Integration column with high heat resistance

An integral column and high heat-resistant technology, applied in optics, instruments, projection devices, etc., can solve the problems of lens warping and deformation, affecting projection effects, etc., and achieve the effect of preventing deformation, ensuring projection effect, and novel structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The technical solutions of the present invention will be further described below in conjunction with the accompanying drawings and through specific implementation methods.

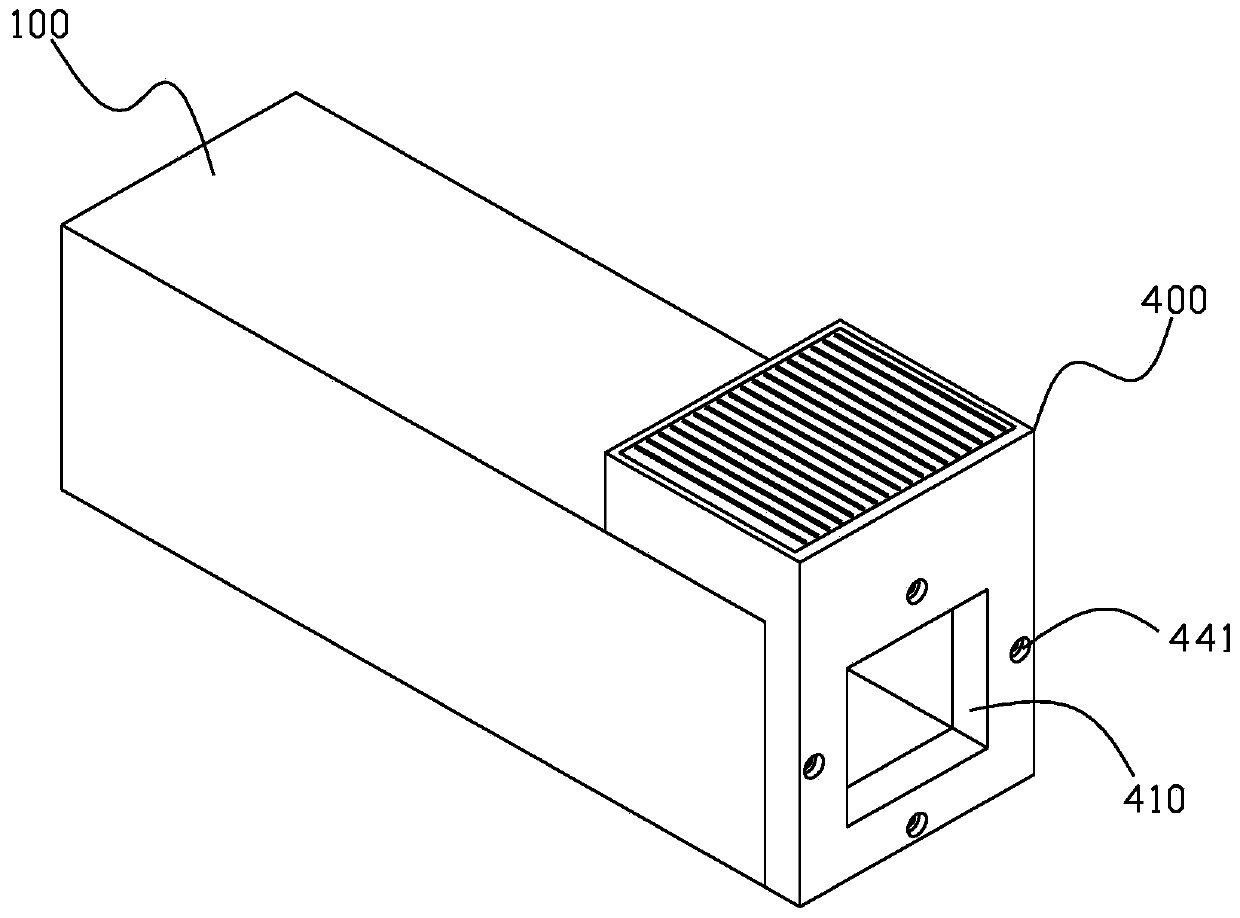

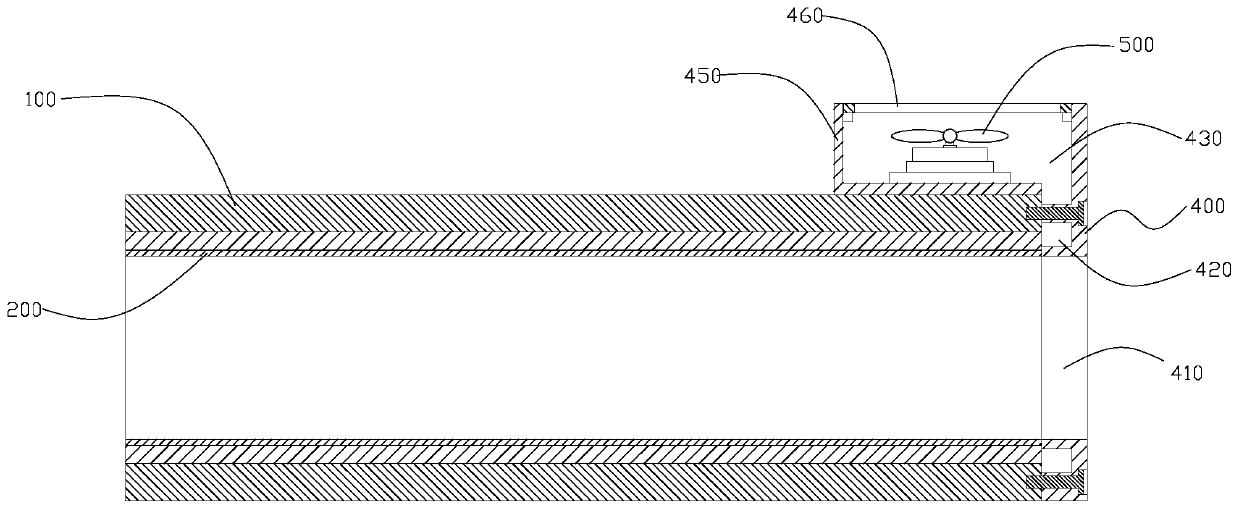

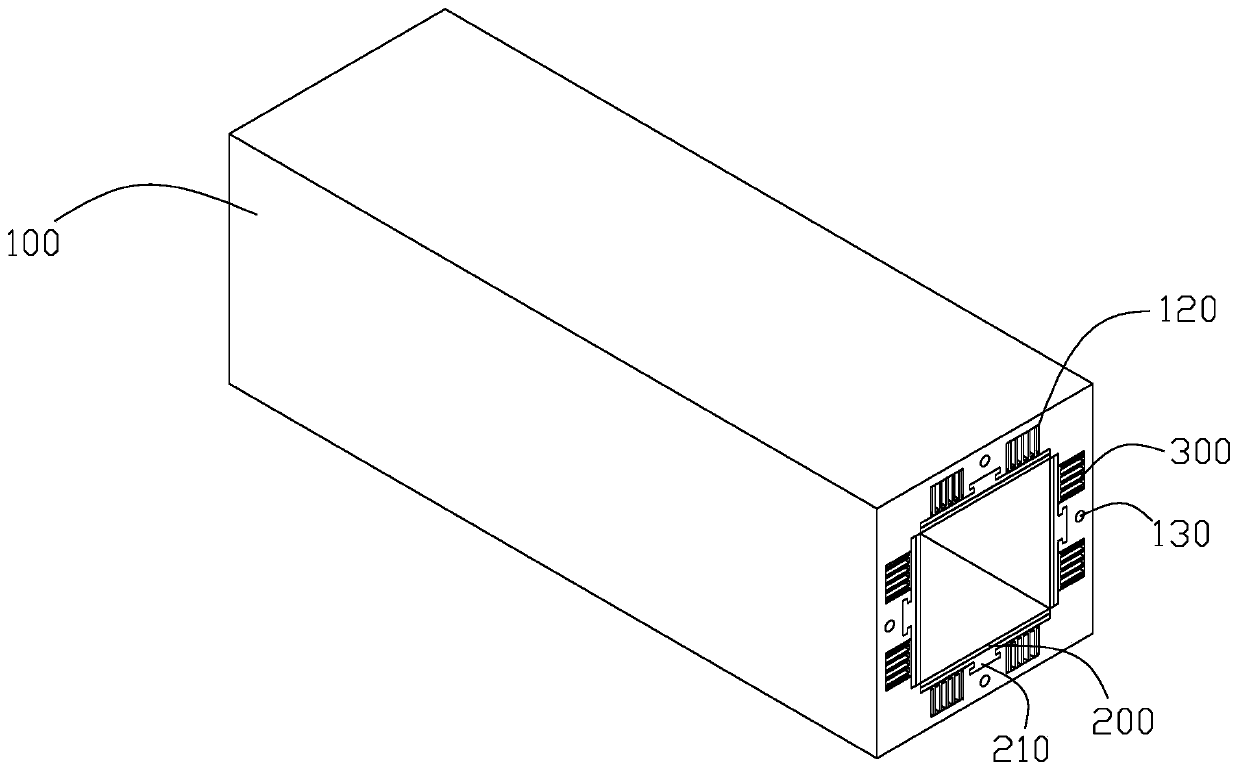

[0025] Such as figure 1 , figure 2 As shown, a high heat-resistant integrating column is disclosed in a specific embodiment of the present invention, which includes a frame body 100 with open ends, such as Figure 4 As shown, the inner wall of the frame body 100 is a rectangular through hole, and each inner wall is concavely provided with a mounting groove 110, and the two ends of the mounting groove 110 extend to the two ends of the frame body 100, and each of the mounting grooves 110 are equipped with reflective lenses 200, optical path passages are formed between a plurality of said reflective lenses 200; set in the length direction and extend to both ends of the frame body 100; as image 3 As shown, each of the grooves 120 is provided with a heat conducting member 300; one end of the frame b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com