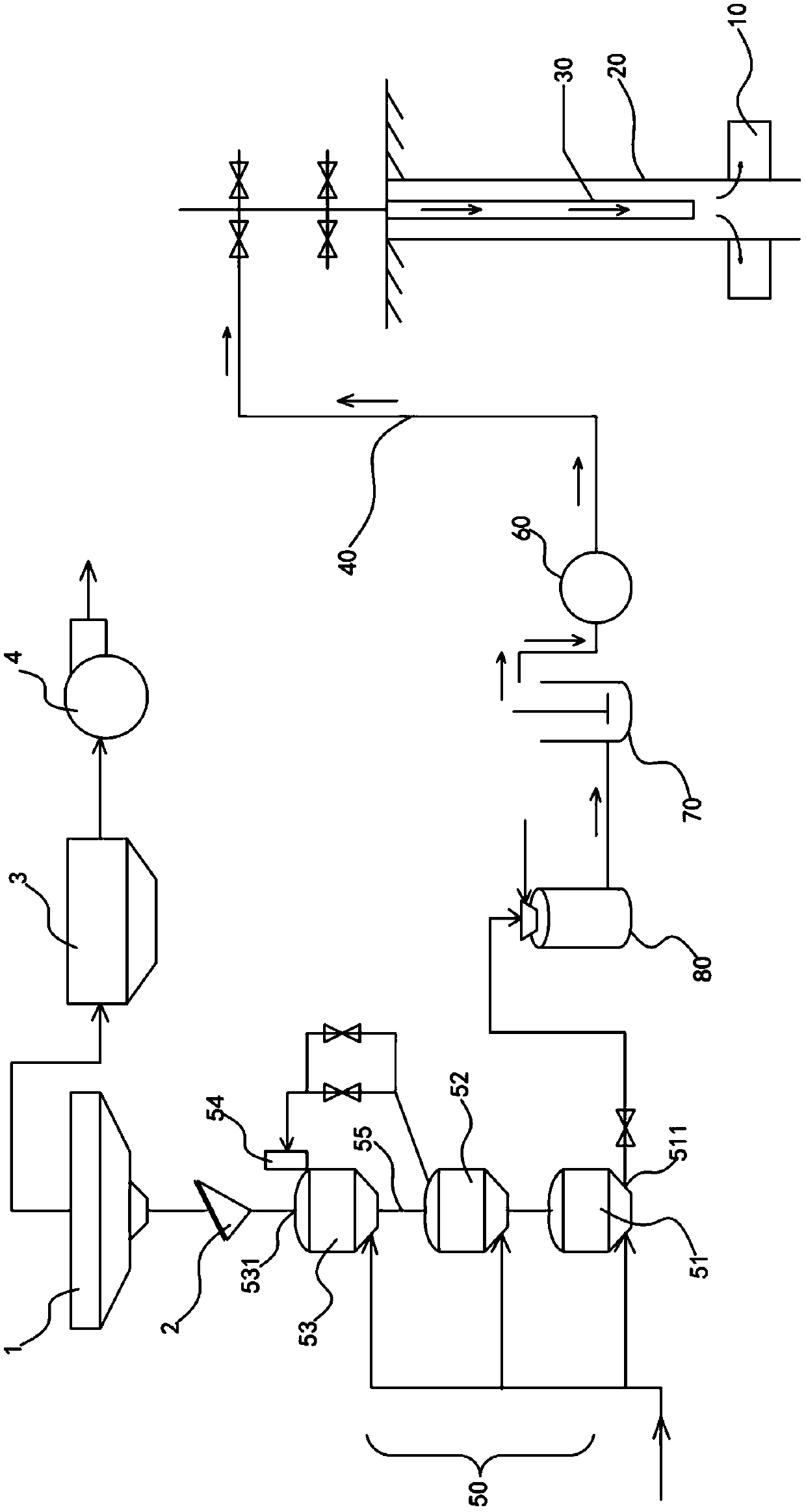

Low-permeability oil reservoir non-mixed-phase gas-water alternate injection and fluctuation depressurization augmented injection device and method

InactiveCN103993863AReduce the number of timesImprove gas injection production efficiencyFluid removalInjection pressureLiquid storage tank

The invention discloses a low-permeability oil reservoir non-mixed-phase gas-water alternate injection and fluctuation depressurization augmented injection device and method. The device mainly comprises a gas-liquid injection device on the ground and a gas-water alternate injection and fluctuation depressurization augmented injection device in a downhole. The gas-liquid injection device mainly comprises a low-temperature high-pressure liquid storage tank, a liquid distribution tank and a plunger pump on the ground. The gas-water alternate injection and fluctuation depressurization augmented injection device comprises a mixed fluid acceleration inlet segment, a collision body, a shell and a mixed fluid outlet segment. According to the device, the effects of the elasticity modulus difference and gravitational differentiation of gas and liquid are utilized to achieve mutual conversion between gas-water alternate injection, injected liquid fluctuation depressurization augmented injection and non-mixed-phase gas bubble anti-channeling functions, and therefore injection efficiency is enhanced, and the phenomenon of gas channeling is eliminated. The device is simple in structure, the construction method is simple, and operation cost is low; the operation process can be adjusted in real time according to injection pressure, the effect of gas (liquid) absorption is effectively improved, and the production efficiency of the low-permeability oil reservoir non-mixed-phase gas drive is substantially enhanced.

Owner:CHINA UNIV OF PETROLEUM (EAST CHINA)

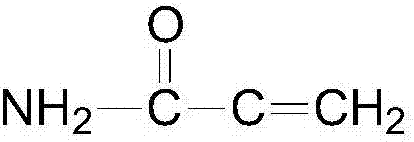

Polymer gel, polymer and application thereof

ActiveCN106928402AGood shear recoveryHigh viscoelasticityDrilling compositionFunctional monomerWater soluble

The invention provides a polymer gel. The polymer is formed in water via physical actions such as Van der Waals' force, hydrogen bond and electrostatic action, and the acrylamide monomer unit in the polymer is a hydrophilic group, so that the polymer has good water solubility; and by introducing a hydrophobic monomer unit and a functional monomer unit, the polymer has good hydrophobic property and good temperature and salt resistance. The polymer gel is low in viscosity under high speed shear, has good injection property, and can ensure large-dose injection of a plugging control system; and the polymer gel has good shear restoration and high visco-elasticity, is stable at the frontal slug of a near borehole zone, strong in water invasion resistance, unique in overall propulsion and high in plugging success rate, can effectively change the subsequent water flooding seepage path and improve the swept volume, has good temperature and salt resistance and long-term stability, and can be used as a profile control plugging agent.

Owner:SICHUAN GUANGYA POLYMER CHEM

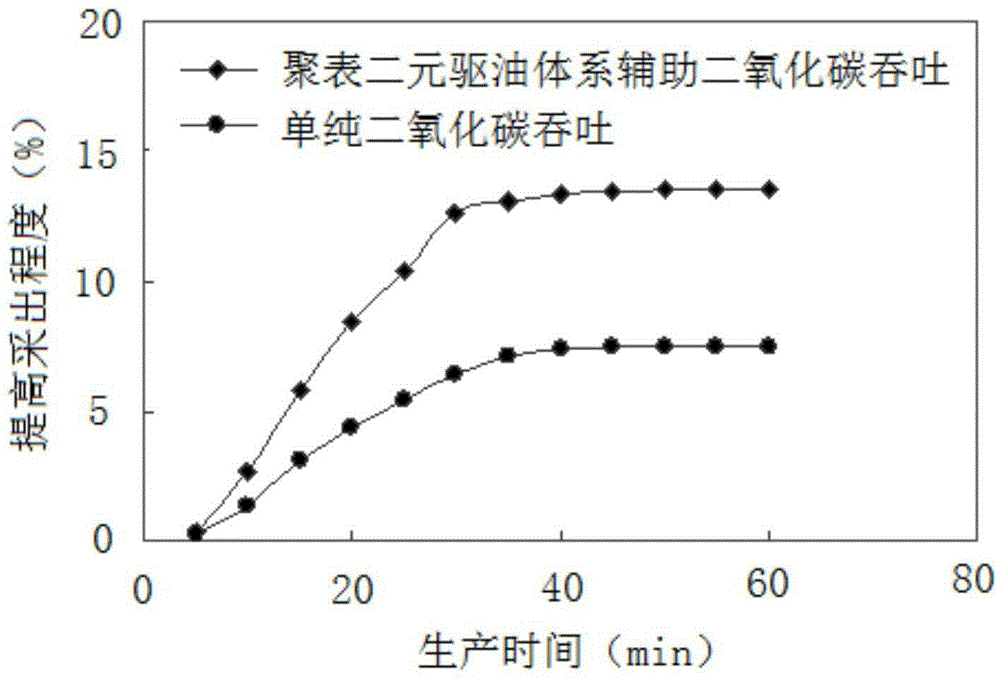

Oil extraction method with polymer-surfactant binary oil displacement system assisting in carbon dioxide huff and puff

ActiveCN106812509AReduce the impact of the sweepAdvance evenlyFluid removalDrilling compositionAmmonium bromideSURFACTANT BLEND

The invention discloses an oil extraction method with a polymer-surfactant binary oil displacement system assisting in carbon dioxide huff and puff and belongs to the technical field of increasing the crude oil recovery rate. The method includes the steps that a polymer-surfactant binary oil displacement system front plug, a carbon dioxide main plug, a polymer-surfactant binary oil displacement system rear plug, a blocking agent plug and water are sequentially injected into an oil reservoir; well opening is carried out after well shutting-in is carried out for a preset time, and crude oil extraction is carried out. The polymer-surfactant binary oil displacement system front plug and the polymer-surfactant binary oil displacement system rear plug are prepared from, by mass, 0.10%-0.40% of polyacrylamide, 0.05%-0.20% of surfactant compounded by N-dodecyl-N,N-dimethylglycine and hexadecyl trimethyl ammonium bromide and the balance water. The blocking agent plug is prepared from, by mass, 0.25%-0.50% of partially hydrolyzed polyacrylamide, 0.20%-0.50% of cross-linking agent, 0.01%-0.03% of stabilizer, 0.01%-0.02% of pH modifier and the balance water. By means of the method, the mobility ratio can be reasonably controlled, the displacement efficiency is improved, the carbon dioxide utilization rate is increased, and the recovery rate is increased.

