Automatic tracking seam filling robot

An automatic tracking and robotic technology, applied in the field of robotics, can solve the problems of material waste cleaning, affecting the appearance, uneven surface unevenness, and saving manpower.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] Preferred embodiments of the present invention will be described in detail below with reference to the accompanying drawings.

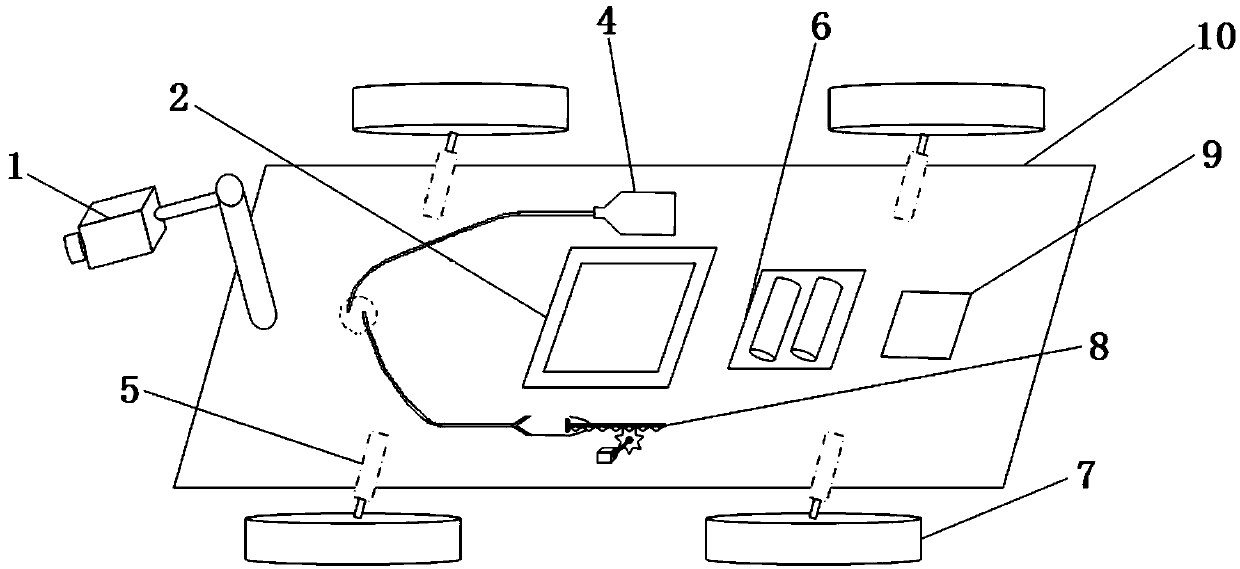

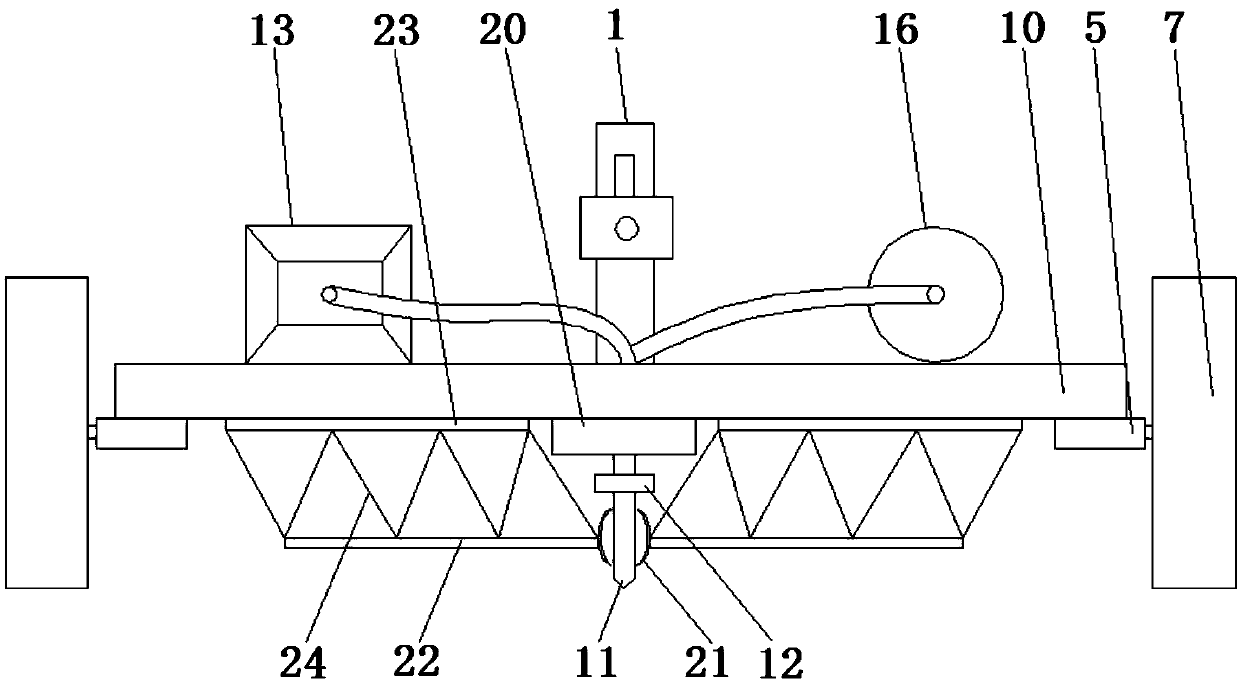

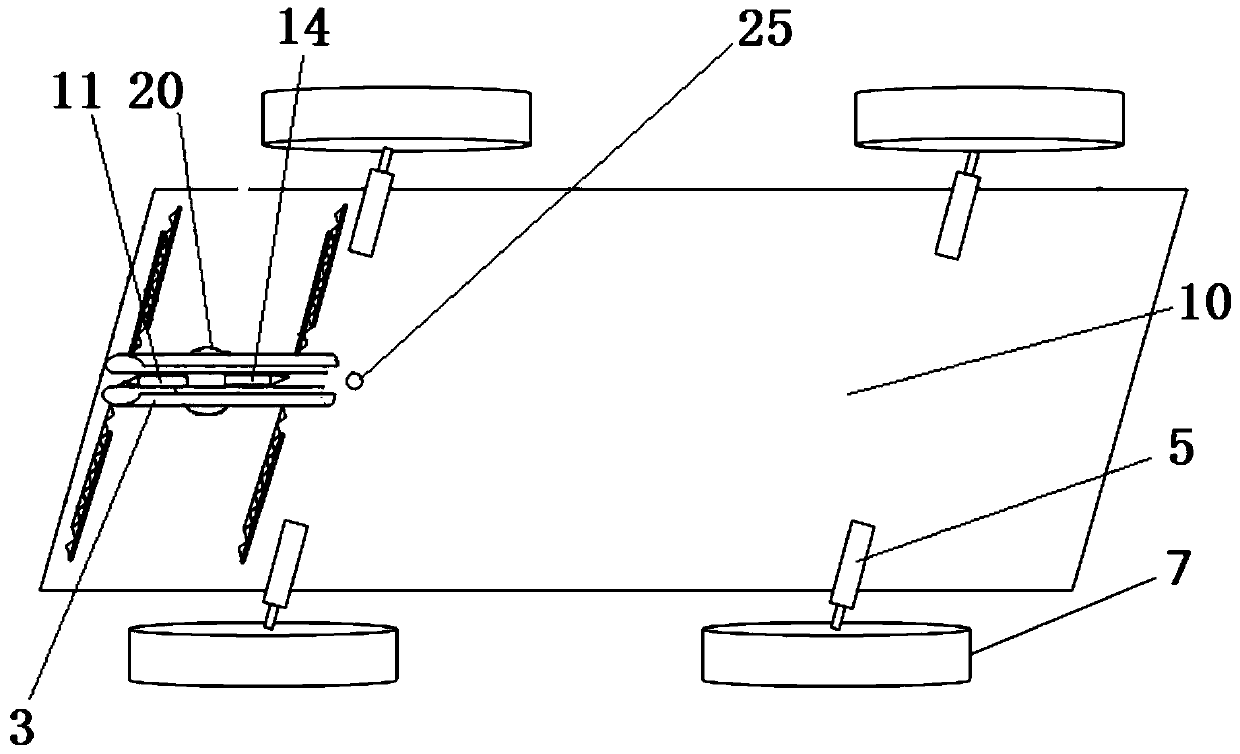

[0027] Such as Figure 1 to Figure 9 As shown, the automatic tracking beautifying seam filling robot of the present invention includes a camera and a pole 1, a processor and a controller 2, a rotating device 3, a seam cleaning device 4, a DC motor 5, a power supply 6, wheels 7, and a beautifying machine. Seam filling device 8, driving device 9, chassis 10;

[0028] The chassis 10 is sequentially installed with a camera, a frame rod 1, a processor and a controller 2, a power supply 6 and a driving device 9 from left to right, and the two sides of the processor and the controller 2 are respectively provided with a seam cleaning device 4 and a seam filling device. Sewing device 8; Chassis 10 both sides are provided with a plurality of DC motors 5, and the output end of each DC motor 5 is all equipped with wheel 7;

[0029] Further: the rotating ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com