Patents

Literature

50results about How to "Prevent gas blowing" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

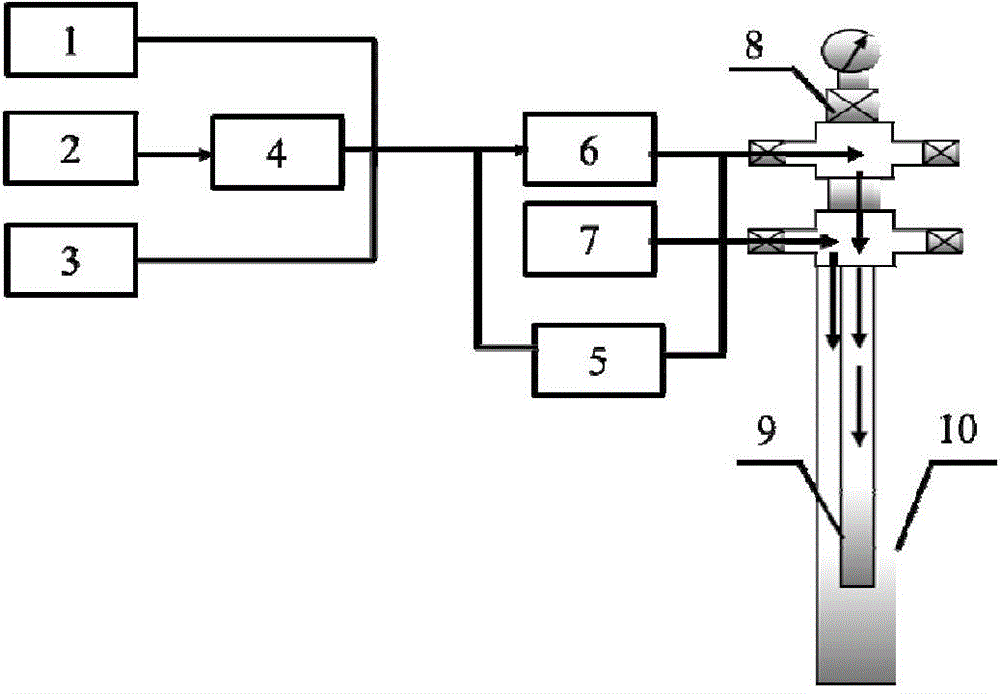

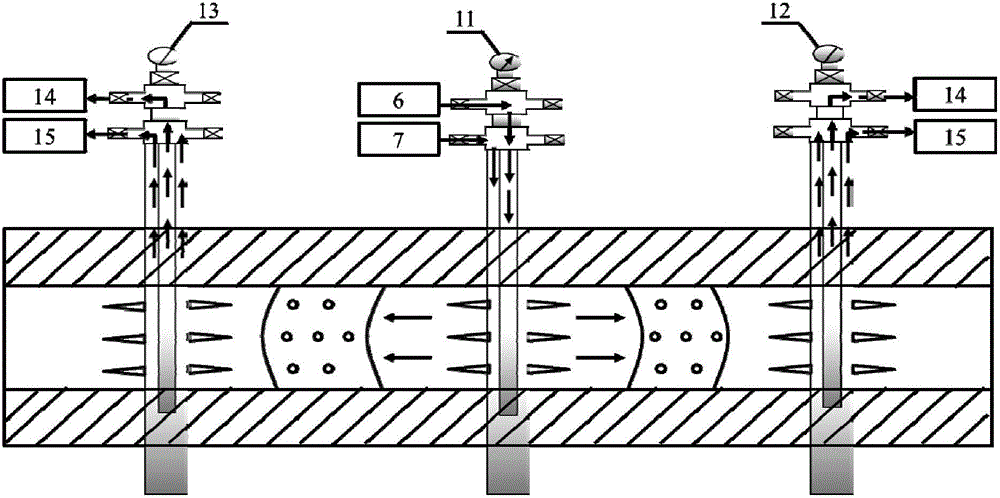

Method for coal bed methane mining by multi-element thermal fluid foam displacement

ActiveCN103061730AImprove permeabilityHard to getOther gas emission reduction technologiesFluid removalHigh pressure waterHigh pressure

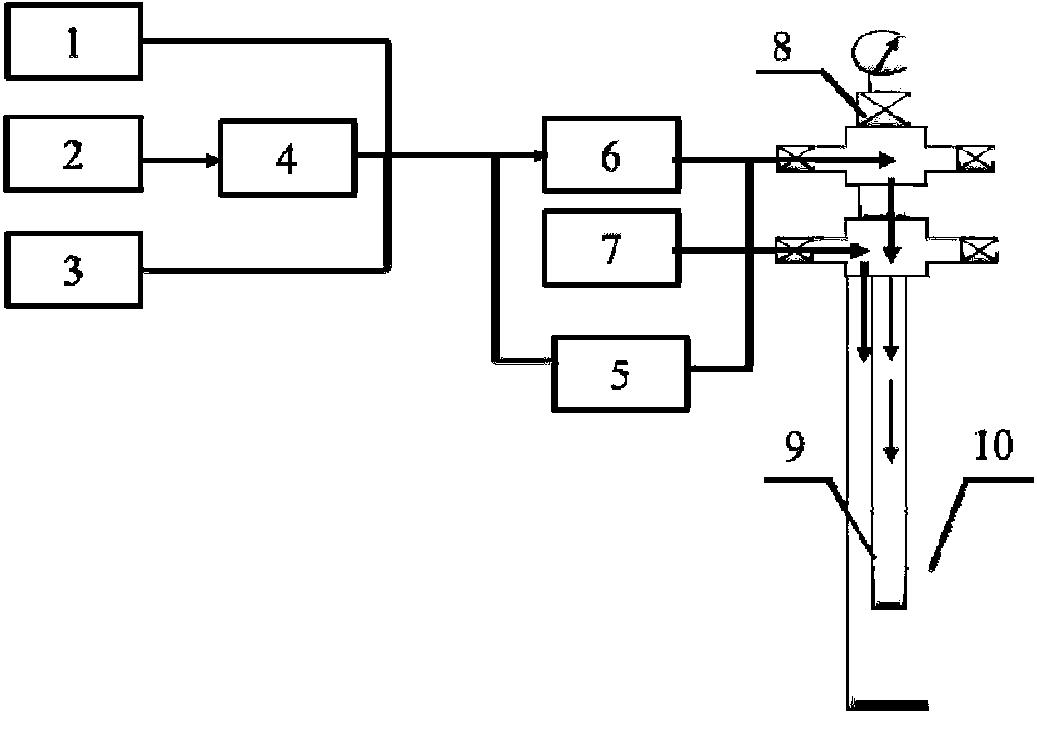

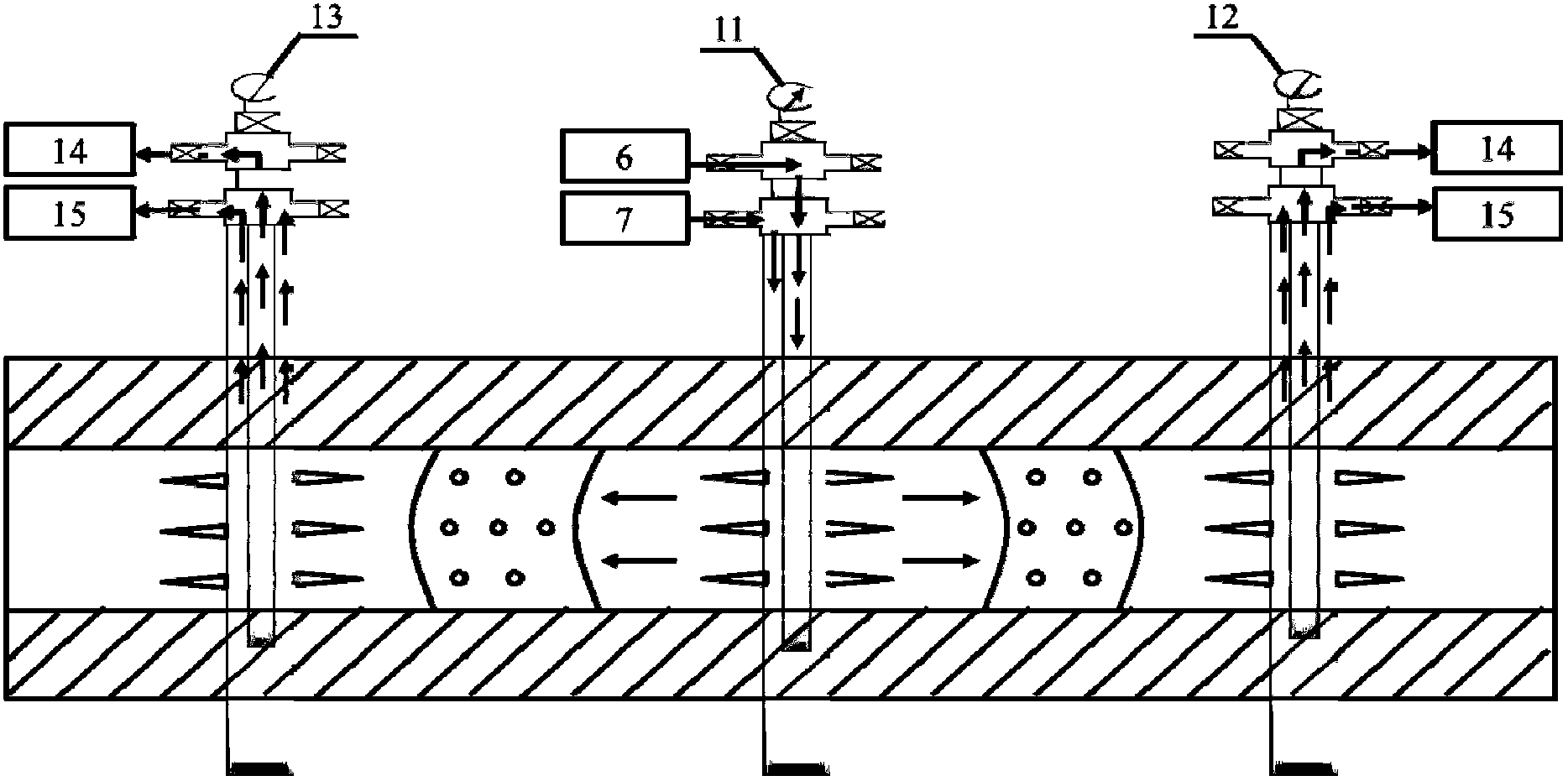

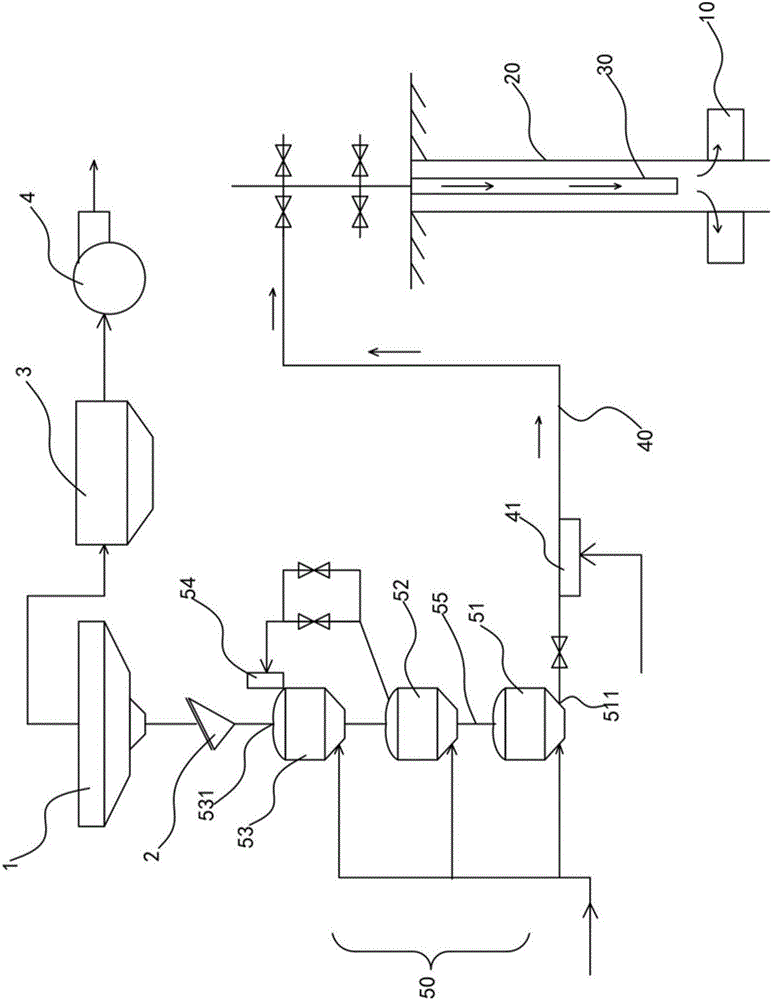

The invention discloses a method for coal bed methane mining by multi-element thermal fluid foam displacement. Multi-element thermal fluid is injected into a coal bed of an injection-production well group through an injection well, and foaming agent is injected at intervals. A multi-element thermal fluid foam slug is formed in the coal bed to displace the coal bed methane in order to improve the recovery efficiency of the coal bed methane. The method specifically includes that extracted coal bed methane is compressed and mixed with compressed air, and then the mixture is injected into a multi-element thermal fluid generation device for ignition, extracted processed ground water is mixed to produce the multi-element thermal fluid mainly with high-temperature and high-pressure water vapor and mixed gas of carbon dioxide and nitrogen, the produced multi-element thermal fluid is injected into the underground coal bed through the injection well, a foaming system composed of preferred alkyl ether sulfonate and corrosion inhibitor is injected from an oil jacket annulus at intervals, the multi-element thermal fluid foam slug is formed under the ground to displace the coal bed methane, and water is drained and gas is recovered from a production well. The method has the advantages that fuel is easy to obtain, principles are clear and distinct, and the like, and can provide guidance for implementation of well stimulation of the coal bed methane.

Owner:CHINA UNIV OF PETROLEUM (EAST CHINA)

