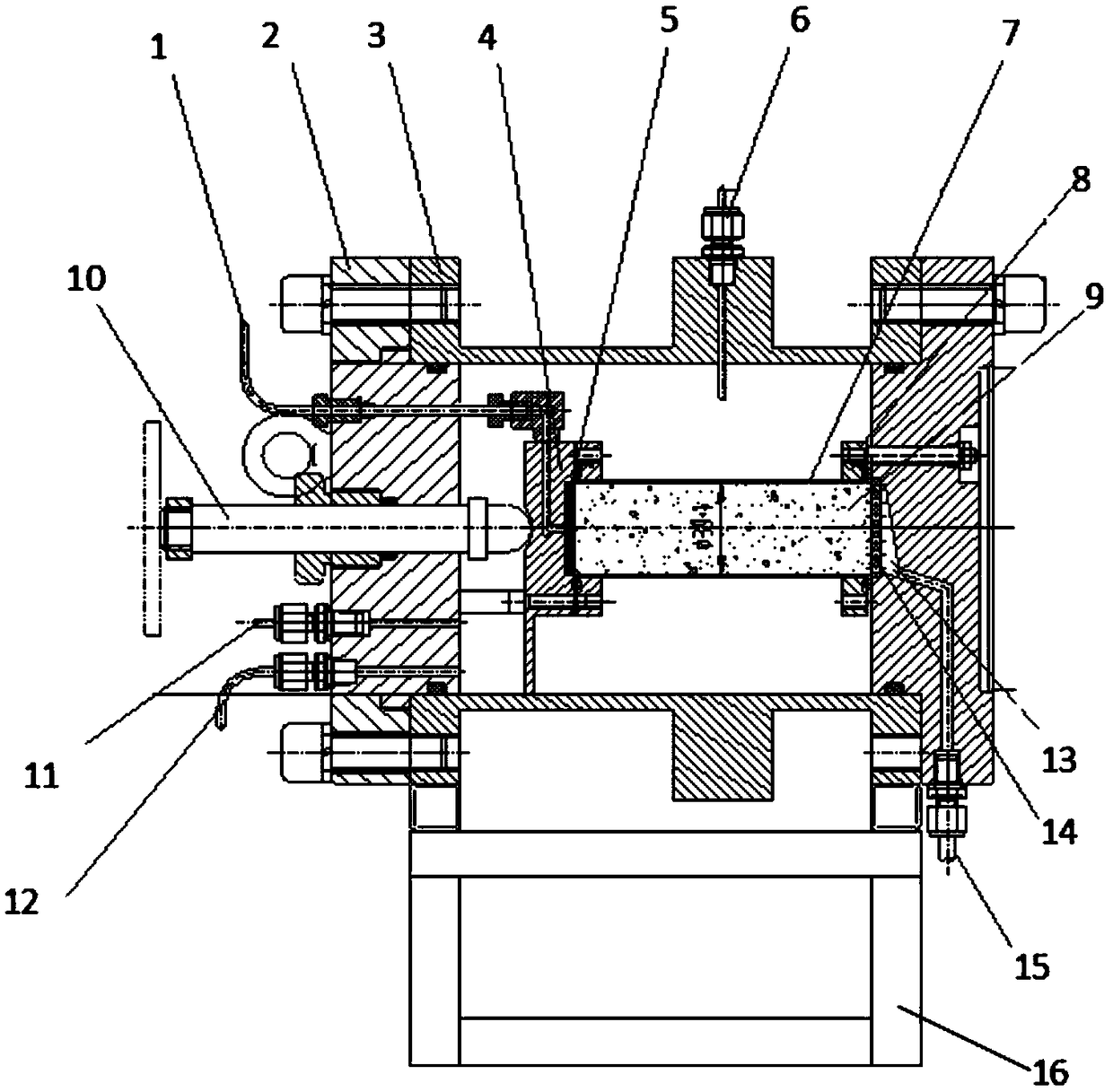

Special reaction kettle for simulating sand production process of hydrate-containing sediments and its test method

A hydrate-containing, process simulation technology, applied in measurement devices, particle and settlement analysis, permeability/surface area analysis, etc. Accurate measurement of sand output and the effect of avoiding accumulation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

