Low-permeability oil reservoir non-mixed-phase gas-water alternate injection and fluctuation depressurization augmented injection device and method

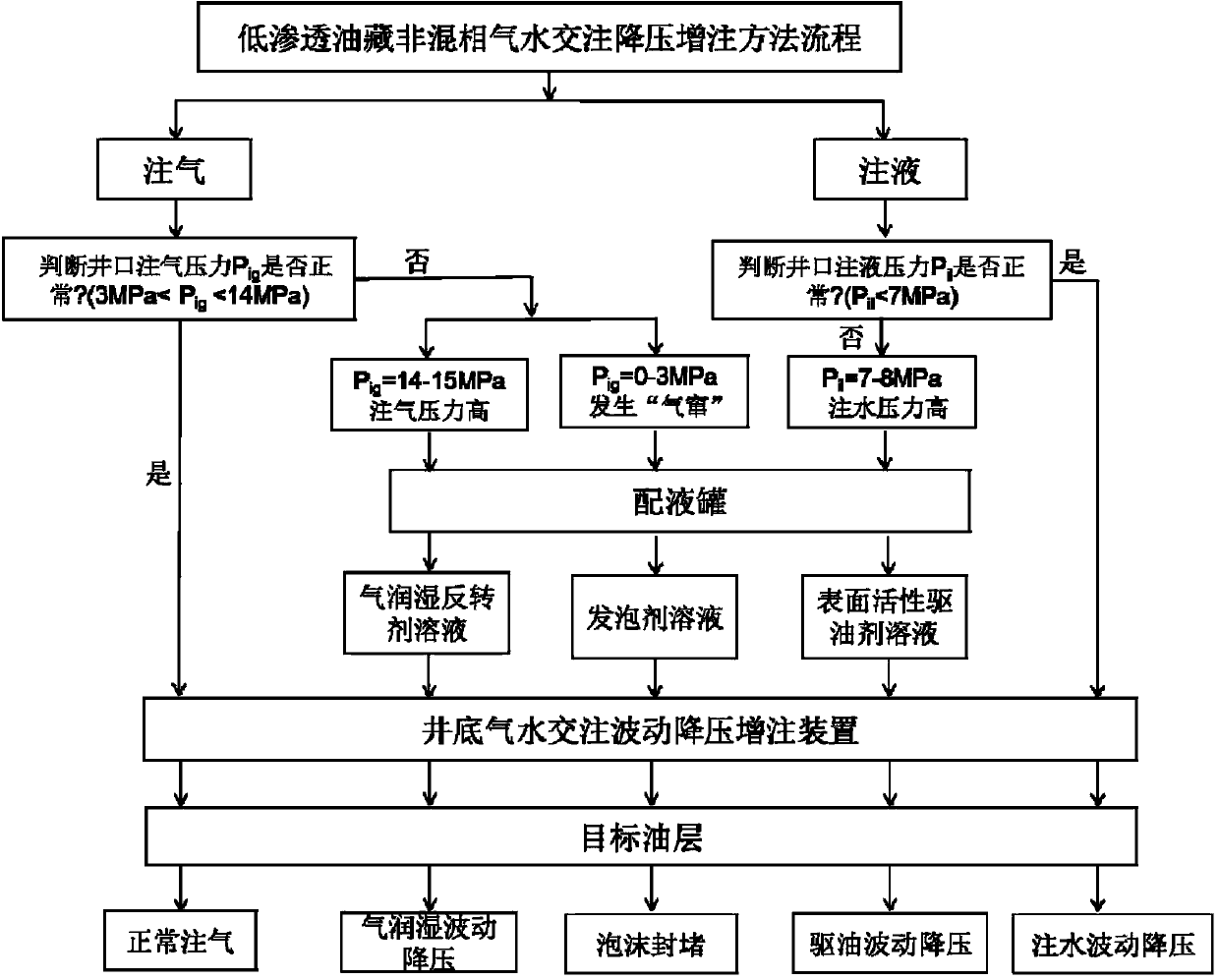

An immiscible, low-permeability technology, applied in the direction of earthwork drilling, production fluid, wellbore/well components, etc., can solve the problems of high gas injection pressure, difficulty in achieving development results, and high water injection pressure in low-permeability reservoirs, and achieve improved Oil recovery, reducing gas injection development costs, and solving the effects of high injection pressure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0042] The present invention will be described in detail below in conjunction with the accompanying drawings and embodiments, but the present invention is not limited to the following embodiments.

