Laser medium cooling device of thin laser

A thin-sheet laser and laser medium technology, applied in lasers, laser components, phonon exciters, etc., can solve problems such as ineffective cooling and hard mechanical damage, and achieve good heat conduction and cooling effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The present invention will be further described below in conjunction with accompanying drawings and implementation.

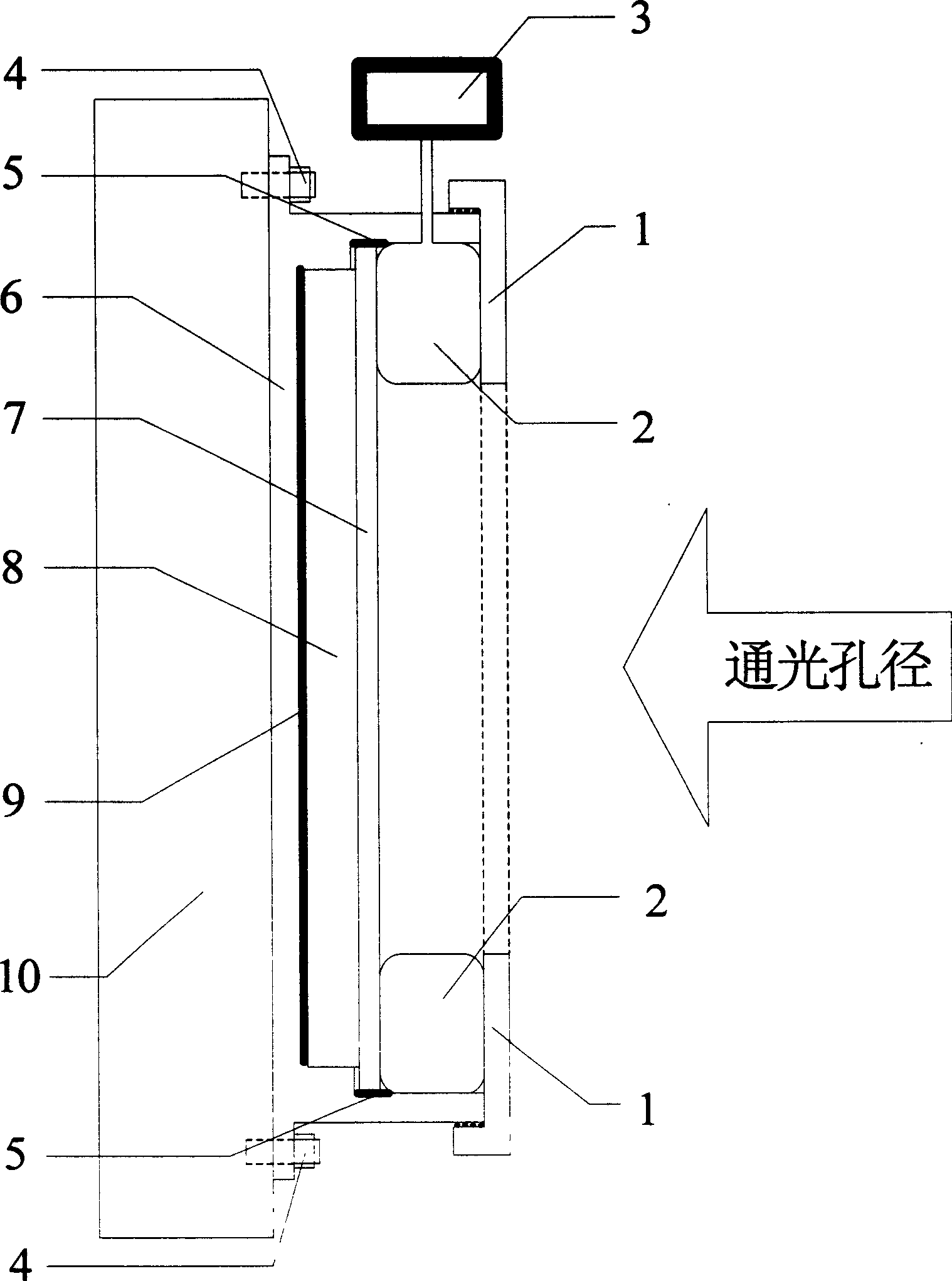