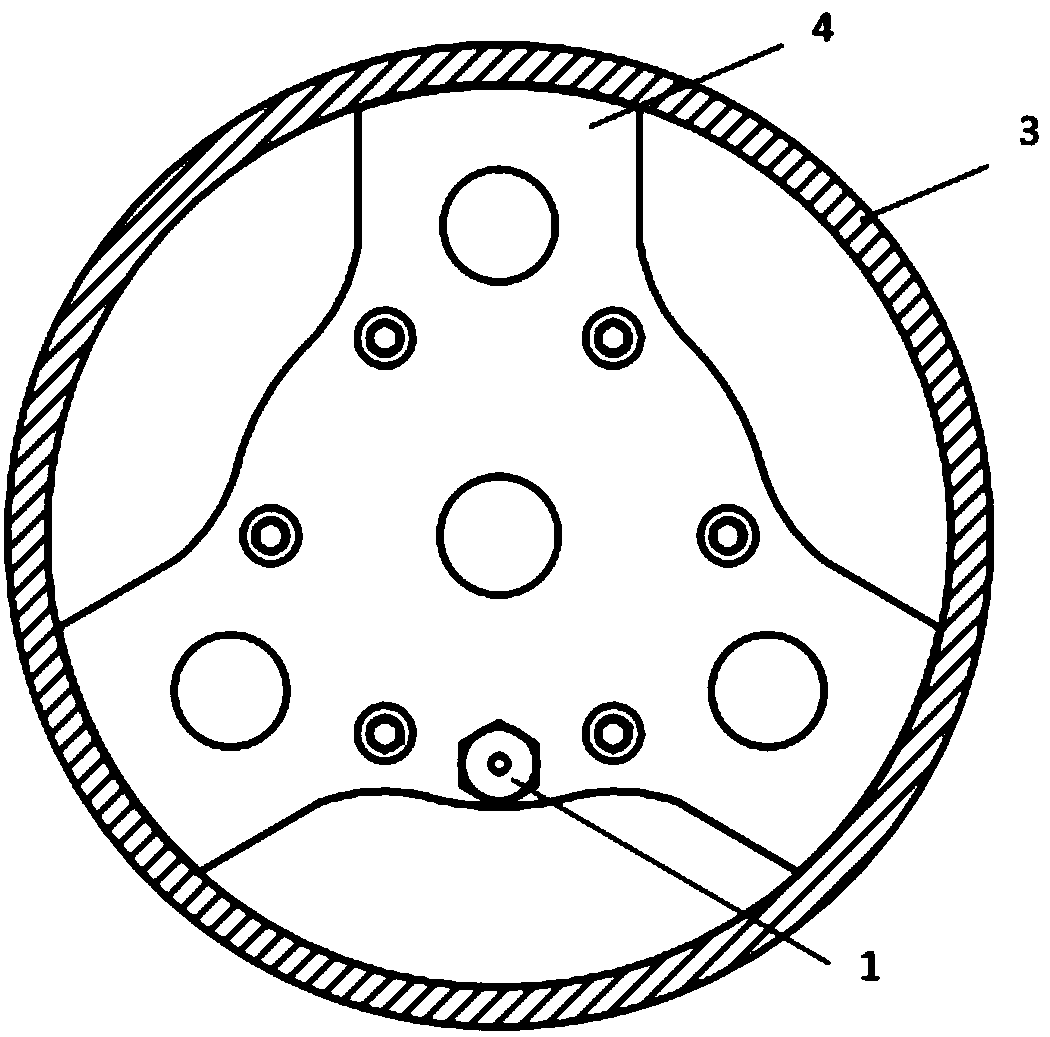

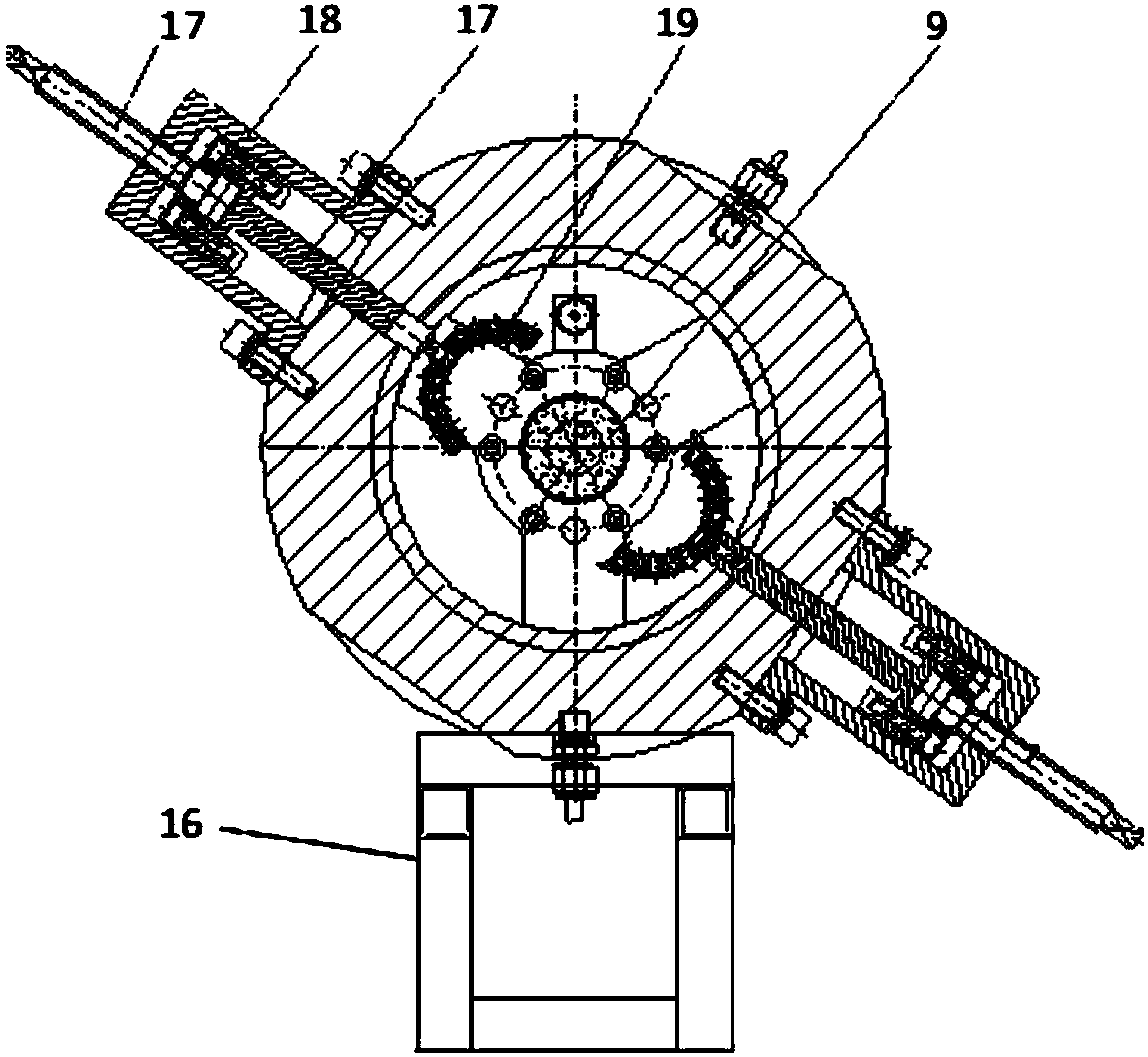

[0070] A test method for simulating a reactor for testing the sand production of hydrate-containing sediments, comprising the following steps:

[0071] The first step, sealing inspection:

[0072]Connect the upper and lower flange covers without installing the sample, inject 20MPa hydraulic pressure into the kettle body, and check whether the sealing rings at each sealing position are intact. The main inspection points are the piston pressurized ejector rod 10 and the upper flange cover 2, the dynamic seal between the pore pressure injection straight pipe 1 and the upper flange cover 2, the dynamic seal between the adjustment connecting rod 17 and the kettle body 3, and the upper flange cover 2 and the kettle body 3 The seal between the lower flange cover 8 and the kettle body 3, the standard that each sealing point does not leak is that the internal pressure of the kettle body remains constant for more than 10h.

[0073] The second step, sample loading:

[0074] Turn the au...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com