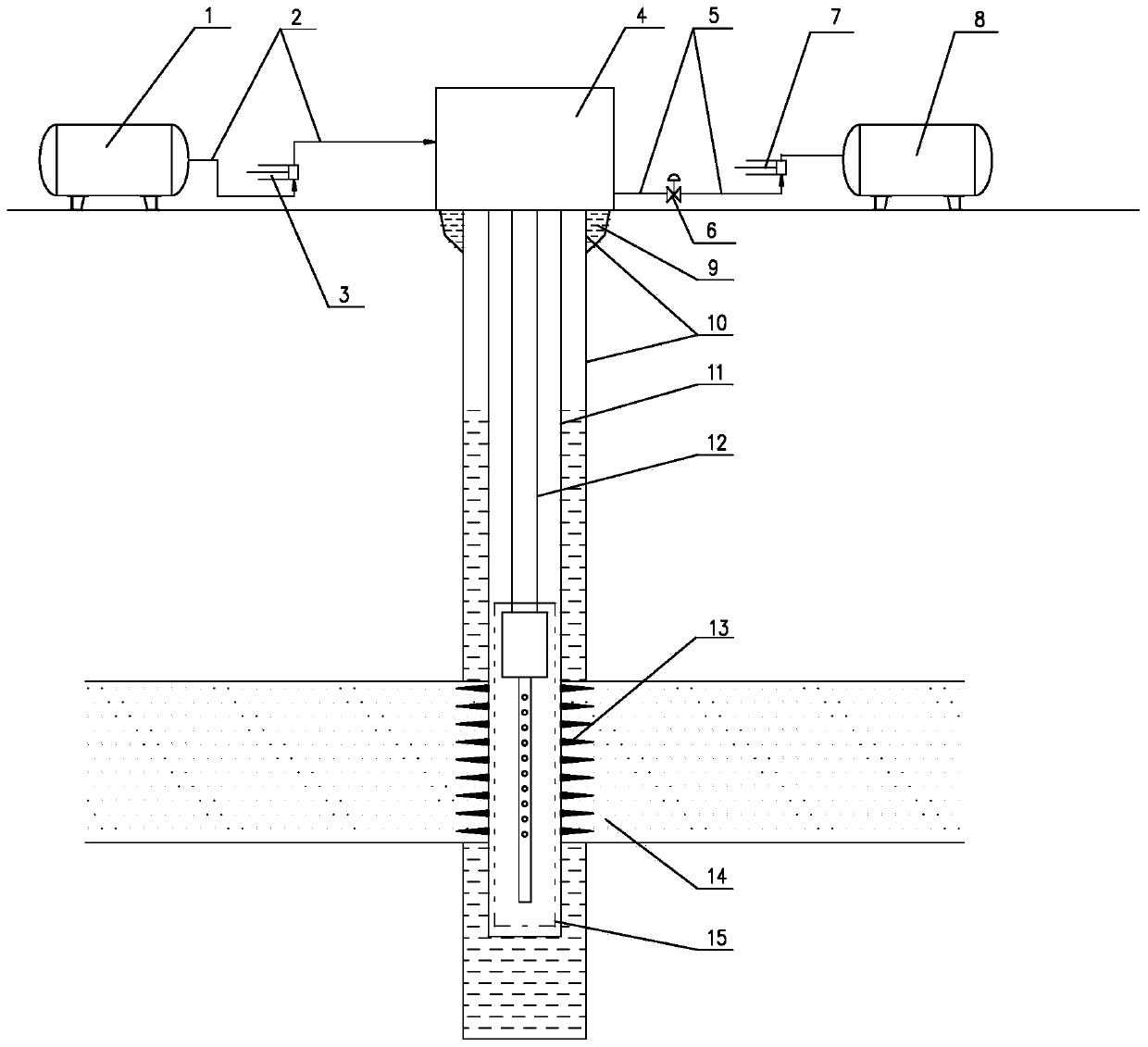

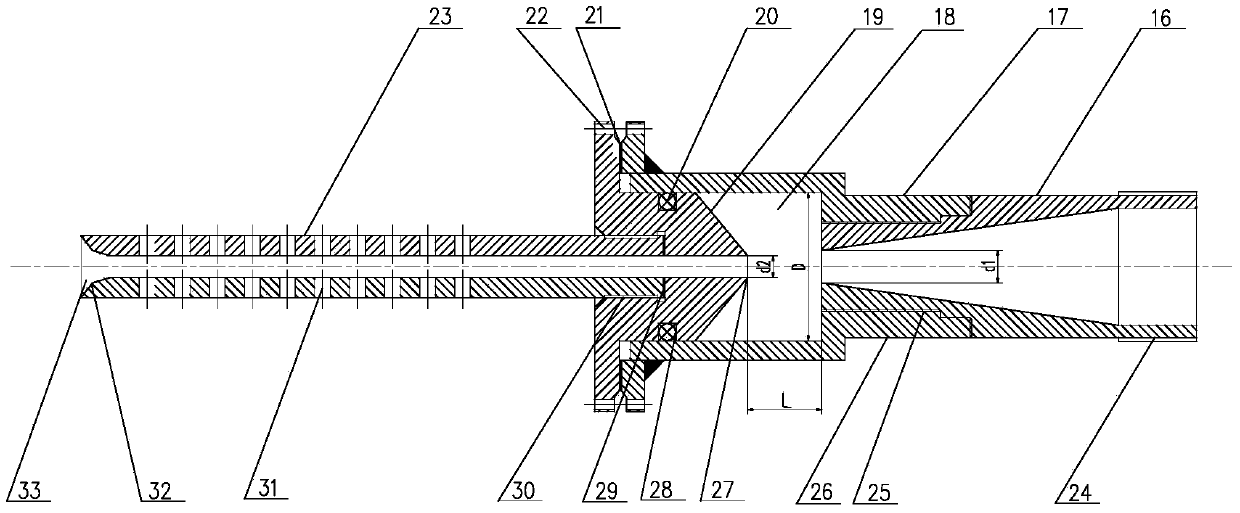

[0043] Such as figure 1 , 2 As shown, a low-permeability oil reservoir immiscible gas-water cross-injection fluctuating pressure-reducing and increasing-injection device includes a gas injection and liquid device arranged on the ground and a bottom-hole gas-water cross-injection fluctuating depressurizing and increasing-injection device arranged at the bottom of the well 15 . The gas and liquid injection device includes a liquid distribution tank 1 and a low-temperature and high-pressure liquid storage tank 8. The liquid distribution tank 1 is connected to the cross of the wellhead 4 of the injection well through the first pipeline 2, and the first plunger is arranged on the first pipeline 2. pump3. The low-temperature and high-pressure liquid storage tank 8 is connected to the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com