Owner:PETROCHINA CO LTD

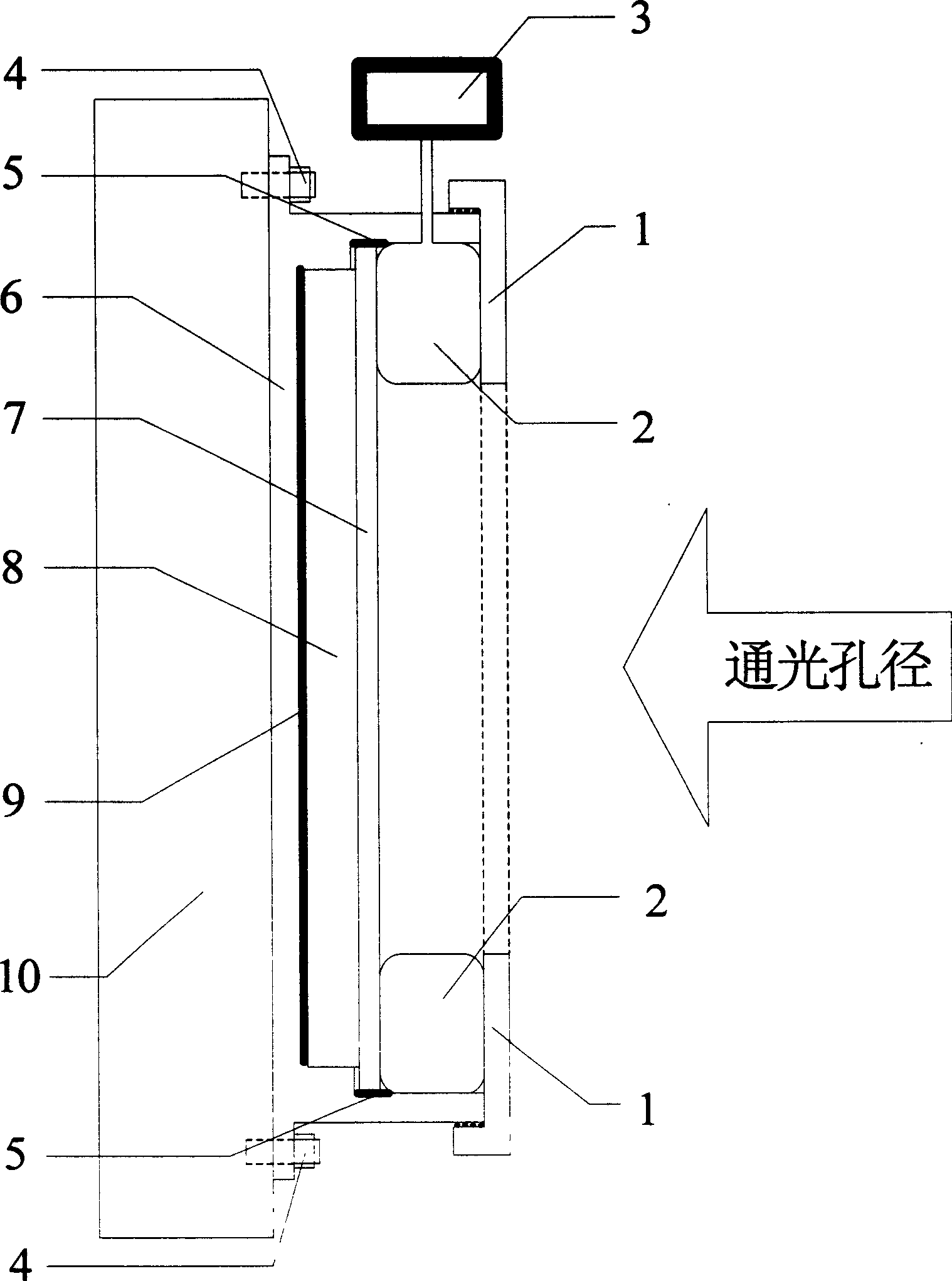

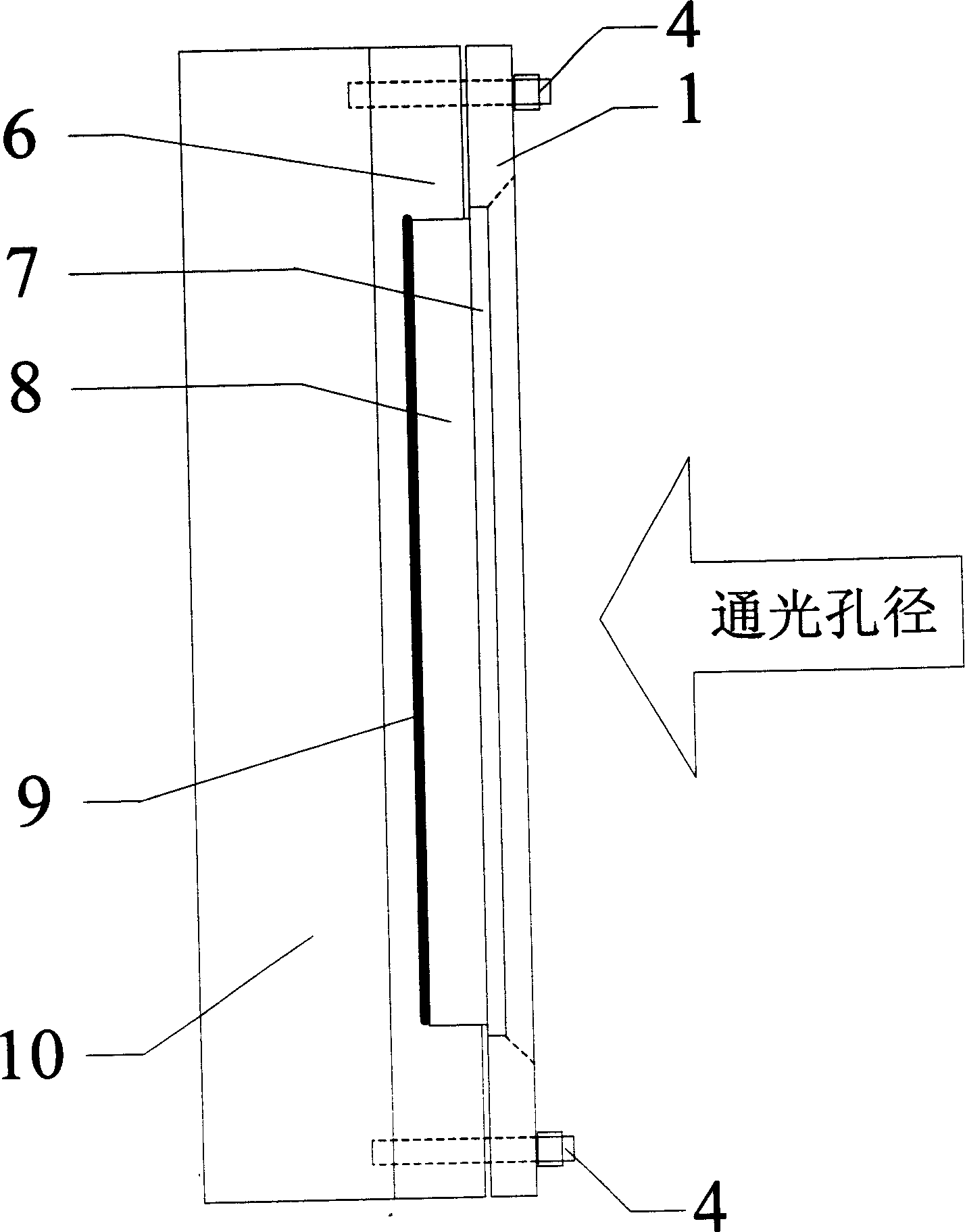

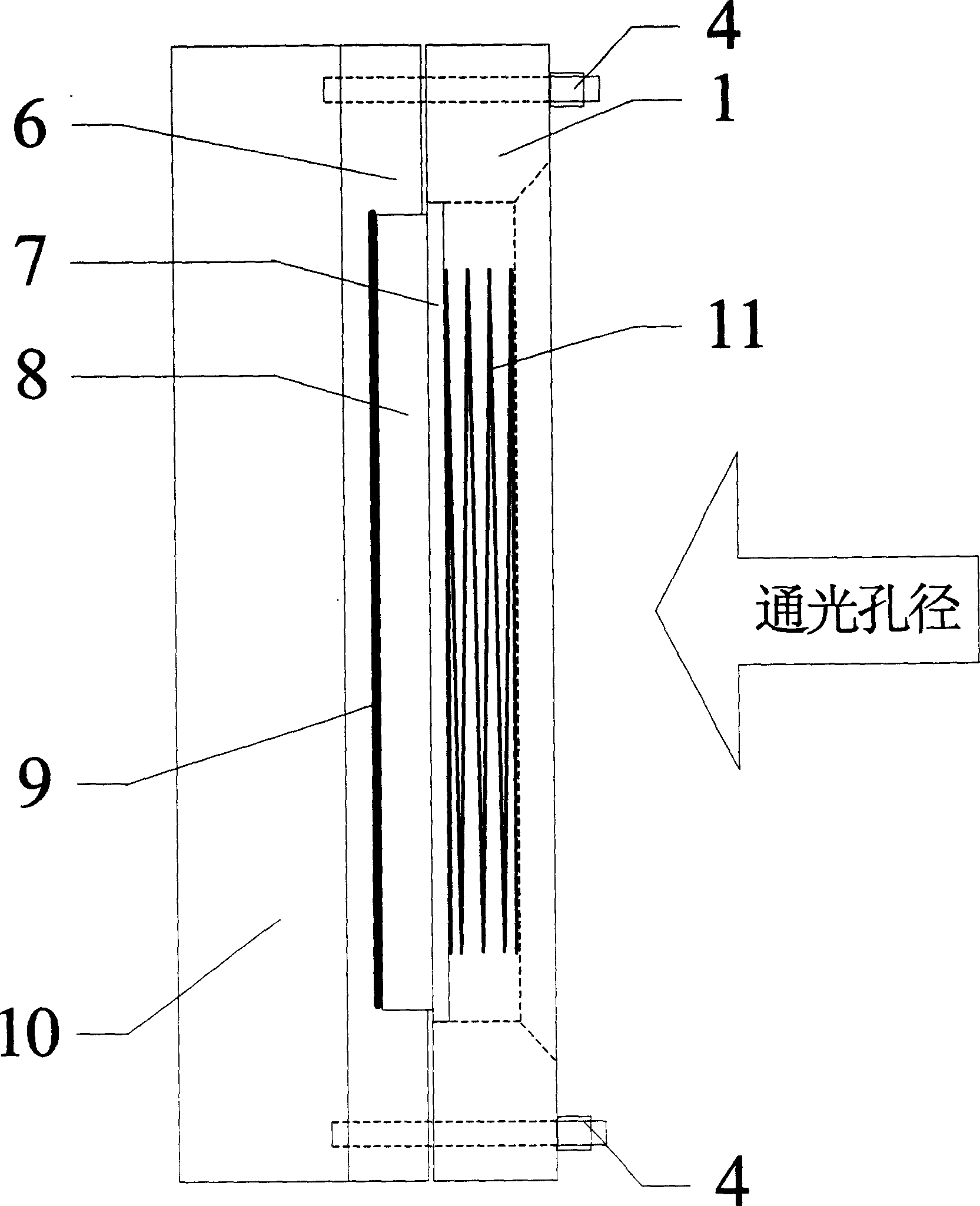

Laser medium cooling device of thin laser

InactiveCN1794522AGood heat conduction and cooling effectAdvance evenlyLaser detailsEngineeringRefrigerated temperature

A laser medium refrigerator of a film laser characterizes that the edge of a disk like sliding guide way providing slide of a white jewel window panel has a red copper clamp with outer screw thread to be fixed on a cooling plate by screws, the internal base of the red copper clamp has a thin In layer orderly set with said laser gain medium, the white jewel window panel and a micro-ring like sealed hydraulic pressure bag, then the ring inner screw thread with a cover presses said outer screw thread of the copper clamp to apply a force on the hydraulic bag connected with a meter externally.

Owner:SHANGHAI INST OF OPTICS & FINE MECHANICS CHINESE ACAD OF SCI

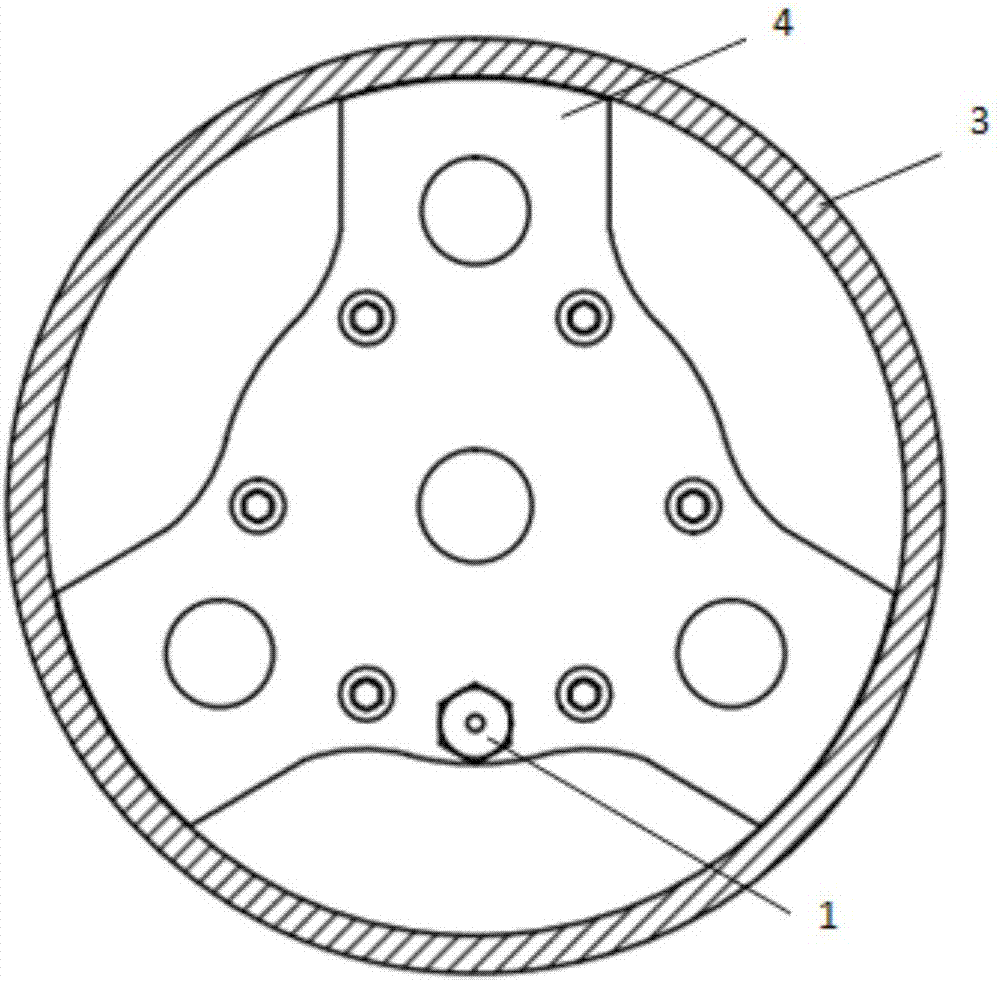

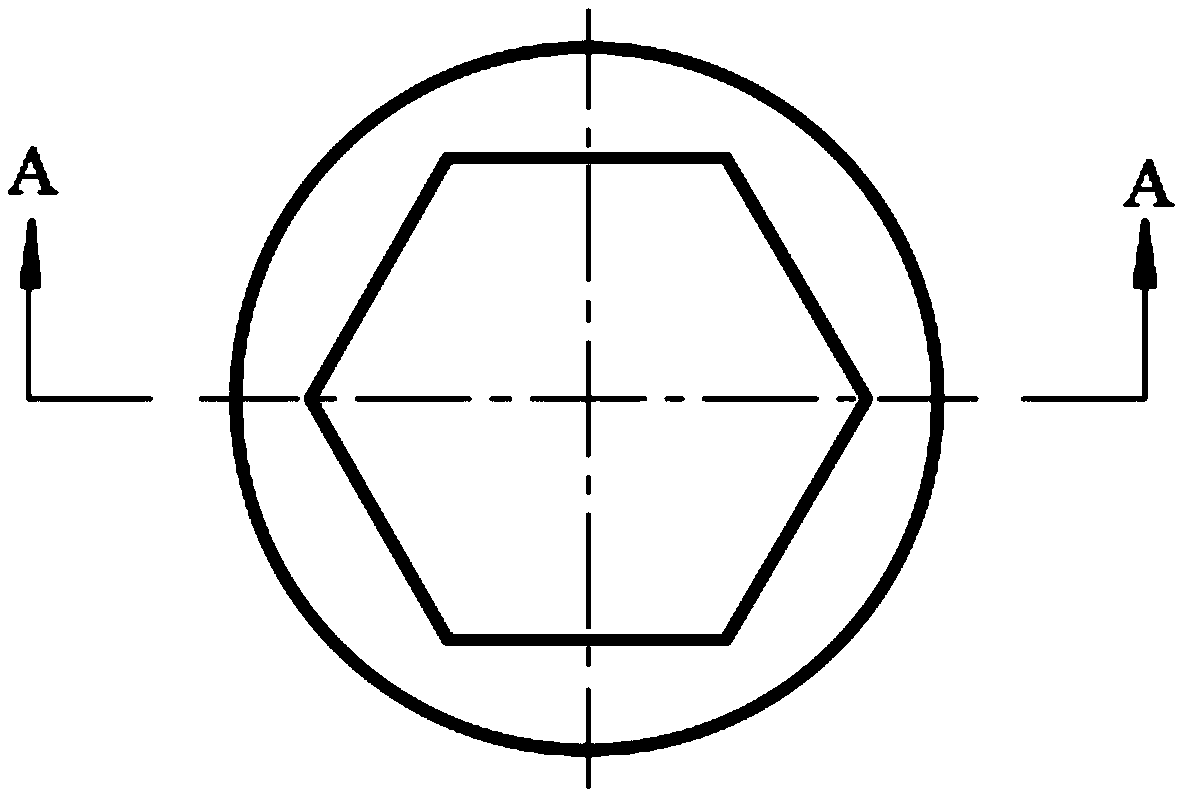

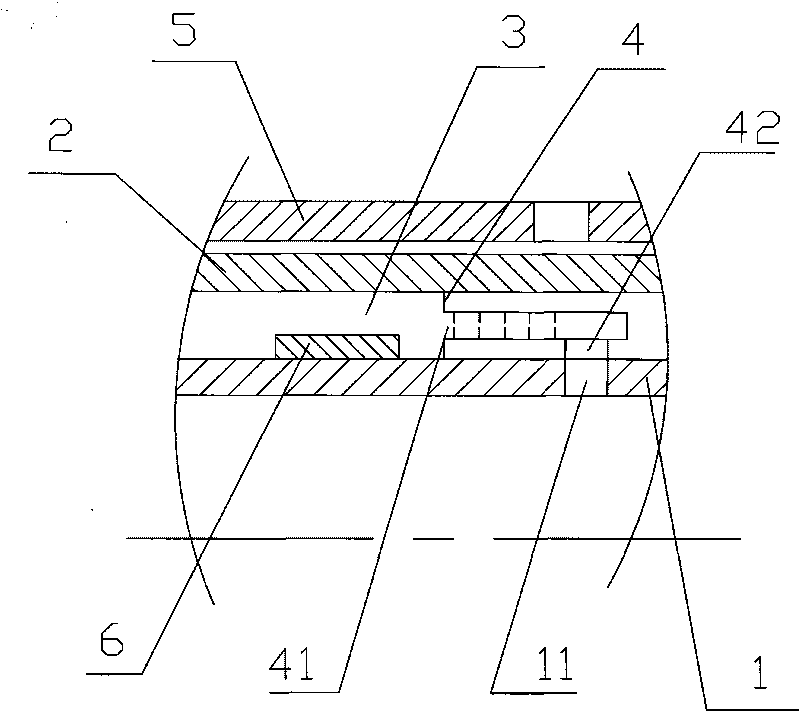

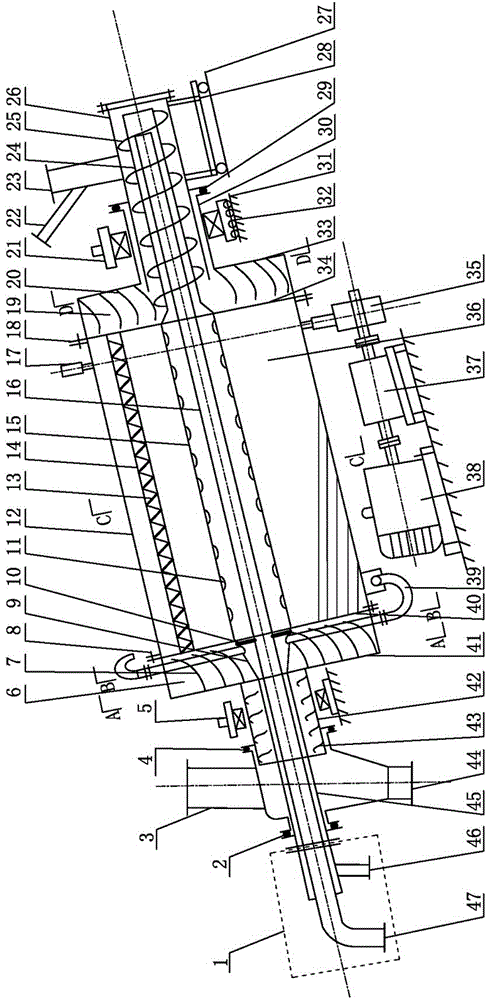

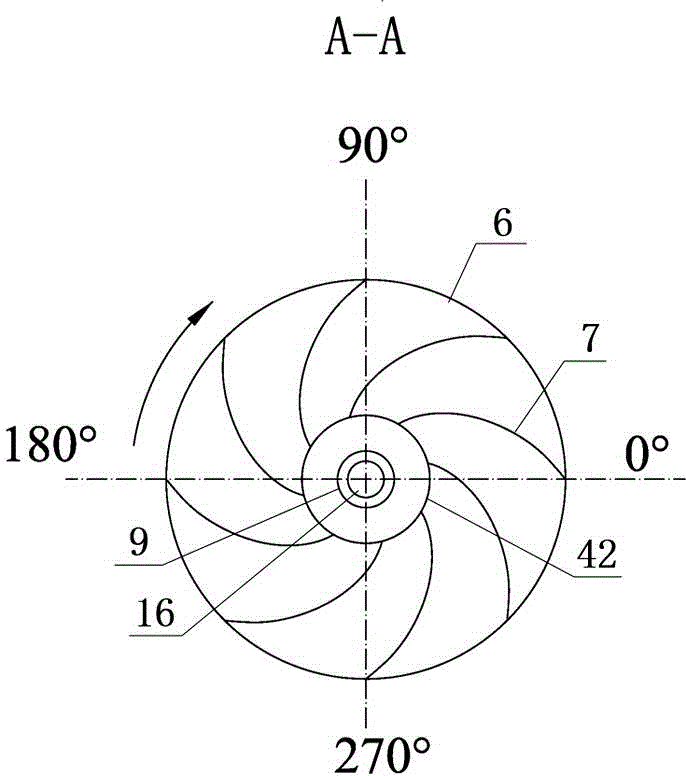

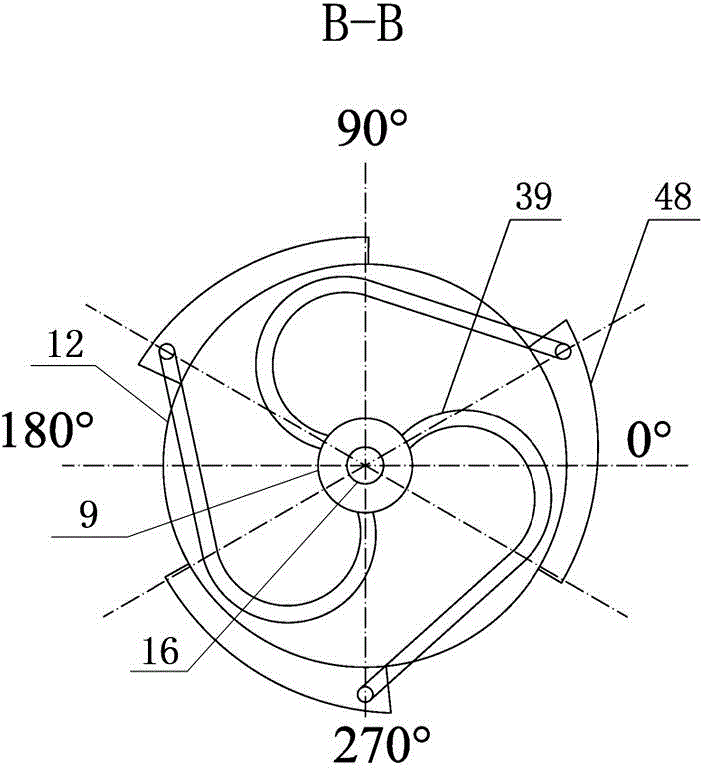

Cyclone type inflow control valve

ActiveCN109138939AAdvance evenlyExtend oil production timeFluid removalWell/borehole valve arrangementsCycloneEngineering