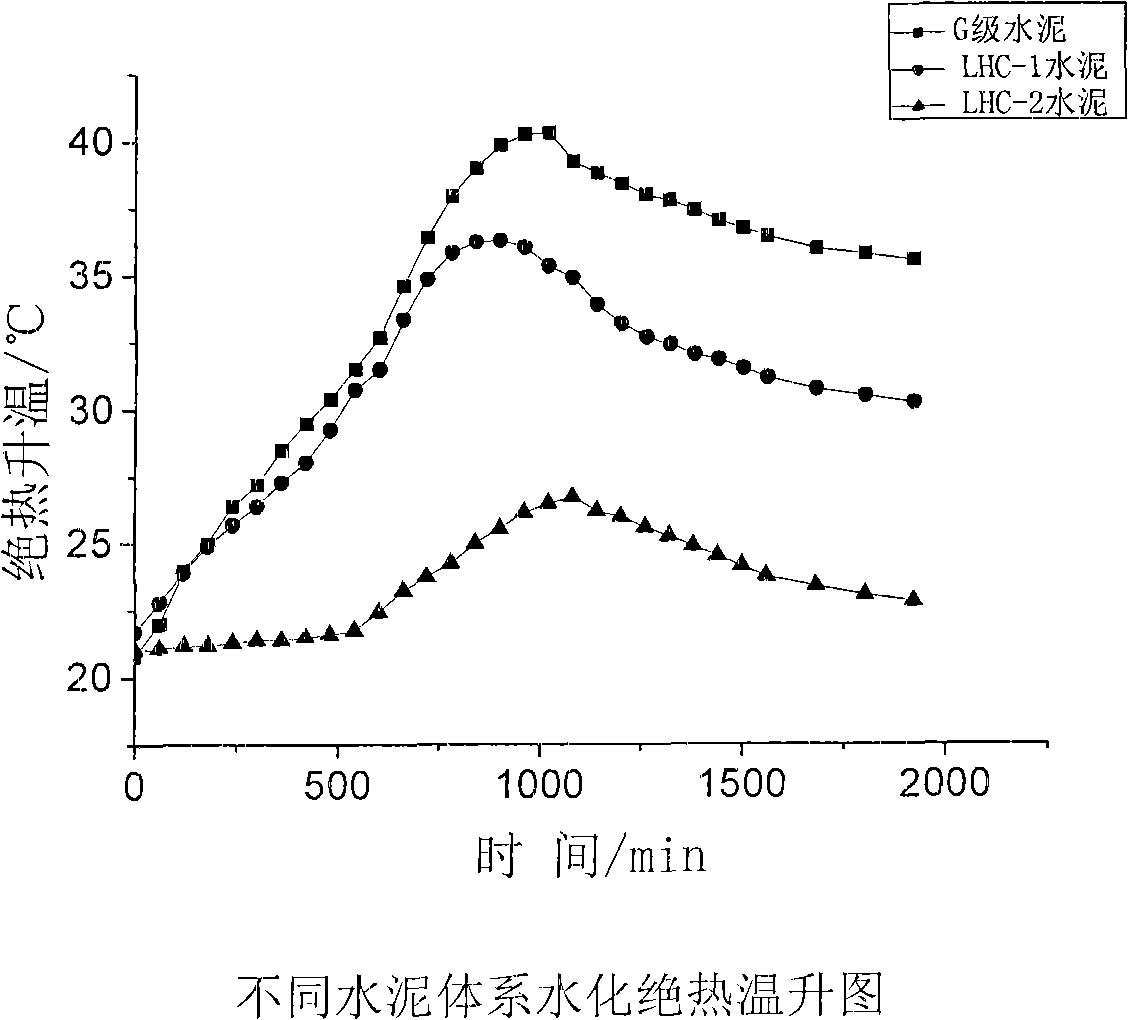

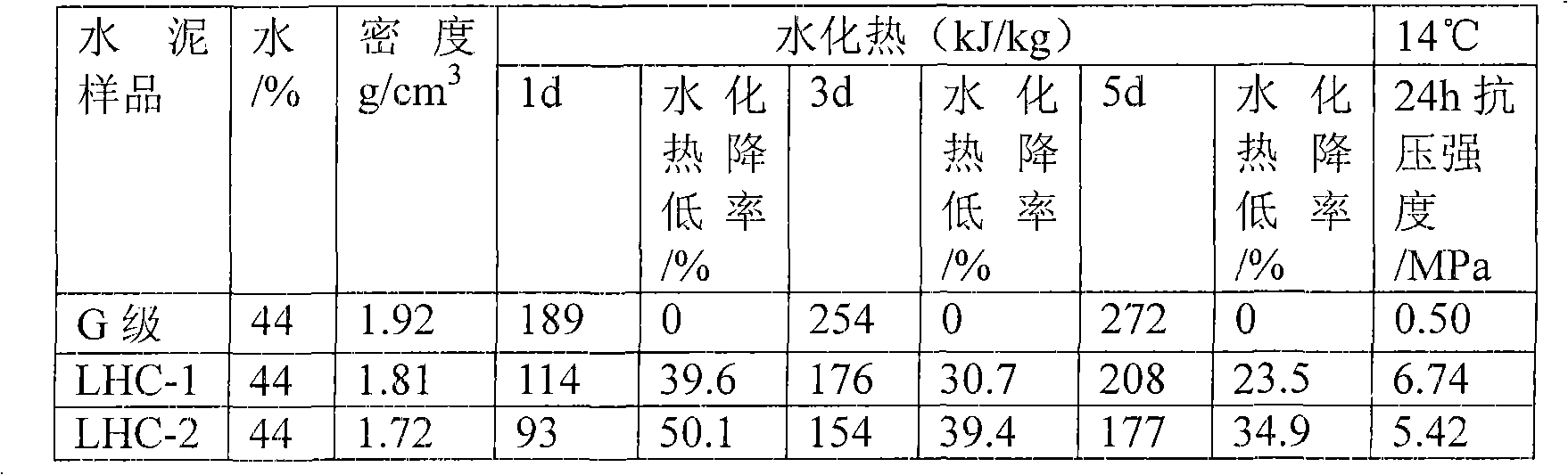

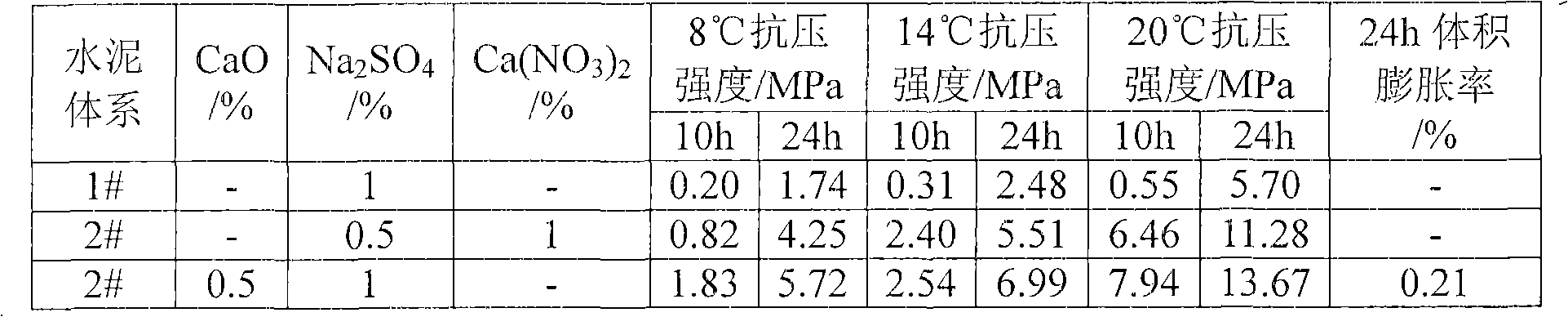

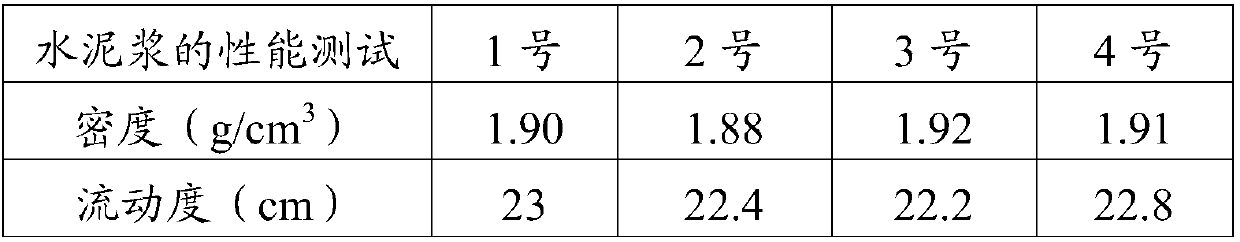

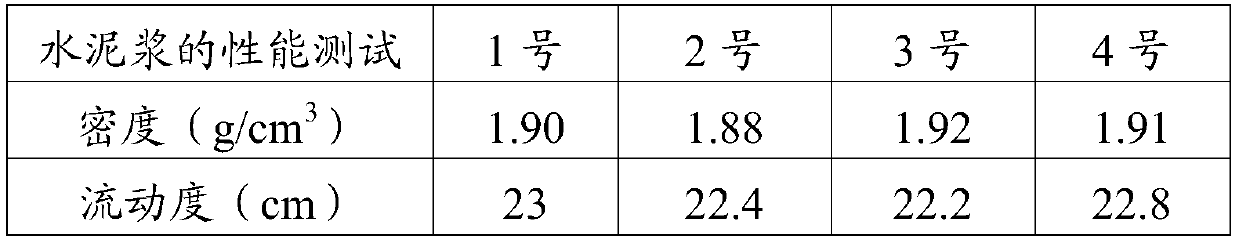

Low temperature low hydration heat cementing cement system

InactiveCN101328050AImprove performanceAvoid thermal decompositionSolid waste managementDrilling compositionSlagHydrate decomposition

The invention relates to a low temperature and low hydration heat cementing concrete system used in the natural gas hydrate layer cementing field. The objective of the invention is to effectively reduce the heat release of the cement hydration, prevent the hydrate from decomposing because of large heat and reduce the harm of the hydrate to the cementing. The whole performance of the cement under the low heat release condition is improved by adding materials which can reduce the whole hydration heat release of the cement using G grade oil well cement as base material. (1) The proper addition of superfine slag with a specific surface area between 6000 and 12000cm2 / g can make sure the strength properties of the early and later stage of the cement. (2) The hydration heat is further reduced by adding fly ash with a lower hydration activity. (3) An amount of gypsum component is added so that the cement paste has certain expansion property at a low temperature to prevent the cement paste shrinking at a low temperature. The low temperature and low hydration heat cementing concrete provided by the invention has an obvious effect for reducing the whole cement hydration heat and a good effect for preventing the deep water hydrate decomposition.

Owner:CHINA UNIV OF PETROLEUM (EAST CHINA)

