Cylinder type wall plastering rod

A syringe type, wall technology, applied in the direction of construction, building construction, etc., can solve the problems of paint waste, low work efficiency, low work efficiency, etc., and achieve the effect of simple and fast operation, improved efficiency, and improved use efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

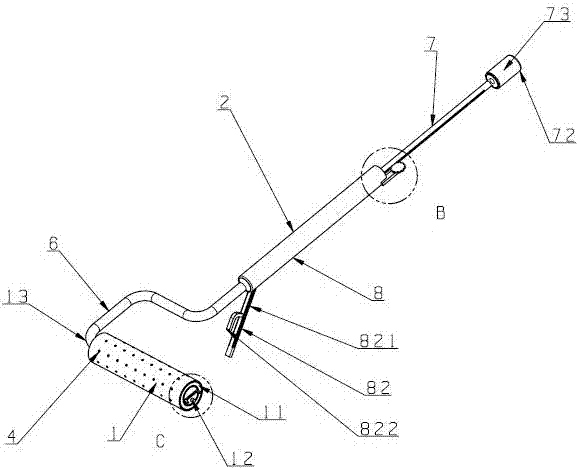

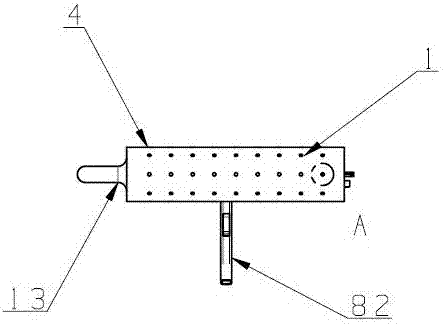

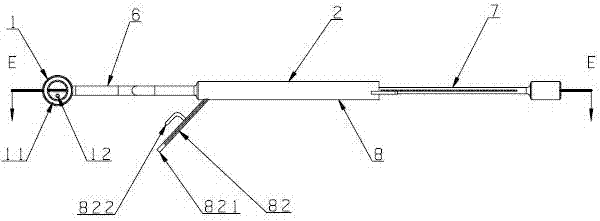

[0045] Embodiment: The present invention mainly consists of a painting head and a painting handle. The painting head is in a circular cylinder structure, and the middle part is a cavity, which is used to store the paint to be painted. The paint is placed in the cavity by being arranged on the painting head. A number of through holes on the wall are connected to the outside, that is, when the internal pressure is greater than the outside, the paint flows out through the through holes. The single upper blade is composed of two opposite semicircular pieces, which can only be opened from the inside of the cavity to the outside when there is pressure in the cavity, so that the paint forms a one-way flow guide;

[0046] Further, the through-holes provided on the brush head are arranged in a matrix or irregularly dislocated, and the radii of the through-holes are arranged at intervals from one end close to the conduit to the other end, thereby forming a one-to-one correspondence with ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com