The invention discloses a cyclone type inflow control valve comprising a base pipe. A top cover and a sieving pipe sleeve the outside of the base pipe. A plurality of liquid inlets are formed in the middle of the base pipe; flow-limiting valves are installed at the liquid inlets and include upper end covers and bases; swirling chambers and swirling water chambers are arranged at the bases; nozzlescommunicated with the base pipes are arranged at the bottoms of the swirling chambers; guiding diversion grooves communicated with annular flowing channels and the swirling chambers are arranged on the side walls of the swirling chambers; nozzles communicated with the base pipes are arranged at the bottoms of the swirling chambers; and base pipe liquid inlets communicated with the flow-limiting valve are formed in the base pipe. The cyclone type inflow control valve has the following beneficial effects: the pressure drops of fluid flowing into the cyclone type inflow control valve can be adjusted automatically based on the nature of the fluid; and the cyclone type inflow control valve is suitable for the edge / bottom water reservoir and the gas capped reservoir with high anisotropy.

Owner:SICHUAN UNIVERSITY OF SCIENCE AND ENGINEERING

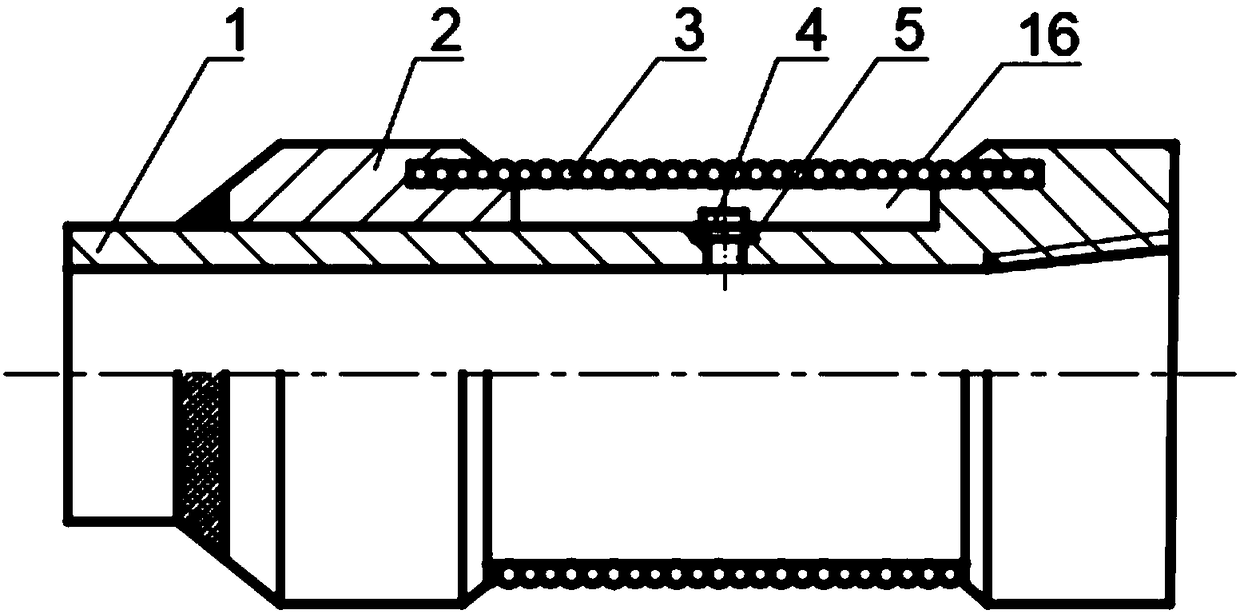

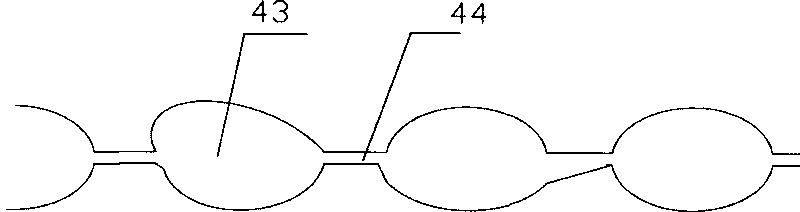

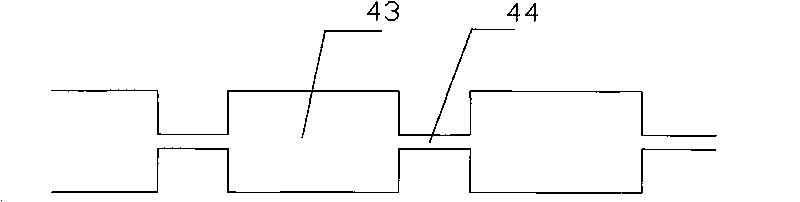

Highly-efficient flow control sieve tube

The invention discloses a highly-efficient flow control sieve tube. The sieve tube comprises a parent tube, wherein the parent tube is provided with a parent tube inlet; a filtering sleeve is sleeved outside the parent tube; a circumferential seam between the parent tube and the filtering sleeve is a flow deflecting layer; and the sieve tube is provided with a flow control device of which an inlet is communicated with the flow deflecting layer, while an outlet is communicated with the parent tube inlet. Under the condition of the relatively greater viscosity ratio of oil water, the sieve tube of the invention is cased off so that water yield is greatly reduced and oil production is slightly reduced. Before the surface of the oil water reaches the sieve tube, the flow velocities of a fluid at each position along a production section are substantially the same, which plays a role in controlling the uniform advancing of the oil water and delaying water breakthrough time.

Owner:ANTON OILFIELD SERVICES (GRP) LTD

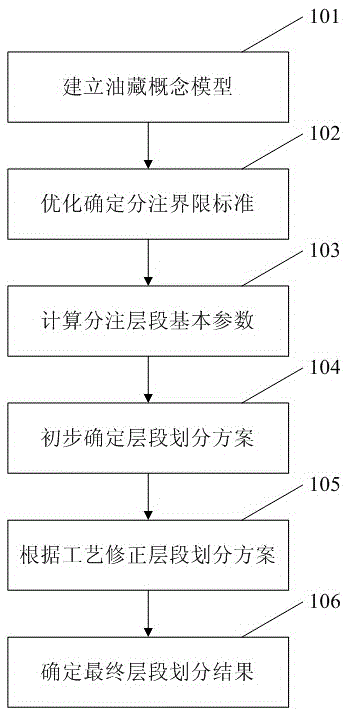

New method for dividing water injection layer sections of offshore water injection well

InactiveCN106801596AClear technical thinkingSimple applicationFluid removalInjection wellEnvironmental geology

The invention provides a new method for dividing water injection layer sections of an offshore water injection well. The new method for dividing the water injection layer sections of the offshore water injection well includes the following steps: a step 1, comprehensively considering the permeability gradational difference, the thickness gradational difference, the number of small layers in each layer, the water logging degree of each layer and the pressure difference so as to determine a water injection well layered injection boundary standard through a numerical simulation method; a step 2, counting the number of layers, the sand thickness, the permeability, the water logging degree and pressure distribution of an injection opened layer position of an existing layer section of the water injection well, and calculating the thickness gradational difference and the permeability gradational difference of each water injection layer section; a step 3, performing layer section primary division on the water injection well according to the layered injection boundary standard; and a step 4, considering the water injection process, performing suitable adjustment, and acquiring a final division result. The new method for dividing the water injection layer sections of the offshore water injection well is clear in thinking , is simple to apply, is feasible in offshore and similar oil reservoir water injection well layer section division.

Owner:CHINA PETROLEUM & CHEM CORP +1

Cylinder type wall plastering rod

ActiveCN106930507AImprove efficiencyImprove the efficiency of painting different wallsBuilding constructionsEngineeringMechanical engineering

The invention discloses a cylinder type wall plastering rod which comprises a plastering head used for plastering a wall surface and a plastering handle held by a user, wherein the plastering head is of a cylindrical structure; a cavity for storing oil paint is arranged in the cylinder; the cavity is communicated with outside through a plurality of through holes formed in the plastering head; first one-way blades are arranged in the through holes; each first one-way blade is composed of two semicircular blades opposite to each other and only can be opened from the inner side to the outer side of the cavity, so that the oil paint is in a one-way diversion form; the plastering head is connected with the plastering handle through a guide pipe; and the plastering handle is composed of a piston pipe and a handle tube. By sliding the piston pipe up and down, a pressure in the handle tube is changed, and the oil paint can be sucked into the handle tube by a feed pipe under the pressure effect. The operation is simple and rapid, and a process of repeatedly dipping the oil paint by a user is avoided.

Owner:山东远腾环保设备有限公司

Connection tool used for connecting pipelines and method for connecting pipelines through connection tool

InactiveCN108705482AUniform and stable movementNot easy to tiltPipe-jointsMetal-working hand toolsHydraulic pumpEngineering

The invention relates to the technical field of pipeline connection for construction, and discloses a connection tool used for connecting pipelines. The connection tool comprises a fixed frame, a movable frame and a manual hydraulic pump. The movable frame and the fixed frame are connected through a plurality of connecting columns which are evenly arranged in the circumferential direction. One endof each connecting column is fixedly connected with the movable frame, and the other end of each connecting column is slidably connected with the fixed frame. The manual hydraulic pump is connected with the connecting columns and is used for controlling sliding of the connecting columns. The connecting columns are evenly arranged between the fixed frame and the movable frame in the circumferential direction. The pipelines can move stably and uniformly in the moving process and are not prone to inclination, so that a sealing ring is prevented from turning, and the sealing performance of the sealing ring is ensured.

Owner:江苏无锡二建建设集团有限公司

Biomass hot blast stove device

InactiveCN106322359AStrong thrustBroad orientationSolid fuel combustionLump/pulverulent fuel feeder/distributionCombustionHot blast

The invention discloses a biomass hot blast stove device. The biomass hot blast stove device comprises a stove body. A main hearth, a first auxiliary hearth, a second auxiliary hearth and an air heating tube are arranged in the stove body and communicate in sequence. A secondary oxygen supply blast nozzle is connected with the air heating tube. The air heating tube penetrates the main hearth and the first auxiliary hearth to enter the second auxiliary hearth. The stove body is provided with a fuel inlet, the secondary oxygen supply blast nozzle and a gasifying agent, wherein the fuel inlet, the secondary oxygen supply blast nozzle and the gasifying agent communicate with the main hearth. The stove body is further provided with a hot air outlet. The hot air outlet communicates with a heating tube. Air duct interlayers are arranged on the two sides of the stove body. Air conveying plates are arranged in the air duct interlayers. An air conveying cover is arranged on the upper side of the stove body. The air conveying cover is provided with an air conveying opening. The biomass hot blast stove device is high in heat utilization rate, capable of achieving clean and complete combustion, convenient to use, high in safety and good in heat radiating performance.