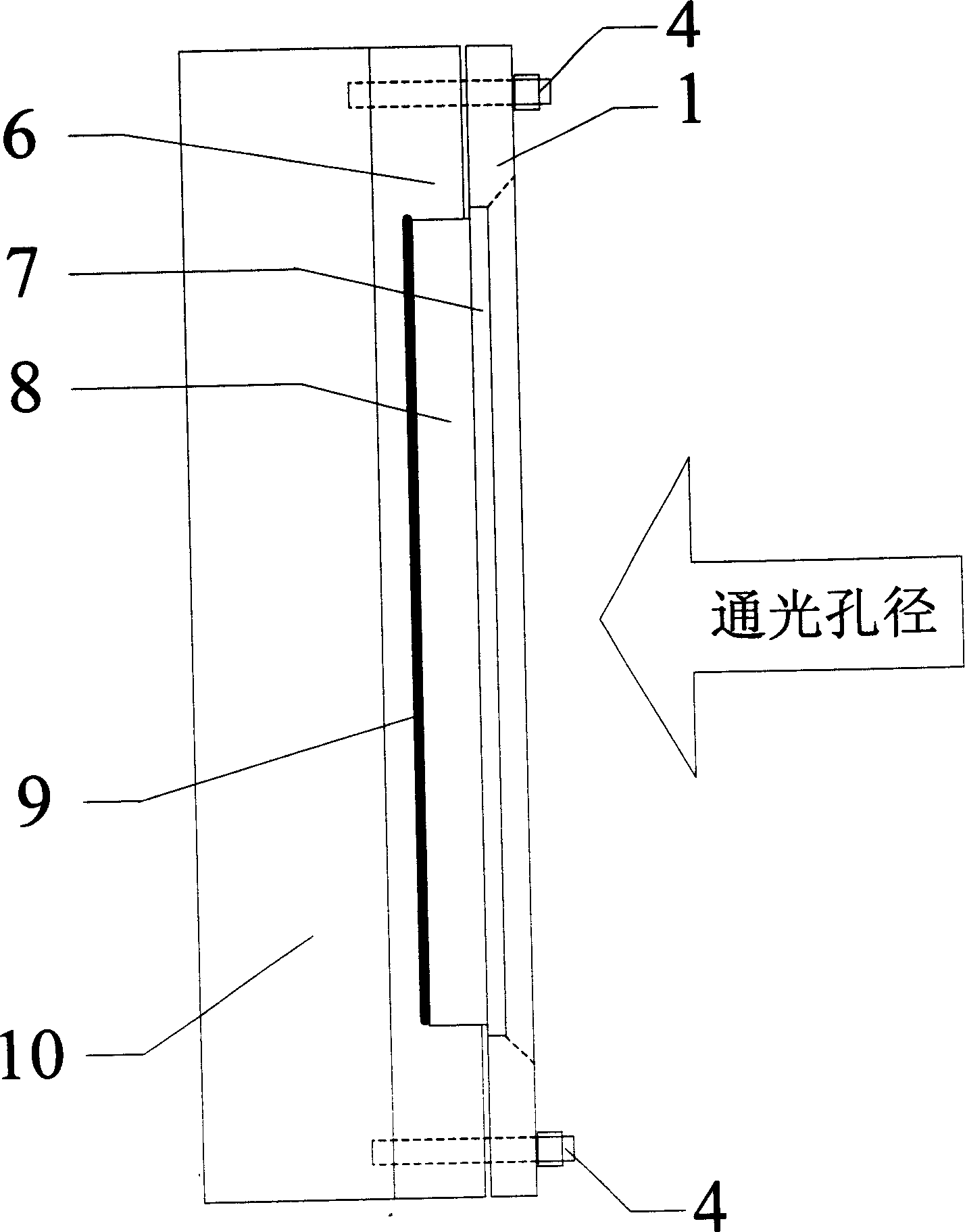

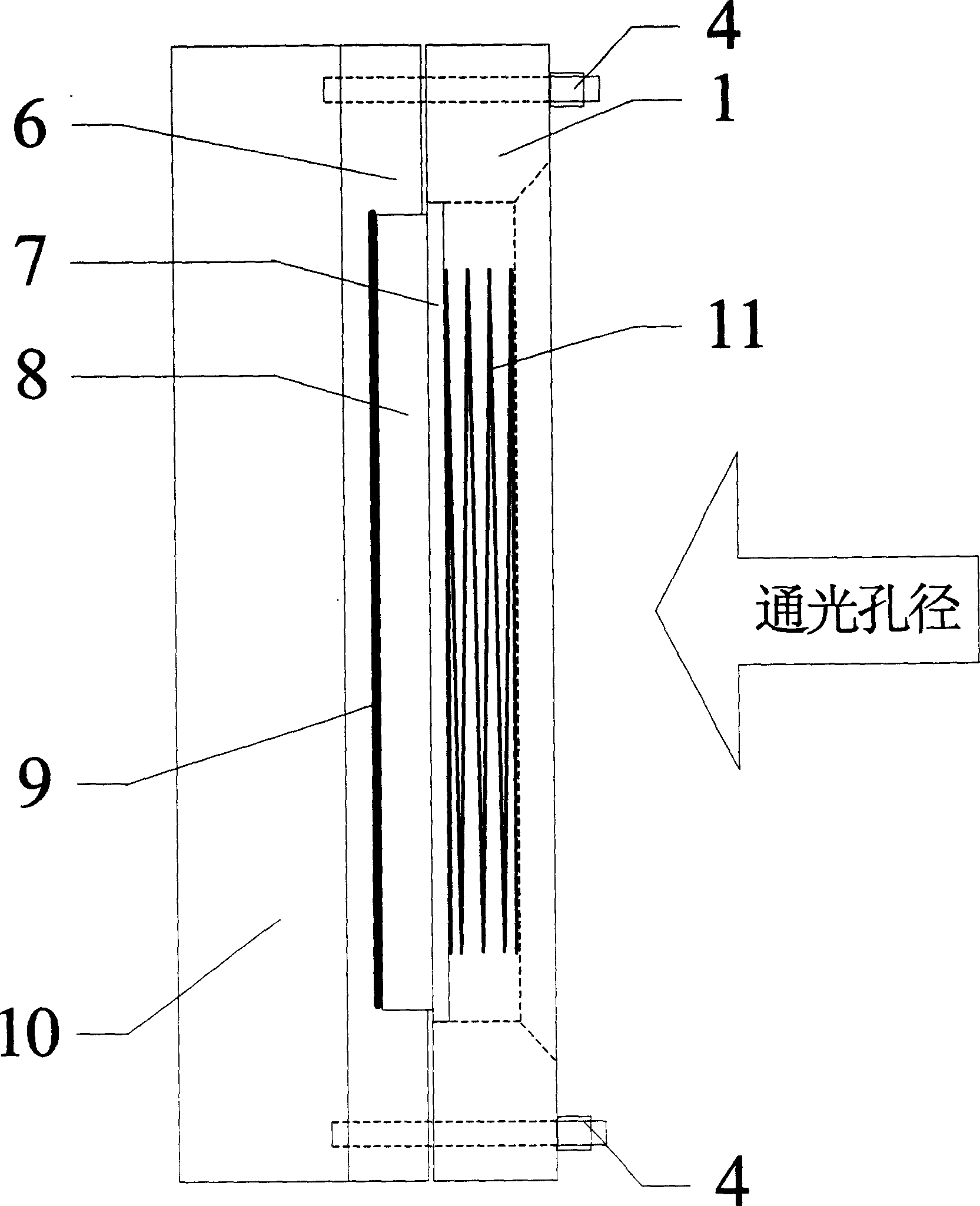

[0019] see first figure 1 , figure 1 It is a structural schematic diagram of the laser medium cooling device of the thin-sheet laser of the present invention. As can be seen from the figure, the laser medium cooling device of the sheet laser of the present invention comprises a semiconductor thermoelectric cooling chip 10, a laser gain medium 8, a white gem window plate 7 and a clamp 6, which is characterized in that the clamp 6 is a flat-bottomed disk-shaped There is a red copper clamp 6 with an external thread in the mouth of the sliding guide rail 5 for the sliding of the white gemstone window plate 7, and the red copper clamp 6 is fixed on the semiconductor thermoelectric cooling sheet 10 by the fixing screw 4. There is also a thin metal indium layer 9 on the inner bottom of the fixture 6, and the laser gain medium 8, the white sapphire window pl...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com