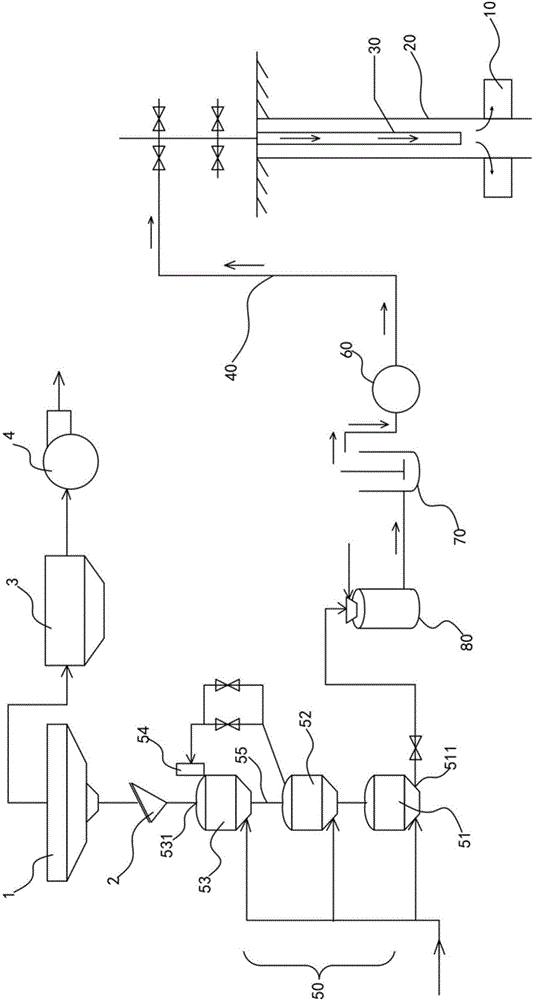

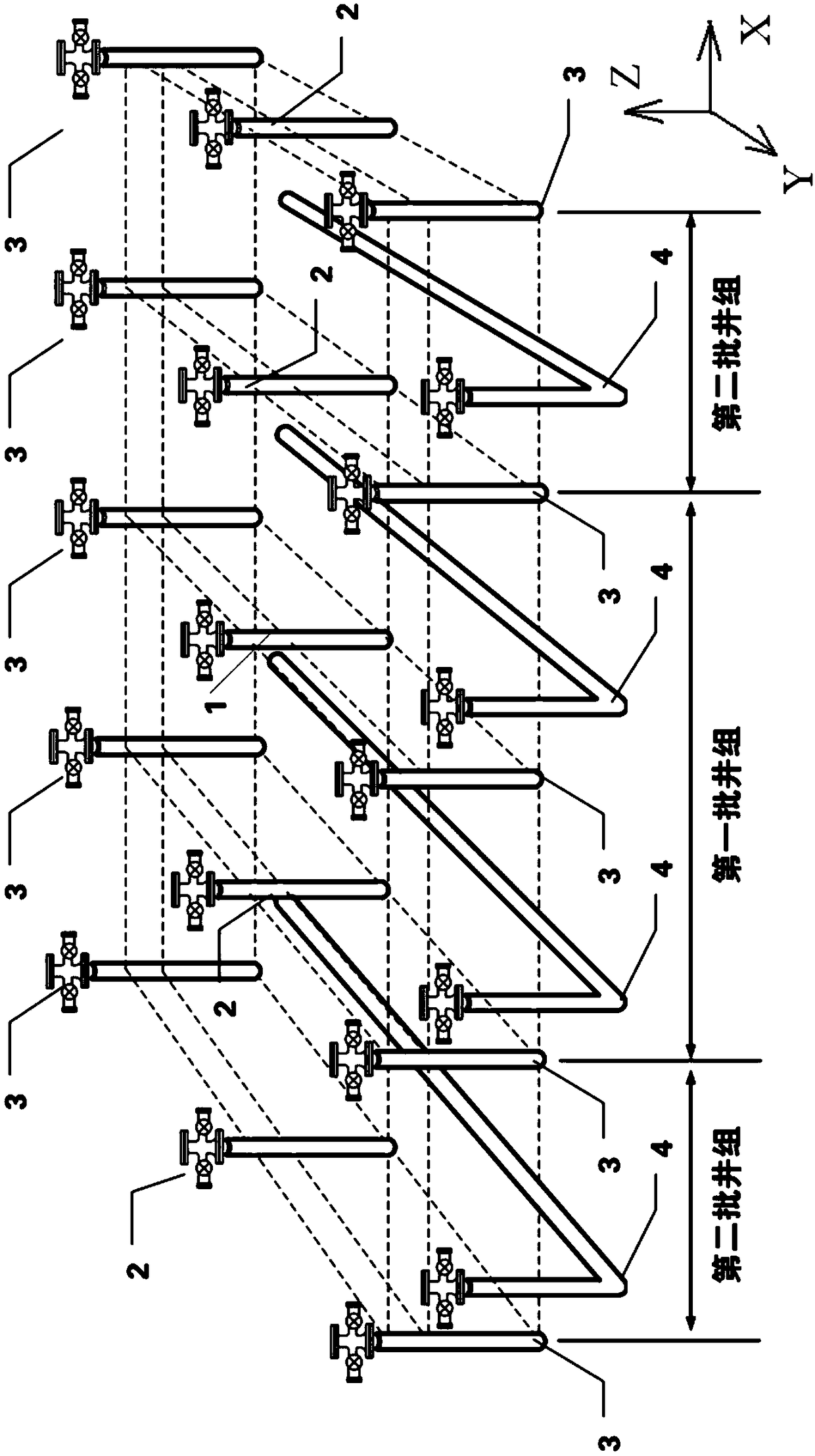

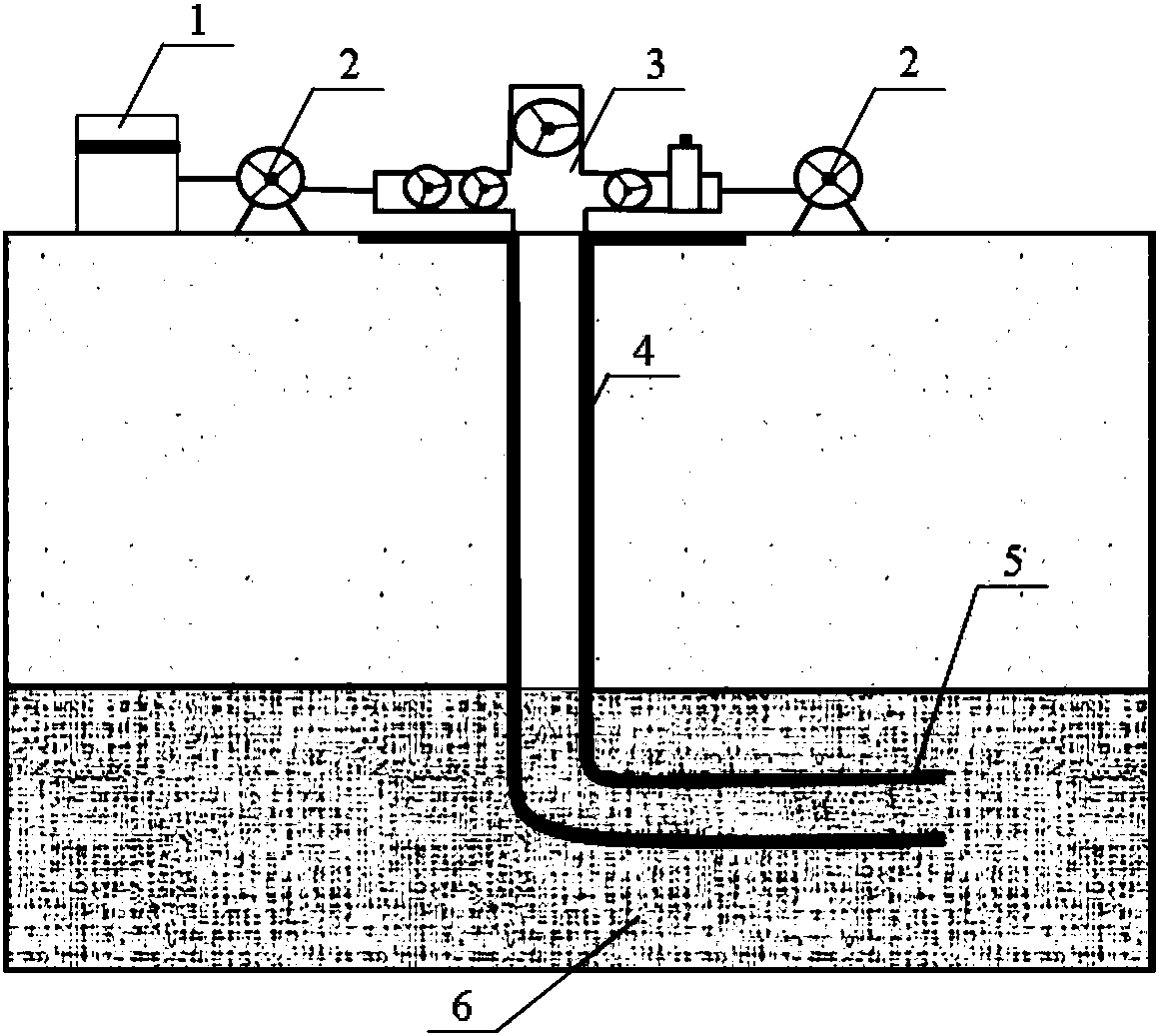

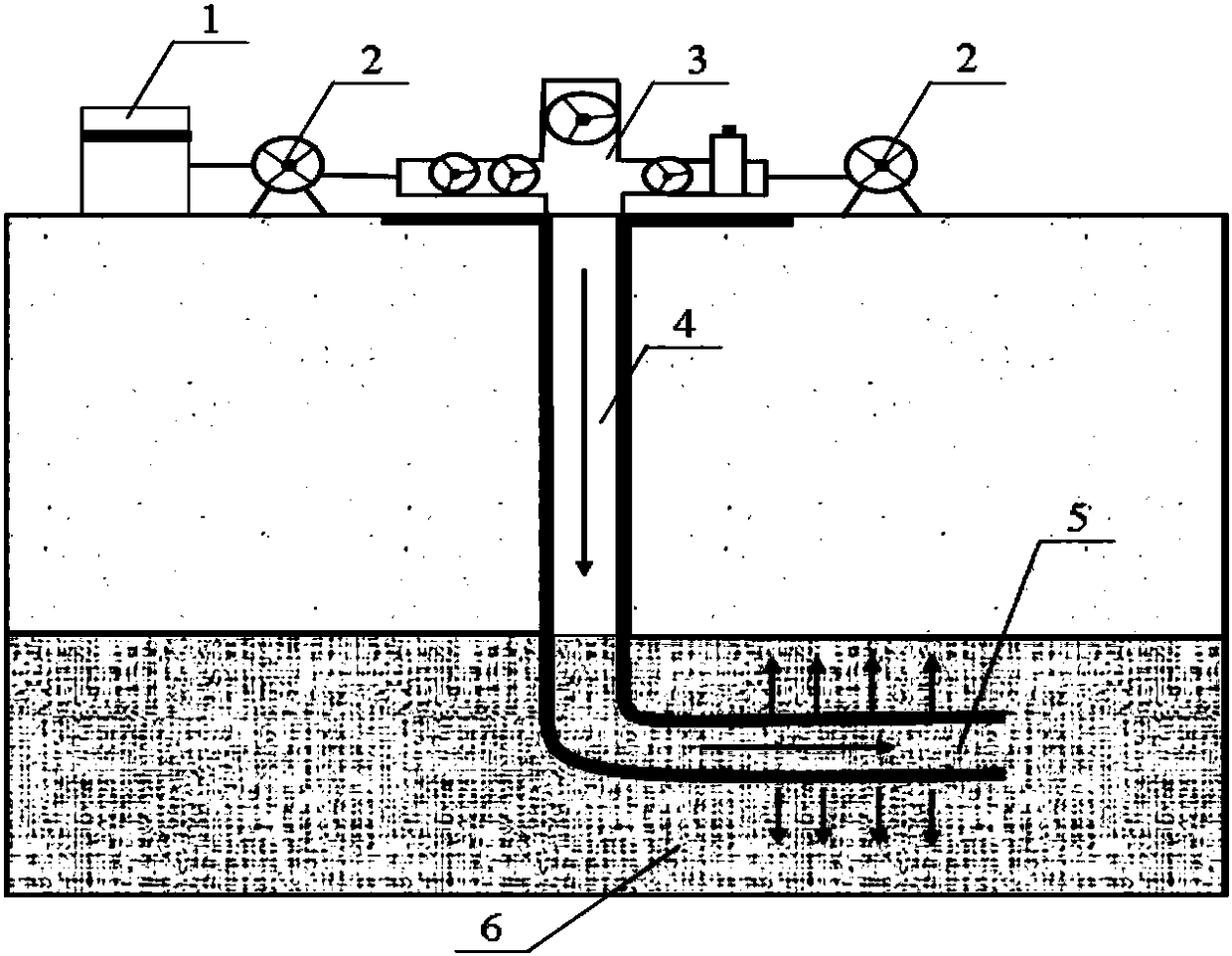

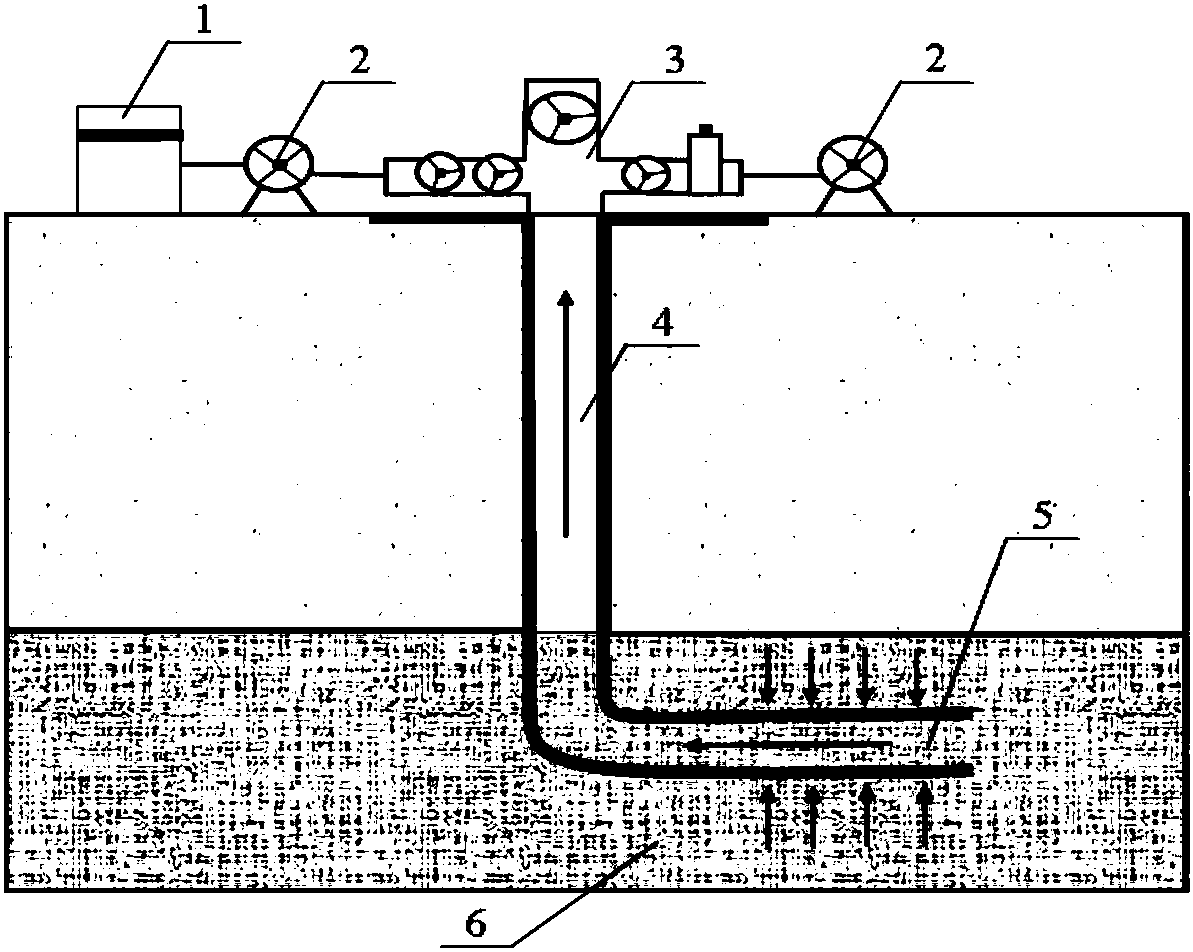

Propane-injecting shallow heavy oil reservoir exploitation method

The invention relates to a propane-injecting shallow heavy oil reservoir exploitation method. The propane-injecting shallow heavy oil reservoir exploitation method includes the following steps: a horizontal injection and production well network is arranged in a shallow heavy oil reservoir exploitation area, an injection well and a production well are arranged in the oil layers at the same vertical plane position to form an injection and production well pair, the injection well is a horizontal injection well, the production well is a horizontal production well, and the horizontal injection and production well network comprises at least one injection and production well pair; injected steam circulation preheating is carried out simultaneously via the injection well and the production well; after the temperature of the oil layer between the horizontal section of the injection well and the horizontal section of the production well is increased to a predetermined temperature, the injection well and the production well simultaneously stop circulation preheating, propane starts to be continuously injected into the injection well, and the amount of the injected propane is 5000m3 / d to 25000m3 / d; and the production well starts continuous oil production. The propane-injecting shallow heavy oil reservoir exploitation method has the characteristics of high recovery rate, propane recycling, low exploitation cost, high economic benefit, low energy consumption, low emission, environment-friendliness and the like, and is easy and safe to operate.

Owner:PETROCHINA CO LTD

Deep water low temperature cementing cement system

InactiveCN101054513AImprove performanceRapid development of strengthDrilling compositionWell cementingCement slurry

The invention belongs to sea deep water complex well cementing which is suitable for low temperature, tending to superficial water-gassed-out. The mineral components and mass percent composition are: 23-45 wt.% of tricalcium silicate, 12-25 wt.% of calcium sulphoaluminate, 15-23 wt.% of dicalcium silicate, 3-10 wt.% of gypsum, 4-8 wt.% of calcium carbonate, and residual celite, calcium aluminate and other microelement. The using process of the deep water complex well cementing includes: adding 0-3 wt.% of coagulant, 0-1.2 wt.% of retarder, 15-45 wt.% of hollow microglobin and water to prepare a low density cement slurry system of 1.35-1.60g / cm3 which has a controllable gelled time and has a perfect right-angle gelling capacity, a set cement volume microdilatancy and develops fast at low temperature. The inventive deep water low temperature complex well cementing has a high early strength, a short curing time, a powerful channeling-preventing ability, and microdilatancy, which provides a powerful guarantee to improve the deep water complex well quality.

Owner:CHINA UNIV OF PETROLEUM (EAST CHINA)

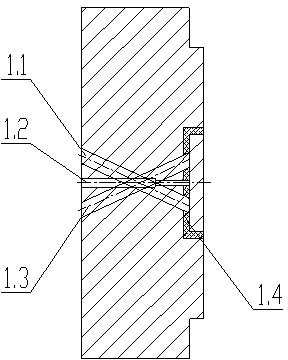

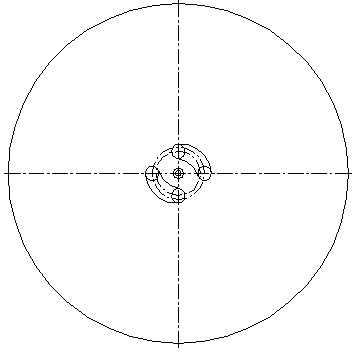

Device for injecting pulverized coal into oil layer and ignition method for in-situ oil combustion

ActiveCN106050207AReduce moisture contentImprove ignition performanceFluid removalCombustionInjection well

The invention provides a device for injecting pulverized coal into an oil layer and an ignition method for in-situ oil combustion and belongs to the field of exploitation through in-situ oil combustion. The device for injecting the pulverized coal into the oil layer comprises an oil pipe arranged in an injection well or a production well, a pulverized coal spray-blowing system arranged on the ground and an injection pipeline, wherein the pulverized coal spray-blowing system is provided with a pulverized coal input port and a spray-blowing port, the spray-blowing port sprays out the pulverized coal, the injection pipeline is connected between the oil pipe and the spray-blowing port of the pulverized coal spray-blowing system, and the pulverized coal sprayed out of the spray-blowing port is delivered to the oil pipe. The device can improve the ignition effect for in-situ oil combustion and can also improve the development effect of the in-situ oil combustion.

Owner:PETROCHINA CO LTD

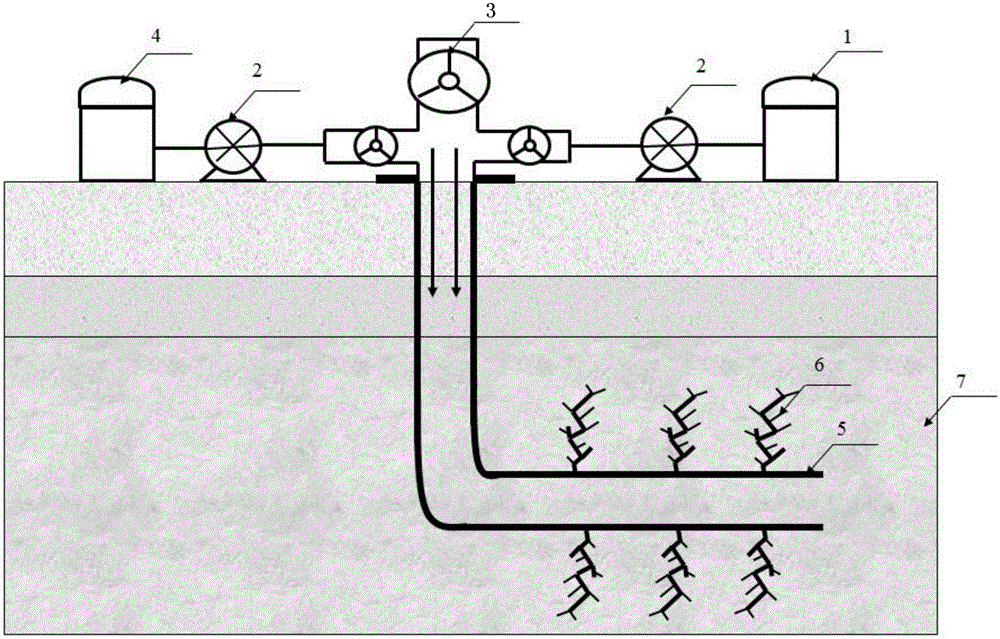

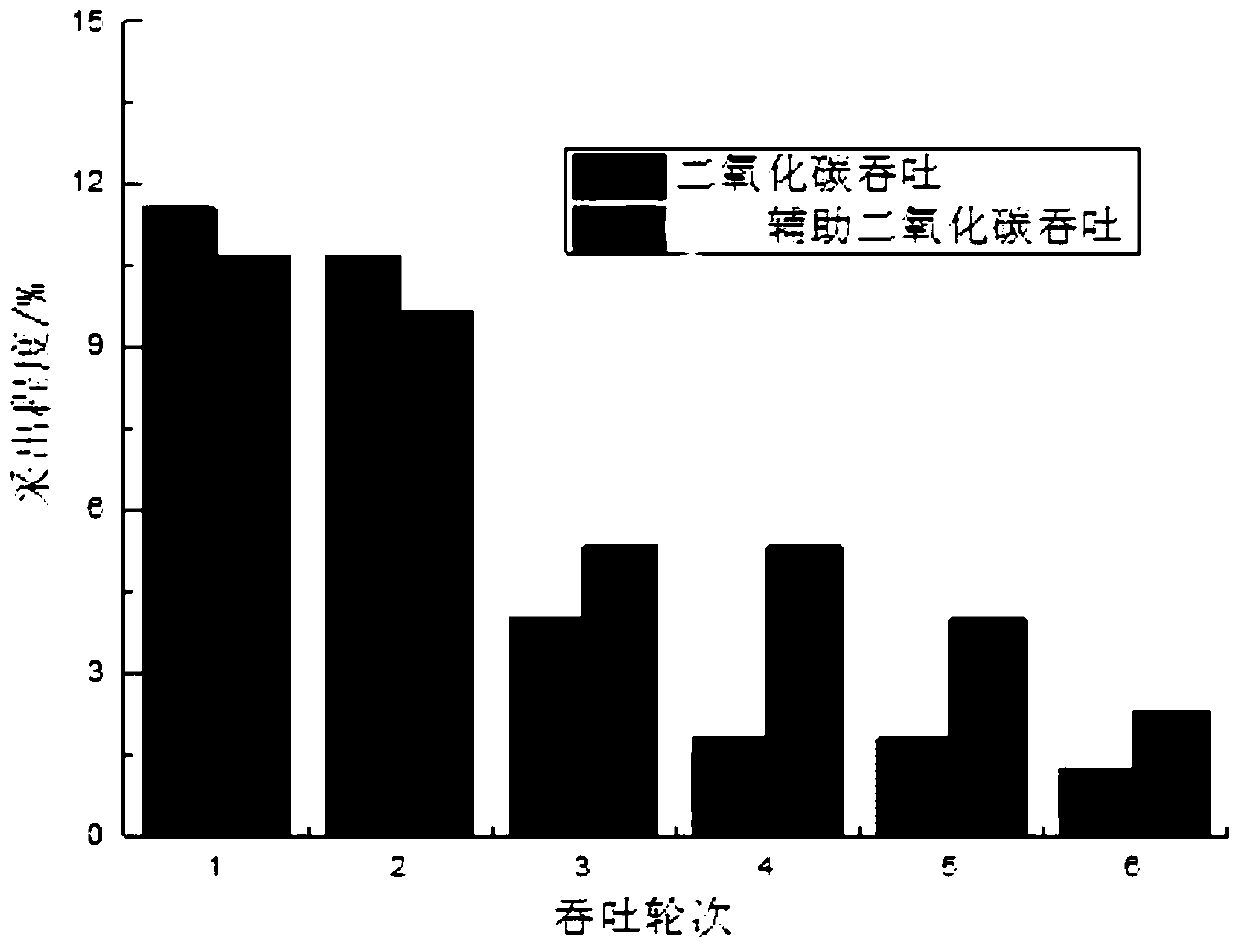

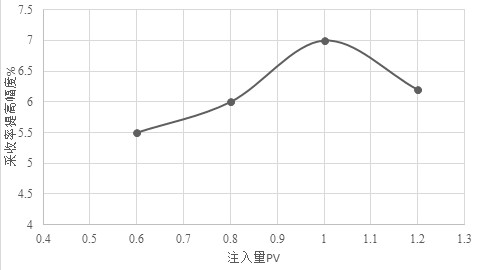

Method for increasing recovery ratio of tight oil reservoir through CO2 foam huff and puff

The invention relates to a method for increasing the recovery ratio of a tight oil reservoir through CO2 foam huff and puff. The method comprises the steps that high-pressure CO2 is injected into the fractured tight oil reservoir for slugging, cracks are mainly filled with CO2 for soaking, and crude oil enters the cracks from the matrix under the actions such as extraction, volume expansion and dissolution and viscosity reduction; and after the pressure of a wellhead is stable, a well is opened for production, in the formation seepage process, CO2 makes contact with a surface active agent aqueous solution to generate foam, the CO2 foam displaces the crude oil so that the crude oil can flow from the cracks to a shaft, and finally the crude oil is recovered to the ground. According to the method, no foam is generated in the CO2 injection process, and the situation that the generated CO2 foam displaces the crude oil to the deep position of the oil reservoir is prevented; and in the recovery process, the CO2 makes contact with the surface active agent aqueous solution so that the foam can be generated in the stratum, through the mechanisms that the CO2 foam conducts oil cleaning in the cracks and the fluidity of CO2 is effectively controlled, more crude oil in the cracks can be displaced into the shaft, and the recovery ratio of the tight oil reservoir is increased.