Owner:SHUANGFENG ZHONGXIN TECH CO LTD

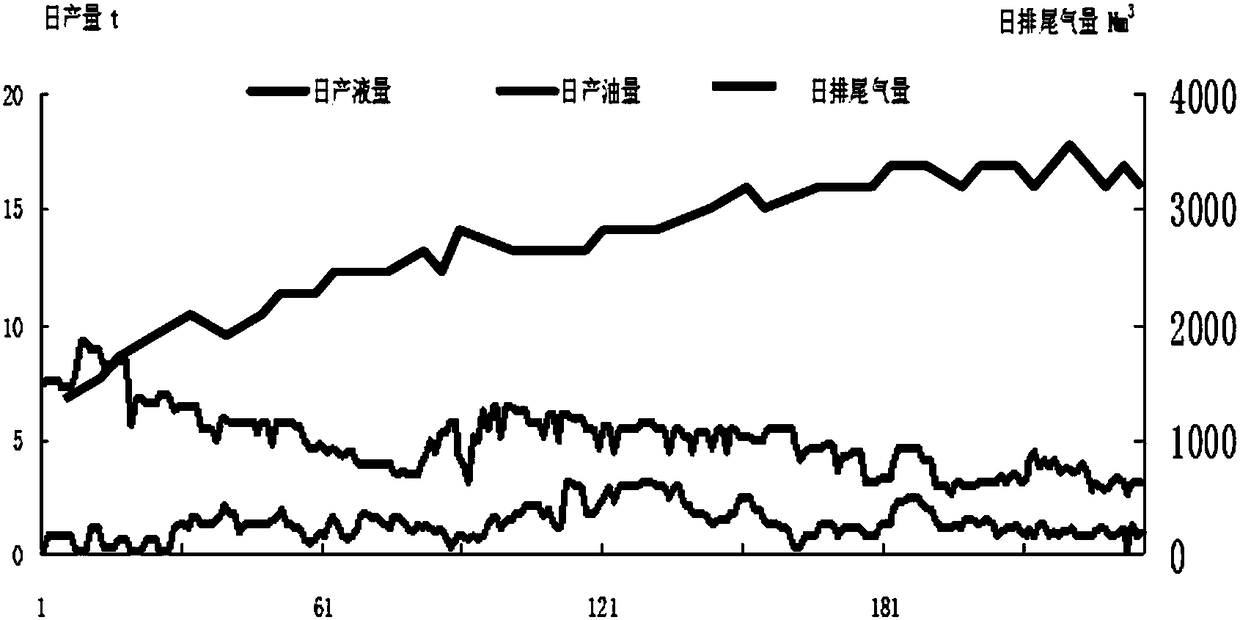

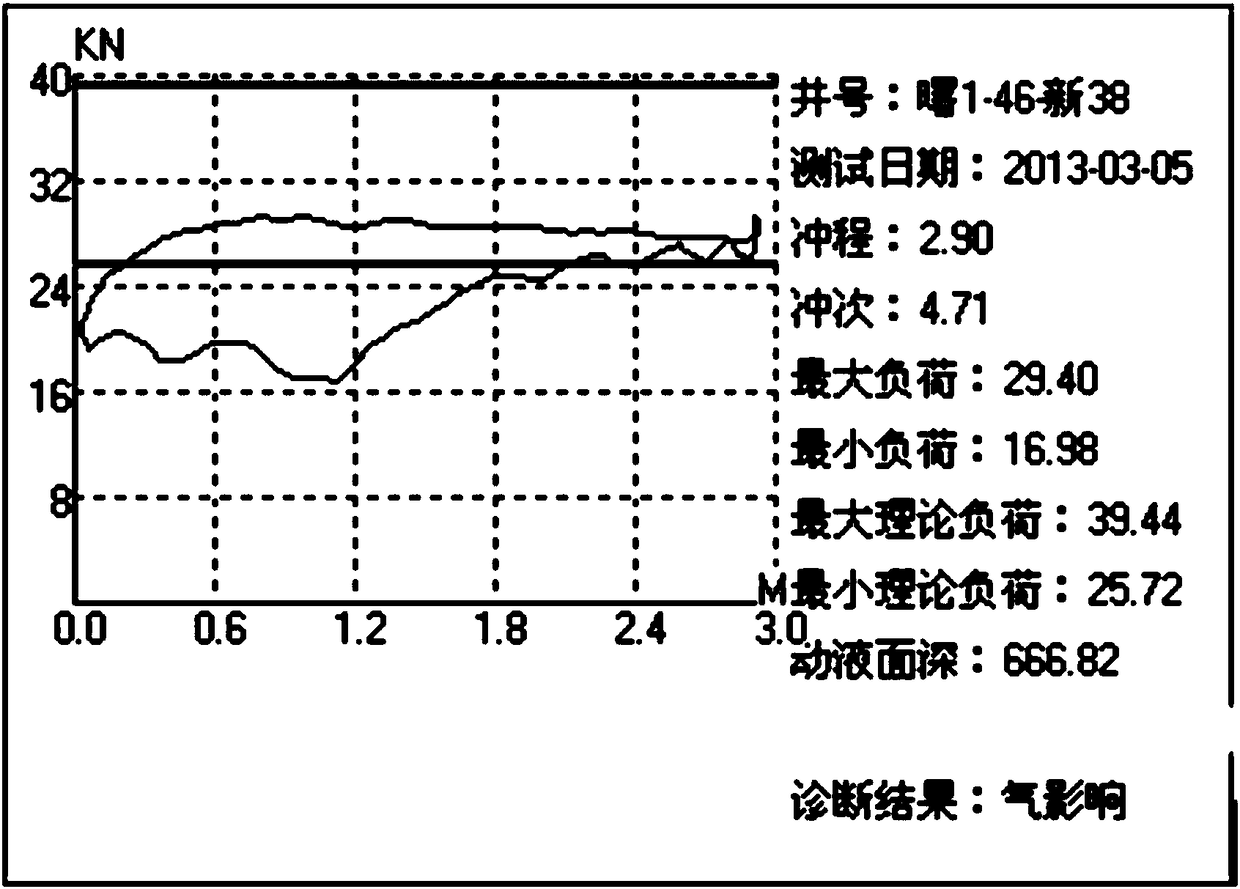

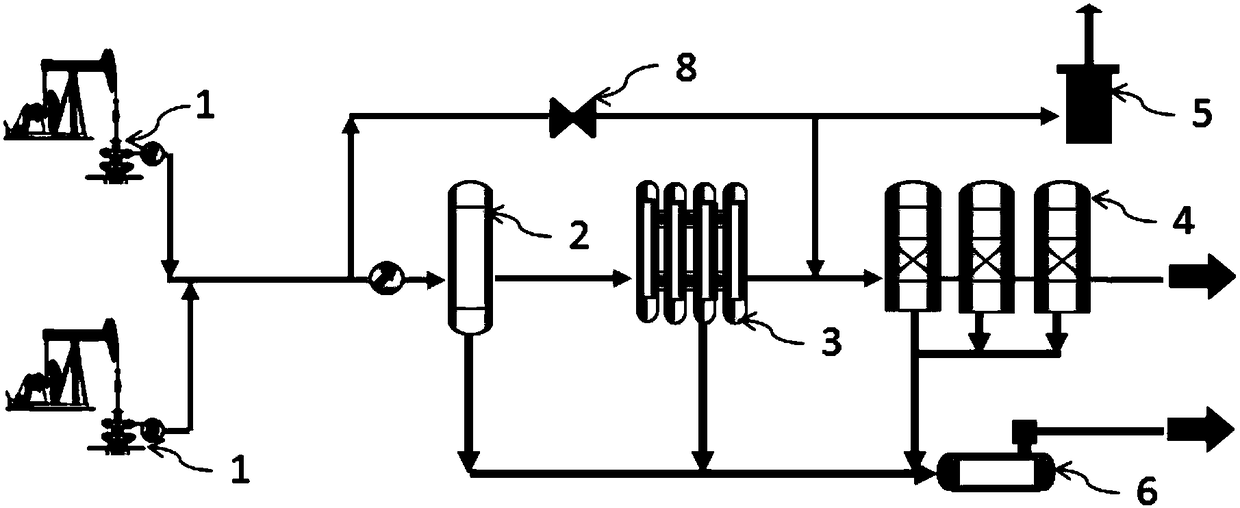

Treatment system and treatment method for fireflooding high exhaust gas well

InactiveCN108392958ARealize gas-liquid separationEnsure safetyGas treatmentDispersed particle separationExhaust gasWater content

The invention discloses a treatment system and a treatment method for a fireflooding high tail gas well and relates to the technical field of thickened oil fireflooding oil wells. The treatment systemfor the fireflooding high tail gas well comprises a cyclone gas-liquid separator communicated with an oil extraction wellhead, an air cooler connected with the cyclone gas-liquid separator as well asa desulfurizing tower and a plurality of desulfurizing tanks connected with the air cooler, wherein the cyclone gas-liquid separator is used for reducing the water content of tail gas inputted fromthe oil extraction wellhead; the inlet end of the cyclone gas-liquid separator can be communicated with the outlet end of the air cooler; the plurality of desulfurizing tanks are connected in parallel. According to the application, the problems of effusion and freeze blockage of a tail gas pipeline and failure of a desulfurization agent caused by water logging can be solved; meanwhile, the purification degree of the tail gas is improved.

Owner:PETROCHINA CO LTD

Brown coal rotary drying water removing device and brown coal rotary drying water removing method

ActiveCN104964537ASimple equipment structureGood securityDrying gas arrangementsDrying machines with non-progressive movementsBrown coalWater recovery

The invention discloses a brown coal rotary drying water removing device and a brown coal rotary drying water removing method. The water removing device comprises a rotary drying main machine, a driving device, a jacket type material screw feeder, a gas-solid product separation box and a rotation connector, wherein the rotary drying main machine is provided with a feeding end and a discharging end, and the rotary drying main machine is set to move in the axial direction when thermal expansion happens; the driving device is used for driving the rotary drying main machine to rotate around a shaft; the jacket type material screw feeder is connected with the feeding end of the rotary drying main machine; The jacket type material screw feeder is set to move in the axial direction of the rotary drying main machine when thermal expansion happens; one end of the gas-solid product separation box is connected with the discharging end of the rotary drying main machine; the rotation connector is connected with the other end of the gas-solid product separation box. The brown coal rotary drying water removing device is simple in structure, good in safety, efficient in heat exchanging, capable of saving energy, large in single machine processing amount, complete in water recovery, good in adjustability and capable of being widely applied to drying of brown coal of various grades.

