Preparation method of self-healing agent for oil well cement, well cementation self-healing cement slurry and application

A technology for oil well cement and mixture, applied in the field of petroleum exploration, can solve the problems of low use temperature, low success rate, economic loss and the like of self-healing agent, achieve good thermal stability, good hydrolysis stability, and improve the effect of cementing quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

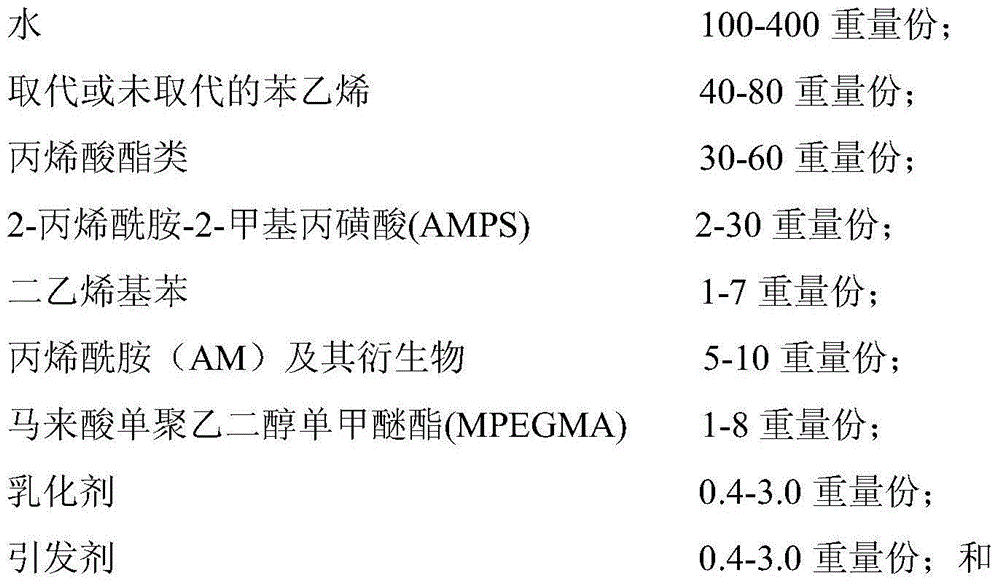

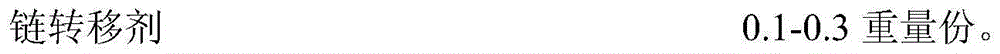

[0049] The preparation method of self-healing agent for oil well cement of the present invention can specifically comprise:

[0050] Specifically, the method of the present invention can also be:

[0051] i) Styrene, acrylates, 2-acrylamide-2-methylpropanesulfonic acid, divinylbenzene, acrylamide and its derivatives, monopolyethylene glycol monomethyl ether maleate, emulsifier , chain transfer agent and deionized water (80% of the total water) are mixed for pre-emulsification to obtain pre-emulsion A;

[0052] ii) Deionized water and initiator of 20% total water content are made into initiator solution B to carry out;

[0053] iii) Put a part of the pre-emulsion A as the base material, put it into the reactor and heat it to 70-90°C, and then add a part of the initiator solution B to react;

[0054] iv) drop the remaining amount of pre-emulsion A and the remaining amount of initiator solution B into the reactor simultaneously within 4-6 hours, and continue to react for 1-2 ho...

Embodiment 1

[0058] Step 1) 70 parts by weight of styrene, 40 parts by weight of acrylate, 15 parts by weight of 2-acrylamide-2-methylpropanesulfonic acid, 1 part by weight of divinylbenzene, 9 parts by weight of acrylamide, mono 1 part by weight of polyethylene glycol monomethyl ether ester, 0.7 part by weight of emulsifier, 0.1 part by weight of chain transfer agent, 120 parts by weight of deionized water (80% of the total water content of 150 parts by weight), pre-emulsified to obtain pre-emulsion A ;

[0059] Step 2) 30 parts by weight of deionized water (20% of 150 parts by weight of total water) and 0.7 parts by weight of initiator are formulated into initiator solution B;

[0060] Step 3) Add 20% by weight of pre-emulsion A as a base material into the reactor, heat and stir, raise the temperature to 90°C, and add 20% by weight of initiator solution B into the reactor;

[0061] Step 4) Drop the remaining 80% by weight of the pre-emulsion A and the remaining 80% of the initiator solu...

Embodiment 2

[0064] Step 1) Mix 50 parts by weight of styrene, 55 parts by weight of acrylate, 20 parts by weight of 2-acrylamide-2-methylpropanesulfonic acid, 5 parts by weight of divinylbenzene, 7 parts by weight of acrylamide, mono 7 parts by weight of polyethylene glycol monomethyl ether ester, 2.5 parts by weight of emulsifier, 0.3 parts by weight of chain transfer agent, 280 parts by weight of deionized water (80% of the total water content of 350 parts by weight), pre-emulsified to obtain pre-emulsion A ;

[0065] Step 2) 70 parts by weight of deionized water (20% of the total water content of 350 parts by weight) and 2.5 parts by weight of initiator are made into initiator solution B;

[0066] Step 3) Add 20% by weight of pre-emulsion A as a base material into the reactor, heat and stir, and raise the temperature to 70°C, and add 20% by weight of initiator solution B into the reactor;

[0067] Step 4) Drop the remaining 80% of the pre-emulsion A and the remaining 80% of the initia...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com