Owner:CHINA UNIV OF PETROLEUM (EAST CHINA)

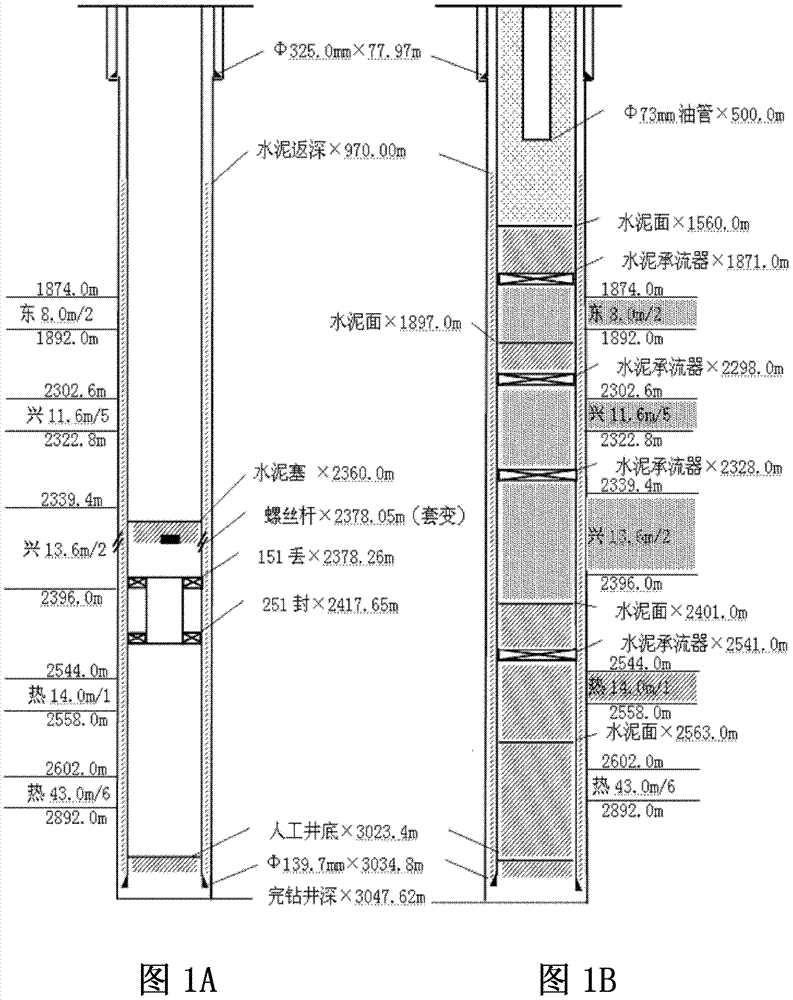

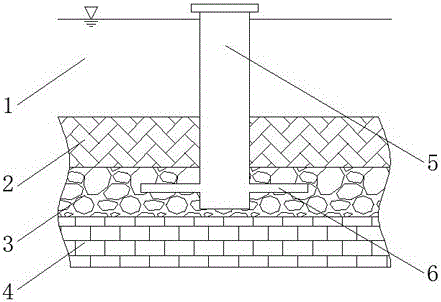

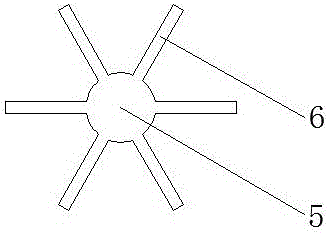

Method for plugging old underground gas storage well

ActiveCN103244071APrevent gas blowingMeet the requirements of normal production operationSealing/packingWell cementingMaterial Perforation

The invention discloses a method for plugging an old underground gas storage well. The method comprises the steps of utilizing a cement bearing device and adopting padding mixed with superfine cement to plug a jetted air reservoir target layer in an extruding mode and reserving a cement plug; utilizing the cement bearing device and adopting padding mixed with superfine cement to plug perforated well sections under the jetted air reservoir target layer in the extruding mode and reserving a cement plug; utilizing the cement bearing device and adopting padding mixed with superfine cement to plug perforated well sections above the jetted air reservoir target layer in the extruding mode and reserving a superfine cement plug; selecting superfine sections with high superfine permeability to solve the problem that the well cementation quality of well sections above the target layer is disqualified, and arranging cement partition plates after perforation so as to prevent gas channeling outside tubes; plugging the target layer and other perforated well sections and waiting on cement setting under pressure by utilizing the cement bearing device; and arranging a whole cement plug and reserving cement faces to be 300m higher than the perforated well sections. The method for plugging the old underground gas storage well can effectively save plugging materials and improve the plugging effect.