Owner:BEIJING GUODIAN LONGYUAN ENVIRONMENTAL ENG +1

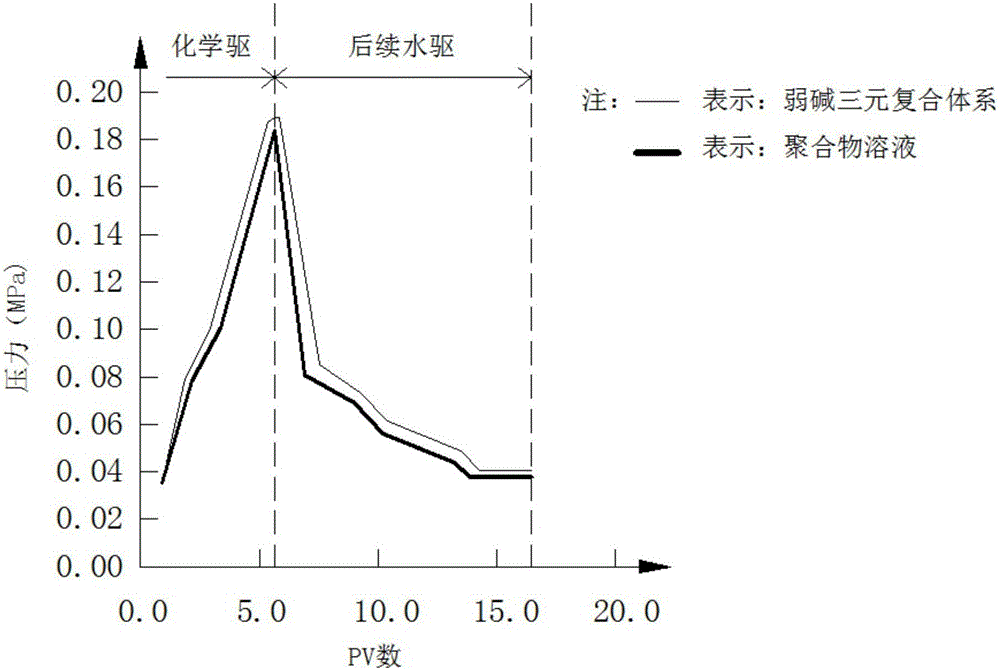

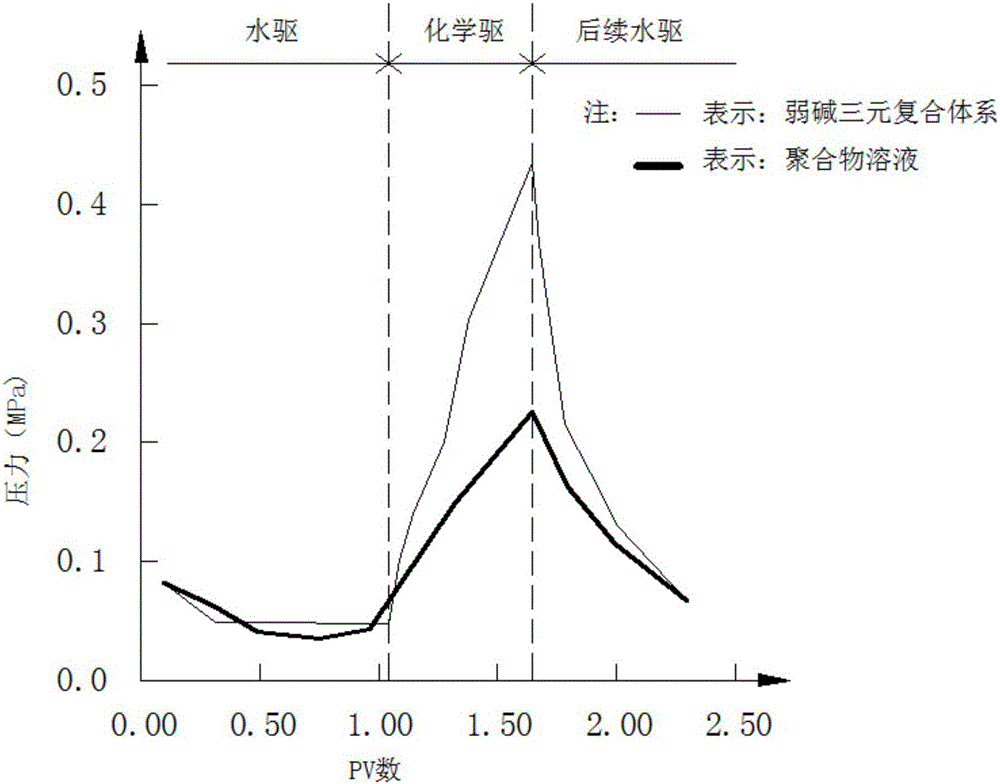

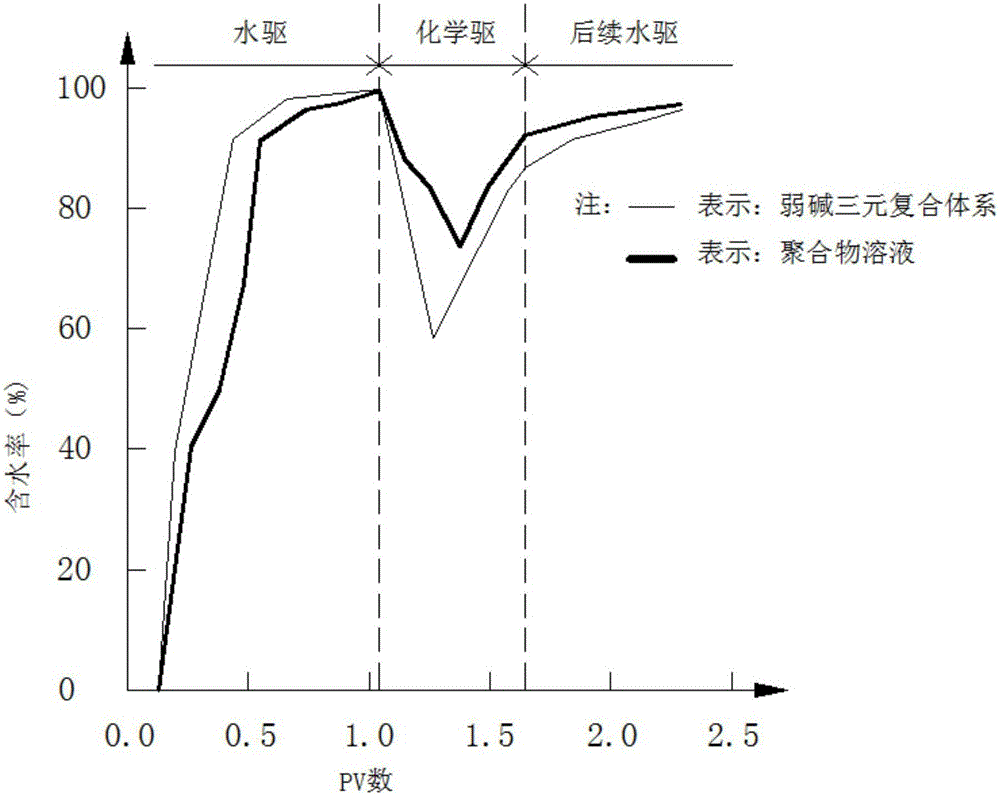

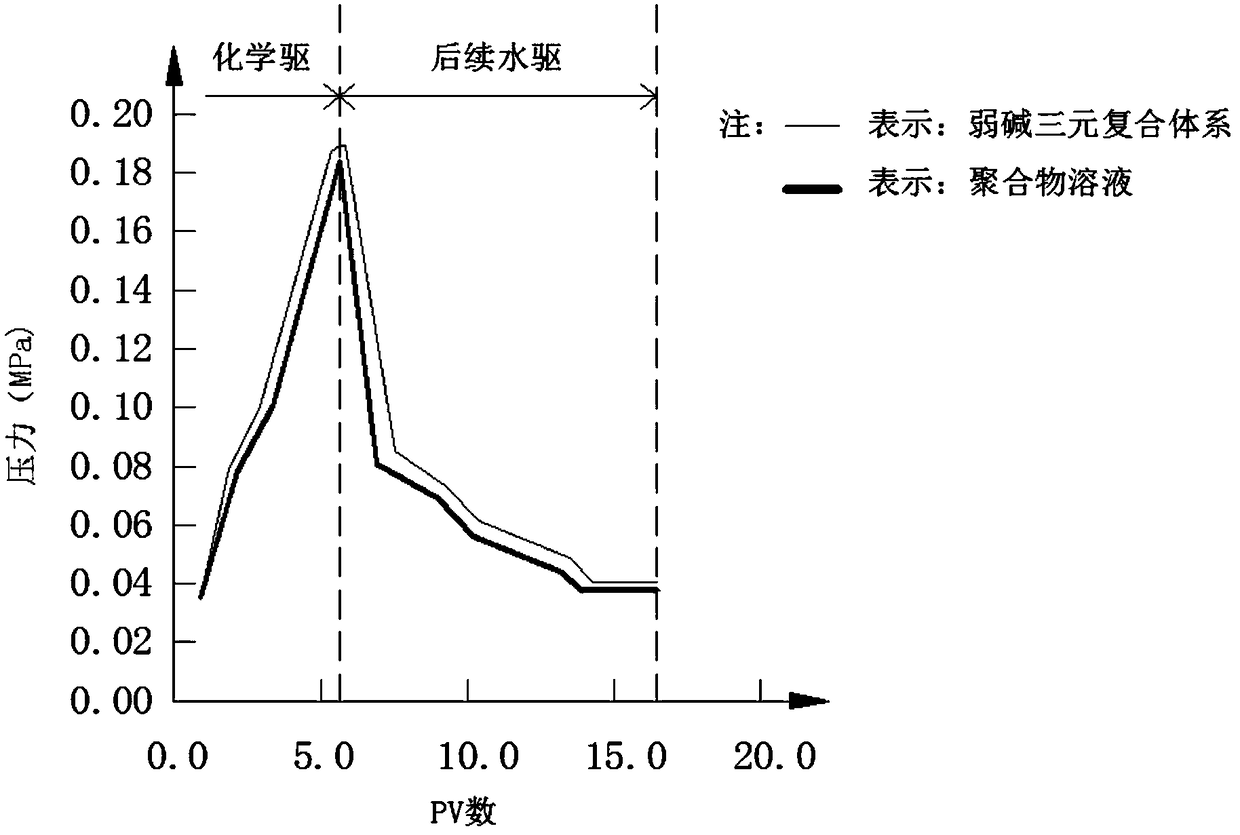

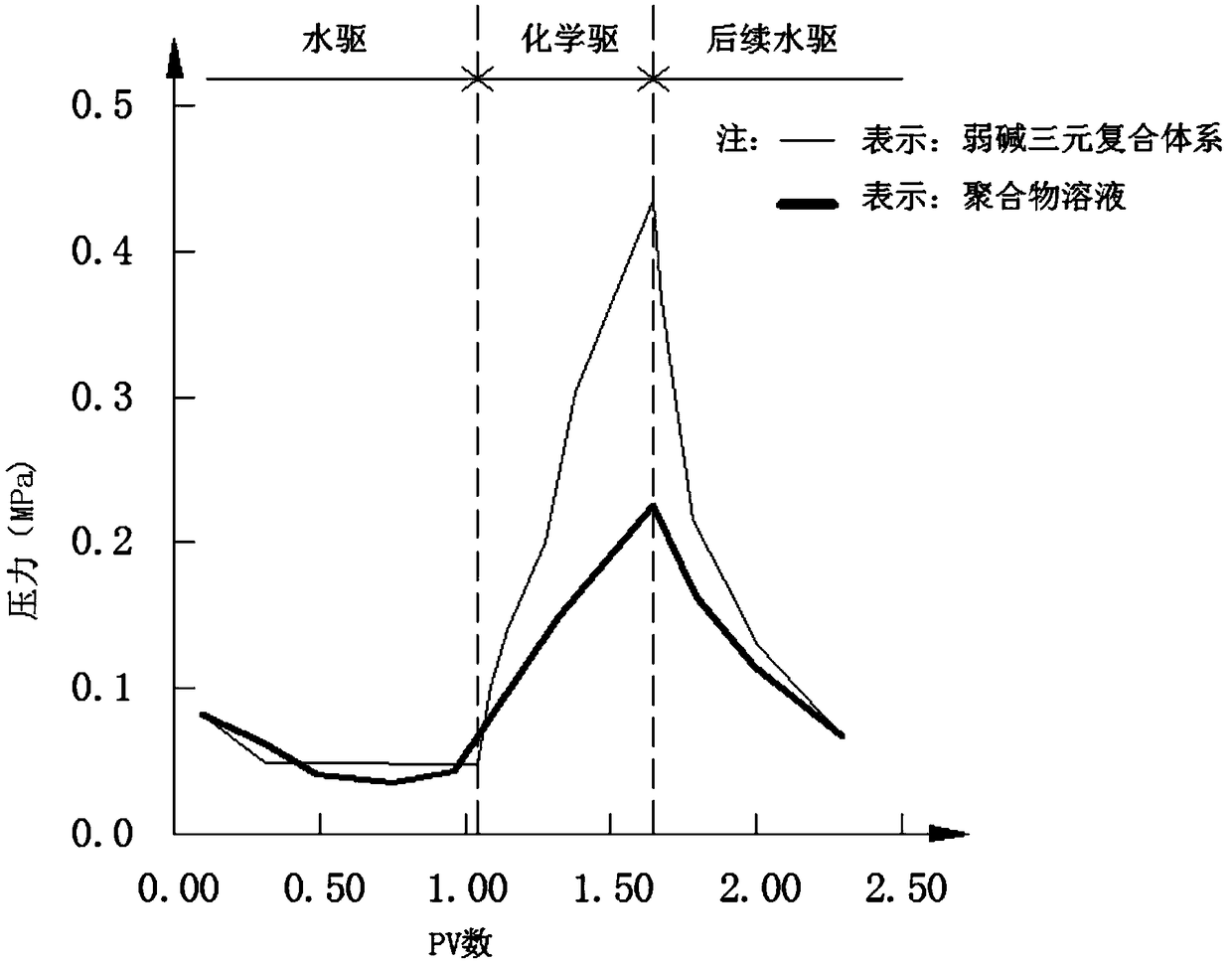

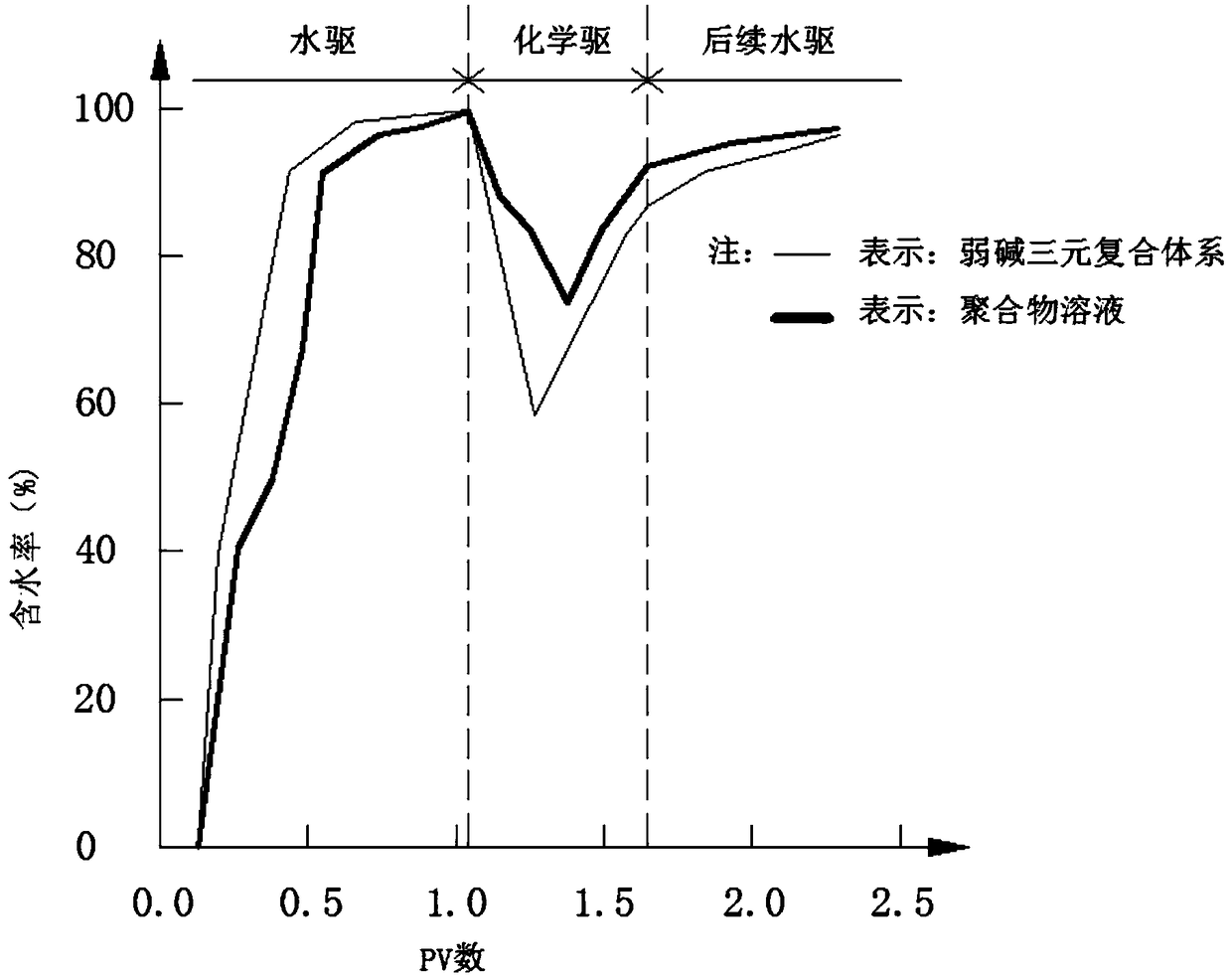

Analysis method for oil enhancing production mechanism of weak-based ASP flooding

The invention, which belongs to the technical field of petroleum reservoir exploration, particularly relates to an analysis method for an oil enhancing production mechanism of weak-based ASP flooding. The analysis method comprises an emulsification oil enhancing production mechanism analysis method, a solvent water oil enhancing production mechanism analysis method, and an injection-mode oil enhancing production mechanism analysis method. According to the emulsification oil enhancing production mechanism analysis method, on the condition of the same oil-displacing agent viscosity and same slug dimension, a polymer solution and weak-based ASP system seepage characteristic experiment is carried out in an unsaturated oil state of a core; and a polymer solution and weak-based ASP system oil displacement efficiency experiment is carried out in a saturated oil state of a core. According to the solvent water oil enhancing production mechanism analysis method, on the condition of the same oil-displacing agent viscosity and same slug dimension, a weak-based ASP flooding oil displacement efficiency experiment of sewage and a weak-based ASP system oil displacement efficiency experiment of descaling water are carried out respectively. And according to the injection-mode oil enhancing production mechanism analysis method, on the condition of the same oil-displacing agent viscosity and same slug dimension, a weak-based ASP system oil displacement efficiency experiment of sewage and a weak-based ASP system oil displacement efficiency experiment of descaling water are carried out respectively by means of constant-speed displacement injection; and a weak-based ASP system oil displacement efficiency experiment of sewage and a weak-based ASP system oil displacement efficiency experiment of descaling water are carried out respectively by means of constant-pressure displacement injection.

Owner:NORTHEAST GASOLINEEUM UNIV

Gem slicer

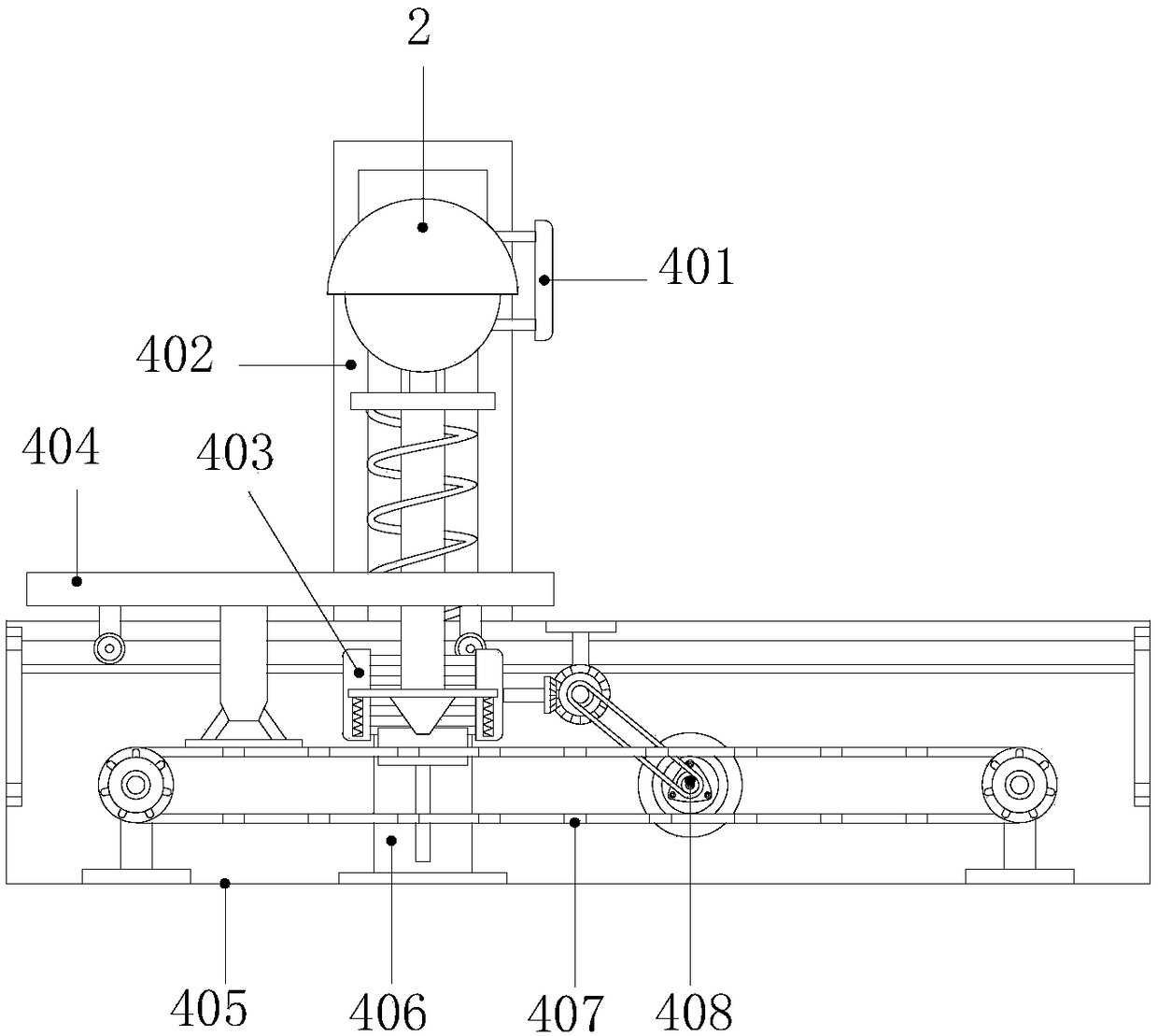

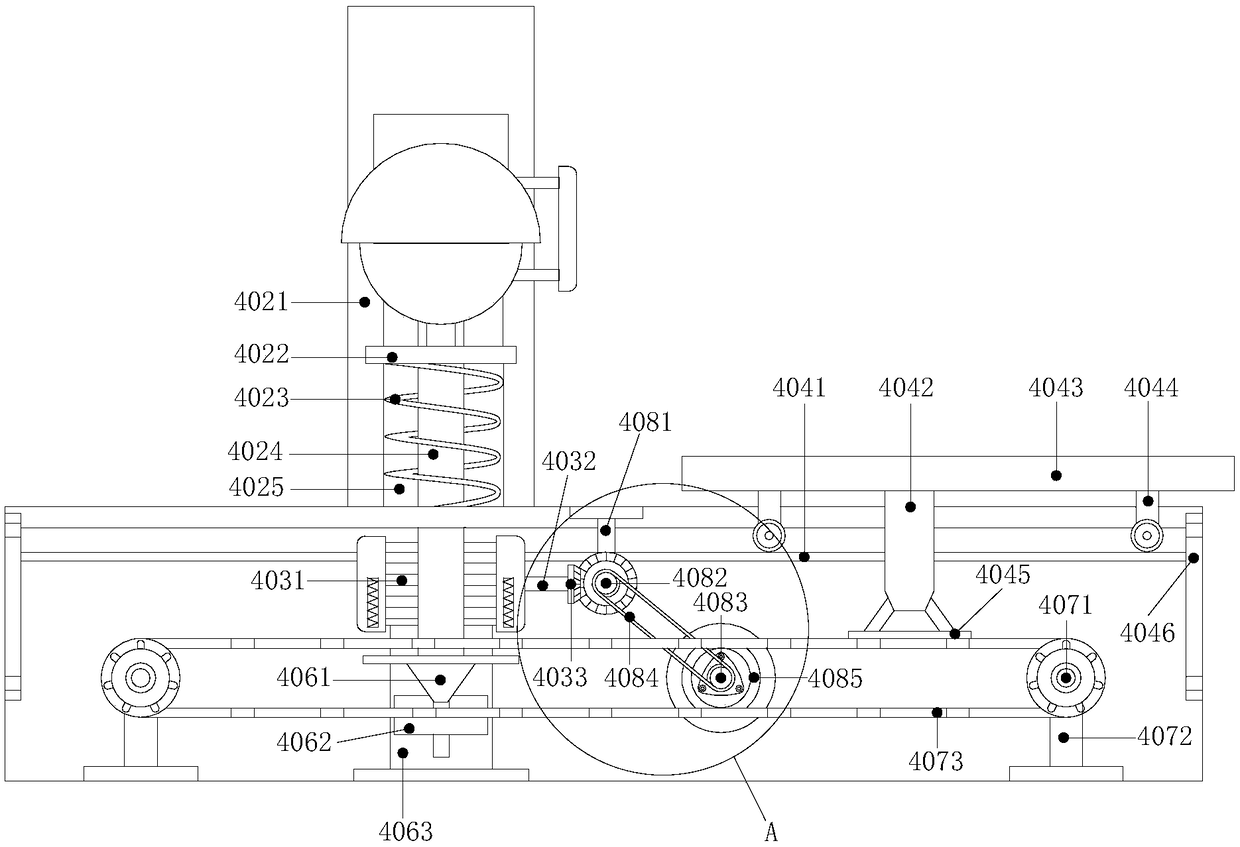

The invention discloses a gem slicer, which structurally comprises a slicing platform, a slicing main engine, a positioning vertical arm, an equipment main body, fixed ground feet and storage cabinets; the number of the arranged fixed ground feet is four, and the four fixed ground feet are evenly arranged at two ends of the bottom part of the equipment main body at an equal distance in a manner ofwelding; and each of two ends of the surface of the equipment main body is provided with the storage cabinet. According to the gem slicer disclosed by the invention, when the slicing main engine is controlled by a control handle of the equipment main body to press down to be ready for slicing, an installed vertical arm elevating mechanism presses down synchronously, and a starter is triggered; adriving mechanism is started; then, a transmission mechanism is driven by a link gear; the bottom part of the installed platform structure is connected with the transmission mechanism in a manner of meshing, so that the power of the transmission mechanism can be obtained; finally, gems on a holding plate are driven to be evenly pushed towards the right, therefore facilitating the slicing main engine to perform slicing. The step of manual pushing is canceled, so that time is shortened, uniformity of gem pushing is guaranteed, slices are prevented from being fractured, and the damage rate is reduced.

