A kind of preparation method of ether highly dispersed high slump polycarboxylate water reducer

A high-dispersion, polycarboxylic acid technology, applied in the field of construction admixtures, can solve problems such as slump, concrete slump loss, and concrete slump loss that cannot be fundamentally solved, and achieve large steric resistance and Anti-intercalation, easy construction and pumping, and improved dispersion performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

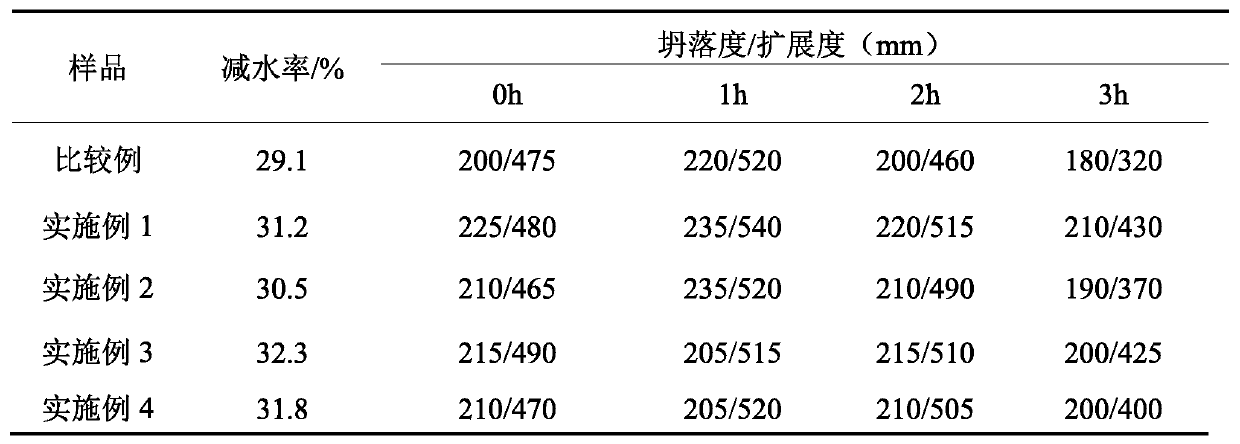

Embodiment 1

[0026] (1) Esterification reaction: add 58.80g of maleic anhydride, 120.00g of polyether diol with a molecular weight of 600, and 2.10g of hydroquinone into the first reaction vessel for mixing, and heat up to 60-80°C under nitrogen protection. ℃, then add 3.66g p-toluenesulfonic acid, raise the temperature to 100℃, keep the temperature for 2 hours, remove water during the reaction, cool down to room temperature after the reaction, and obtain the first mixture containing esterification product and unreacted unsaturated acid anhydride.

[0027] (2) Copolymerization reaction: add 20.00g of the first mixture prepared in step (1), 20.00g of isobutenol polyethylene glycol ether with a molecular weight of 2000 and 80.00g of isoprenol polyethylene glycol with a molecular weight of 3000 in the second reaction vessel Glycol ether, and 130.00g water, stir until dissolving evenly, obtain comonomer mixture solution, then add 1.50g hydrogen peroxide, and ascorbic acid aqueous solution (wher...

Embodiment 2

[0030] (1) Esterification reaction: Add 52.95g of itaconic anhydride, 180.00g of polyether diol with a molecular weight of 1000, and 3.33g of phenothiazine into the first reaction vessel for mixing, and heat up to 60-80°C under nitrogen protection , then add 5.10g of benzenesulfonic acid, raise the temperature to 110°C, keep the temperature for 2 hours, remove water during the reaction, and cool down to room temperature after the reaction, to obtain the first mixture containing the esterification product and unreacted unsaturated anhydride.

[0031] (2) Copolymerization: In the second reaction vessel, add 16.00g of the first mixture prepared in step (1), 10.00g of isobutenol polyethylene glycol ether with a molecular weight of 2400 and 90.00g of isoprenol polyethylene with a molecular weight of 4000 Glycol ether, and 124.50g of water, stir until dissolved evenly, obtain comonomer mixture solution, and ammonium persulfate aqueous solution (wherein, ammonium persulfate 1.00g, wat...

Embodiment 3

[0034] (1) Esterification reaction: Add 32.36g of succinic anhydride, 220.00g of polyether glycol with a molecular weight of 2000, and 3.60g of diphenylamine into the first reaction vessel and mix them. Under nitrogen protection, heat up to 60-80°C, and then Add 2.80 g of 98% concentrated sulfuric acid, raise the temperature to 120° C., keep the temperature for 1.5 h, remove water during the reaction, and cool down to room temperature after the reaction to obtain the first mixture containing the esterification product and unreacted unsaturated anhydride.

[0035](2) Copolymerization: In the second reaction vessel, add 15.00g of the first mixture prepared in step (1), 15.00g of isobutylene alcohol polyethylene glycol ether with a molecular weight of 1200 and 85.00g of isoprenol polyethylene glycol with a molecular weight of 2400 Glycol ether, and 121.00g of water, stir until dissolved evenly, obtain the comonomer mixture solution, and the aqueous solution of trichomonas (among t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com