Owner:PETROCHINA CO LTD

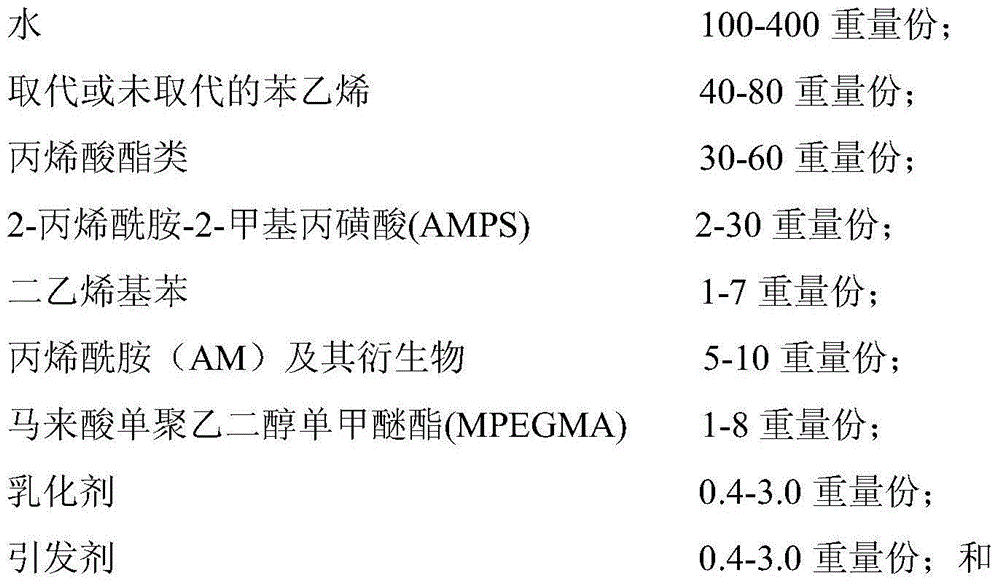

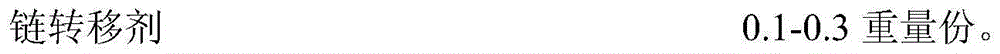

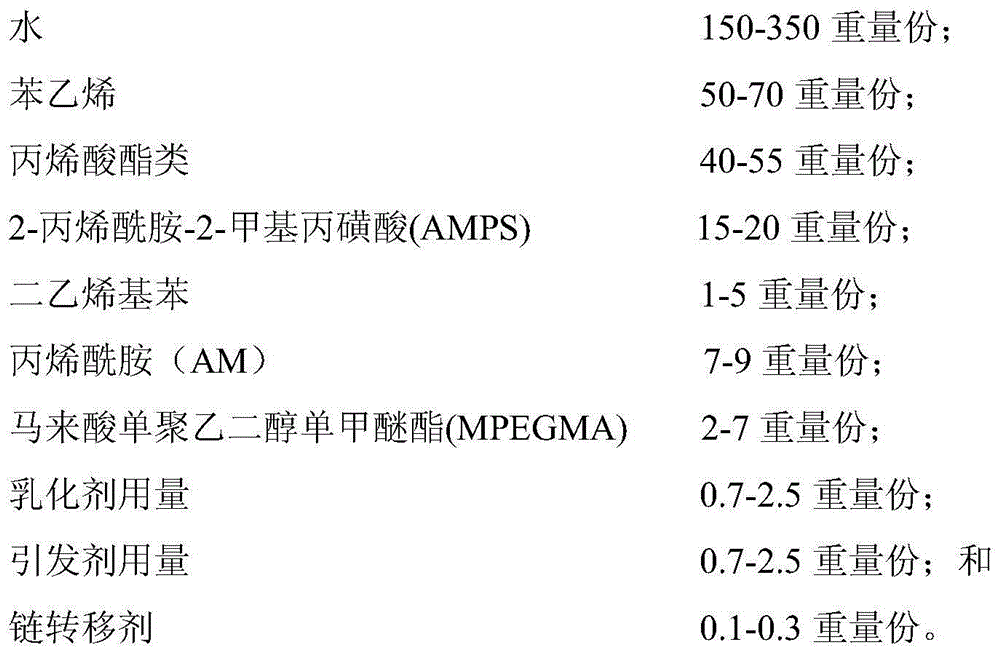

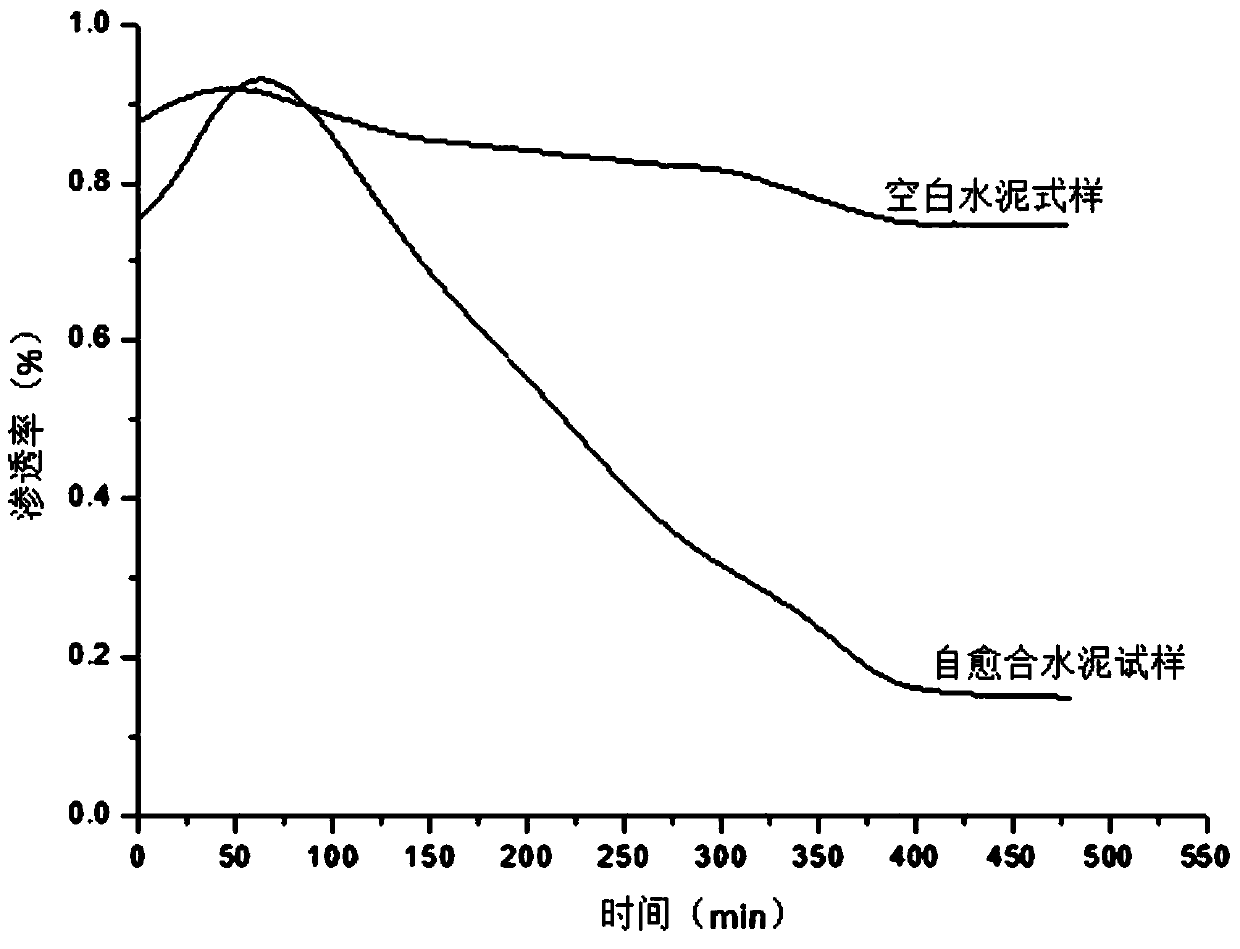

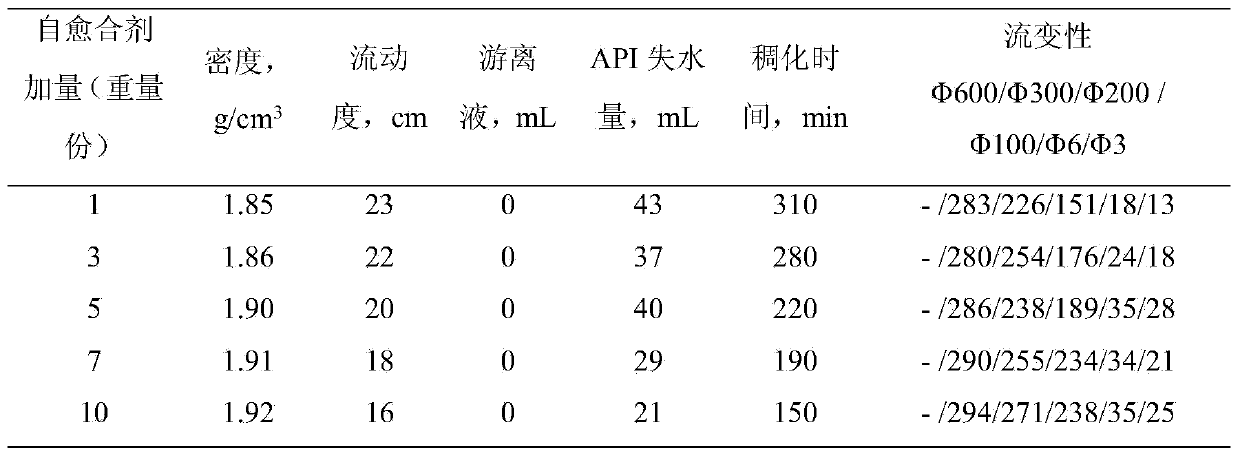

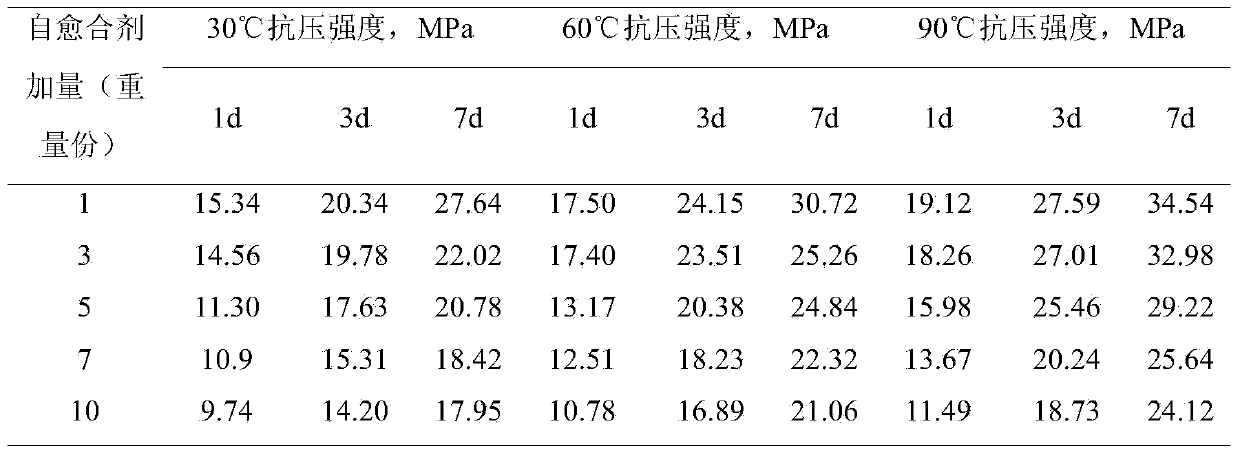

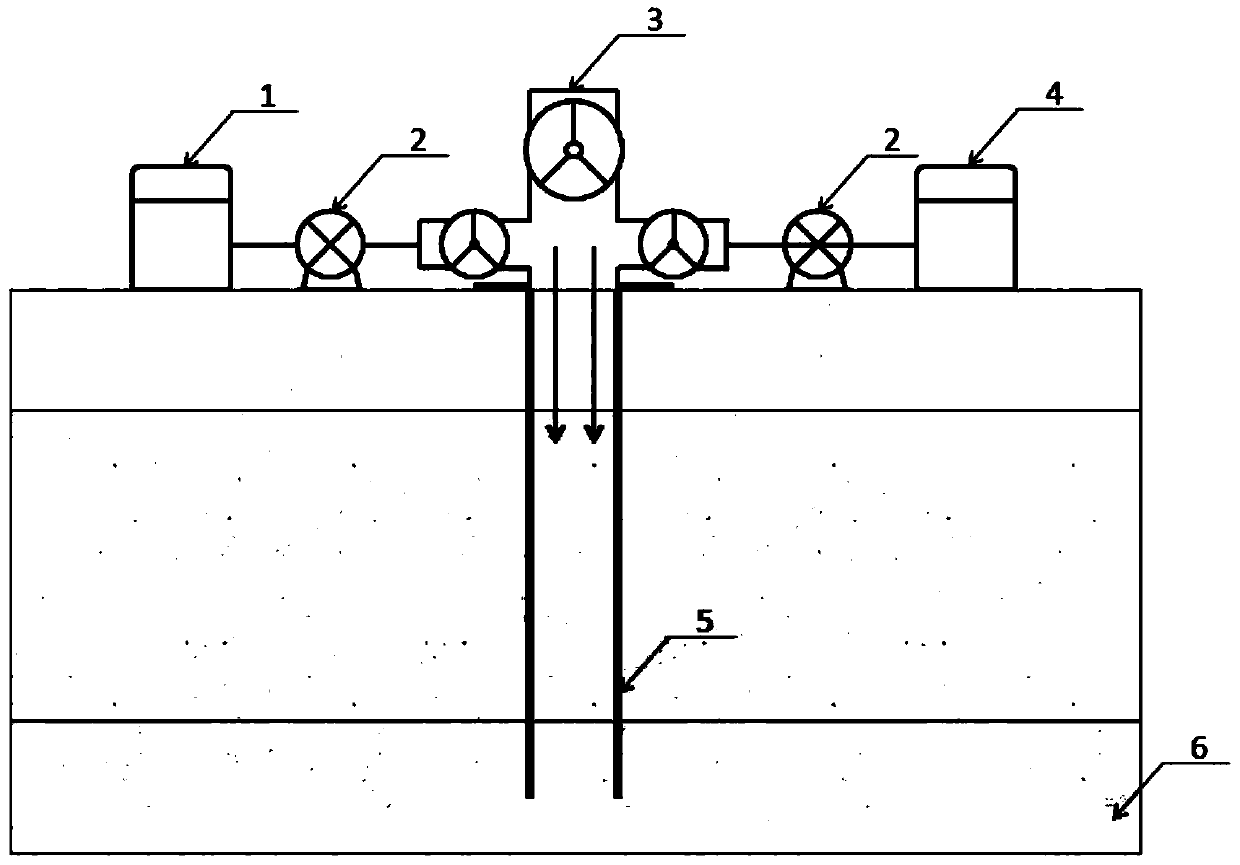

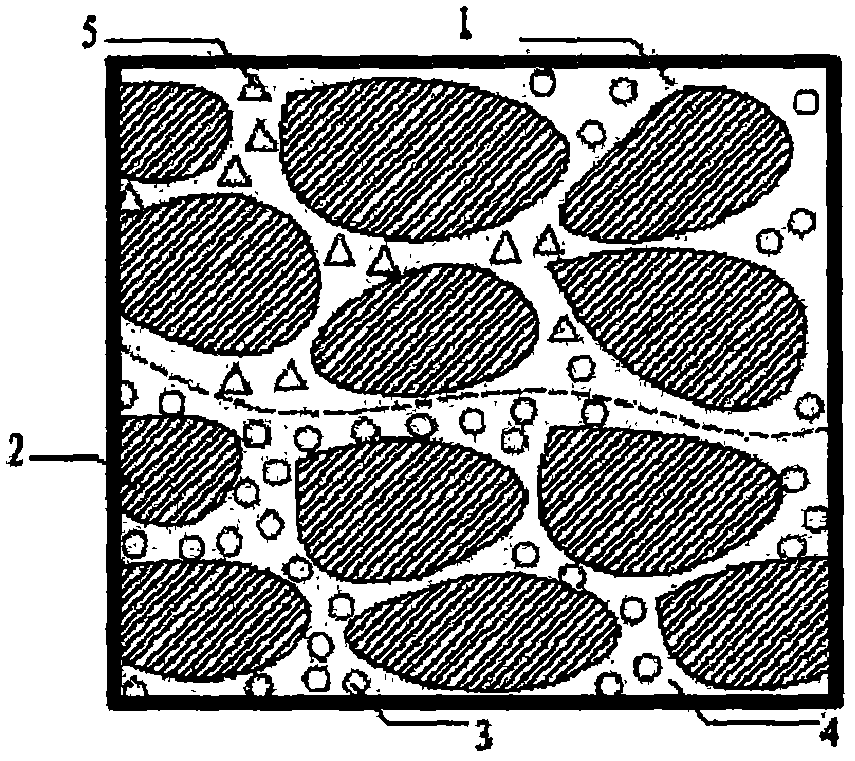

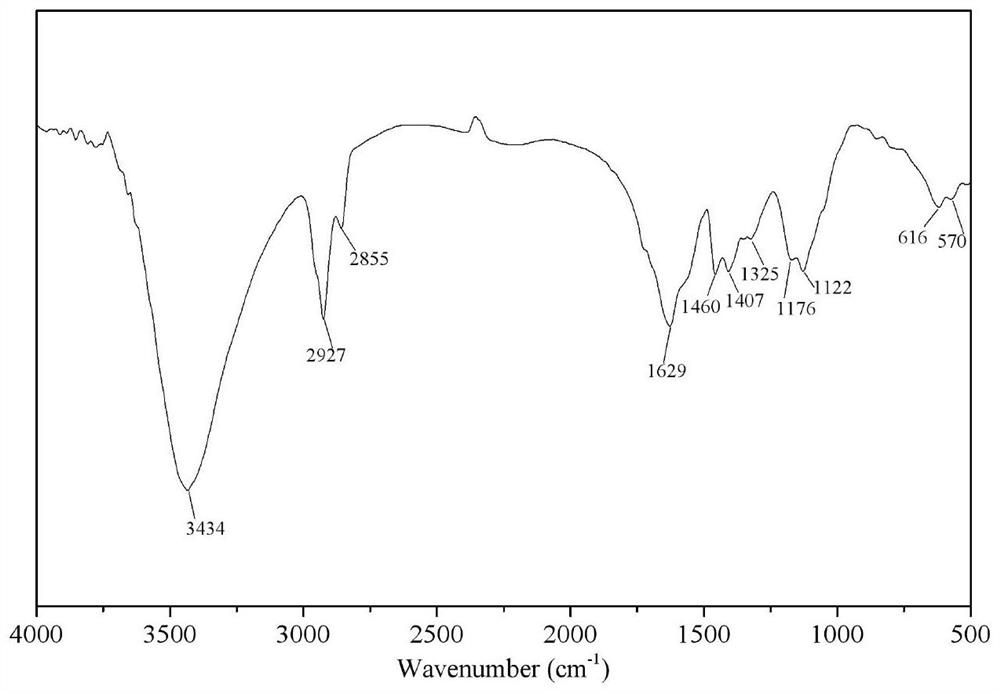

Preparation method of self-healing agent for oil well cement, well cementation self-healing cement slurry and application

ActiveCN104418965ATo achieve the effect of oil expansionEasy construction pumpingDrilling compositionSelf-healingPolyethylene glycol

The invention discloses a preparation method of a self-healing agent for oil well cement. The preparation method comprises the following steps: i) mixing substituted or unsubstituted styrene, acrylates, 2-acrylamide-2-methyl propane sulfonic acid, divinyl benzene, acrylamide and derivatives thereof, mono polyethylene glycol maleate, an emulsifier and a chain transfer agent with water and pre-emulsifying to obtain a pre-emulsion A; ii) preparing an initiator solution B by water and an initiator; iii) heating a part amount of the pre-emulsion A to 70-90 DEG C and then adding a part amount of the initiator solution B; then, further adding the residual amount of the pre-emulsion A and the initiator solution B; and iv) after reaction, adjusting the pH value to 7-9 to obtain the self-healing agent for oil well cement. The invention further relates to well cementation self-healing cement slurry which contains the self-healing agent prepared by the method as well as an application of the self-healing agent or the well cementation self-healing cement slurry in oil gas well cementing operation.

Owner:CHINA PETROLEUM & CHEM CORP +2

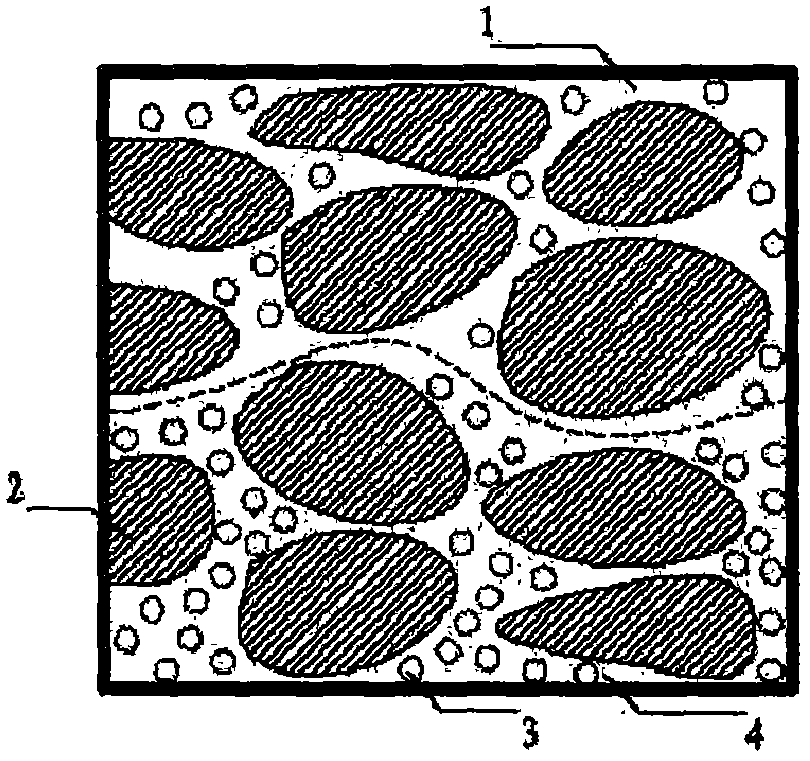

Oil well cement swelling agent

InactiveCN101240163AHigh expansion rateNo effect on compressive strengthDrilling compositionCeramicwareSlurryOil well

An oil-well cement expander is provided, characterized by consisting of 70% calcium light and 30% azo compounds. The present invention has advantages of making the cement volume expand, effectively improving cementing property between cement columns and sleeves or stratums, improving capability of cement columns supporting sleeves and separating stratums, compensating the liquid column pressure during slurry curing to avoid gas channeling, so the expander is also called the prevention of gas channeling with property in promoting solidification.

Owner:TIANJIN TEWEI TRADE

Formula for improving recovery ratio of authigenic CO2

A formula for improving the recovery ratio of authigenic CO2 comprises, by mass, 5-15 parts of ammonium bicarbonate, 1-5 parts of bioactive agents, and the balance water which is not beyond 35 DEG C. In use, the formula is directly injected in the stratum and dissolved to generate CO2 through heat of the stratum; when the temperature of the stratum is below 35 DEG C, the CO2 is obtained through composite effect of the heat of the stratum and the bioactive agents. The formula can be applied to the fields of oil field oil displacement, fracturing and well repair, and achieves the purposes of improving the recovery ratio, and promoting fracturing fluid flowing-back. Foams are generated while gas is formed, stability of the foams is high, gas channeling can be effectively prevented, and the formula has the advantages of foam displacement of reservoir oil and foam well killing.

Owner:SUNCOO PETROLEUM TECH

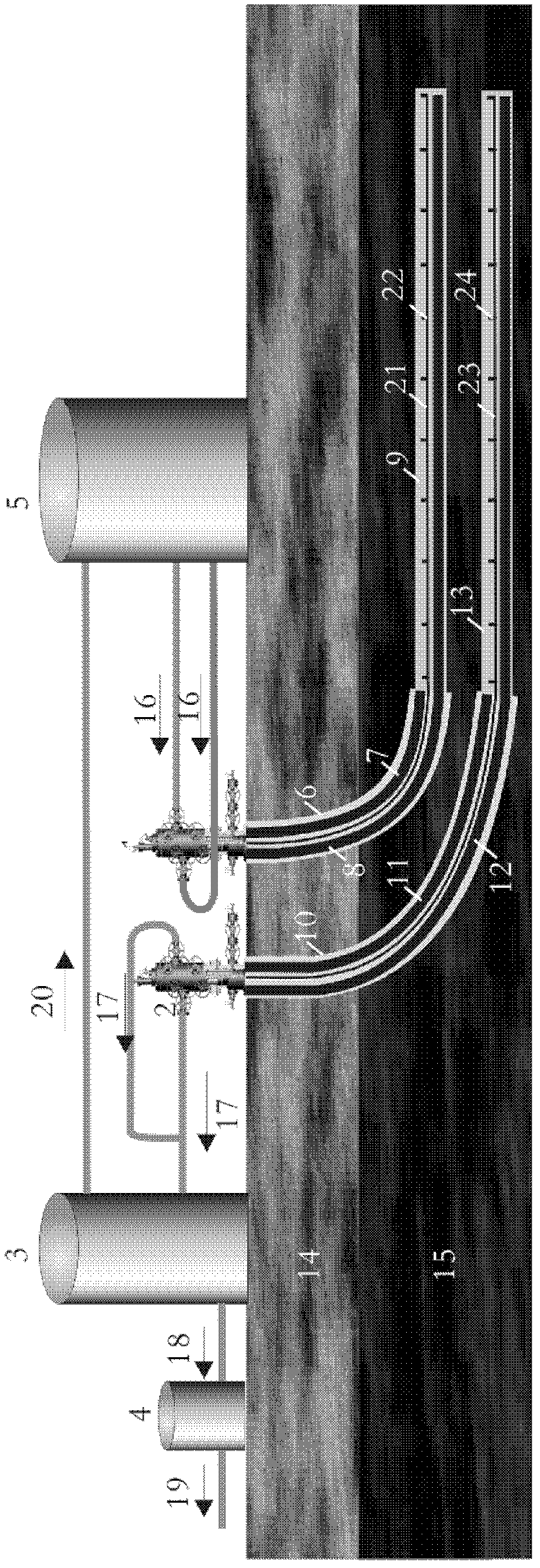

Natural gas horizontal well completion method

ActiveCN106285617AIncrease the number ofAvoid or reduce downhole complicationsConstructionsLiquid/gas jet drillingSoil scienceCement slurry

The invention relates to a natural gas horizontal well completion method. According to the technical scheme, the natural gas horizontal well completion method comprises the steps that the target well depth is drilled at a time with a large-size drill bit, and a large hole is formed; a plurality of horizontal branch holes are drilled out in a natural gas hydrate reservoir through the horizontal well technology; and the contact surface area between the reservoir and the holes is increased to the greatest extent. The natural gas horizontal well completion method has the beneficial effects that the downhole complex conditions in the exploitation process is avoided or decreased; the number of the holes can be greatly increased; the bare area and the depth of the natural gas hydrate reservoir are increased to the greatest extent by the holes; the recovery ratio is greatly increased; the well spacing number and the development investment are decreased; and a window sealant is adopted, thus, a cement slurry system is stable, strength development is rapid, the thickening time is adjustable, hydrate layer sealing shallow water-gas channeling can be effectively prevented, and the construction performance is good.

Owner:HUAXIN TANGSHAN PETROLEUM EQUIP CO LTD

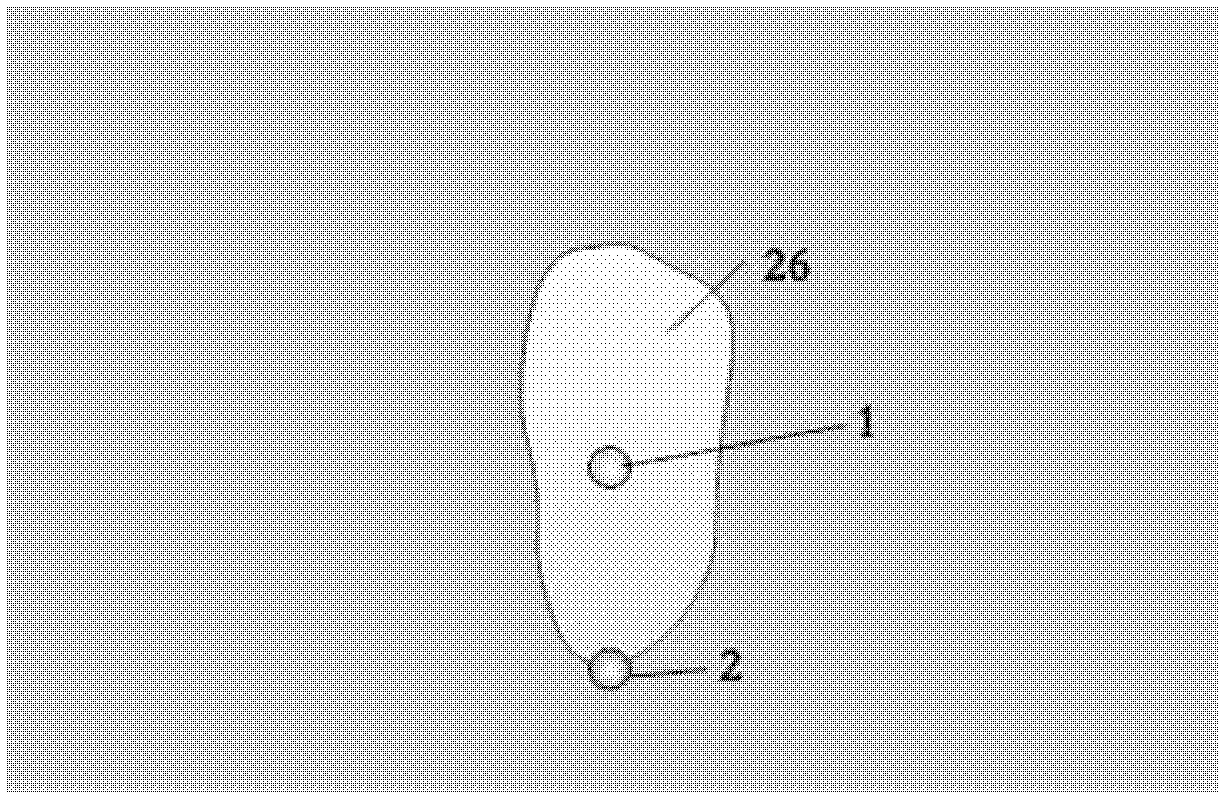

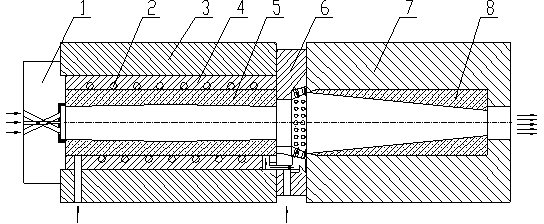

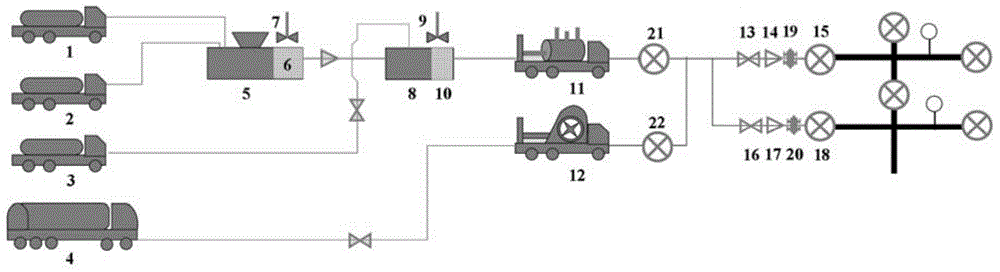

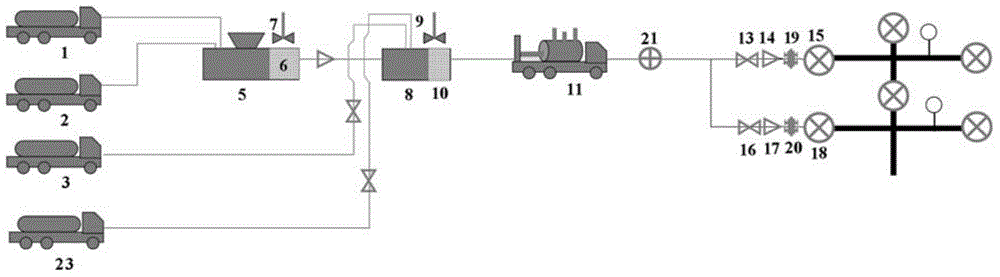

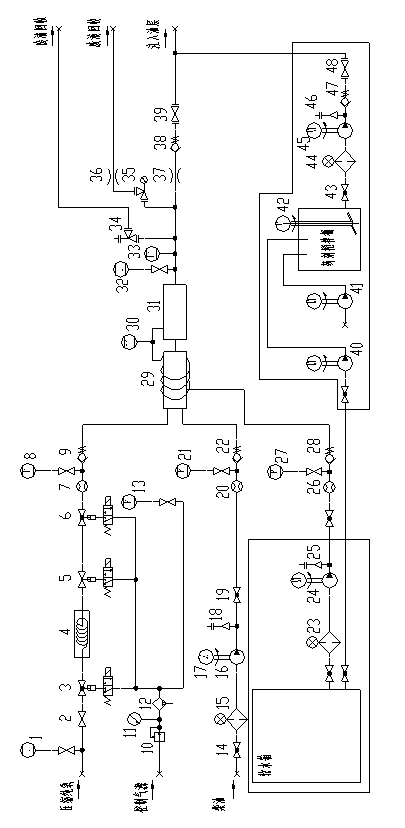

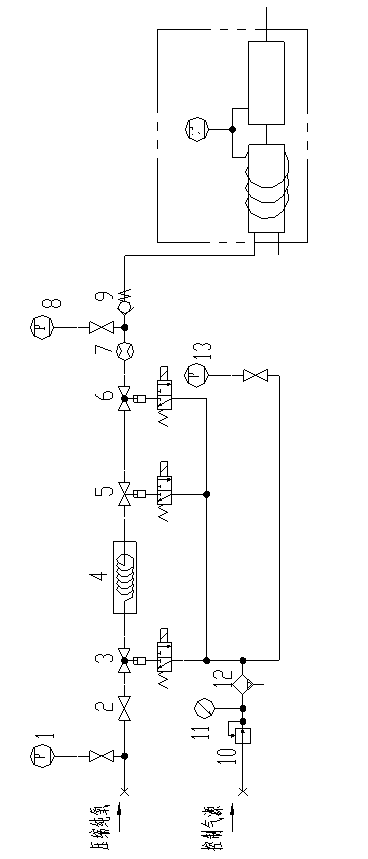

High-temperature high-pressure combustion structure of pure oxygen combined heat carrier generator