Owner:FOSHAN XUNTUOAO TECH CO LTD

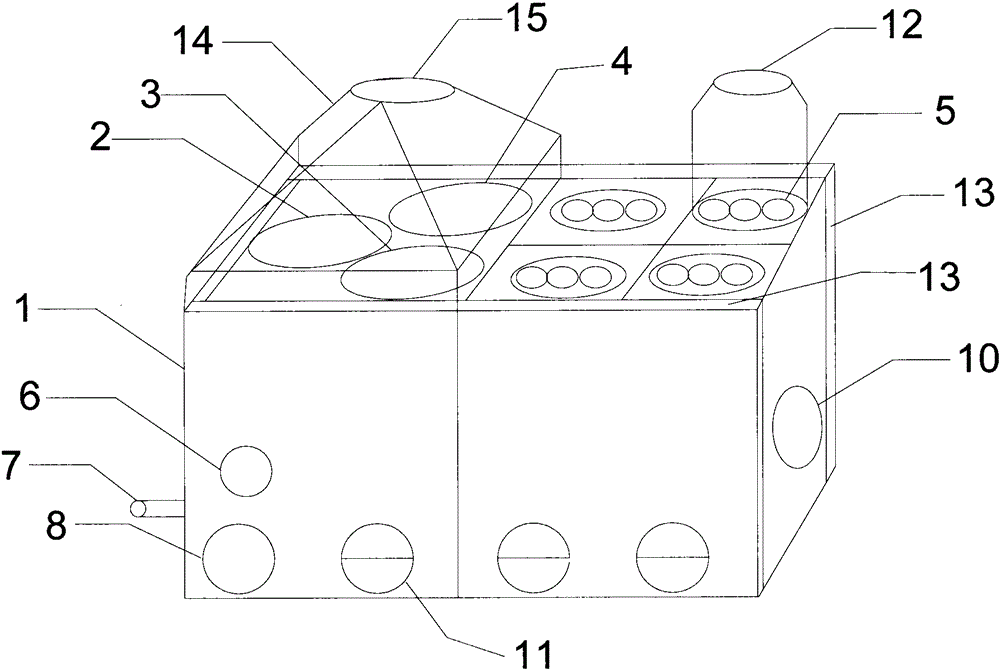

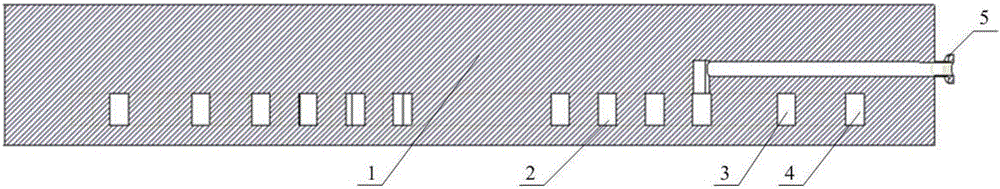

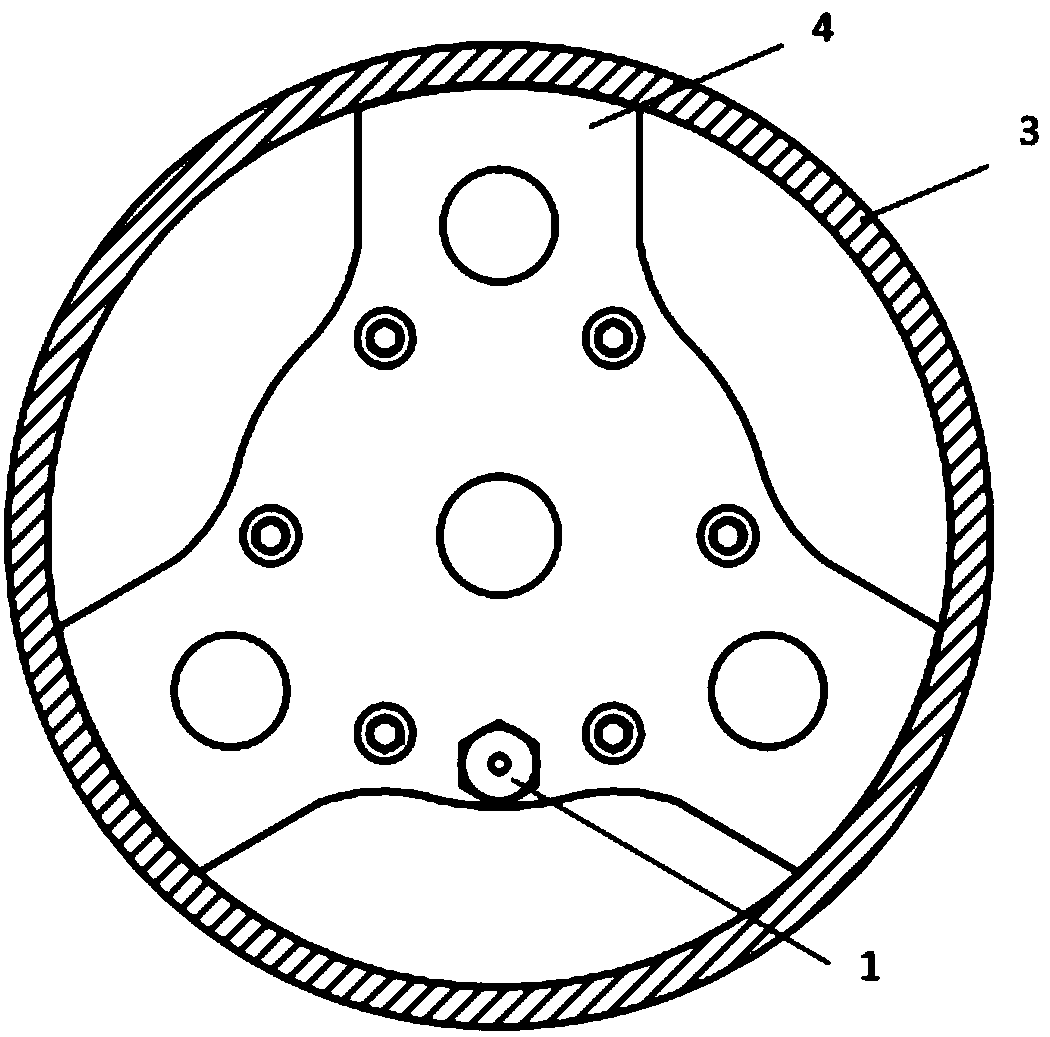

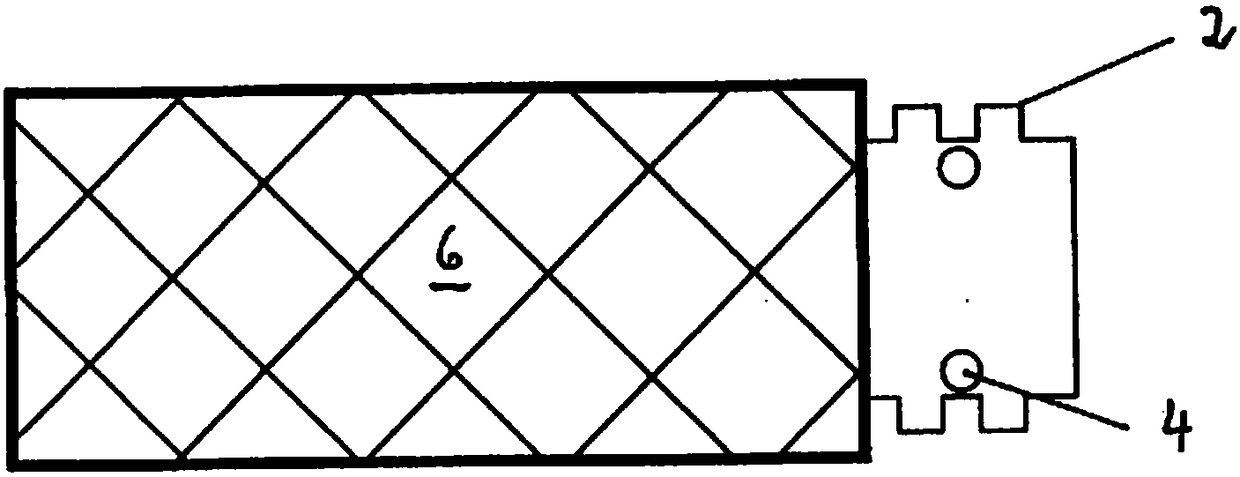

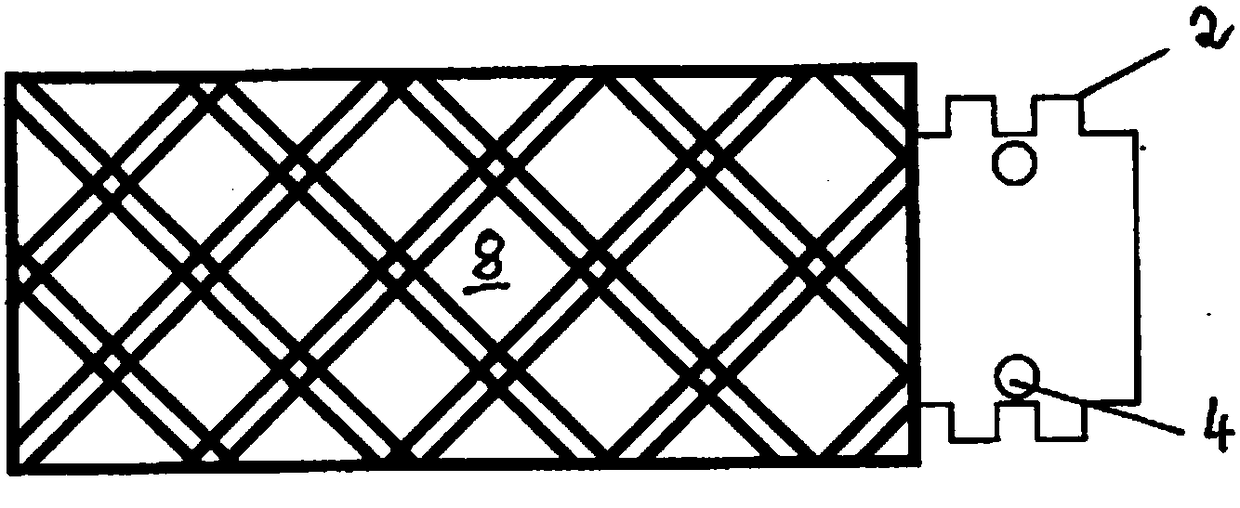

Extrusion die for producing high molecular weight polyethylene sheet material with breadth between 500 and 2,000mm

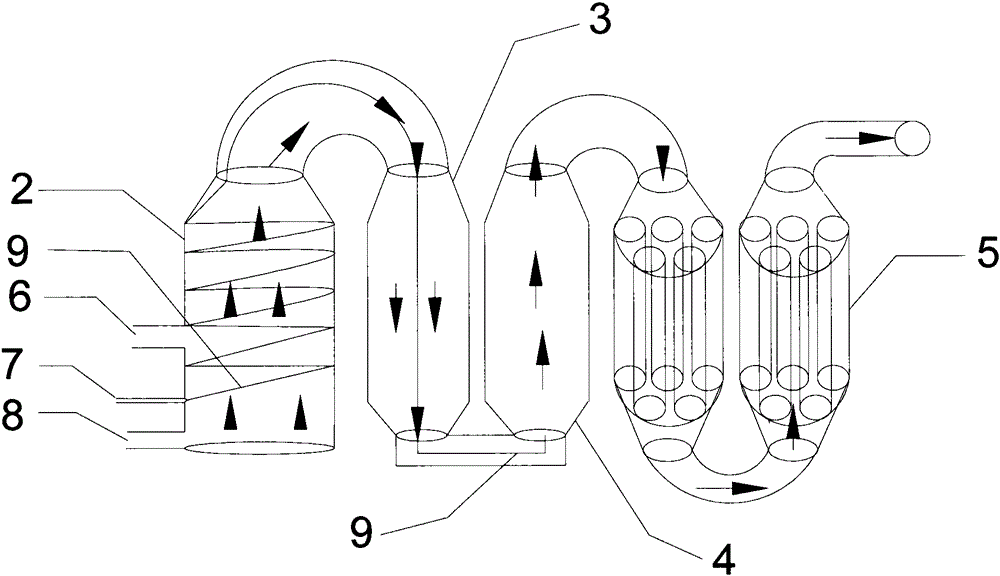

InactiveCN101804690AGuaranteed front pressureEnough front pressureFlat articlesEngineeringUltrahigh molecular weight

The invention provides an extrusion die for producing a high molecular weight polyethylene sheet material with a breadth between 500 and 2,000mm, which comprises guiding feeding channel structure main bodies 1, guiding feeding channels 2, adjustment monitoring valves 3, a die group 4, an interflowing body 5, dendritic channels 6 and adjustment plunger valves 7, wherein the guiding feeding channel structure main bodies are arrayed side by side; a plurality of extruders feed to the main bodies 1 respectively; a plurality of channels 2 are arranged in each main body 1; the channels are dispersed at the feed inlet of each main body 1 and are communicated with the die group 4 at the channel discharge end; the paths of the channels are independent mutually and are not communicated with each other; one adjustment monitoring valve 3 is arranged in each channel 2; the diameter of the adjustment monitoring valve is between 16 and 36mm; the die group 4 consists of the interflowing body 5 and a plurality of dendritic channels 6; the dendritic channels 6 are dispersed at the feed inlet of the die group 4 and are communicated with the interflowing body 5 at the channel discharge end; one adjustment plunger valve 7 is arranged in each dendritic channel 6; and the diameter of the adjustment plunger valves is between 9 and 26mm.

