Polymer gel, polymer and application thereof

A technology of polymers and gels, applied in the direction of drilling compositions, chemical instruments and methods, etc., can solve the problem of gel system strength, long-term stability of plugging integrity not meeting expectations, poor plugging integrity, suspension Poor performance and other problems, to achieve good long-term stability, high plugging success rate, high viscoelastic effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

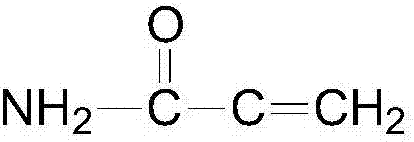

[0034] The present invention has no special limitation on the preparation method of the polymer, as long as the acrylamide monomer, the unsaturated hydrophobic monomer and the functional monomer are polymerized.

[0035] The invention mixes the polymer with water, and after stirring, the polymer gel can be obtained, which can be used as a profile control leakage plugging agent and a water blocking agent. Wherein, the mass concentration of the polymer in water is 0.3%-5%. The water can be clear water, salt water or on-site sewage.

[0036] After the polymer gel is obtained, it can be used as a profile control plugging agent and a water blocking agent.

Embodiment 1

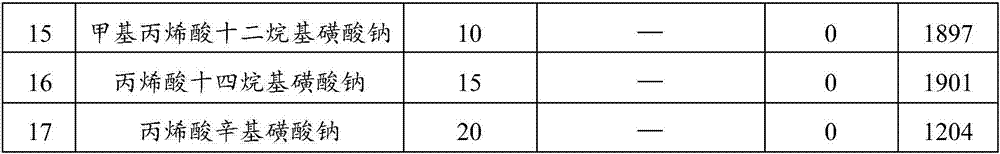

[0039] According to the types and ratios of monomers shown in Table 1, acrylamide monomers, unsaturated hydrophobic monomers and functional monomers were used as raw materials to carry out polymerization reactions to obtain the random copolymers shown in Table 1.

[0040] Table 1 Types and proportions of polymer monomers

[0041]

[0042]

Embodiment 2

[0044] In the experiment, clean water was used to dissolve the 1# polymer in a water bath at a temperature of 45°C, and the polymer mass concentration was 0.3%, to obtain a gel.

[0045] Under low-speed stirring conditions, slowly add the gel into a beaker with 500ml of clear water. Laboratory experiments show that in clear water, the gel dissolves for 2 hours at 50°C; stand still for 4 hours, on the Brookfield DV-Ⅲ viscometer The viscosity of the test gel is 25260mPa.s, the solution can be picked up, and the 1min static shear force of the gel tested on a six-speed rotary viscometer (64# rotor, 6r / min) is 21Pa; its indoor aging stability is 180d viscosity retention The rate is 73%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Viscosity | aaaaa | aaaaa |

| Static shear force | aaaaa | aaaaa |

| Viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com