InactiveCN103452537AImprove combustion efficiencyImprove heat utilizationFluid removalHeat carrierCombustion chamber

The invention relates to a high-temperature high-pressure combustion structure of a pure oxygen combined heat carrier generator. The high-temperature high-pressure combustion structure comprises a generator fuel-pure oxygen combined supply and ignition structural part (1), a strength retainer shell (3), a main combustion chamber (4), an inflammable bin (5), a mix connector (6), a main gasification shell (7), and a gasification zone heat-resisting layer (8). The main gasification shell (7) is disposed behind the strength retainer shell (3). The strength retainer shell (3) is fixedly connected with the main gasification shell (7) through the mix connector (6). The inner wall of the strength retainer shell (3) is provided with the main combustion chamber (4). The inflammable bin (5) is formed inside the main combustion chamber (4). The gasification zone heat-resisting layer (8) is disposed inside the main gasification shell (7). The high-temperature high-pressure combustion structure has the advantages that operating pressure can meet the requirement for operational combustion reliability under the subcritical pressure when combustion temperature exceeds 3000 DEG C.

Owner:JIANGSU GREATRIVER OTECH

Super heavy oil well profile control agent and application

InactiveCN104863554AImprove throughputReduce the impactFluid removalDrilling compositionMass ratioComposition B

The invention provides a super heavy oil well profile control agent which comprises composition a and composition b, wherein the composition a comprises components in percentage by mass as follows: 0.5%-1% of hydrolysis polyacrylamide, 0.5%-2% of an organic crosslinking agent, 0.1%-0.5% of a heat stabilizer, 0%-1% of a slow gelatinizing agent and the balance of water; the composition b comprises a gas generation agent and a surfactant; the gas generation agent is liquid carbon dioxide or urea; when the gas generation agent is liquid carbon dioxide, the mass ratio of liquid carbon dioxide to the surfactant is (80-100): (6-8); when the gas generation agent is urea, the mass ratio of urea to the surfactant is (70-150): (5-12). The super heavy oil well profile control agent can effectively prevent gas channeling, influence of planar gas channeling on oil displacing is reduced, voidage of the stratum can be effectively compensated, the stratum pressure is increased, the throughput effect of an oil well is improved, and the output per period is increased.

Owner:PETROCHINA CO LTD

Oil well cement paste self-healing agent suitable for acid gas pool

ActiveCN104004504AGood compatibilityImprove compactnessDrilling compositionTemperature resistanceCopper sulfate

The invention discloses an oil well cement paste self-healing agent suitable for an acid gas pool. The method for preparing the oil well cement paste self-healing agent suitable for the acid gas pool comprises the steps that (1) acid activation treatment and modification treatment are conducted on expanded perlite with the particle size ranging from 80 meshes to 120 meshes; (2) one or more of the self-healing materials such as copper sulfate, silver nitrate, barium hydroxide and lead acetate are mixed with water with the mass ratio of 1:50-100; (3) 10 g to 50 g of the modified expanded perlite is added to 200 mL to 1000 mL of a self-healing solution, so that a modified expanded perlite-seal-healing material mixed solution is prepared; (4) the mixed solution is placed in a spray dryer to be dried for two hours at the temperature of 250 DEGC to 300 DEG C, and then the oil well cement paste self-healing agent is obtained. The oil well cement paste self-healing agent can be adapted to the underground complicated working condition, is good in durability and temperature resistance, and capable of improving the mechanical property of set cement, the long-term sealing integration of acid gas well cement rings is guaranteed, and the production life of a gas well is prolonged.

Owner:SOUTHWEST PETROLEUM UNIV

A chemical agent-assisted CO2 huff and puff method to improve the recovery of ordinary heavy oil reservoirs

Owner:CHINA UNIV OF PETROLEUM (EAST CHINA)

Combined thermal recovery method for thickened oil reservoir with gas cap

The invention discloses a combined thermal recovery method for a thickened oil reservoir with a gas cap. According to the method, heating of the top of an oil layer is achieved through a method of igniting the gas cap, and combustion heat of a top air layer is utilized to heat the whole oil layer, thereby reducing viscosity of crude on the contact face between the gas cap and a thickened oil layerand achieving the cross-well communication between a vertical well and a horizontal well; flue gases produced after combustion further reduces the viscosity of the thickened oil and provides energy to the entire oil reservoir. The combined thermal recovery method for the thickened oil reservoir with the gas cap not only achieves the exploitation of the thickened oil reservoir with the gas cap, but also saves the steam injection amount through the combustion of the gas cap, and entirely improves the comprehensive benefits of the thickened oil exploitation in the vertical well and horizontal well in a steam driving stage.

Owner:PETROCHINA CO LTD

Air foam flooding method for reducing gas channeling for underground thickened oil exploitation and air foaming agent of foam flooding for reducing gas channeling for underground thickened oil exploitation

ActiveCN112796717AImprove the blocking effectImprove efficiencyFluid removalDrilling compositionFoaming agentWater flooding

The invention discloses an air foam flooding method for reducing gas channeling for underground thickened oil exploitation and a foaming agent of the foam flooding for reducing gas channeling for the underground thickened oil exploitation. The method comprises the following steps of S1, preparation work; S2, pre-injection; S3, slug injection, specifically, the slug injection are divided three groups in total, a slug combination 1 is repeated twice for 0.06PV air foam flooding and 0.04PV water flooding, a slug combination 2 is repeated for six times for 0.03PV air foam flooding and 0.03PV water flooding, and a slug combination 3 is repeated for four times for 0.05PV three-phase mixed foam flooding and 0.05PV water flooding; S4, post-injection; and S5, parameter adjustment, and the foaming agent is prepared from the following components of, in percentage by mass, 0.43%-0.46% of anionic surfactant, 0.32%-0.35% of ampholytic surfactant and the balance water. According to the air foam flooding method, the purpose of effectively reducing the gas channeling is achieved in a step-by-step injection mode, the nitrogen content is monitored in real time, the gas injection speed and the liquid injection speed are regulated and controlled, the plugging effect of air foam flooding is effectively improved on the premise that the gas channeling does not occur, and the profile control and displacement and the oil washing efficiency of the air foam flooding are greatly improved.

Owner:西安石油大油气科技有限公司

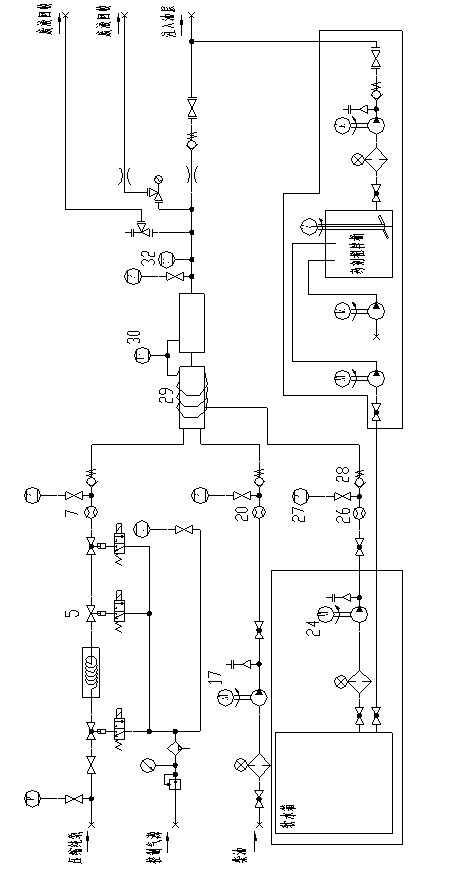

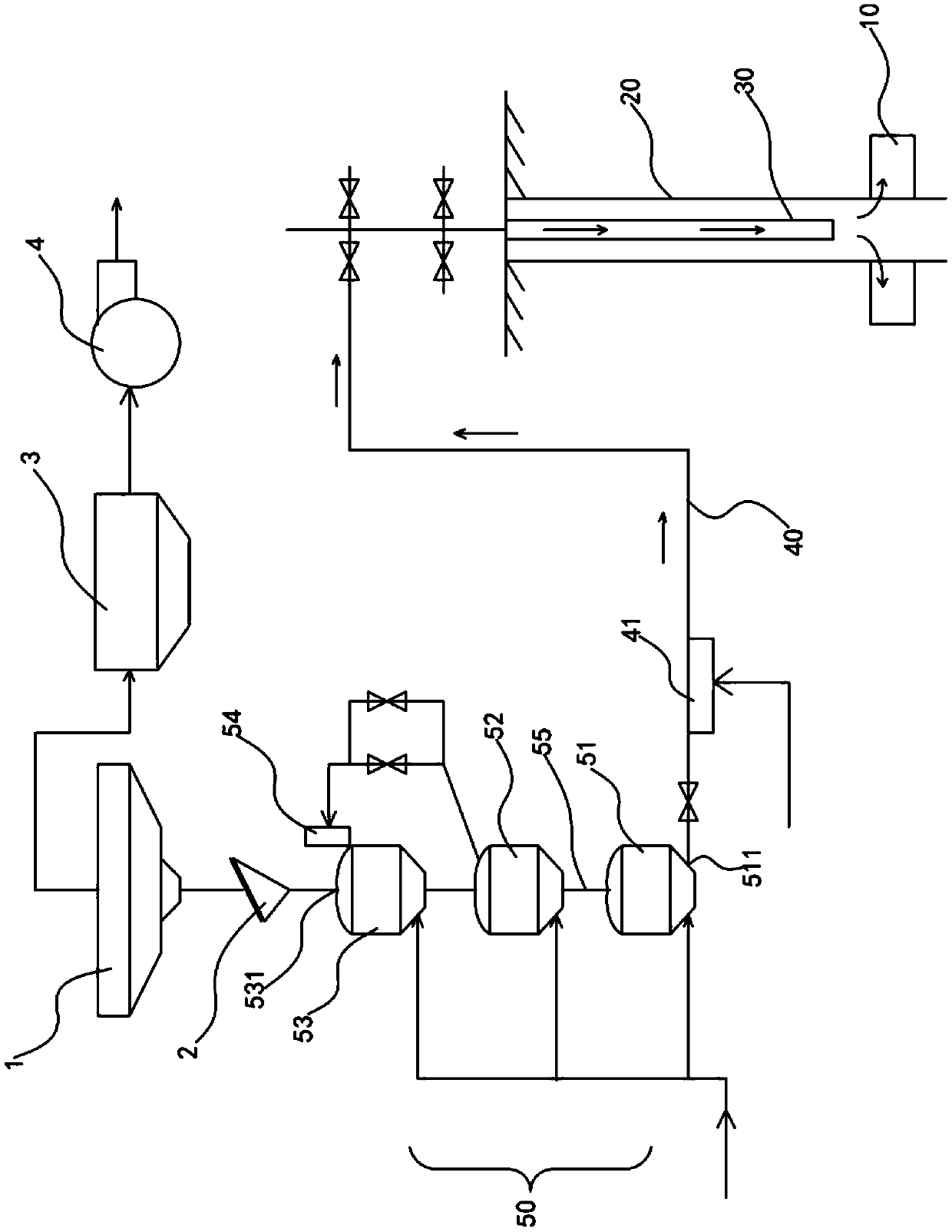

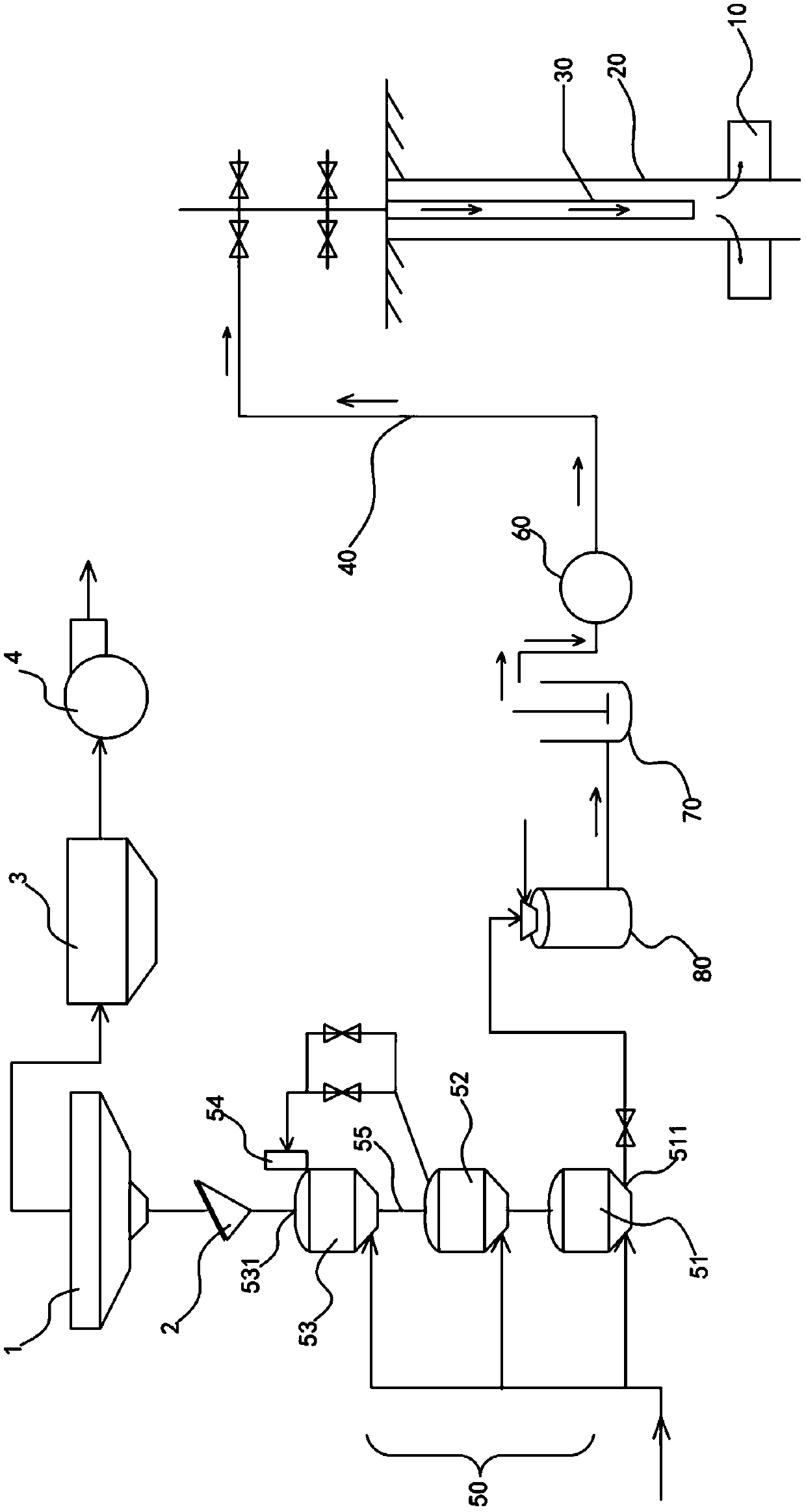

Pure oxygen and diesel combined heat carrier generator system

InactiveCN103452539AEnhanced overall recoveryLow running costFluid removalCombustion chamberHeat carrier

The invention relates to a pure oxygen and diesel combined heat carrier generator system comprising a pure oxygen combined heat carrier generator. The input end of the pure oxygen combined heat carrier generator is connected respectively with a pure oxygen pipeline, a diesel pipeline and a water pipeline. The output end of the pure oxygen combined heat carrier generator is connected with an oil layer through a combined heat carrier delivery pipeline. The combined heat carrier delivery pipeline comprises a pure oxygen combustion chamber (29), a circulating water temperature sensor (30), a heat carrier gasification chamber (31), a heat carrier pressure transmitter (32), a heat carrier temperature sensor (33), a heat carrier safety bypass device (34), and a heat carrier safety emptier (35), wherein the pure oxygen combustion chamber (29), the circulating water temperature sensor (30), the heat carrier gasification chamber (31) and the heat carrier pressure transmitter (32) are connected in sequence through a pipeline. The pure oxygen and diesel combined heat carrier generator system has the advantages that operation cost can be reduced effectively, zero carbon emission and energy-saving emission are achieved, gas channeling caused by increased nitrogen content is prevented, and the system is applicable to the exploration of heavy oil and oil sands by the SAGD technology.