Owner:江苏联冠高新技术有限公司

Automatic cutting saw machine

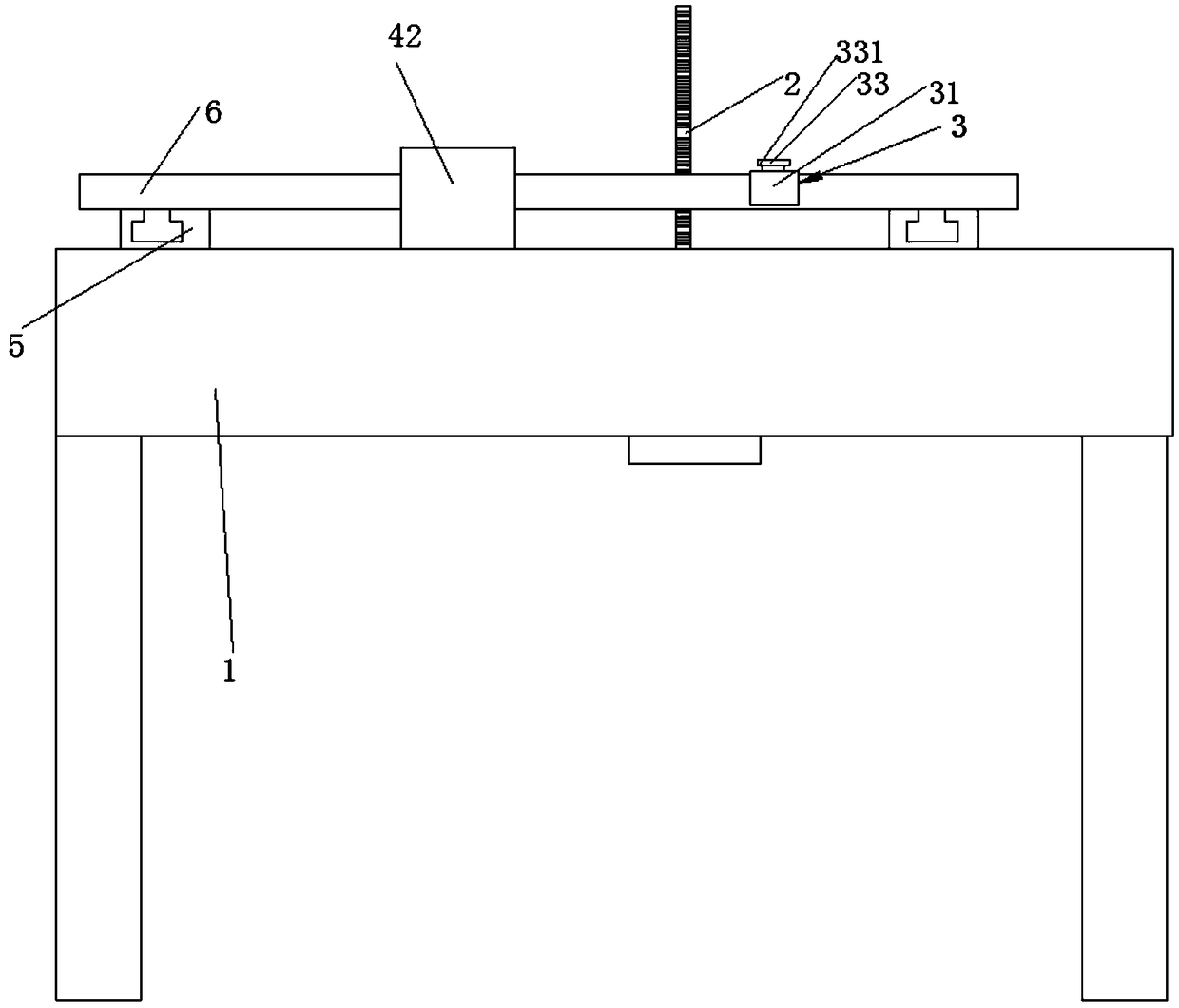

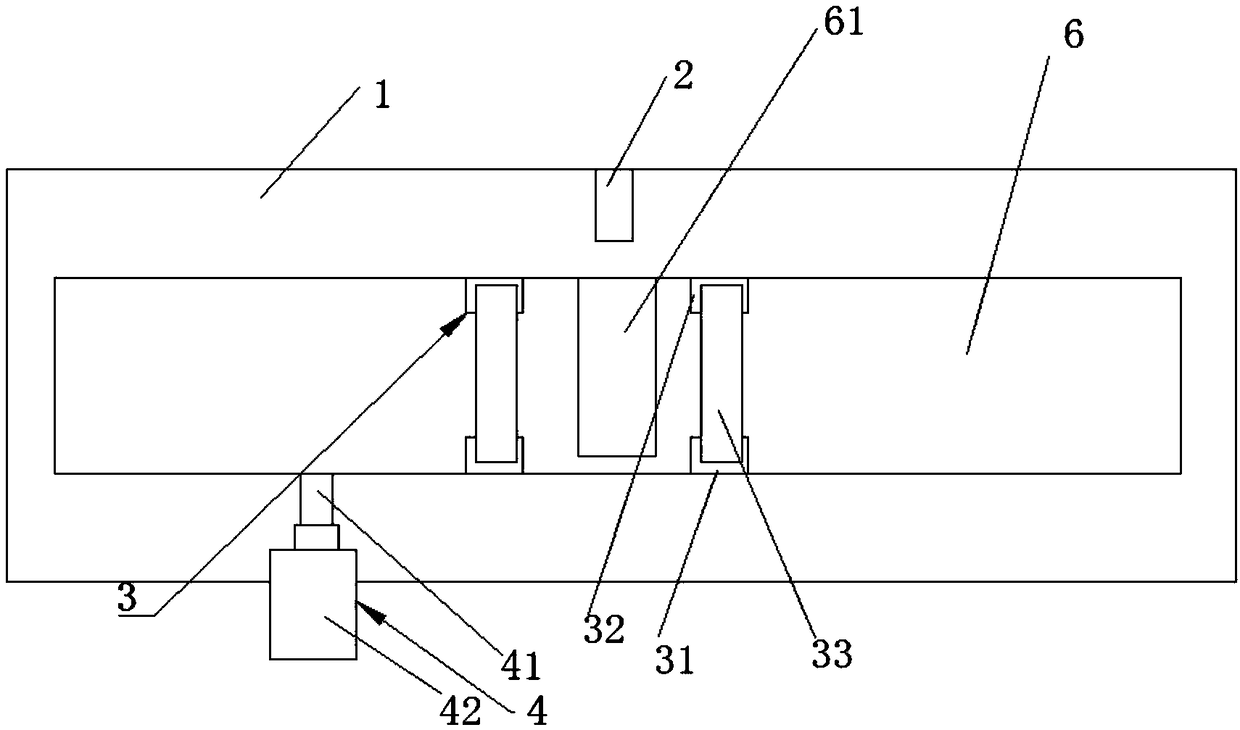

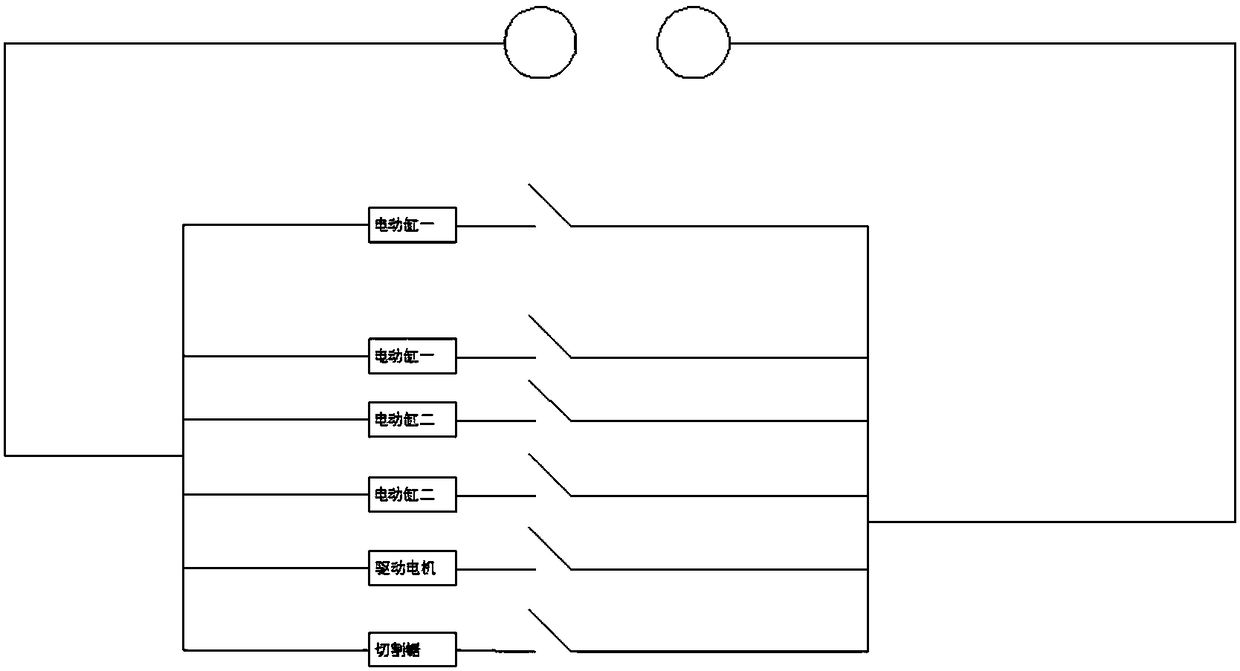

The invention provides an automatic cutting saw machine which comprises a cutting platform, a cutting saw, a fixing device and a pushing device. Guide rails are arranged at two ends of the cutting platform along the width direction, a support plate is arranged on the guide rails, two ends of the support plate are respectively and slidably connected with the guide rails, an opening is arranged in the position of the support plate and relative to the position of the cutting saw, the opening is used for cutting the path of walking, the pushing device comprises a screw and a drive motor, the screwpenetrates the support plate and is in threaded connection with the support plate, the end part of the support plate is fixedly connected with the output end of the drive motor, the drive motor is fixedly arranged on the cutting platform, the fixing device comprises a first electric cylinder and a second electric cylinder, the first electric cylinder and the second electric cylinder are respectively arranged on two sides of the support plate in an opposite manner, the seat of the first electric cylinder and the seat of the second electric cylinder are respectively arranged in the cutting platform fixedly, and the output end of the first electric cylinder and the output end of the second electric cylinder are connected through a pressing plate.

Owner:衢州聚英科技有限公司

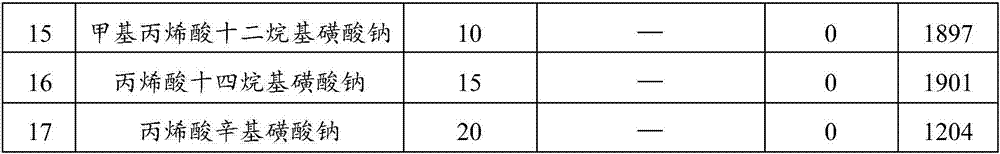

Composite oil-displacing agent for improving recovery efficiency as well as preparation method and application of composite oil-displacing agent

ActiveCN113621359AImprove utilization efficiencySuitable supercritical densityFluid removalDrilling compositionCyclopenteneActive agent

The invention discloses a composite oil-displacement agent for improving the recovery efficiency and a preparation method and application thereof, and belongs to the technical field of carbon dioxide displacement. The composite oil-displacing agent is obtained by mixing supercritical carbon dioxide and a surfactant according to a weight ratio of (100-1000): 1, the preparation method of the surfactant comprises the following steps: in formic acid, reacting a first monomer with formaldehyde to obtain a first reactant; reacting a second monomer with acyl chloride to obtain a second reactant; in the presence of an initiator, carrying out polymerization reaction on the first reactant and the second reactant to obtain the surfactant, wherein the first monomer is selected from at least one of 3-phenyl-4-pentene-1-amine, 4-pentene-1-amine, 4-methyl-pentene-1-amine and 2-amino-4-pentenoic acid, the second monomer is at least one of 1-butene, 1-pentene, 1-hexene and cyclopentene.

Owner:DESHI ENERGY TECH GRP CO LTD +1

Timber feeding device for furniture production

InactiveCN110843042AEasy to useAvoid shakingProfiling/shaping machinesStructural engineeringMechanical engineering

The invention discloses a timber feeding device for furniture production. The timber feeding device for the furniture production comprises an installing frame, a fixing frame and a plurality of conveying rollers, wherein each conveying roller comprises two rotating shafts and a roller shaft, a plurality of telescopic supporting columns are arranged at the lower end of the installing frame, the plurality of roller shafts are distributed on the inner side of the installing frame along the length direction of the installing frame and are connected with the installing frame through the rotating shafts, and a cutting space for installing cutting cutter bodies is reserved between any two roller shafts in the plurality of roller shafts; and a plurality of first placing grooves are uniformly formed in the roller shafts along the length direction of the roller shafts, second placing grooves are formed in the inner walls of the first placing grooves along the median line of the roller shafts inan extending mode, the first placing grooves and the cutting cutter bodies are in a one-to-one correspondence mode, the rotating shafts on the two adjacent roller shafts are in transmission connectionwith each other, and any rotating shaft is in transmission connection with a driving device, a fixing frame is arranged on the installing frame, and multiple pressure applying assemblies are uniformly arranged on the end face, facing the roller shafts, of the fixing frame, and the pressure applying assemblies are in one-to-one correspondence with the first placing grooves. The timber feeding device is simple to operate and convenient to use, and timber can be quickly and efficiently cut.

Owner:北京世纪京洲家具有限责任公司

Automatic tracking seam filling robot

The invention provides an automatic tracking seam beautifying and filling robot and belongs to the technical field of robots. The automatic tracking seam beautifying and filling robot is to solve the problems that labor is needed to clear tile seams for tile seam beautifying and filling, seam beautifying wastes time and labor, and uneven smearing is prone to occurring, so that a seam beautifying material overflows, therefore the material is wasted, and the overflowed material is troublesomely cleared. A base plate is sequentially provided with a camera, a hack lever, a processor, a controller, a power supply and an actuating device from left to right. The two sides of the processor and the controller are provided with a seam clearing device and a seam beautifying and filling device correspondingly, and the two sides of the base plate are provided with a plurality of direct current motors, and the output end of each direct current motor is provided with a wheel. A rotary device is installed at the bottom of the base plate and located at the left end of the base plate. According to the automatic tracking seam beautifying and filling robot, a tile can be automatically subjected to seam clearing and beautifying and can be protected, and impurities such as dust are prevented from flying upward.

Owner:HARBIN UNIV OF SCI & TECH

Method for greatly improving recovery ratio of permanently modified non-homogeneous oil reservoir

InactiveCN110905461ALower permeability limitAdvance evenlyFluid removalSealing/packingFluid phaseWater flooding

The invention discloses a method for greatly improving the recovery ratio of a permanently modified non-homogeneous oil reservoir. A dynamic balance control principle is put forward. Through continuous "establishing, breaking and re-establishing' of seepage resistance balance, the permeability limit of the oil reservoir is reduced to the maximum extent. A 'driving, adjusting and plugging integration' varied technical system is developed and is characterized in that an injection system is converted from a complete liquid phase to liquid and solid phase coexistence, and the viscosity of a solution becomes smaller to be in concert with the varied oil reservoir, so that the self-adaptive matching with complex rock pores is realized. After polymer flooding, low-permeability part oil which has not been used is harder to use compared with the condition of water flooding, so that the damage to a low-permeability part must be reduced in the oil reservoir non-homogeneous modifying process, adverse factors must be changed to favorable factors, polymer which exerts the displacement effect precipitates out of an injection liquid and becomes a solid phase to block a large pore passage, and meanwhile, liquid turning to the low-permeability part is like water as the precipitation of the polymer, and the damage to the oil reservoir is very small. Through the measures, the recovery efficiency can be theoretically improved by more than 30% on the basis of water flooding.

Owner:郭志东

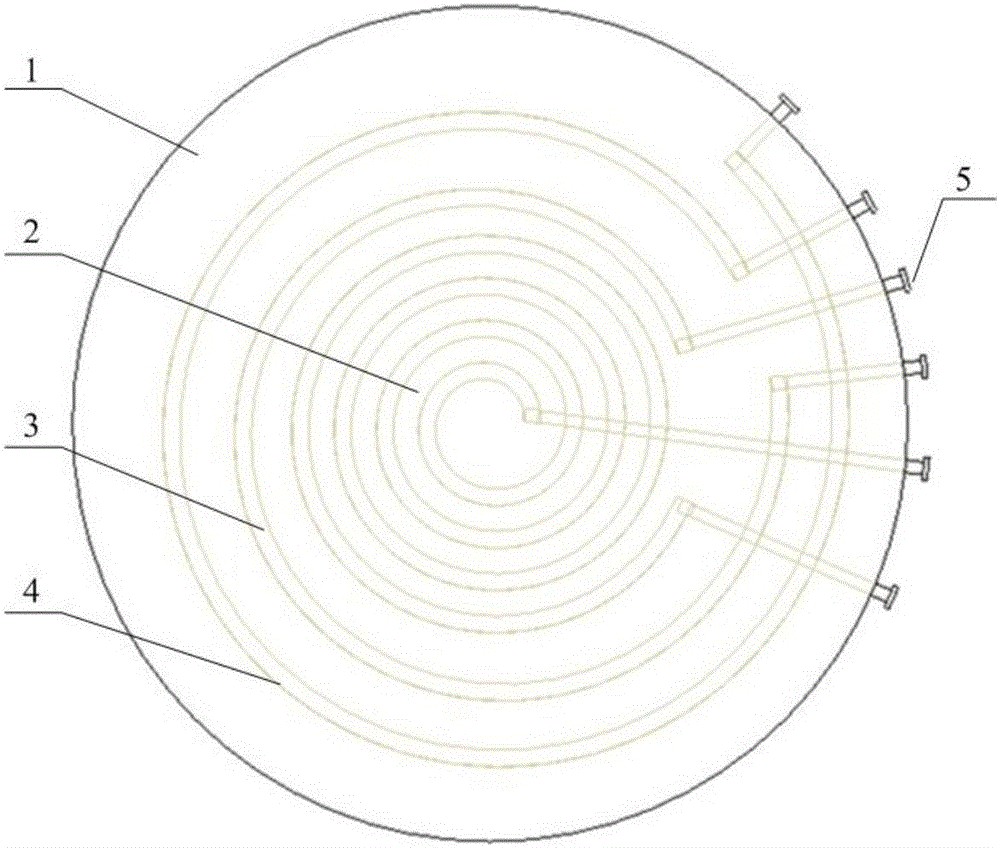

Water-cooling chassis for casting large steel ingot and using method

InactiveCN106623823AEnsure safetyReduce shrinkage porosity defectsIngot castingVolumetric Mass Density

The invention relates to a water-cooling chassis for casting a large steel ingot. The water-cooling chassis is used for a large steel ingot casting production process in the metallurgical industry and comprises a chassis body, multiple stages of cooling rings (a first-stage cooling ring, a second-stage cooling ring, a third-stage cooling ring and the like) and flanges, wherein the multiple stages of cooling rings are sequentially arranged in the chassis body from the center to the edge, and the distribution density of the cooling rings decreases progressively along with increase of the distance to the center; the chassis body takes the shape of a circle, a square or a rectangle, and accordingly, the multiple stages of cooling rings take the shapes of circles, squares or rectangles; and the flanges for connecting a cooling water system are arranged at the inlet ends and the outlet ends of the multiple stages of cooling rings. The water-cooling chassis can shorten the steel ingot coagulation time to improve the production efficiency, can enhance the up-down solidification sequence during the steel ingot solidification process, and particularly can improve the cooling strength of a central area at the bottom of the large steel ingot to promote uniform propulsion of a longitudinal solidification layer and alleviate the shrinkage cavity loose defect of the center of the large steel ingot.

