Gem slicer

A slicer and gemstone technology, applied in stone processing equipment, fine working devices, manufacturing tools, etc., can solve the problems of fragile cutting tools, broken gem slices, low efficiency, etc., to ensure balance, uniform cutting control, The effect of convenient cutting

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

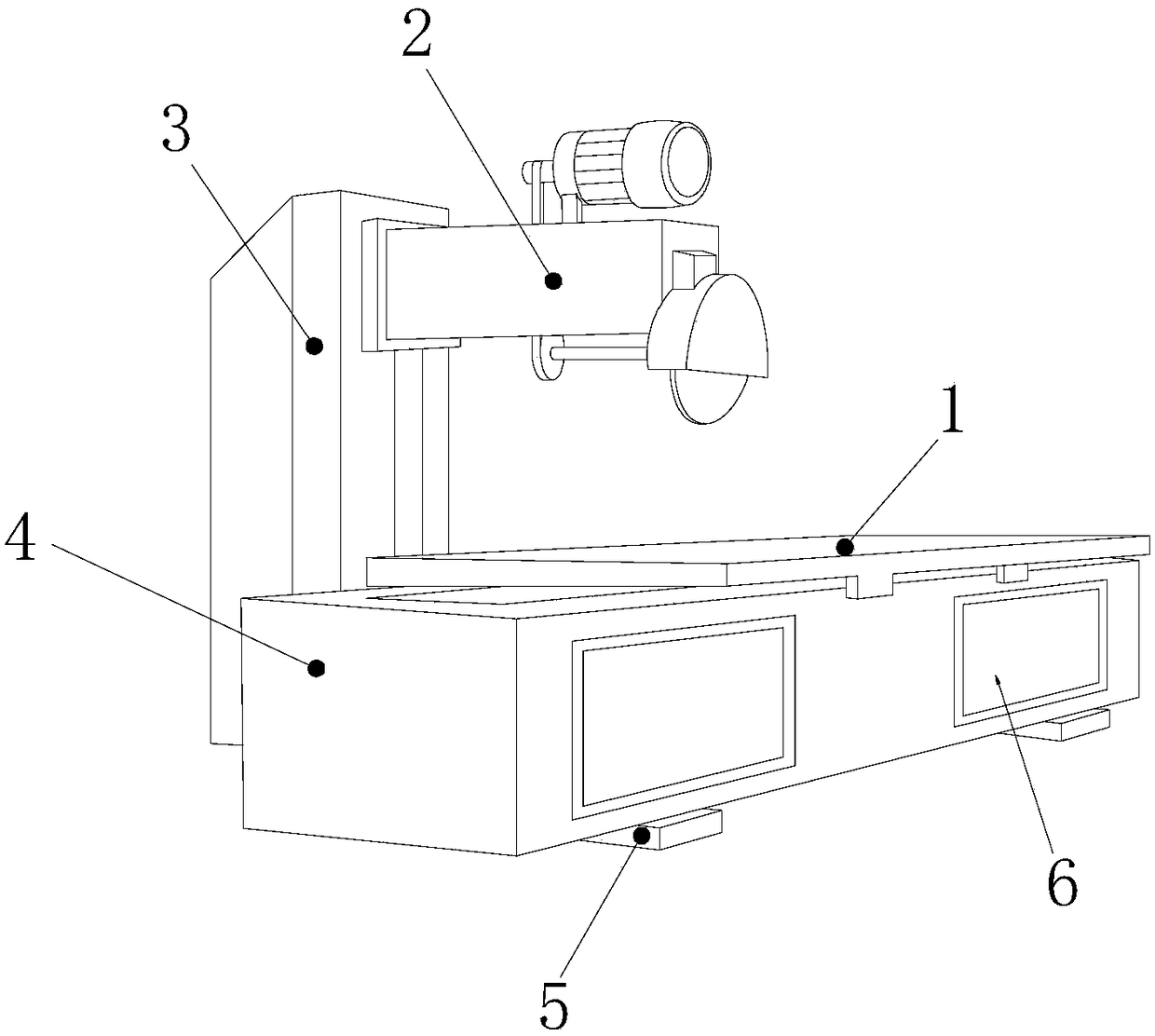

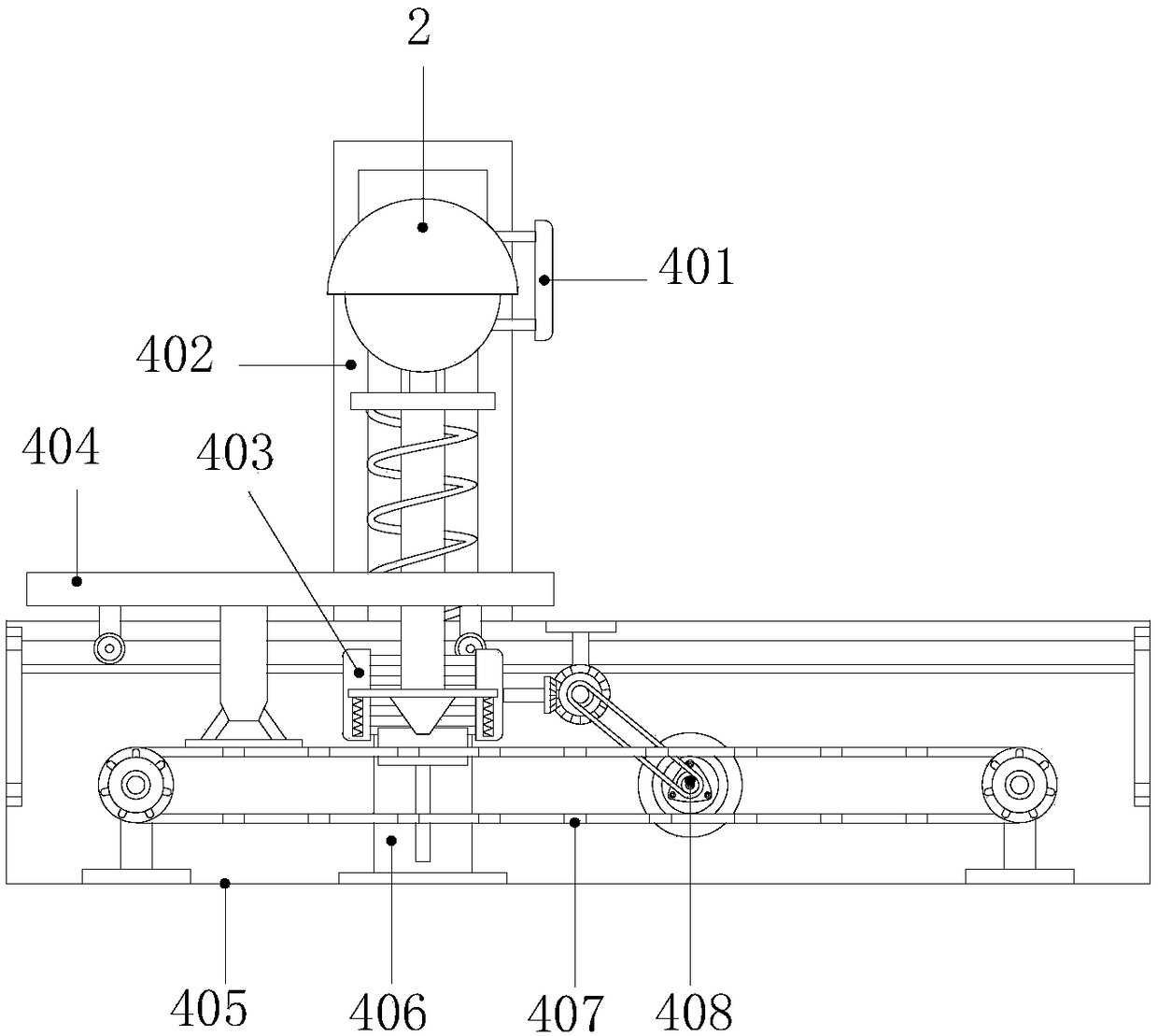

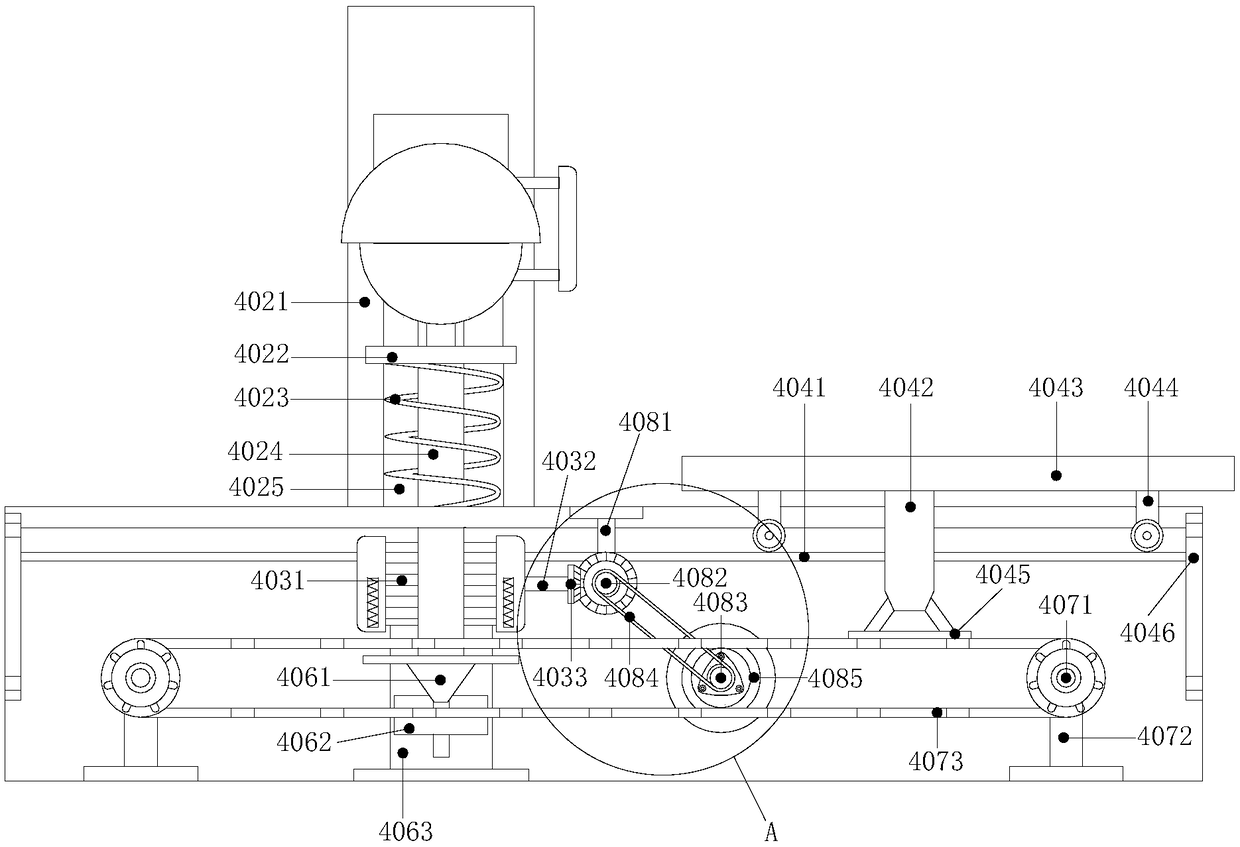

[0020] see Figure 1-Figure 4, the present invention provides a gem slicer, the structure of which includes a cutting platform 1, a cutting host 2, a positioning arm 3, a device main body 4, a fixed foot 5, and a locker 6, and the fixed foot 5 is provided with four , and are evenly and equidistantly arranged at both ends of the bottom of the equipment main body 4 by welding, the two ends of the surface of the equipment main body 4 are respectively provided with lockers 6, and the top is provided with a cutting platform 1, and the lower end of the positioning vertical arm 3 passes through the buckle It is installed on the rear end of the equipment main body 4 in a combined manner, and the upper end is provided with a groove that is engaged with the rear end of the cutting host 2. The equipment main body 4 includes a control handle 401, a vertical arm lifting mechanism 402, a driving mechanism 403, and a platform structure 404. , housing 405, starting device 406, transmission me...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com