Owner:JIANGSU GREATRIVER OTECH

A multi-component thermal fluid foam displacement coalbed methane mining method

ActiveCN103061730BImprove permeabilityHard to getOther gas emission reduction technologiesFluid removalHigh pressure waterHigh pressure

The invention discloses a method for coal bed methane mining by multi-element thermal fluid foam displacement. Multi-element thermal fluid is injected into a coal bed of an injection-production well group through an injection well, and foaming agent is injected at intervals. A multi-element thermal fluid foam slug is formed in the coal bed to displace the coal bed methane in order to improve the recovery efficiency of the coal bed methane. The method specifically includes that extracted coal bed methane is compressed and mixed with compressed air, and then the mixture is injected into a multi-element thermal fluid generation device for ignition, extracted processed ground water is mixed to produce the multi-element thermal fluid mainly with high-temperature and high-pressure water vapor and mixed gas of carbon dioxide and nitrogen, the produced multi-element thermal fluid is injected into the underground coal bed through the injection well, a foaming system composed of preferred alkyl ether sulfonate and corrosion inhibitor is injected from an oil jacket annulus at intervals, the multi-element thermal fluid foam slug is formed under the ground to displace the coal bed methane, and water is drained and gas is recovered from a production well. The method has the advantages that fuel is easy to obtain, principles are clear and distinct, and the like, and can provide guidance for implementation of well stimulation of the coal bed methane.

Owner:CHINA UNIV OF PETROLEUM (EAST CHINA)

Method for extracting oil by injecting foam air and oxygen-enriched pyrolysis thermochemical composite air into oil reservoir in flooding mode

ActiveCN106677751ARapid start pyrolysis temperatureImprove oil production rateFluid removalDrilling compositionFoaming agentResidual oil

The invention discloses a method for extracting oil by injecting foam air and oxygen-enriched pyrolysis thermochemcial composite air into an oil reservoir in a flooding mode. The method comprises the steps that in the first injection step, a foaming agent is injected into the oil reservoir so as to generate foam; in a second injection step, an oxygen-enriched air mixture is injected subsequently, and ignition is conducted on a stratum; and subsequently, the air is injected for oil displacement production. Large pore paths can be blocked by the foam, water is blocked while oil is not blocked, and hypertonic pore paths are sealed; and since the foam and the air are alternately injected, gas channeling can be effectively prevented, the purposes of modifying and flooding can be achieved, residual oil can be better displaced, communication of areas unswept by injected water is achieved, and the crude oil displacement and sweeping efficiency are improved. The foaming agent is an anionic surfactant with high activity, and can be used for lowering oil-water interfacial tension greatly, improving the wettability of the surface of rock and improving the displacement efficiency of an injectant, and accordingly the purpose of increasing the recovery ratio is achieved. Advantages of the technologies of foam flooding and air flooding are fully achieved, the sweeping coefficient is increased more efficiently, and the displacement efficiency is improved more efficiently.

Owner:中嵘能源科技集团有限公司

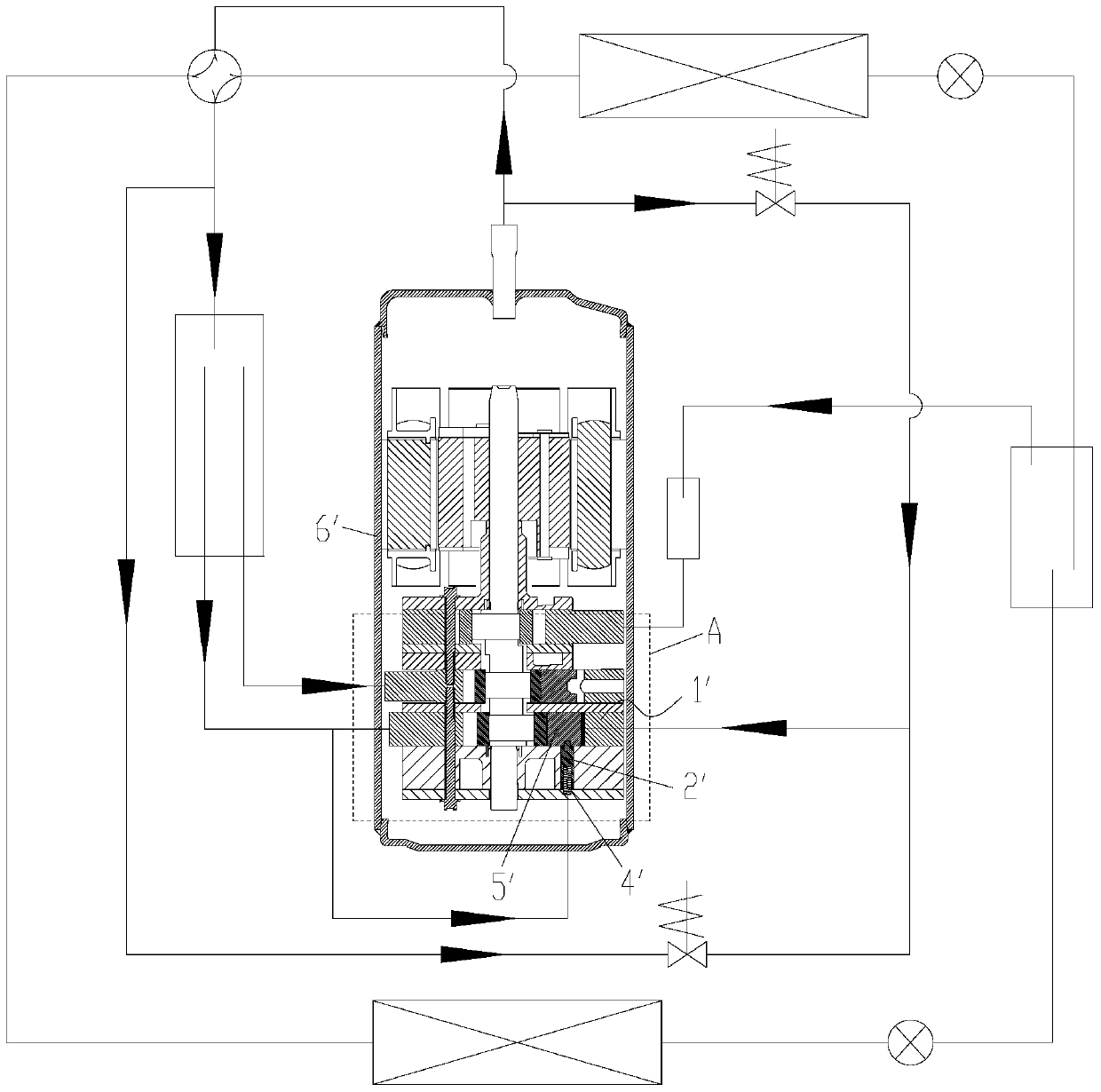

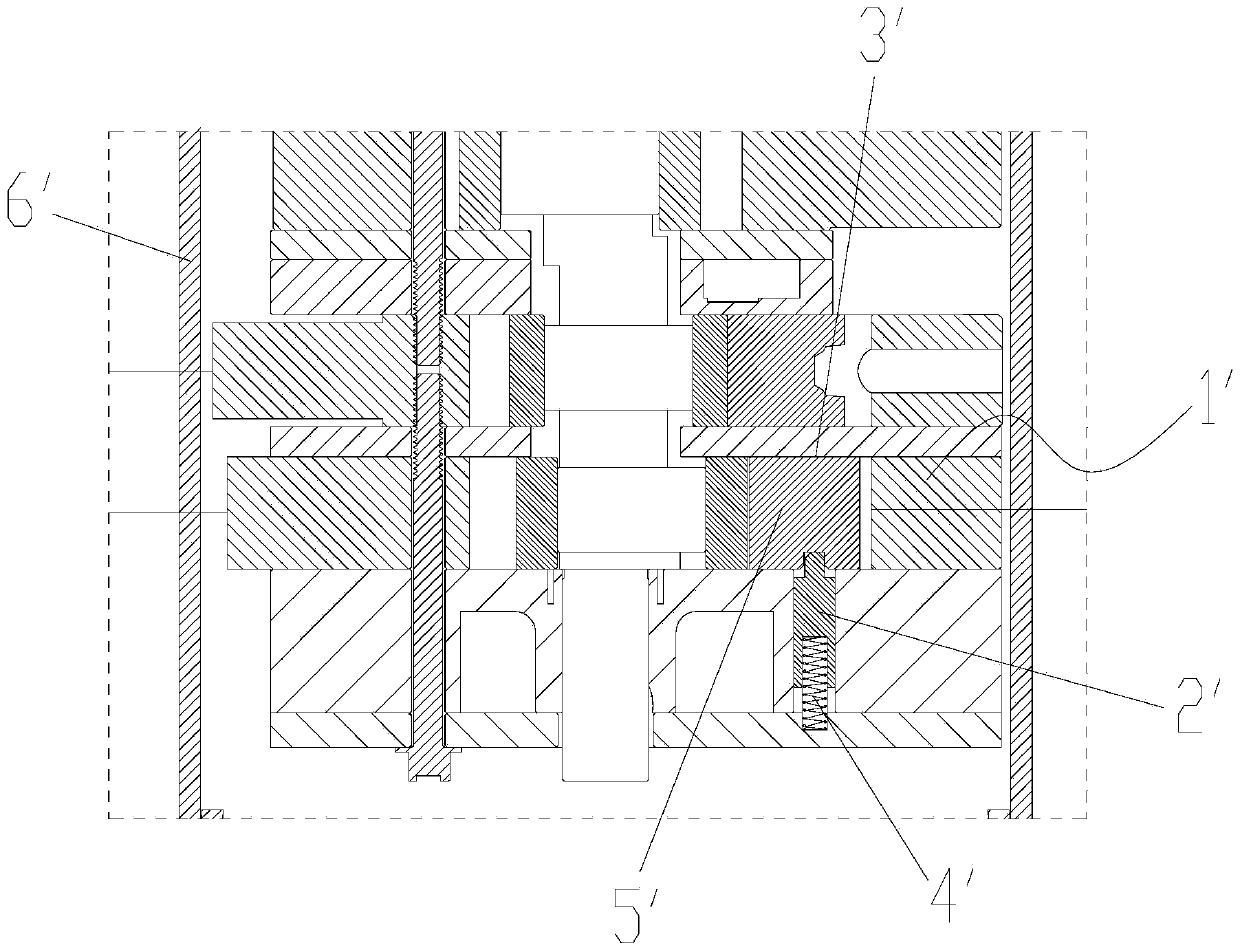

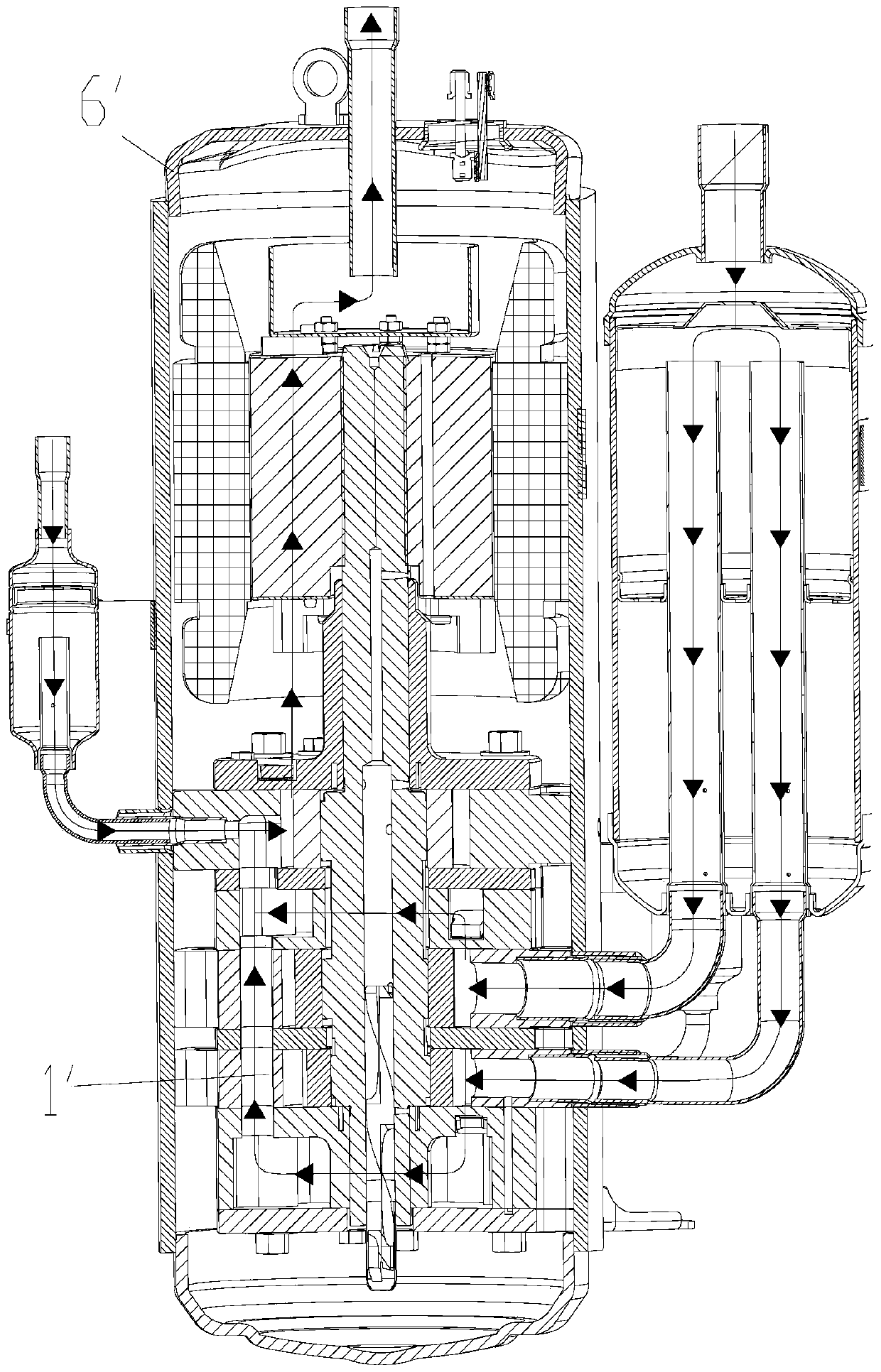

Compressor and refrigeration system with same

ActiveCN105545752BSolve the problem of prone to excessive loadAvoid load increaseRotary/oscillating piston combinations for elastic fluidsCompressorEngineeringRefrigeration

The present invention provides a compressor and a refrigeration system thereof, wherein the compressor includes: a shell, a lower flange structure arranged in the shell from bottom to top, a first compression cylinder and a second compression cylinder, the first The compression cylinder includes: a cylinder body, a roller and a sliding piece. A sliding piece groove is arranged on the inner wall of the cylinder body. The roller is arranged in the cylinder body. The sliding piece is arranged in the sliding piece groove and cooperates with the roller. There is a first reset part between the slide grooves, a lock groove corresponding to the position of the pin groove is arranged on the slide piece, the end of the slide piece far away from the roller forms a first cavity with the bottom of the slide piece groove, and a second A channel to connect the first cavity with the inner cavity of the housing; a second cavity is formed between the first end of the pin and the sliding piece, and a third cavity is formed between the second end of the pin and the bottom of the pin groove , the technical solution of the present invention solves the problem in the prior art that the capacity-changing cylinder of the compressor is easily overloaded after being unloaded and then restarted.