Owner:UNIV OF SCI & TECH BEIJING

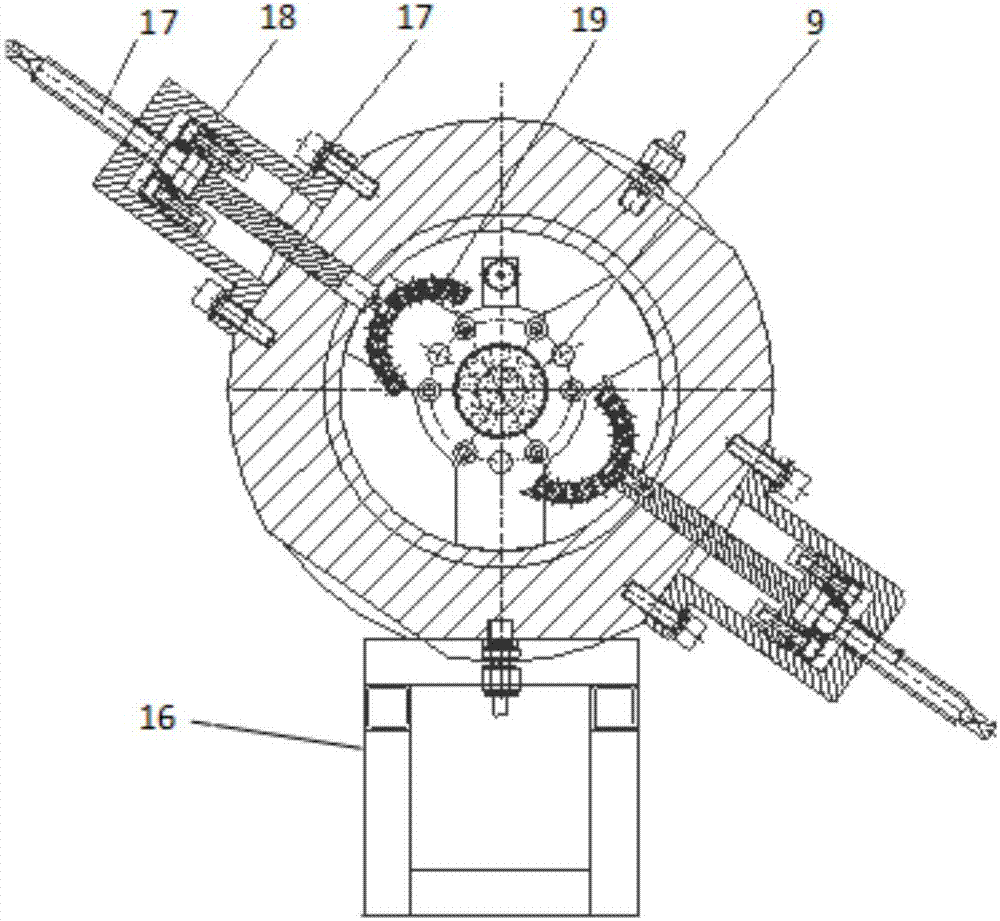

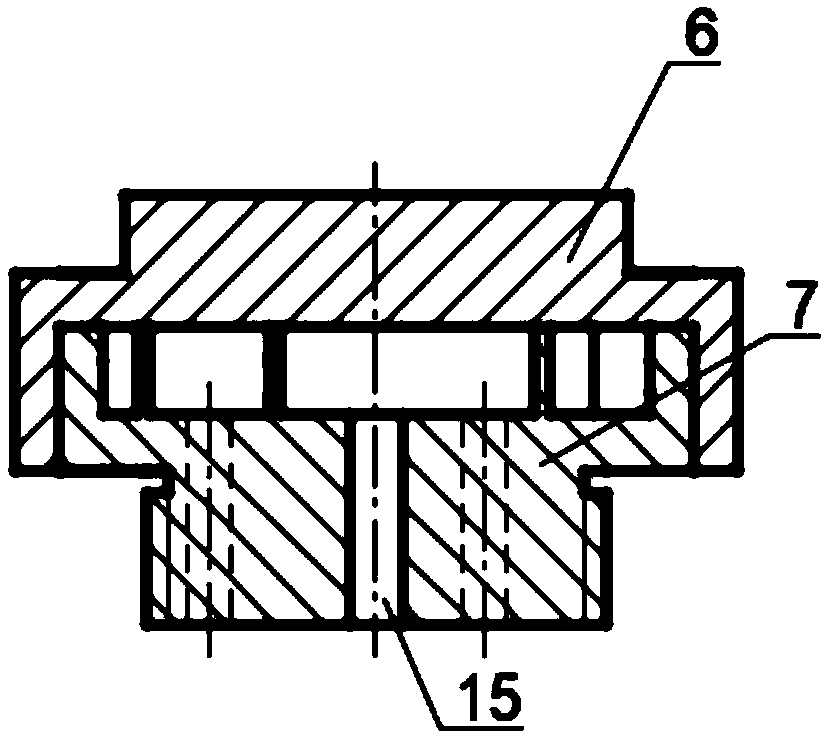

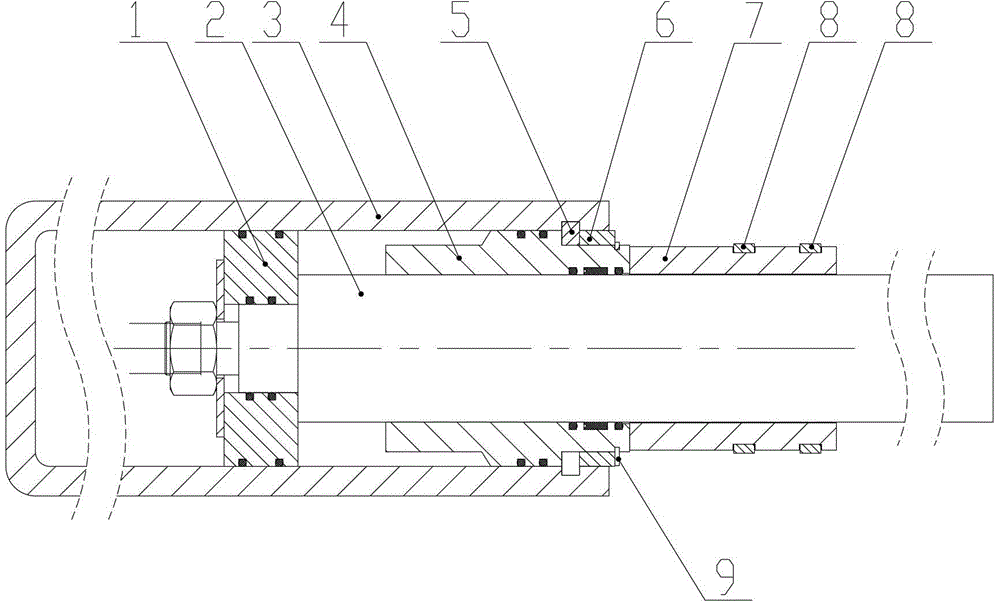

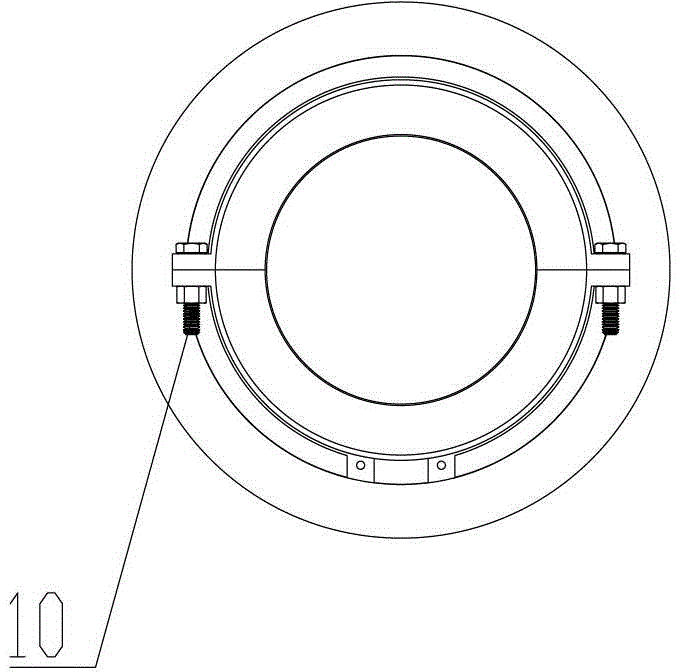

Inner semi-ring connected oil cylinder dismantling tool

ActiveCN103144074BAdvance smoothlyAdvance evenlyMetal-working hand toolsMechanical engineering technologyEngineering

The invention relates to an inner semi-ring connected oil cylinder dismantling tool, and belongs to the technical field of mechanical engineering. The tool is characterized by comprising a jack sleeve, a jack sleeve locking ring and a fastening piece, wherein the jack sleeve is mounted on a piston rod; the jack sleeve is provided with the jack sleeve locking ring; and the fastening piece for clamping is mounted on the jack sleeve locking ring. The tool has the advantages of simple structure, compact assembly, low cost, convenience in use, high dismantling efficiency, no damage to the piston rod and a cylinder barrel and the like.

Owner:TIANJIN ENG MACHINERY INST

Special reaction kettle for simulating sand production process of hydrate-containing sediments and its test method

ActiveCN106950153BAchieving a stressful environmentSolve the technical problem of "standing" difficultyFlow propertiesParticle size analysisStress conditionsTest sample

The invention belongs to the technical field of marine gas hydrate resource exploitation engineering and in particular relates to a special reaction kettle capable of simulating a dynamic variation rule of parameters in a sand production process of a hydrate-containing sediment under a true stress condition and a testing method thereof. The reaction kettle comprises a pressurizing kettle device and a holding device. The pressurizing kettle device comprises a reaction kettle body, a sediment clamping rubber gasket, an upper flange disc, a supporting flange, a lower flange cover and a piston pressurizing ejector rod. The sediment clamping rubber gasket and the supporting flange are arranged in the reaction kettle body, the supporting flange slides along the inner wall of the reaction kettle body, and a flowing channel where a confining pressure liquid circulates is arranged between the supporting flange and the inner wall of the reaction kettle body; one end of the piston pressurizing ejector rod penetrates through the upper flange cover and is in contact with the supporting flange, and a groove in contact with the piston pressurizing ejector rod is arranged on the end surface of the corresponding supporting flange. An in-situ forming demand of a hydrate sediment test sample is met, and sand production dynamic simulation in a condition of hydrate saturated degree of actual stratum is achieved.

Owner:QINGDAO INST OF MARINE GEOLOGY

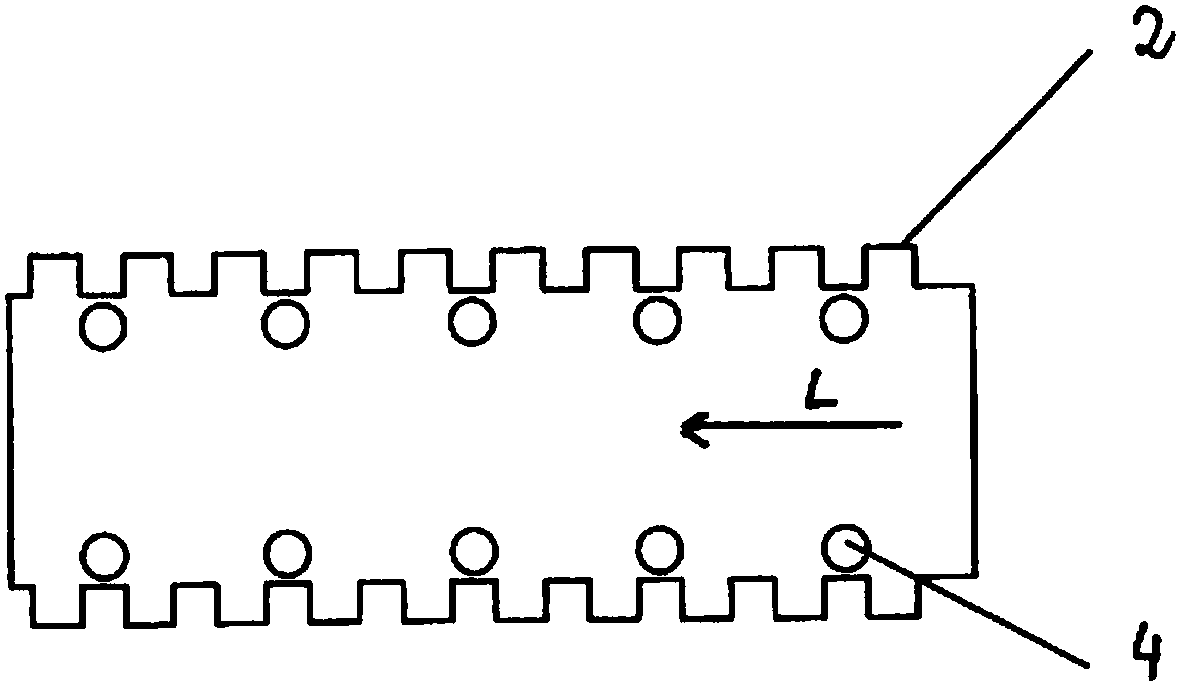

Resin line with peripheral openings

The invention relates to a resin line with peripheral openings. In order to provide a resin line that can be produced inexpensively, that meets the static requirements under action of the vacuum, andthat enables a more precise discharge of the matrix material independent of the bending radii at which the resin line is laid, the resin line is formed of a corrugated pipe (2) whose wall comprises through openings (4).

Owner:纤维复合材料创新有限责任公司

A method for analyzing the oil-increasing mechanism of weak alkali ASP flooding

The invention belongs to the technical field of oil reservoir development, and in particular relates to an analysis method for the oil increase mechanism of weak alkali three-element compound flooding, including emulsification, solvent water and injection methods for oil increase mechanism analysis; 1. In terms of oil displacement agent viscosity and slug Under the condition of the same size, the seepage characteristics experiments of the polymer solution and the weak base three-component compound system were carried out in the unsaturated oil state of the core, and the oil displacement effect of the polymer solution and the weak base three-component compound system was carried out under the saturated oil state of the core. Experiment; 2. Under the condition of the same oil displacement agent viscosity and slug size, carry out the oil displacement effect experiment of sewage weak alkali ASP flooding and descaling water weak alkali ASP system respectively; 3. In the oil displacement agent viscosity and Under the condition of the same slug size, the oil displacement effect experiments of the sewage weak alkali three-component composite system and the descaling water weak alkali three-component composite system were carried out by the constant-speed displacement injection method, and the sewage weak-base three-component composite system was tested by the constant pressure displacement injection method. Oil displacement experiment of three-component compound and descaling water weak base three-component compound system.

Owner:NORTHEAST GASOLINEEUM UNIV

A device for injecting coal powder into an oil layer and an ignition method for burning the oil layer

ActiveCN106050207BReduce moisture contentImprove ignition performanceFluid removalCombustionEngineering

The invention provides a device for injecting pulverized coal into an oil layer and an ignition method for in-situ oil combustion and belongs to the field of exploitation through in-situ oil combustion. The device for injecting the pulverized coal into the oil layer comprises an oil pipe arranged in an injection well or a production well, a pulverized coal spray-blowing system arranged on the ground and an injection pipeline, wherein the pulverized coal spray-blowing system is provided with a pulverized coal input port and a spray-blowing port, the spray-blowing port sprays out the pulverized coal, the injection pipeline is connected between the oil pipe and the spray-blowing port of the pulverized coal spray-blowing system, and the pulverized coal sprayed out of the spray-blowing port is delivered to the oil pipe. The device can improve the ignition effect for in-situ oil combustion and can also improve the development effect of the in-situ oil combustion.

Owner:PETROCHINA CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com