Owner:GREE ELECTRIC APPLIANCES INC +1

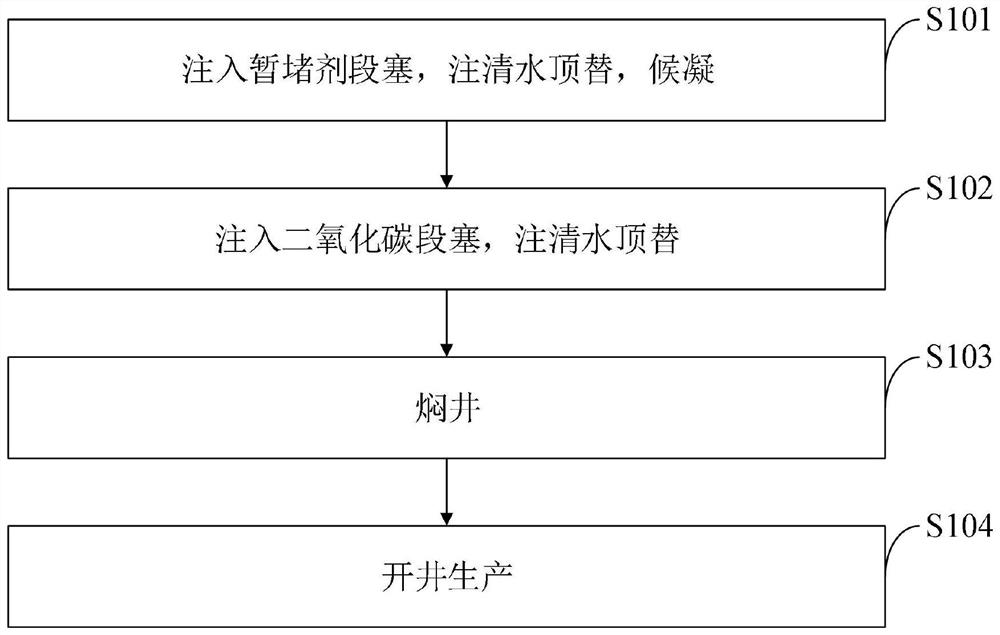

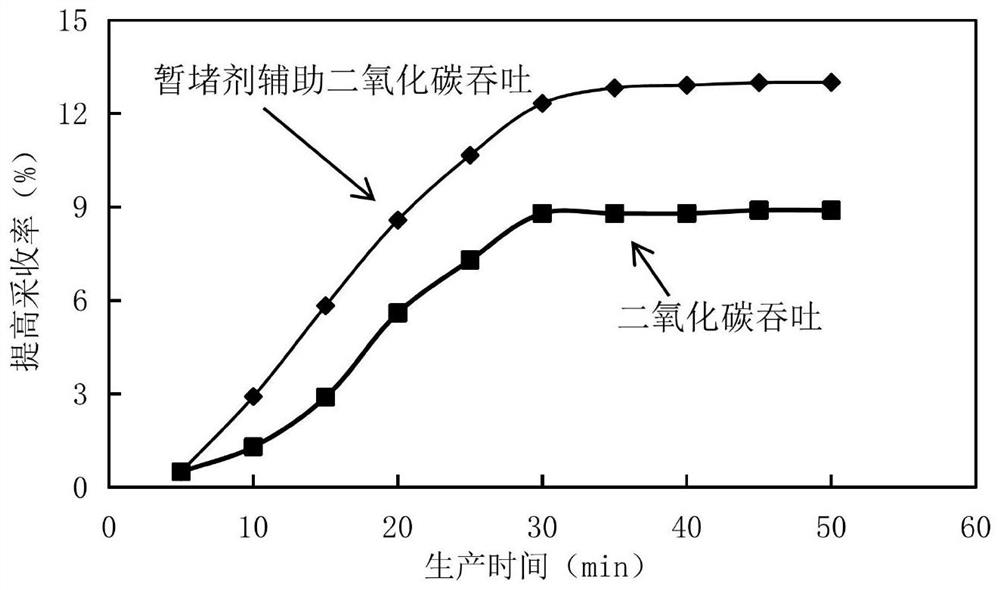

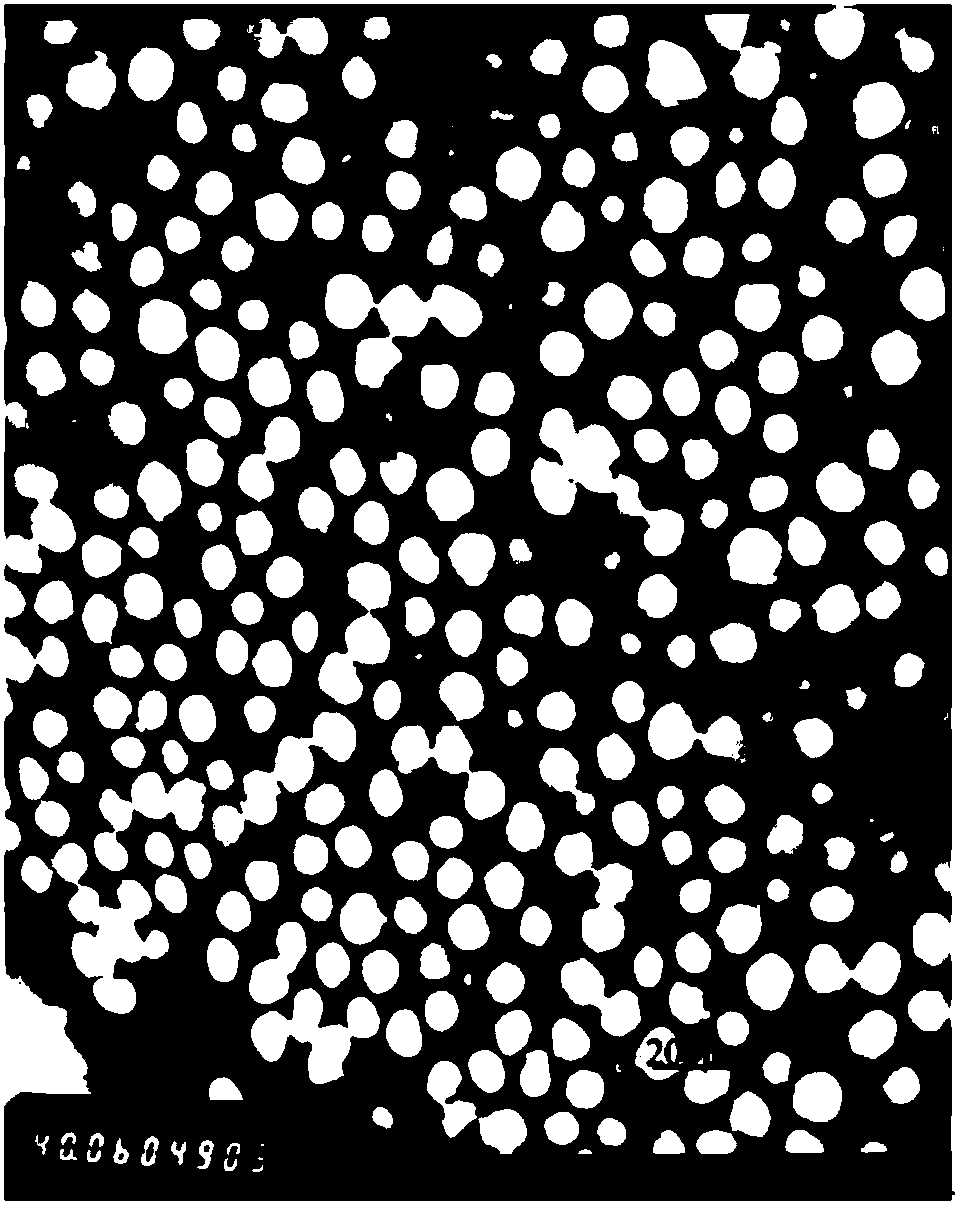

Temporary plugging agent assisted carbon dioxide huff and puff oil extraction method

PendingCN114109304APrevent gas blowingExpand the affected volumeFluid removalDrilling compositionOil fieldProcess engineering

The invention belongs to the technical field of medium and low permeability oil field recovery efficiency improvement, and discloses a temporary plugging agent assisted carbon dioxide huff and puff oil extraction method which comprises the steps of injecting a temporary plugging agent slug, injecting clear water for replacement and waiting for setting. Injecting a carbon dioxide slug, and injecting clear water for replacement; soaking the well; and opening the well for production. According to the temporary plugging agent assisted carbon dioxide huff and puff oil extraction method provided by the invention, a dominant seepage channel in a reservoir can be effectively plugged, and carbon dioxide is prevented from forming gas channeling along the dominant seepage channel, so that the swept volume of the carbon dioxide can be enlarged, and the carbon dioxide can enter a remaining oil enriched area and play a role; in the well opening production process, the temporary plugging agent can be degraded under the reservoir condition, so that permanent damage to the reservoir is avoided, the plugging strength is greatly improved, and flowing of crude oil after huff and puff is facilitated. In addition, the temporary plugging agent assisted carbon dioxide huff and puff oil extraction method provided by the invention also has the characteristics of simple process, wide application range and the like.

Owner:SICHUAN UNIVERSITY OF SCIENCE AND ENGINEERING

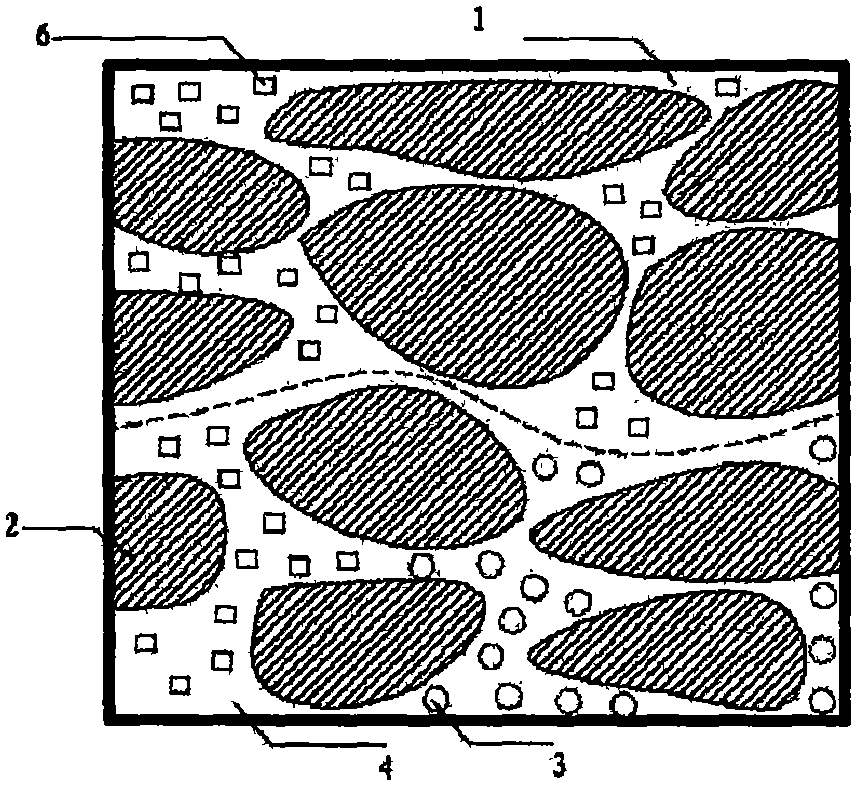

Styrene and acrylate latex and preparation method and application thereof

The invention discloses styrene and acrylate latex and a preparation method and application thereof, and belongs to the field of well cementing materials. The preparation method of the styrene and acrylate latex comprises the following steps of polymerizing of seed emulsion: adding styrene, acrylate, unsaturated acid or salt thereof, a buffer agent, and deionized water into a reactor, leading nitrogen gas, adding an initiator, and reacting for 80 to 100min at the temperature of 60 to 88 DEG C, so as to obtain the seed emulsion polymerizing part; singly dripping the acrylate, and the mixture ofthe initiator, the buffer agent, and the unsaturated acid or salt thereof into a reactor, simultaneously finishing dripping, and warming at the temperature of 80 to 90 DEG C, so as to obtain the styrene and acrylate latex. The seed emulsion polymerizing monomer contains 14% to 75% of styrene and 24% to 85% of acrylate; the soap-free emulsion polymerizing monomer contains 92% to 99% of acrylate; the percentage of the seed emulsion polymerizing part in the total polymer is 5% to 25%. The preparation method has the advantages that the technology is simple, the consumption time is short, the prepared styrene and acrylate latex has good stability, and the properties of cement mortar are greatly improved.

Owner:PETROCHINA CO LTD

Method and system for increasing compact oil storage layer recovery ratio

InactiveCN109386261APrevent gas blowingEfficient SupplementOther gas emission reduction technologiesFluid removalSurface-active agentsEnvironmental geology

The invention provides a method and system for increasing the compact oil storage layer recovery ratio. The method for increasing the compact oil storage layer recovery ratio comprises the following steps that 1, water is injected into a compact oil storage layer for performing water drive; 2, a gas soluble surface active agent and super-critical CO2 are mixed to be uniform, super-critical CO2 mixed fluid is obtained, and the super-critical CO2 mixed fluid is injected into the compact oil storage layer obtained after water drive; 3, a well is shut in for soaking, then, the wheel is opened forexploiting. The method can effectively avoid CO2 gas channeling, and the compact oil storage layer recovery ratio is greatly increased.

Owner:PETROCHINA CO LTD

Cement additive and preparation method thereof

The invention discloses a cement additive and a preparation method thereof. The cement additive comprises the following components, by weight: 15-20 parts of acrylamide, 40-60 parts of xylene, 5-10 parts of organic boron, 10-20 parts of triethanolamine, 10-20 parts of urea, 0.5-2 parts of mirabilite, 3-6 parts of gypsum, 12-30 parts of calcium chloride, 3-10 parts of sodium acetate, and 100-150 parts of water. The additive has the following advantages: when the additive is added into cement, the volume of the additive is expanded, such that cement gas channeling can be effectively prevented, while cement body strength can be improved. The method is simple and feasible; investment is low; and the method is easy to realize.

Owner:李尧

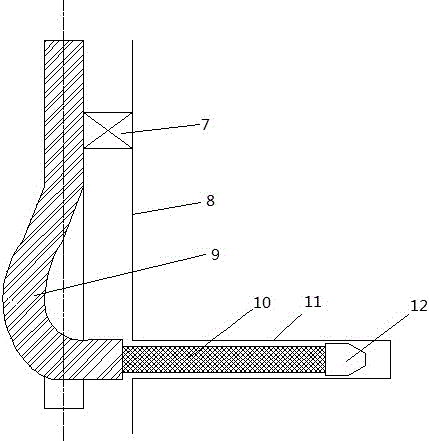

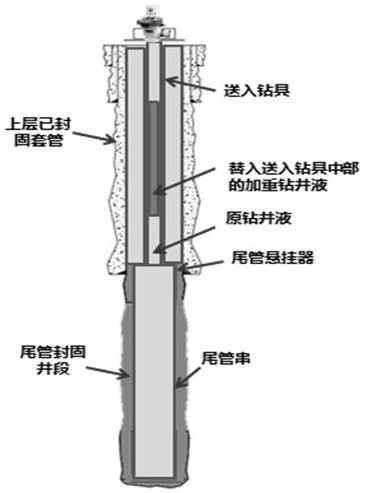

Method to prevent gas channeling after liner cementing of high pressure gas well

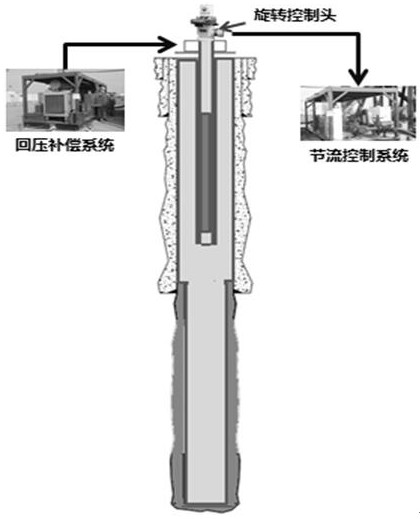

ActiveCN108915635BAnnular pressure controllableAvoid suction-induced air channelingFlushingSealing/packingWell cementingCement slurry

The invention discloses a method for preventing gas channeling after liner cementing of a high-pressure gas well. Casing pressure: After the slurry replacement operation is completed, with the help of the casing pressure established by the heavy drilling fluid sent into the drilling tool, the surface back pressure pump and the throttle valve group work together to maintain the liquid level of the drilling tool water eye and achieve a constant casing pressure. Drilling; tripping out to the design well depth, implement different annulus slurry column time at different stages of heavy drilling fluid in the drill tool, heavy drilling fluid exiting the pipe shoe, all the heavy drilling fluid reaching the annulus, and the heavy drilling fluid circulating out of the wellhead. Ground back pressure compensation, so that the high-pressure air layer is stable without pressure leakage. The invention aims at the fine pressure control of the annulus after the completion of the cementing injection of the cement slurry, realizes the full pressure control of the liner cementing without short boards, and eliminates the loss of weight caused by the drilling suction and gelation during the stationary period of the annulus cement slurry column after the cementing gas channeling phenomenon.

Owner:CHINA NAT PETROLEUM CORP CHUANQING DRILLING ENG CO LTD +1

Application method of cement additive

The invention discloses an application method for a cement additive, which includes the following steps: (a) 4-8% weighted acrylamide, 2-4% weighted cross linker, 1-3.5% weighted evocating agent, 1-4%weighted intensifier and residual water is cross-linked under normal pressure and at the temperature of 75-90 DEG C, gel is formed, dried and crashed to obtain the cement additive; (b) the prepared cement additive is added to cement slurry, wherein, 1.5-3 parts by weight of cement additive is added into 100 parts by weight of cement slurry, and 2 parts by weight of cement additive is preferred. By adopting the application method of the invention and applying the cement additive to the cement system of oil field cementing, the phenomenon of gas channeling is prevented and the cementing qualityis improved; the qualification rate of the cementing quality is improved from the original 45% to more than 94%.

Owner:ANTON OILFIELD SERVICES (GRP) LTD

Method for preparing cement additive

The invention discloses a preparation method of a cement additive, which comprises the following steps: a) adding 4-8% by weight of acrylamide, 2-4% by weight of a crosslinking agent, 1-3.5% by weight of an initiator, 1- 4% by weight of the reinforcing agent and the rest of the water are cross-linked and polymerized under normal pressure to form a gel; b) drying and pulverizing the above-mentioned gel to obtain a cement additive. The cement additive prepared by the method of the invention is applied to the cement system of oil field cementing, which can prevent gas channeling, improve the cementing quality, and the qualified rate of the cementing quality is increased from the original 45% to more than 94%.

Owner:ANTON OILFIELD SERVICES (GRP) LTD

A device for injecting coal powder into an oil layer and an ignition method for burning the oil layer

ActiveCN106050207BReduce moisture contentImprove ignition performanceFluid removalCombustionEngineering

The invention provides a device for injecting pulverized coal into an oil layer and an ignition method for in-situ oil combustion and belongs to the field of exploitation through in-situ oil combustion. The device for injecting the pulverized coal into the oil layer comprises an oil pipe arranged in an injection well or a production well, a pulverized coal spray-blowing system arranged on the ground and an injection pipeline, wherein the pulverized coal spray-blowing system is provided with a pulverized coal input port and a spray-blowing port, the spray-blowing port sprays out the pulverized coal, the injection pipeline is connected between the oil pipe and the spray-blowing port of the pulverized coal spray-blowing system, and the pulverized coal sprayed out of the spray-blowing port is delivered to the oil pipe. The device can improve the ignition effect for in-situ oil combustion and can also improve the development effect of the in-situ oil combustion.

Owner:PETROCHINA CO LTD

A kind of styrene-acrylic latex and its preparation method and application

The invention discloses a styrene-acrylic latex and its preparation method and application, belonging to the field of well cementing materials. The preparation method of this styrene-acrylic latex is, seed emulsion polymerization: styrene, acrylate, unsaturated acid or its salt, buffering agent, deionized water are added in the reactor, pass into nitrogen, add initiator, at 60 React at ℃-88℃ for 80-100min to obtain the seed emulsion polymerization part, and then separately add acrylates, and a mixture composed of initiator, buffer, unsaturated acid or its salts into the reactor at the same time, At the same time, the drops are completed, and the temperature is kept at 80°C-90°C to obtain styrene-acrylic latex. In the monomers of seed emulsion polymerization, styrene accounts for 14%-75%, and acrylates account for 24%-85%; in the monomers of soap-free emulsion polymerization, acrylates account for 92%-99%; seed emulsion The percentage of the polymerized portion to the total polymer is 5%-25%. The preparation method has simple process and short time consumption, and the prepared styrene-acrylic latex has good stability and can greatly improve various properties of cement slurry.

Owner:PETROCHINA CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com